압력 다이 캐스팅에서 구리 합금 다이의 열 거동에 대한 실험적 조사

L. D. Clark, M. T. Alonso Rasgado, K. Davey, S. Hinduja

Author and Article InformationJ. Manuf. Sci. Eng. Nov 2006, 128(4): 844-859 (16 pages)

https://doi.org/10.1115/1.2280586

Published Online: February 3, 2006

Abstract

The rate of heat extraction during the pressure die casting process is central to both the quality and the cost of finished castings. Recent efforts to reduce the thermal resistance of dies by optimizing the effectiveness of the cooling channels have shown the potential for improvement. Reducing the thermal resistance of the coolant boundary layer means that a significant proportion of the total thermal resistance becomes attributable to the die steel. Further significant reductions in die thermal resistance can be obtained by replacing the steel with copper. This paper investigates the feasibility of using copper dies, reinforced with steel inserts and coated with a thin layer of wear resistant material, which is deposited using the thermal arc spray process. Experimental work relating to the thermal spray process has been undertaken to establish bond strengths and thermal conductivities for various process parameters. Moreover, experimental investigations have been carried out using two copper coated dies, the first of which was a pseudodie block heated by an infrared heater. The second die was tested on a die casting machine and produced zinc alloy castings at a greatly increased production rate when compared to its steel counterpart. The experimental results from the two dies are compared with those predicted by an in-house thermal-cum-stress model based on the boundary element method. Reasonable agreement between the predicted and experimental results is shown and the feasibility of copper-alloyed dies for pressure die casting is established.

Korea Abstract

압력 다이 캐스팅 공정 중 열 추출 속도는 완성된 주물의 품질과 비용 모두의 핵심입니다. 냉각 채널의 효율성을 최적화하여 다이의 열 저항을 줄이려는 최근의 노력은 개선 가능성을 보여주었습니다.

냉각수 경계층의 열 저항을 줄인다는 것은 전체 열 저항의 상당 부분이 금형강에 기인한다는 것을 의미합니다. 강철을 구리로 교체하면 다이 열 저항을 더욱 크게 줄일 수 있습니다.

