This introduction paper is based on the paper "Strength of Aluminum Borate Whisker Reinforced Alkali Halides Salt Core" published by "J. JFS (Journal of the Japan Foundry Engineering Society)".

1. Overview:

- Title: Strength of Aluminum Borate Whisker Reinforced Alkali Halides Salt Core (Original Japanese Title: ホウ酸アルミニウムウィスカで強化したアルカリハライド中子の強度)

- Author: Jun Yaokawa, Tomoki Sawada, Koichi Anzai, Youji Yamada, Hiroshi Yoshii and Hiroyuki Fukui

- Year of publication: 2006

- Journal/academic society of publication: J. JFS, Vol. 78, No. 2 (2006) pp. 59~64

- Keywords: salt core, alkali halide, aluminum borate whisker, die casting, expendable core

2. Abstract:

Salt core for the high pressure die casting was investigated. Three alkali halides, i.e. sodium chloride NaCl (98%), potassium bromide KBr (99.7%) and sodium bromide NaBr (99.7%) were prepared as salt material. Aluminum borate whisker which is the best reinforcement for potassium chloride KCl was chosen for the reinforcement of the salt core. These salt materials were melted in an electric resistance furnace and poured into a permanent mold with 30 K super-heat. 4 point bending test was carried out to determine the strength. The maximum whisker addition ratio of KBr and NaBr was about 10 vol% and their strength increased linearly up to about 25 MPa with increasing whisker addition. In contrast to these salts, NaCl could not be reinforced by aluminum borate whisker. SEM-EDX local analysis result shows that magnesium impurity could only be found near the agglomerated whisker in NaCl, suggesting that magnesium impurity in NaCl affects strength to some extent. High purity NaCl (99.5%) could actually be strengthened by aluminum borate whisker; the maximum whisker addition was about 7.6 vol% and the maximum strength increased linearly with the addition of whiskers to about 20 MPa.

3. Introduction:

Die casting processes utilizing expendable cores are gaining attention for manufacturing products with complex undercut geometries. While die casting offers high productivity and cost-effectiveness, its application to parts requiring expendable cores for undercuts has been challenging. There is a growing demand for die-cast undercut components, particularly in the automotive industry, driven by needs for lightweighting, enhanced mechanical strength, and cost reduction through parts consolidation. Expendable cores in die casting must possess high strength to withstand the significant impact forces during high-speed molten metal injection. Additionally, easy and rapid removal of the core after casting, without requiring heat treatment, is crucial. Various types of expendable cores, including sand cores [Ref. 1, 2], metal insert cores [Ref. 3, 4], plastic cores, and salt cores [Ref. 5-7], have been proposed. Salt cores are noted for their high strength, comparable to concrete, and excellent removability due to their water solubility. Although melt-forming of salt cores offers greater freedom in shape design compared to sintering, it has been less studied. A previous study by the authors [Ref. 7] demonstrated that KCl salt cores reinforced with aluminum borate whiskers through melt-forming exhibited exceptionally high strength, suitable for die casting applications. This paper extends that research to investigate whether other alkali halides chemically similar to KCl—specifically, sodium chloride (NaCl), potassium bromide (KBr), and sodium bromide (NaBr)—can also be effectively strengthened using aluminum borate whiskers.

4. Summary of the study:

Background of the research topic:

The research addresses the need for high-strength, easily removable expendable cores for producing complex undercut shapes in high-pressure die casting, particularly for automotive components. Salt cores show promise, but their reinforcement for optimal performance requires further investigation.

Status of previous research:

Previous work indicated that salt cores made from KCl reinforced with aluminum borate whiskers by melt-forming showed high strength [Ref. 7]. However, the applicability of this reinforcement method to other alkali halides was not well understood. Sintering and melt-forming are known methods for salt core production, with melt-forming offering better shape freedom but being less researched.

Purpose of the study:

The purpose of this study was to investigate the strengthening effects of aluminum borate whiskers on different alkali halide salts (NaCl, KBr, NaBr) when prepared by melt-forming, and to compare their performance with previously studied KCl-based cores, particularly focusing on the influence of impurities on the reinforcement of NaCl.

Core study:

The core of the study involved preparing salt cores from three alkali halides (industrial grade NaCl, KBr, NaBr, and high-purity NaCl) reinforced with varying amounts of aluminum borate whiskers. These materials were melted and cast into a permanent mold. The mechanical strength of the resulting salt cores was determined using a 4-point bending test. Microstructural analysis, including SEM and EDX, was performed to understand the whisker distribution, fracture behavior, and the role of impurities, especially in NaCl.

