This introduction paper is based on the paper "Optimisation of die casting process in Zamak alloys" published by "Procedia Manufacturing".

1. Overview:

- Title: Optimisation of die casting process in Zamak alloys

- Author: Helder Pinto, F. J. G. Silva

- Year of publication: 2017

- Journal/academic society of publication: Procedia Manufacturing

- Keywords: Modelling and Simulation, High-Pressure Die Casting, Sustainable Manufacturing, Zero-Defect Manufacturing, Artificial Intelligence in Manufacturing.

2. Abstract:

The casting industry is one of the major industries in the world with a great impact in everybody's life. Die casting is a process where a permanent mould is used, and melted metal is injected by pressure, allowing smaller cycles and continuum parts production. This study is focused in die casting applied to automobile industry where many casted parts are used in their components. The study was developed in order to maximise the quality of small parts injected in Zamak alloy for automotive components. Using simulation, the runners' location was improved as well as gas relief.

3. Introduction:

The automotive industry is one of the most demanding sectors, driven by restrictive laws on safety and environmental concerns. This necessitates continuous technological advancement to meet goals like reduced emissions, improved fuel economy, enhanced safety, and better performance, often at lower costs [1, 2, 3]. Quality is a paramount factor in this industry; poor-quality products can lead to severe consequences, including reputational damage, injuries, and financial losses [4]. Consequently, robust quality standards and management philosophies like Total Quality Management (TQM) are widely implemented [5, 6, 7].

High-pressure die casting is a prevalent manufacturing process for producing accurate, sharply defined metal parts, especially nonferrous castings, at high speeds using reusable steel dies [8, 9]. The process involves injecting molten metal under high pressure into a die, which must incorporate features like runners, a thermal system, gates, and vents to ensure proper filling and solidification, and to allow gases to escape. Many variables, including temperatures, pressures, and times, must be precisely controlled to achieve defect-free parts.

4. Summary of the study:

Background of the research topic:

The research is set against the backdrop of the automotive industry's stringent requirements for component quality and the widespread use of high-pressure die casting for manufacturing small, complex parts from alloys like Zamak. Specifically, it addresses the challenges in producing command cable terminals, where defects can compromise functionality. The inherent complexity of die casting, with its numerous interacting process parameters, makes defect prevention a significant concern.

Status of previous research:

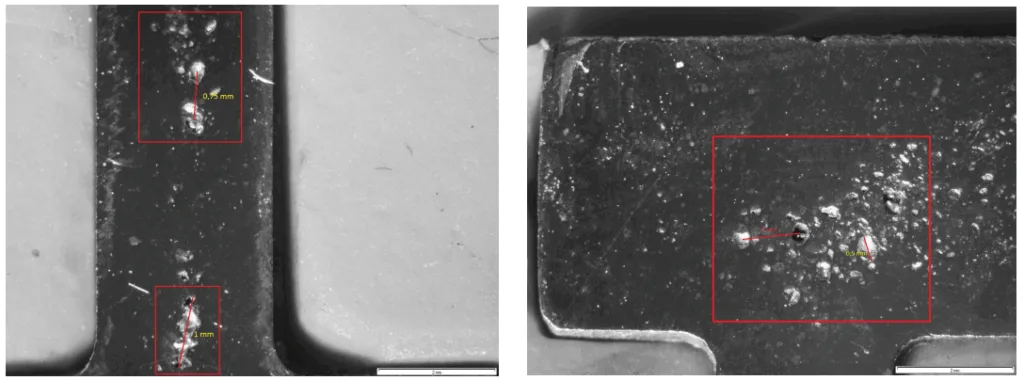

Previous work and industry practice acknowledge that die casting defects such as porosities are common if process parameters are not carefully controlled [12]. Finite Element Methods (FEM) and Scientific Fluid Dynamics (CFD) are recognized as valuable tools for analyzing and optimizing the die casting process, as advised by organizations like NADCA [10]. However, practical understanding of the specific part's geometry and its influence on metal flow remains crucial. Initial investigation of the parts under study revealed micro-porosities, primarily attributed to entrapped gases, as shown by microscopic analysis (Fig. 3b), indicating a need for mould design improvements.

Purpose of the study:

The primary goal of this study was to maximise the quality of small Zamak alloy parts used in automotive command cables. This was to be achieved by improving the mould design, specifically focusing on optimising the runners' location and incorporating effective gas relief. The study also aimed to use simulation as a tool to understand the factors causing defects and to develop guidelines for designing moulds for these types of components.

Core study:

The core of the study involved the optimisation of the high-pressure die casting process for a specific Zamak alloy terminal, characterized by an "extended H shape" (Fig. 2b), which was prone to casting defects. The research utilized simulation to:

- Analyse the existing casting process, identifying the root causes of defects such as micro-porosities (Fig. 3).