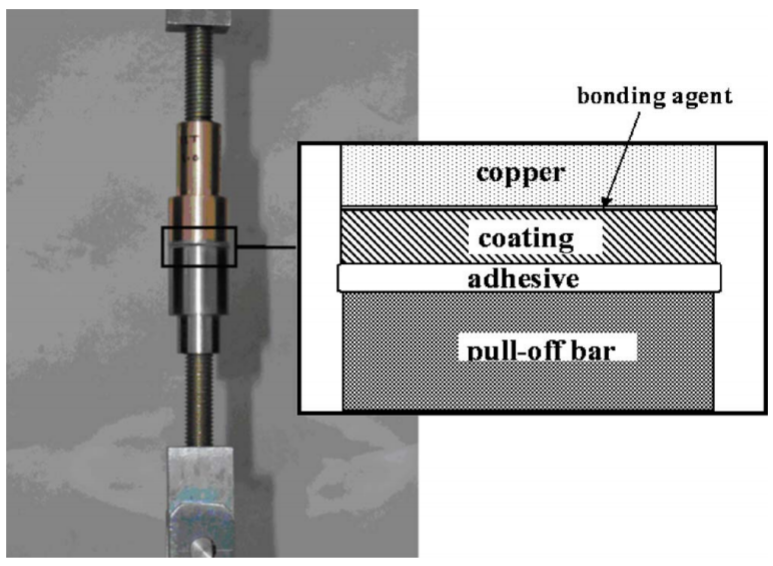

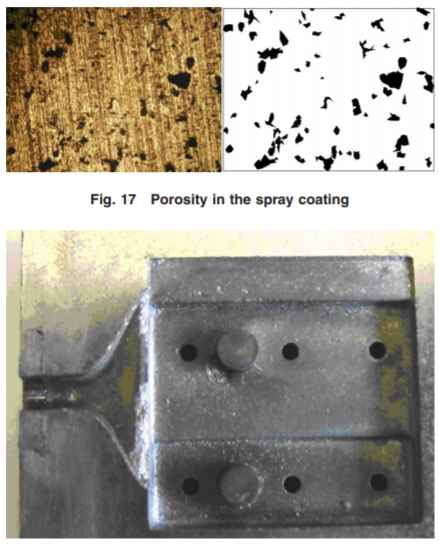

이 논문은 강철 인서트로 강화되고 내마모성 재료의 얇은 층으로 코팅된 구리 다이를 사용하는 가능성을 조사하고 열 아크 스프레이 공정을 사용하여 증착됩니다. 다양한 공정 매개변수에 대한 접착 강도와 열전도도를 설정하기 위해 열 분무 공정과 관련된 실험 작업이 수행되었습니다.

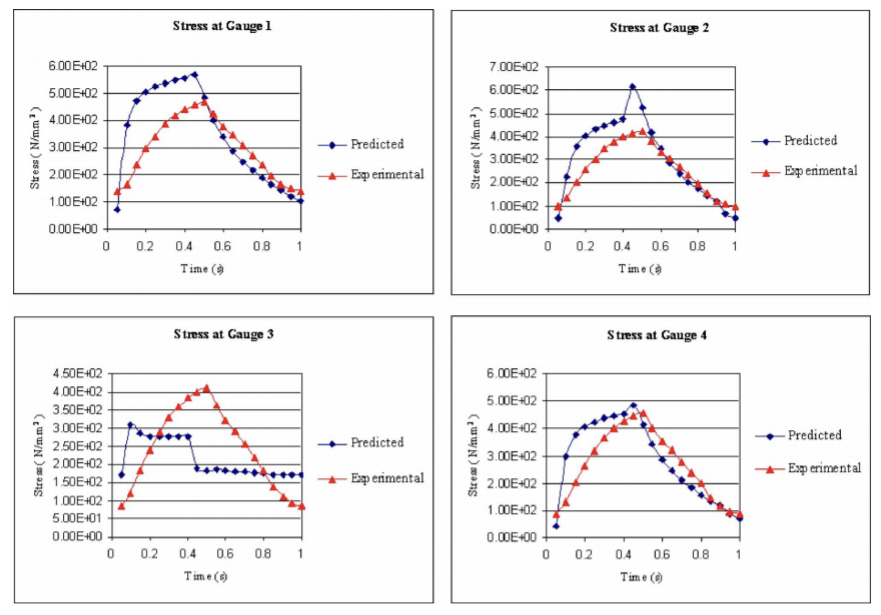

더욱이, 두 개의 구리 코팅된 다이를 사용하여 실험적 조사가 수행되었으며, 그 중 첫 번째는 적외선 히터로 가열된 유사 다이 블록이었습니다. 두 번째 다이는 다이캐스팅 기계에서 테스트되었으며 강철 대응물과 비교할 때 크게 증가한 생산 속도로 아연 합금 주물을 생산했습니다.

두 다이의 실험 결과는 경계 요소 방법에 기반한 사내 열-컴-응력 모델에 의해 예측된 결과와 비교됩니다. 예측 결과와 실험 결과 사이에 합리적인 일치가 나타나며 압력 다이 캐스팅을 위한 구리 합금 다이의 실행 가능성이 설정됩니다.

Keywords:copper alloys, dies (machine tools), die casting, wear resistant coatings, thermal spraying, thermal resistance, boundary-elements methods

Topics:Casting, Cavities, Copper, Die casting (Process), Pressure, Steel, Temperature, Coatings, Bond strength, Cooling, Thermal conductivity, Sprays, Transients (Dynamics), Die castings (Product), Stress, Thermal resistance, Thermocouples, Boundary element methods

Reference

1.Street, A., 1975, “Developments in Pressure Diecasting,” Int. Metall. Rev. 0367-9020, 20, pp. 121–136.

2.Bounds, S., Davey, K., and Hinduja, S., 2000, “An Experimental and Numerical Investigation Into the Thermal Behavior of the Pressure Die Casting Process,” ASME J. Manuf. Sci. Eng. 1087-1357, 122(1), pp. 90–99.