5. Research Methodology

Research Design:

The research was designed to compare the reinforcement effect of aluminum borate whiskers on different alkali halide salts (NaCl, KBr, NaBr) and to investigate the impact of salt purity (industrial vs. high-purity NaCl). Salt-whisker mixtures were melted, stirred, and poured into a permanent mold. The primary outcome measured was bending strength.

Data Collection and Analysis Methods:

Test specimens were prepared by melting the salt materials with aluminum borate whiskers in an electric resistance furnace and pouring them into a permanent mold with a 30 K superheat. Strength was determined using a 4-point bending test (upper span 10 mm, lower span 50 mm, test speed 1.6×10⁻² mm s⁻¹), with strength calculated using the formula σ = 3LP/BH². Microstructural characterization was performed using Scanning Electron Microscopy (SEM) to observe whisker dispersion, agglomeration, and fracture surfaces. Energy Dispersive X-ray Spectroscopy (EDX) was used for local chemical analysis to identify impurities and their distribution.

Research Topics and Scope:

The research focused on:

- Investigating the strengthening potential of aluminum borate whiskers in NaCl, KBr, and NaBr salt cores.

- Determining the maximum whisker addition ratio and corresponding bending strength for these salts.

- Comparing these results with previous findings for KCl.

- Analyzing the effect of impurities (specifically magnesium in NaCl) on the reinforcement mechanism and strength.

- Comparing industrial grade NaCl (97.93% and 98%) with high-purity NaCl (99.5%).

6. Key Results:

Key Results:

- For KBr and NaBr, bending strength increased linearly with aluminum borate whisker addition, similar to KCl. The maximum whisker addition for KBr was about 11.3 vol% (strength ~27 MPa) and for NaBr was about 10.8 vol% (strength ~21 MPa). [Fig. 3]

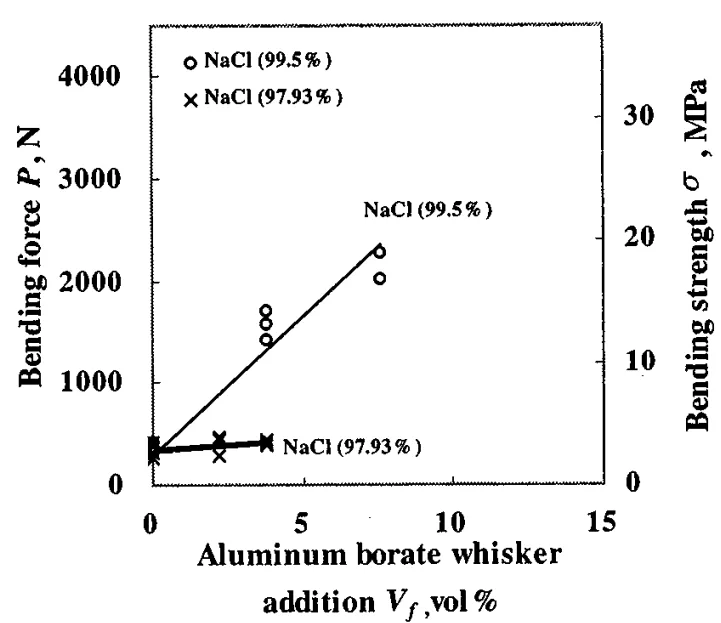

- Industrial grade NaCl (97.93% or 98% purity) could not be effectively reinforced by aluminum borate whiskers. The maximum whisker addition was only about 4 vol%, and the strength (around 3 MPa) was similar to unreinforced NaCl. [Fig. 3]

