Unlocking Lightweighting: A Deep Dive into Cast Lattice Structures

This technical summary is based on the academic paper "The skeleton castings as a new type of cast lattice structures" by M. Cholewa, T. Szuter, T. Wróbel, and M. Kondracki, published in the Journal of Achievements in Materials and Manufacturing Engineering (2012).

Keywords

- Primary Keyword: Cast Lattice Structures

- Secondary Keywords: Skeleton Casting, Porous Materials, Aluminium Casting, Lightweighting, Cellular Metals

Executive Summary

- The Challenge: To develop a cost-effective manufacturing method for lightweight, periodic cellular metals that offer a superior strength-to-weight ratio and energy absorption capabilities.

- The Method: The study investigated the gravity casting of aluminum "skeleton" structures with an octahedron topology, using mould-filling simulations and detailed microstructural analysis to optimize the process.

- The Key Breakthrough: The research demonstrates that complex, defect-free Cast Lattice Structures with a homogenous microstructure can be successfully manufactured in a typical foundry, proving casting is a viable alternative to more complex and costly fabrication methods.

- The Bottom Line: By carefully controlling technological parameters, particularly the thermal properties of core materials, casting can produce intricate, high-performance cellular structures for demanding applications in automotive and aerospace.

The Challenge: Why This Research Matters for HPDC Professionals

In the aerospace and automotive industries, the demand for lightweight materials that don't compromise on strength or stiffness is relentless. While solutions like metal foams exist, they often lack the predictable, ordered structure needed for optimized performance. Periodic cellular metals, or Cast Lattice Structures, offer a solution by providing a defined internal geometry. However, traditional manufacturing methods, which involve forming and bonding individual sheets and rods, are often complex, costly, and limited by material plasticity and joint strength. The core challenge addressed by this research is the need for a simpler, more economical manufacturing process that can produce these advanced structures without sacrificing quality or performance, making them accessible even to a typical foundry.

The Approach: Unpacking the Methodology

The research team focused on creating a skeleton casting using a near-eutectic AlSi11 alloy. The chosen design was a three-dimensional structure based on an octahedron elementary cell, selected for its optimal stress distribution properties.

The methodology involved a two-pronged approach:

1. Simulation: The team used Nova Flow & Solid software to simulate the mould cavity filling process. This allowed them to analyze metal temperature distribution, liquid phase share during solidification, and predict the location of potential shrinkage defects. The simulation assumed a pouring speed of 0.5 kg/s.

2. Experimental Validation & Analysis: Three skeleton castings were produced using quartz sand moulds and a porous corundum brick core, a material chosen for its high thermo-insulating properties. The researchers then conducted a detailed microstructural investigation on five key areas of the casting (nodes, ligaments, and walls) to analyze the size and distribution of silicon crystals, confirming the real-world results against the simulation predictions.

The Breakthrough: Key Findings & Data

The study yielded critical insights into the feasibility and control of casting complex lattice structures.

Finding 1: Simulation Accurately Predicts Flow but Underestimates the Power of Thermal Control

The mould-filling simulations successfully predicted a complete and undisturbed filling of the complex mould cavity. Critically, the simulation identified potential "hot spots" at the geometric nodes, predicting shrinkage porosity of around 8% in these areas (Figure 7). However, the physical castings produced using high thermo-insulating corundum bricks for the core showed no such porosity. This demonstrates that while simulation is a powerful predictive tool, the strategic selection of mould and core materials with specific thermal properties is paramount to overcoming defects and achieving sound castings.