- Propose and evaluate modifications to the mould design, including changes to the runner system (from two runners to one), the introduction of a venting system, and redesign of sprues.

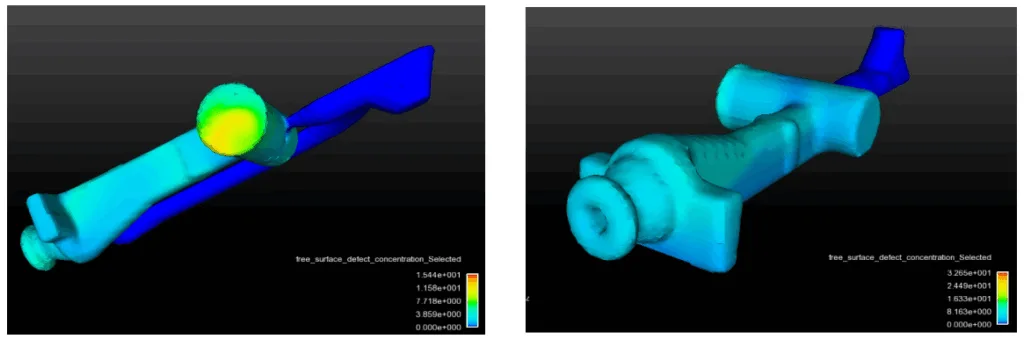

- Assess the impact of these changes on reducing defects like air entrapment (Figure 5) and surface defects (Figure 6 on page 7), aiming for improved part quality.

5. Research Methodology

Research Design:

The research employed a comparative study methodology based on simulation. The existing die casting process and mould design for the selected Zamak terminal were first simulated to establish a baseline and identify problem areas. Subsequently, modifications to the mould design (runners, venting system, sprues) were conceptualized. These modified designs were then simulated to predict their effectiveness in improving the filling process and reducing defects, allowing for a comparison with the initial design.

Data Collection and Analysis Methods:

Finite element simulation software, specifically SOLIDCast and FLOWCast from Finite Solutions, Inc., with additional support from FLOW3D, was the primary tool. Key parameters used in the simulations (Table 1) included: molten Zamak temperature (440°C), mould temperature (100°C), injection speed (5.093 m/s), injection time (0.30 s), and solidification time (0.35 s). Boundary conditions for the Steel H-13 mould material were defined as per Table 2. The analysis of simulation outputs focused on parameters such as fluid velocity vectors during mould filling (figure 4a), air entrainment, temperature distribution, cavitation potential, and the concentration of surface defects. Additionally, physical parts were subjected to microscopic analysis to observe and characterize existing defects (Fig. 3).

Research Topics and Scope:

The study concentrated on the high-pressure die casting of small Zamak 3 alloy terminals used in automotive command cables (Figure 1). A specific terminal geometry (Fig. 2b), known for its susceptibility to casting defects like micro-porosities, was selected as the case study. The scope of the research encompassed:

- Analysis of the existing mould filling conditions, particularly the flow pattern with two runners (figure 4a).

- Identification of issues such as air entrapment and turbulence resulting from the initial runner design.

- The proposal and simulation-based evaluation of improvements, including:

- Changing the runner configuration from two runners to a single runner.

- Designing and incorporating a venting system to allow trapped gases to escape.

- Redesigning sprues to optimize filling pressures and speeds.

6. Key Results:

Key Results:

The simulation results demonstrated that the initial design with two runners led to turbulence as the fluid jets collided, causing air and gases to be entrapped within the part (Figure 5a). This turbulence was exacerbated when the returning fluid, after hitting the front of the piece, collided with the incoming filling stream. This process resulted in the formation of micro and macroporosities.

Comparisons between the initial (two-runner) and modified (single-runner) designs showed significant improvements:

- Air Entrapment: The volume fraction of entrained air was higher with two runners because gases were divided and spread during filling, and turbulence increased gas mixing. The single runner design concentrated gases at the front of the stream, reducing dispersion and leading to a better filling process (Figure 5, Table 3).

- Surface Defects: Free surface defects were also more prevalent in the two-runner configuration compared to the single-runner design (Figure 6 on page 7, Table 3).

- Mould Design Modifications:

- Runners Redesign: Changing from two runners to a single runner filling the back of the part was implemented to achieve a more laminar flow and reduce turbulence (as depicted in the mould changes from Figure 6a to Figure 6b on page 8).

- Venting System: A venting system was created and strategically placed where gas accumulation was highest (front and back sides of the part, Figure 6b on page 8) to allow gases to escape.

- Sprues Redesign: Sprues were redesigned (diameter change) to optimize pressures and speeds, aiming to prevent shrinkage porosities during solidification.