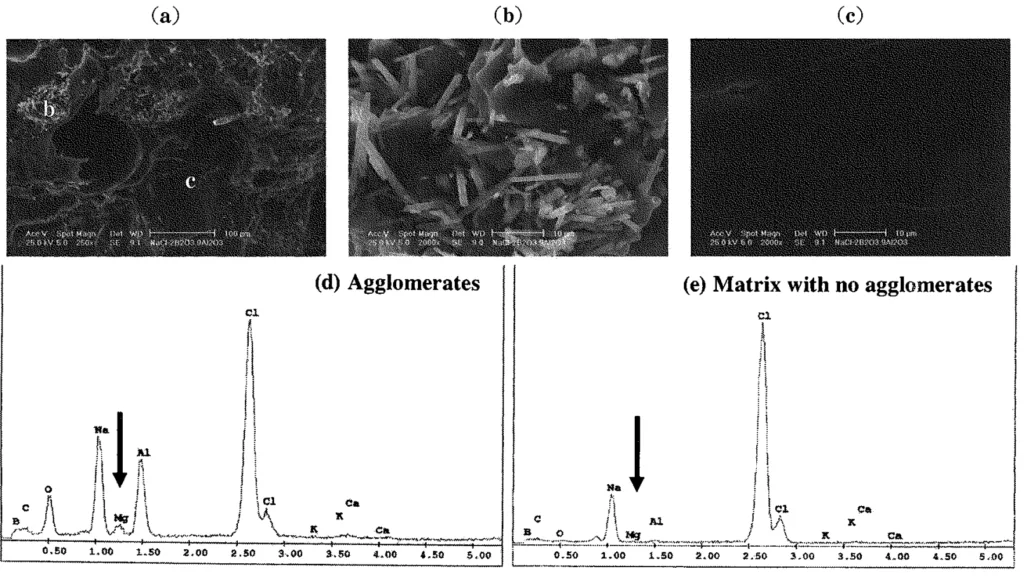

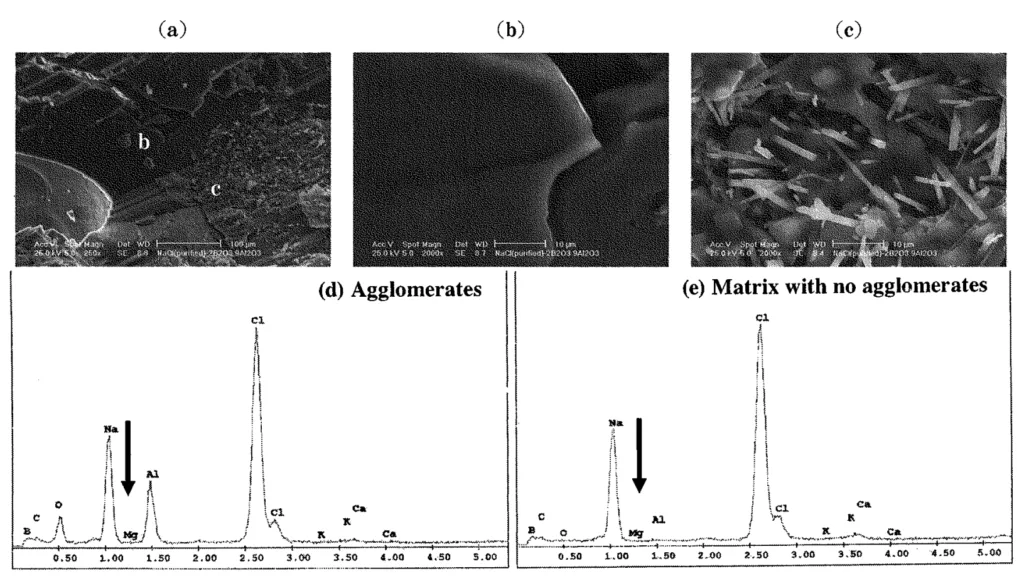

- SEM-EDX analysis of industrial NaCl revealed that magnesium impurity was found near agglomerated whiskers, suggesting it adversely affects strength. [Fig. 6]

- High-purity NaCl (99.5%) could be strengthened by aluminum borate whiskers. The maximum whisker addition increased to about 7.6 vol%, and the maximum strength increased linearly with whisker addition to about 20 MPa. [Fig. 7]

- EDX analysis of high-purity NaCl did not show magnesium segregation near whiskers. [Fig. 9]

- The strengthening mechanism in these salt cores is suggested to be bridging by whiskers, with interfacial strength between the whisker and salt matrix being critical. [Fig. 5, Fig. 8(b)]

- The presence of magnesium impurity in industrial NaCl is thought to interfere with this interfacial strength, possibly through reactions or by altering interfacial properties, rather than causing general whisker degradation.

Figure Name List:

- Table 1: Material properties and purity of alkali halides used in this research 8,9).

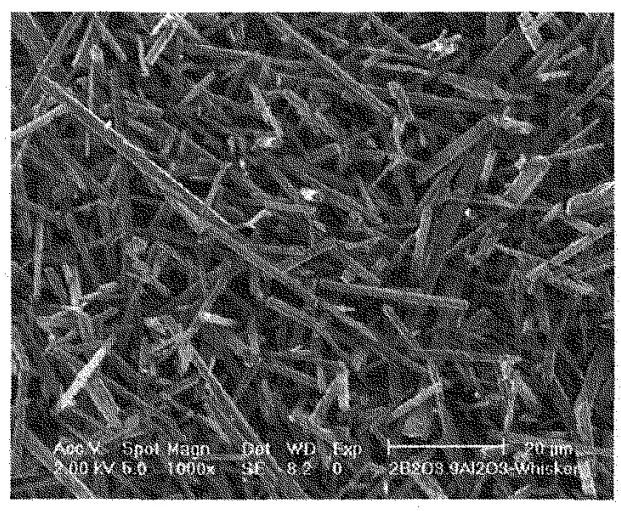

- Fig. 1: SEM image of aluminum borate whisker.