Finding 2: Homogenous Microstructure Achieved in a Geometrically Complex Casting

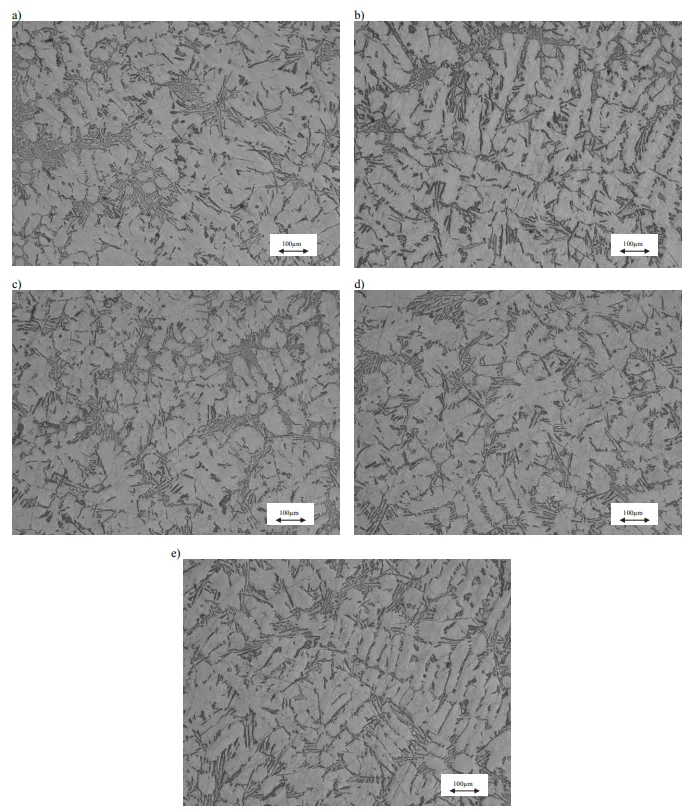

A key concern with complex castings is the variation in microstructure due to different cooling rates in thick and thin sections. This study confirmed that a remarkably homogenous microstructure can be achieved throughout the entire skeleton casting. The quantitative analysis of silicon crystals (Table 2) showed that stereological parameters were similar across all five regions analyzed, from the thick nodes to the thin connecting ligaments. The histograms in Figure 10 further support this, showing a consistent distribution of crystal sizes. The only notable exception was in the cross-section between nodes (region 3), which exhibited a considerably finer structure, likely due to the combination of the low-diameter ligaments and the excellent insulating properties of the core, promoting uniform crystallization.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting the thermal conductivity of core materials is a critical lever for controlling solidification. Using highly insulating cores may contribute to reducing shrinkage porosity in complex geometries with varying section thicknesses, even in areas identified as hot spots by simulation.

- For Quality Control Teams: The data in Table 2 and the micrographs in Figure 9 of the paper illustrate the effect of a high-insulation core on microstructural homogeneity. This could inform new quality inspection criteria that focus on ensuring consistent crystal structure across both nodes and ligaments as a key indicator of mechanical integrity.

- For Design Engineers: The findings indicate that the octahedron topology provides excellent stress distribution and is manufacturable via casting. This confirms that Cast Lattice Structures can be designed as single, integral elements, eliminating weak points that arise from joining separate components and opening new possibilities for complex, lightweight component design.

Paper Details

The skeleton castings as a new type of cast lattice structures

1. Overview:

- Title: The skeleton castings as a new type of cast lattice structures

- Author: M. Cholewa, T. Szuter, T. Wróbel, M. Kondracki

- Year of publication: 2012

- Journal/academic society of publication: Journal of Achievements in Materials and Manufacturing Engineering

- Keywords: Skeleton casting; Metallic alloy; Porous materials; Aluminium casting; Simulation purpose

2. Abstract:

Purpose: of this paper is to present selected achievements in field of new type material - skeleton structures. Actual state of knowledge about periodic cellular materials was described. The aim of this work is to show results about mechanically optimised skeleton casting with octahedron topology. Correctness of technological parameters was investigated by microstructural research. Most important parameters of the manufacturing process were identified. Design/methodology/approach: The influence of technological parameters to the microstructure in different points of casting was described. Simulations of the mould filling processes were also carried out. Real experiments were performed to prove the simulation results. The qualitative and quantitative metallographic analysis was also carried out. Findings: It was found that the octahedron shape of internal cell causes best stress distribution and that the skeleton castings are a good alternative for cellular materials such as metal foams, lattice structures or sandwich panels. Research limitations/implications: Casting methods used to manufacture materials such as described skeleton castings confirmed their usefulness. Not well known and used yet rheological properties of liquid metals allow obtaining shape complicated structures near to metallic foams but with periodic structure. Practical implications: Technological parameters of the skeleton castings manufacturing process were developed. Without use of advanced techniques there is a possibility to manufacture relatively low cost skeleton structures in a typical foundry. Originality/value: Three dimensional cast skeleton structures with internal topology of octahedron confirmed their usefulness as elements used for energy dissipation. Obtaining the homogenous microstructure in the whole volume of complicated shape castings can be achieved.