The critical analysis indicated that these mould layout changes (feeding, venting, and sprue adjustments) could lead to improved, conformal parts without requiring expensive equipment changes. The shift to a single runner promoted laminar flow, gas escapes prevented entrapment, and sprue improvements led to steadier filling. The overall goal of achieving a laminar flow with minimal gases and porosities was deemed achievable.

Figure Name List:

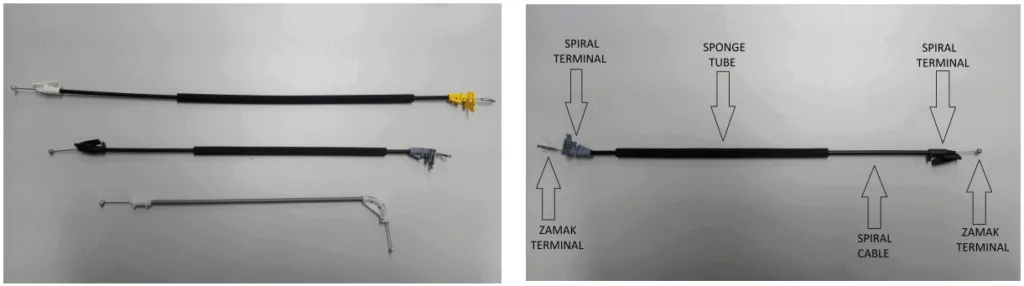

- Figure 1. (a) Examples of command cables; (b) Command cable components

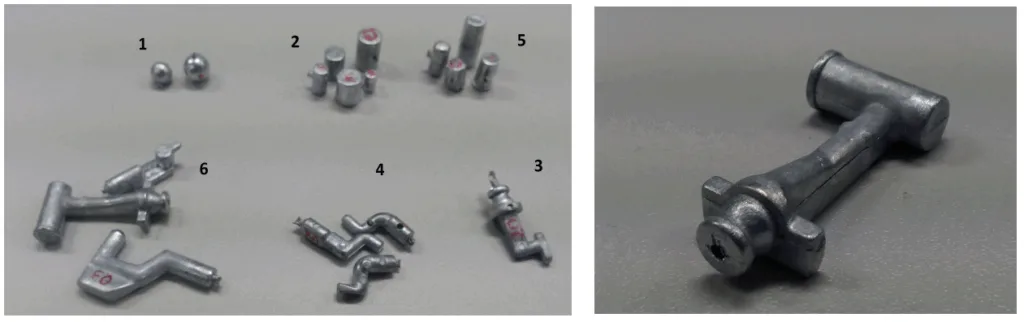

- Fig. 2. (a) Family and shapes of terminals used ((1) spherical, (2) cylinders, (3) L shapes, (4) S shape or cranks, (5) modified cylinders, (6) special shapes); (b) Piece to be studied.

- Fig. 3. (a) Cut view of defects in the middle section of the piece; (b) Transversal cut view of the back section showing the same defects as in a) but in a much larger scale.

- Fig. 4. (a) View from the beginning of the filling (two runners); (b) View of the half-time of process (two streams colliding)

- Figure 5. Volume fraction of entrained air (a) initial situation and (b) after changes

- Figure 6. Free Surface Defects (a) initial situation and (b) after changes

- Figure 6. Mould figures a) before being altered b) after the changes

7. Conclusion:

This study successfully identified key factors affecting the high-pressure die casting process of small Zamak alloy parts, particularly runner location, venting, cooling processes, and parameter selection. Simulation proved invaluable in understanding pore formation mechanisms and highlighting the critical importance of runner design and effective venting to avoid issues stemming from improper cooling, gas entrapment, or poor parameter choices.

The research provides practical guidelines for future mould development for similar parts, potentially saving time and costs by reducing simulation iterations. The main guidelines for a good approach are:

- Determine the metal flow rate based on the cavity volume.

- Optimize sprue flow type using Reynolds' number (aim for laminar flow: Re < 2300, never > 10000).

- Define the appropriate injection speed relative to the target Reynolds' number.

- Calculate sprue cross-sections based on the determined speeds.

- Define the necessary heat extraction rate to prevent solidification shrinkage.

- Establish the cooling fluid flow speed required to dissipate the injected metal's heat.

- Define the optimal mould temperature.

- Utilize flow injection analysis to identify optimal locations for vents, targeting areas with high gas trapping potential based on piece geometry.

The use of FE simulation simplifies feeder positioning and helps prevent unexpected defects. Phenomena like turbulence (influenced by feeding steps/runners) and careful feeder location (ensuring progressive solidification) are crucial aspects that require attention during simulations. These simulation-driven insights can help overcome reliance on empirical rules, thereby improving the quality and reproducibility of small cast parts used in the automotive industry and other sectors.