- Fig. 2: Casting design of bending test specimens.

- Fig. 3: Bending strength of industrial grade alkali halides reinforced by aluminum borate whisker.

- Fig. 4: Macrostructures of alkali halides reinforced by aluminum borate whisker. Whisker additions are (a) 4.1 vol%, (b) 4.7 vol%, (c) 5.5 vol%, (d) 3.8 vol%.

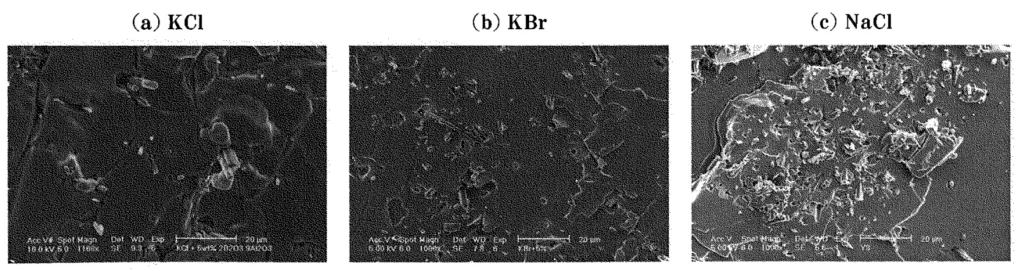

- Fig. 5: Microstructures of industrial grade alkali halides reinforced by aluminum borate whisker. Whisker additions are (a) 4.1 vol%, (b) 4.7 vol% and (c) 3.8 vol%.

- Fig. 6: Microstructures and EDX results of industrial grade NaCl (97.93%) reinforced by 3.8vol% aluminum borate whisker. (a) is SEM image with low magnification. (b) and (c) are enlarged area in fig.6 (a). (d) and (e) are EDX results analyzed at fig. 6 (b) and (c), respectively.

- Fig. 7: Bending strength of industrial grade NaCl (97.93%) and purified NaCl (99.5%) reinforced by aluminum borate whiskers.

- Fig. 8: (a) Macrostructure of purified NaCl (99.5%) reinforced by aluminum borate whisker. Whisker addition is 3.8 vol%. (b) Microstructure of the same specimen.

- Fig. 9: Microstructures and EDX results of purified NaCl (99.5%) reinforced by aluminum borate whisker. Whisker addition is 3.8vol%. (a) is SEM image with low magnification. (b) and (c) are enlarged area in fig. 6 (a). (d) and (e) are EDX results analyzed at fig.6 (b) and (c), respectively.

7. Conclusion:

(1) When reinforcing alkali halides with aluminum borate whiskers, the maximum castable whisker addition was highest for KCl (13 vol%), followed by KBr (11.3 vol%), and then NaBr (10.8 vol%). The maximum bending strength obtained for KCl was approximately 30 MPa, while KBr achieved a similar strength of about 29 MPa. KBr, with a melting point of 1007 K (36 K lower than KCl's 1043 K), is also well-suited for melt forming processes.

(2) Industrial grade NaCl showed poor reinforcement with aluminum borate whiskers; the maximum whisker addition was abnormally low at about 4 vol%, and no significant strengthening was observed. In contrast, high-purity NaCl demonstrated improved reinforcement, with the maximum whisker addition increasing to 7.6 vol% (almost double that of industrial NaCl) and achieving a maximum strength of approximately 20 MPa.

(3) Magnesium impurity present in industrial NaCl was found to segregate to the agglomerated whisker regions. This suggests that such impurities significantly influence the maximum achievable whisker addition and the resulting strength of the composite. Therefore, to effectively strengthen salt cores using aluminum borate whiskers, it is crucial to implement measures to prevent impurity contamination.