3. Introduction:

Novel structural materials are expected to beyond its basic use also multifunctionality. From economics and ecology point of view they should allow to lower the weight of the constructions. This makes possible to save resources and sometimes energy used in manufacturing processes. Lower weight in aerospace and automotive industry also connects with lower energy consumption. Most challenging while designing lightweight material is to achieve good proportion between strength/stiffness and weight. One of the solutions is periodic cellular metals. [1-9] (Terms like macrostructure, internal geometry, and topology have similar meaning and are used alternately.)

4. Summary of the study:

Background of the research topic:

The study is situated within the field of novel structural materials, specifically periodic cellular metals, which are sought after for lightweighting in industries like aerospace and automotive. These materials aim to provide a high strength/stiffness-to-weight ratio.

Status of previous research:

Previous research and manufacturing techniques for periodic cellular materials largely relied on plastic forming and bonding of sheets and rods. These methods are often complex, costly, and have limitations regarding joint strength and geometric complexity. Metal foams exist but lack an ordered, periodic structure.

Purpose of the study:

The purpose was to present achievements in developing a new type of material—skeleton structures—and to demonstrate that casting is a viable, low-cost method for manufacturing them. The aim was to show results for a mechanically optimized skeleton casting with octahedron topology, identify key manufacturing parameters, and investigate the resulting microstructure.

Core study:

The core of the study involved designing, simulating, casting, and analyzing an aluminum skeleton casting with an octahedron-based internal topology. The research focused on optimizing the technological parameters of the casting process to achieve a defect-free part with a homogenous microstructure, proving the method's feasibility for a typical foundry.

5. Research Methodology

Research Design:

The research was designed as a comparative study combining computer simulation with experimental validation. An octahedron elementary cell was chosen for its mechanical properties. The design had a target relative density of under 30%.

Data Collection and Analysis Methods:

- Simulation: Mould cavity filling was simulated using Nova Flow & Solid software to analyze temperature distribution, solidification, and potential porosity.

- Casting: Physical castings were made from near-eutectic AlSi11 alloy using quartz sand moulds and a porous corundum brick core.

- Microstructural Analysis: Samples were taken from five distinct regions of the castings. A quantitative metallographic analysis was performed using the NIS-Elements image analysis system to determine the distribution and stereological parameters (area, perimeter, shape) of silicon crystals.

Research Topics and Scope:

The research focused on the manufacturability of skeleton castings via gravity casting. The scope included the selection of an optimal cell topology (octahedron), simulation of the casting process for an AlSi11 alloy, physical casting experiments, and detailed microstructural analysis to verify the quality and homogeneity of the final product.

6. Key Results:

Key Results:

- The octahedron shape for the internal cell was confirmed to provide the best stress distribution, making it an ideal topology for energy dissipation elements.

- Casting was validated as a good alternative for manufacturing cellular materials like metal foams or lattice structures, allowing for the creation of complex shapes with a periodic structure in a cost-effective manner.

- Simulations of mould filling were successful in predicting the process, but the use of high thermo-insulating corundum bricks as a core material was critical in preventing the predicted shrinkage porosity in the actual castings.

- A homogenous microstructure was achieved throughout the volume of the complex casting, with consistent silicon crystal sizes and shapes in both thick nodes and thin ligaments, ensuring predictable mechanical properties.

- Dynamic strength tests showed that skeleton castings can be used as reinforcement in ceramic matrix composites, with the ability to tailor energy absorption characteristics by filling the internal volume.