3.Prabhu, K. N. , and Cambell, J., 1999, “Investigation of Casting/Chill Interfacial Heat Transfer During Solidification of Al-11% Si Alloy by Inverse Modelling and Real-Time X-Ray Imaging,” Int. J. Cast Metal Res., 12(3), pp. 137–143.

4.Adeleke, J., 1998, “A Steptype Technique of Natural Regularization for Determining Interfacial Conditions in the Diecasting Process,” Scand. J. Metall. 0371-0459, 27(6), pp. 240–245.

5.Das, S., and Paul, A. J. , 1993, “Determination of Interfacial Heat-Transfer Coefficients in Casting and Quenching Using a Solution Technique for Inverse Problems Based on the Boundary Element Method,” Metall. Trans. B 0360-2141, 24(6), pp. 1077–1086.

6.Clark, L. D. , Rosindale, I., Davey, K., and Hinduja, S., 2000, “Predicting Heat Extraction Due to Boiling in the Cooling Channels During the Pressure Die Casting Process,” Proc. Inst. Mech. Eng., Part C: J. Mech. Eng. Sci. 0954-4062, 214(3), pp. 465–482.

7.Clark, L. D. , and Davey, K., 2001, “Novel Cooling Channel Shapes in Pressure Die Casting,” Int. J. Numer. Methods Eng. 0029-5981, 50(10), pp. 2411–2440.

8.Atkinson, H. V. , and Rickinson, B. A. , 1991, Hot Isostatic Processing (The Adam Hilger Series on Manufacturing Processes and Materials), Kluwer, Dordrecht.

9.Pawlowski, L., 1994, The Science and Engineering of Thermal Spray Coatings, Wiley, New York.

10.Davey, K., and Hinduja, S., 1990, “Modelling the Pressure Diecasting Process With the Boundary Element Method: Steady State Approximation,” Int. J. Numer. Methods Eng. 0029-5981, 30(7), pp. 1275–1299.

11.Davey, K., and Hinduja, S., 1990, “Modelling the Transient Thermal Behavior of the Pressure Diecasting Process With the Boundary Element Method,” Appl. Math. Model. 0307-904X, 14(8), pp. 394–409.

12.Davey, K., Bounds, S., Rosindale, I., and Alonso Rasgado, M. T. , 2002, “A Coarse Preconditioner for Multi-Domain Boundary Element Equations,” Comput. Struct. 0045-7949, 80(7–8), pp. 643–658.

13.Brebbia, C. A. , 1978, The Boundary Element Method for Engineers, Pentech Press, London.

14.Clark, L. D. , Davey, K., Rosindale, I., and Hinduja, S., 2002, “Determination of Heat Transfer Coefficients Using a 1-D Flow Model Applied to Irregular Shaped Cooling Channels in Pressure Die Casting,” ASME J. Manuf. Sci. Eng. 1087-1357, 122(4), pp. 678–690.

15.Rizzo, F. J. , and Shippy, D. J. , 1977, “An Advanced Boundary Integral Equation Method for Three-Dimensional Thermoelasticity,” Int. J. Numer. Methods Eng. 0029-5981, 11, pp. 1753–1768.

16.Milroy, J., Hinduja, S., and Davey, K., 1997, “The Elastostatic Three-Dimensional Boundary Element Method: Analytical Integration for Linear Isoparametric Triangular Elements,” Appl. Math. Model. 0307-904X, 21(12), pp. 763–782.

17.Davey, K., and Clark, L. D. , 2003, “Sensitivity and Optimization for Shape and Non-Linear Boundary Conditions in Thermal Boundary Elements,” Int. J. Numer. Methods Eng. 0029-5981, 56(4), pp. 553–587.

18.Alonso Rasgado, M. T. , Davey, K., Hinduja, S., and Clark, L. D. , 2006, “Boundary Element Stress Analysis for Copper Based Dies,” Comput. Struct. 0045-7949, 84, pp. 254–267.