8. References:

- M. Yamazaki, A. Takai, O. Murakami, M. Kawabata, O. Ito and M. Kawabata: SAE Technical Paper 2004-01-1447

- T. Manabe, M. Nitta and M. Yaguchi: SOKEIZAI, 44 (2003) no. 12, pp. 26-30

- Y. Mizukusa, U. S. Patent No. 5, 690, 159 (Nov. 25, 1997)

- R. Izawa, T. Takayama, Y. Mizukusa and T. Komazaki: Report of Japan Die Casting Association, JD02 (2002) 223

- A. D. Ackerman and H. A. Aula, U.S. Patent No. 4, 446, 906 (May 8, 1984)

- Y. Kaneko and A. Morita; Report of Japan Die Casting Association, K71 (1971)45

- J. Yaokawa, K. Anzai, Y. Yamada, H. Yoshii and H. Fukui: J. JFS, 76 (2004)823

- Janz G. J: Molten Salts Handbook, New York, London: Academic press, (1967)

- Japan Society of Thermophysical Properties: Thermophysical Property Handbook, Yokendo, (1990) 106

- Y. Kagawa and H. Hatta: "Ceramic Matrix Composites-Tailoring Ceramic Composites", Agune Shohusha, (1990)

- J. Pan, S. P. Lee, M. Yoshida, G. Sasaki, N. Fuyama, T. Fujii and H. Fukunaga: Adv. Composite Mater., 10 (2001) 299

- X. G. Ning, J. Pan, K. Y. Hu and H. Q. Ye: Mater. Letters, 13 (1992) 377

- W. Y. Zheng, K. Wu, M. Liang, S. Kamado and Y. Kojima: Mater. Sci. Eng. A372 (2004) 66

9. Copyright:

- This material is a paper by "Jun Yaokawa, Tomoki Sawada, Koichi Anzai, Youji Yamada, Hiroshi Yoshii and Hiroyuki Fukui". Based on "Strength of Aluminum Borate Whisker Reinforced Alkali Halides Salt Core".

- Source of the paper: DOI not available in the provided document. J. JFS, Vol. 78, No. 2 (2006) pp. 59~64.

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.

Paper Summarize:

Key questions and answers about the research:

This paper investigated the strengthening effects of aluminum borate whiskers on various alkali halide salt cores (NaCl, KBr, NaBr) for high-pressure die casting, comparing them to previous results with KCl. The study found that KBr and NaBr could be effectively strengthened, similar to KCl, but industrial NaCl showed poor reinforcement due to magnesium impurities affecting the whisker-matrix interface. High-purity NaCl, however, could be strengthened, highlighting the critical role of impurity control in developing high-strength salt cores.

Q1. What was the primary goal of this research regarding salt cores for die casting?

A1. The primary goal was to investigate if alkali halides (NaCl, NaBr, KBr), which are chemically similar to KCl, could be effectively strengthened by aluminum borate whiskers for use as salt cores in high-pressure die casting. [Source: "Strength of Aluminum Borate Whisker Reinforced Alkali Halides Salt Core", Section 1. はじめに]

Q2. How did the reinforcement with aluminum borate whiskers affect KBr and NaBr salts?

A2. For KBr and NaBr, the bending strength increased linearly with increasing whisker addition, reaching up to about 25 MPa, similar to previous findings with KCl. The maximum whisker addition was about 11.3 vol% for KBr and 10.8 vol% for NaBr. [Source: "Strength of Aluminum Borate Whisker Reinforced Alkali Halides Salt Core", Section 3.1, Fig. 3]

Q3. What was observed when industrial grade NaCl was reinforced with aluminum borate whiskers?

A3. Industrial grade NaCl could not be effectively reinforced; the maximum whisker addition was only about 4 vol%, and the strength (about 3 MPa) did not significantly improve compared to unreinforced NaCl. [Source: "Strength of Aluminum Borate Whisker Reinforced Alkali Halides Salt Core", Section 3.1, Fig. 3]

Q4. What was identified as a key factor for the poor reinforcement of industrial NaCl?

A4. SEM-EDX analysis revealed that magnesium impurity in industrial NaCl segregated near agglomerated whiskers, suggesting that this impurity adversely affected the strength. [Source: "Strength of Aluminum Borate Whisker Reinforced Alkali Halides Salt Core", Section 3.2, Fig. 6]

Q5. Did high-purity NaCl show better reinforcement characteristics?

A5. Yes, high-purity NaCl (99.5%) could be strengthened by aluminum borate whiskers. The maximum whisker addition increased to about 7.6 vol%, and the strength increased linearly with whisker addition to about 20 MPa. [Source: "Strength of Aluminum Borate Whisker Reinforced Alkali Halides Salt Core", Section 3.3, Fig. 7]

Q6. What is the main conclusion regarding the use of aluminum borate whiskers for strengthening alkali halide salt cores, especially concerning impurities?

A6. Magnesium impurities present in industrial NaCl were found to segregate at whisker agglomerates and negatively impact the maximum whisker loading and strength. Therefore, to successfully strengthen salt cores using aluminum borate whiskers, it is crucial to prevent the contamination of impurities. [Source: "Strength of Aluminum Borate Whisker Reinforced Alkali Halides Salt Core", Section 4. 結 論 (3)]