Figure Name List:

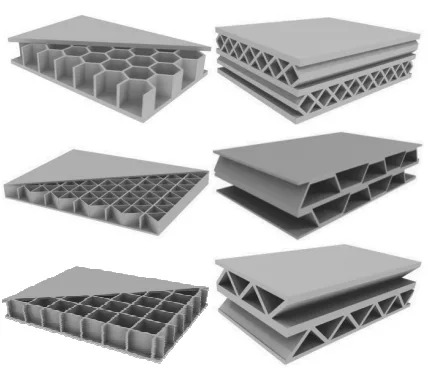

- Fig. 1. Periodic cellular metal sandwich structures

- Fig. 2. Sandwich type periodic lattice cellular metals

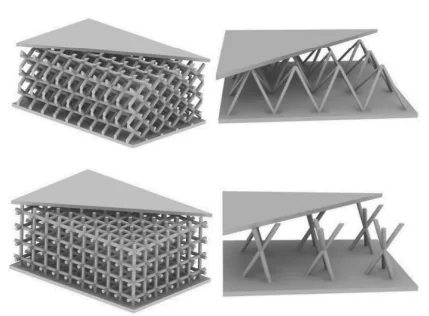

- Fig. 3. Example of topologies of skeleton castings designed in Foundry Department of Silesian University of Technology

- Fig. 4. Example of elementary cell in the form of an octahedron

- Fig. 5. Liquid metal temperature distribution while pouring (axial cross-section)

- Fig. 6. Liquid phase distribution after filling (cross-axial section)

- Fig. 7. Areas of possible shrinkage porosities

- Fig. 8. Specified regions of microstructure investigation; 1 – node; 2 – near node cross-section; 3 – cross-section between the nodes; 4 – cross-section of closing wall; 5 – outside surface of closing wall

- Fig. 9. AlSi11 alloy structure: a – node; b – near node cross-section; c – cross-section between the nodes; 4 – cross-section of closing wall; 5 – outside surface of closing wall

- Fig. 10. Distribution of size of grain in each class of size: 1 – node; 2 – near node cross-section; 3 – cross-section between the nodes; 4 – cross-section of closing wall; 5 – outside surface of closing wall

- Fig. 11. Selected charts of deceleration profile for ceramic core related to time. 1.2 – skeleton casting with ceramic core, 2.2 – skeleton casting with ceramic core infiltrated with mineral oil, 3.2. – skeleton casting with core infiltrated with polymeric liquid.

7. Conclusion:

The study successfully demonstrated that casting is a highly effective method for producing complex, three-dimensional skeleton structures with an octahedron topology. The analysis of silicon crystals showed that the microstructure was largely homogenous, with most crystals being less than 20 µm. The research confirmed the structural correctness of castings manufactured with the proposed moulding materials and highlighted the importance of using insulating materials for the mould and core to ensure good fill and reduce shrinkage porosity. The beneficial effect of these Cast Lattice Structures on energy dissipation was confirmed, particularly when the internal solid-liquid filler is used, which affects the absorption and deformation mechanisms.

8. References:

- [1] M. Cholewa, T. Szuter, M. Dziuba, Basic properties of 3D cast skeleton structures, Archives of Materials Science and Engineering 52/2 (2011) 101-111.

- [2] A.G. Evans, J.W. Hutchinson, N.A. Fleck, M.F. Ashby, H.N.G. Wadley, The topological design of multifunctional cellular metals, Progress in Materials Science 46/3-4 (2001) 309-327.

- [3] H. Wadley, Fabrication and structural performance of periodic cellular metal sandwich structures, Composites Science and Technology 63/16 (2003) 2331-2343.

- [4] J.W.H. Kumar, P.D. Haydn, N.G. Wadley, Z. Xue, Mechanical response of metallic honeycomb sandwich panel structures to high-intensity dynamic loading, International Journal of Impact Engineering 35/9 (2008) 1063-1074.

- [5] H.N.G. Wadley, Multifunctional periodic cellular metals, Philosophical transactions. Series A, Mathematical, Physical, and Engineering Sciences 364/1838 (2006) 31-68.