8. References:

- [1] Brian Cantor, Patrick Grant, Colin Johnston, "Automotive Engineering Lightweight, Functional, and Novel Materials Series in Materials Science and Engineering", CRC Press Taylor & Francis Group, pp 16, 2008

- [2] Brian Cantor, Patrick Grant, Colin Johnston, "Automotive Engineering Lightweight, Functional, and Novel Materials Series in Materials Science and Engineering", CRC Press Taylor & Francis Group, pp 3, 2008

- [3] Brian Cantor, Patrick Grant, Colin Johnston, "Automotive Engineering Lightweight, Functional, and Novel Materials Series in Materials Science and Engineering", CRC Press Taylor & Francis Group, pp 3, 2008

- [4] Jay Hazer, Barry Render, Chuck Munson, "Operations management", 12nd edition, Sustainability and Supply Chain Management, Pearson, pp 219, 2017.

- [6] William J. Stevenson, Operations management 12th edition", McGraw-Hill Education New York, pp 385, 2015. (Note: Reference [5] is missing in the original paper's list, jumping from [4] to [6])

- [7] Jay Hazer, Barry Render, Chuck Munson, "Operations management", 12th edition, Sustainability and Supply Chain Management, Pearson, pp 220, 2017.

- [8] Bill Andersen, "Die Casting Engineering A Hydraulic, Thermal, and Mechanical Process", Marcel Dekker, pp IX, 2005

- [9] Bill Andersen, "Die Casting Engineering A Hydraulic, Thermal, and Mechanical Process", Marcel Dekker, pp X, 2005

- [10] NADCA North American Die Casting Association, "Product Specification Standards for Die Casting," 9th edition, Section 7, page 7-3, 2015.

- [11] Eduardo Miguel Guimarães Ferreira Braga, "Otimização do processo de injeção de Zamak". MSc. Thesis, ISEP – Instituto Superior de Engenharia do Porto, pp 38-41, 2015.

- [12] ASM "Metals Handbook Vol. 15, Casting", ASM International, pp 629, 2002.

9. Copyright:

- This material is a paper by "Helder Pinto, F. J. G. Silva". Based on "Optimisation of die casting process in Zamak alloys".

- Source of the paper: https://doi.org/10.1016/j.promfg.2017.07.145

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.

Key Questions & Answers for Researchers:

Q1. What was the primary cause of porosities in the studied Zamak die cast parts?

A1. Micro-porosities were found to be mainly caused by entrapped gases due to the mould design and filling process, particularly turbulence created during filling, as observed in microscopic analysis (Fig. 3b) and simulation results.

Q2. How did the number of runners affect air entrapment and turbulence during mould filling?

A2. Using two runners created more turbulence due to colliding fluid jets and led to greater air entrapment, with gases being divided by both streams and spread during filling time (Figure 5a). A single runner resulted in gases being more concentrated in front of the stream, decreasing dispersion and leading to a better filling process (Figure 5b, Table 3).

Q3. What specific mould design changes were proposed to improve part quality based on the simulations?

A3. The proposed changes included: A. Redesigning runners from two to a single runner, filling the back of the part (Figure 6 on page 8); B. Creating a venting system with escapes implemented where the biggest gas accumulation could occur (front and back sides, Figure 6b on page 8); C. Redesigning sprues by changing their diameter to set appropriate pressures and speeds to avoid shrinkage porosities.

Q4. What role did simulation play in this study for optimising the die casting process?

A4. Simulation (using SOLIDCast, FLOWCast, and FLOW3D) was the main tool to analyse the filling process (figure 4a), identify factors influencing pore creation (like turbulence from two runners), compare the initial design with improved designs (Figure 5, Figure 6 on page 7), and thereby guide improvements in runner location and gas relief.

Q5. What are the key parameters to control for achieving a laminar flow in die casting according to this study's conclusions?

A5. To achieve laminar flow, the study's guidelines suggest finding the best sprue flow type by using Reynolds' number (a good flow should be laminar, so Reynolds' number should be less than 2300 and never bigger than 10000), defining the right speed relative to the obtained Reynolds' number, and calculating de sprues' sections to the speeds obtained.

Q6. What general guidelines for mould design in high-pressure die casting of small Zamak parts were derived from this research?

A6. The study proposed an 8-step guideline for a good approach: 1. Know cavity volume to find metal flow rate. 2. Find best sprue flow type using Reynolds' number. 3. Define speed relative to Reynolds' number. 4. Calculate sprue sections. 5. Define heat rate for solidification shrinkage. 6. Define cooling fluid flow speed. 7. Define mould temperature. 8. Use flow analysis to define vent locations where gas trapping is high.