- [6] M.F. Ashby, The properties of foams and lattices, Philosophical transactions. Series A, Mathematical, Physical, and Engineering Sciences 364/1838 (2006) 15-30.

- [7] A.G. Evans, J.W. Hutchinson, M.F. Ashby, Multifunctionality of cellular metal systems, Progress in Materials Science 43 (1999) 171-221.

- [8] M. Hostetter, B. Cordner, G.D. Hibbard, Stochastic honeycomb sandwich cores, Composites Part B 43/3 (2012) 1024-1029.

- [9] L. Èí, D. Ostroushko, Z. Szulc, R. Molak, M. Praÿmowski, Properties of sandwich metals joined by explosive cladding method, Archives of Materials Science and Engineering 43/1 (2010) 21-29.

- [10] J. Tian, The effects of topology upon fluid-flow and heat-transfer within cellular copper structures, International Journal of Heat and Mass Transfer 47/14-16, (2004) 3171-3186.

- [11] J. Banhart, Manufacture, characterisation and application of cellular metals and metal foams, Progress in Materials Science 46/6 (2001) 559-632.

- [12] T. Lu, L. Valdevit, A. Evans, Active cooling by metallic sandwich structures with periodic cores, Progress in Materials Science 50/7 (2005) 789-815.

- [13] K. Boomsma, D. Poulikakos, F. Zwick, Metal foams as compact high performance heat exchangers, Mechanics of Materials 35/12 (2003) 1161-1176.

- [14] T.J. Lu, H.A. Stone, M.F. Ashby, Heat transfer in open-cell metal foams, Acta Materialia 46/10 (1998) 3619-3635.

- [15] J. Xiong, L. Ma, L. Wu, M. Li, A. Vaziri, Mechanical behaviour of sandwich panels with hollow Al-Si tubes core construction, Materials & Design 32/2 (2011) 592-597.

- [16] K.P. Dharmasena, H.N.G. Wadley, K. Williams, Z. Xue, J.W. Hutchinson, Response of metallic pyramidal lattice core sandwich panels to high intensity impulsive loading in air, International Journal of Impact Engineering 38/5 (2011) 275-289.

- [17] A. Ajdari, H. Nayeb-Hashemi, A. Vaziri, Dynamic crushing and energy absorption of regular, irregular and functionally graded cellular structures, International Journal of Solids and Structures 48/3-4 (2011) 506-516.

- [18] J. Zhou, P. Shrotriya, W.O. Soboyejo, On the deformation of aluminium lattice block structures: from struts to structures, Mechanics of Materials 36 (2004) 723-737.

- [19] G.W. Kooistra, D.T. Queheillalt, H.N.G. Wadley, Shear behaviour of aluminium lattice truss sandwich panel structures, Materials Science and Engineering A 472/1-2 (2008) 242-250.

- [20] M.G. Hebsur, Processing of IN-718 Lattice Block Castings, NASA/CR-2002-211332, 2002, 1-10.

- [21] D. Manas, M. Manas, M. Stanek, M. Danik, Improvement of plastic properties, Archives of Materials Science and Engineering 32/2 (2008) 69-76.

- [22] G.W. Kooistra, H.N.G. Wadley, Lattice truss structures from expanded metal sheet, Materials & Design 28/2 (2007) 507-514.

- [23] K. Mroczka, A. Pietras, FSW characterization of 6082 aluminium alloys sheets, Archives of Materials Science and Engineering 40/2 (2009) 104-109.

- [24] D.T. Queheillalt, H.N.G. Wadley, Cellular metal lattices with hollow trusses, Acta Materialia 53/2 (2005) 303-313.

- [25] J. Banhart, Aluminium foams for lighter vehicles, International Journal of Vehicle Design 37 (2005) 114-125.

- [26] M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, H.N.G. Wadley, Metal Foams, A design Guide. Elsevier Inc., 2000.

- [27] M. Cholewa, Spatial, composite foam castings, Archives of Foundry 3/9 (2003) 81-88 (in Polish).

- [28] M. Ashby, The Mechanical Properties of Cellular Solids, Metallurgical Transactions 14 (1983) 1755-1769.

- [29] Z. Xue, Preliminary assessment of sandwich plates subject to blast loads, International Journal of Mechanical Sciences 45/4 (2003) 687-705.

- [30] http://www.nasa.gov/topics/aeronautics/features/helo-drop-test.html

- [31] M. Cholewa, T. Szuter, Geometrical and mechanical analysis of 3D casted skeleton structure, Archives of Foundry Engineering 10/2 (2010) 23-26.

- [32] M. Cholewa, M. Dziuba-Kałuża, Structural analysis of aluminium skeleton castings, Archives of Foundry Engineering 8/3 (2008) 29-36.

- [33] M. Cholewa, T. Szuter, Heat-insulating moulding sand with the glycol addition, Archives of Foundry 11/3 (2011) 61-64.

Expert Q&A: Your Top Questions Answered

Q1: Why was an octahedron shape chosen for the elementary cell over other topologies?

A1: The paper states that the octahedron shape was selected because it causes the best stress distribution. This is a critical factor for components intended for energy dissipation, such as impact or explosion absorbers. By maximizing stress dissipation throughout the volume of the casting, the structure can handle loads more effectively without localized failure.

Q2: The simulation in Figure 7 predicted shrinkage porosity, but it wasn't observed in the final casting. Why the discrepancy?

A2: The simulation was carried out assuming thermal parameters of classical moulding materials. However, in the real experiments, a high thermo-insulating corundum brick was used for the core. This material has a low thermal conductivity, which improves the filling conditions and ensures a more controlled solidification process. This thermal management effectively counteracted the formation of shrinkage porosity in the hot spots (nodes), demonstrating a key practical implication for manufacturing.

Q3: How did the microstructure differ between the thick nodes and the thin connecting ligaments?

A3: One of the most significant findings was the microstructural homogeneity. As shown in Table 2 and Figure 9, the stereological parameters of the silicon crystals were remarkably similar in both the thick nodes (region 1) and the thin ligaments (region 3). In fact, the cross-section between the nodes (region 3) exhibited a slightly finer structure, which the paper suggests is due to the good thermo-insulating properties of the core and the low diameter of the ligaments, allowing the entire volume to crystallize uniformly and finely.

Q4: What is the main advantage of this casting method over traditional fabrication from sheets and rods for creating cellular metals?

A4: The primary advantage is the ability to produce complex, three-dimensional shapes as a single, integral component. This eliminates the need for joining (like welding or bonding), which often creates weak points at the nodes. The paper highlights that casting allows for the production of structures with almost any shape and a wide range of dimensions, making it a more flexible and potentially lower-cost method that can be implemented in a typical foundry without advanced techniques.

Q5: The paper mentions dynamic strength tests. What was the key takeaway regarding energy absorption?

A5: The dynamic tests, summarized in Figure 11, showed that these skeleton castings are effective for energy absorption, particularly when used as reinforcement in a composite. The deceleration profile changed dramatically when the internal volume of the casting was filled with a liquid (mineral oil or polymeric liquid). This indicates that the energy absorption characteristics can be tuned, making these structures highly adaptable for applications like crash barriers or impact dampers.

Conclusion: Paving the Way for Higher Quality and Productivity

This research effectively bridges the gap between the theoretical advantages of periodic cellular metals and their practical, cost-effective production. By demonstrating that casting can produce intricate, sound, and microstructurally homogenous components, the study opens a new pathway for manufacturing lightweight parts. The key breakthrough is the confirmation that with intelligent process control—especially thermal management through advanced core materials—foundries can create sophisticated Cast Lattice Structures that were previously the domain of complex, multi-stage fabrication.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "The skeleton castings as a new type of cast lattice structures" by "M. Cholewa, T. Szuter, T. Wróbel, M. Kondracki".

- Source: Journal of Achievements in Materials and Manufacturing Engineering 54/2 (2012) 250-259.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.