This article introduces the paper 'Evaluation of Thermal Stability and Its Effect on the Corrosion Behaviour of Mg-RE Alloys Processed by High-Pressure Torsion' published by MDPI.

1. Overview:

- Title: Evaluation of Thermal Stability and Its Effect on the Corrosion Behaviour of Mg-RE Alloys Processed by High-Pressure Torsion

- Author: Hiba Azzeddine, Abdelkader Hanna, Achour Dakhouche, Thierry Baudin, François Brisset, Yi Huang, and Terence G. Langdon

- Publication Year: 2023

- Publishing Journal/Academic Society: Crystals (MDPI)

- Keywords: high-pressure torsion; magnesium; rare-earth alloys; texture; thermal stability

2. Abstracts or Introduction

This research paper evaluates and compares the microstructure, texture evolution, and corrosion behavior of low light rare-earth (LREE) containing Mg-1.4Nd and low heavy rare-earth (HREE) containing Mg-0.6Gd and Mg-0.4Dy alloys. The alloys were processed using high-pressure torsion (HPT) and subsequently annealed isochronally at 250 °C and 450 °C for 1 hour. The characterization techniques employed were electron backscatter diffraction (EBSD) and electrochemical tests in a 3.5% (wt.%) NaCl solution. The study reveals that dynamic recrystallisation (DRX) was restricted in the Mg-1.4Nd alloy, leading to a heterogenous deformation microstructure, while Mg-0.6Gd and Mg-0.4Dy alloys exhibited homogenous microstructures of equiaxed dynamically recrystallised DRX grains. HPT processing induced a deviated basal texture in all three alloys. Thermal stability at 250 °C was observed for all alloys, whereas annealing at 450 °C resulted in a homogenous equiaxed microstructure and texture weakening in Mg-1.4Nd, and a heterogenous bimodal microstructure with stable basal texture in Mg-0.6Gd and Mg-0.4Dy. HPT processing improved corrosion resistance due to grain refinement. However, the corrosion resistance of Mg-0.6Gd and Mg-0.4Dy decreased with increasing annealing temperature due to grain growth, while Mg-1.4Nd showed improved corrosion resistance after annealing at 450 °C due to precipitation and texture weakening.

3. Research Background:

Background of the Research Topic:

Magnesium (Mg) alloys are increasingly utilized in automotive and aerospace industries and are promising for biomaterial applications. Optimizing their mechanical and corrosion properties involves microstructural modifications and crystallographic texture weakening. Adding rare-earth (RE) elements enhances formability and reduces anisotropy in Mg by altering deformation modes and hindering dislocation and grain boundary motion. This is attributed to RE solute drag and second phases that impede dislocation movement and grain boundary mobility, affecting dynamic recrystallisation (DRX) and texture during annealing. RE elements also improve corrosion performance by reducing corrosion rate and promoting passive film formation. Mg-RE alloys like WE43 and E21 are used in structural components, and are considered for temporary implants. RE elements are categorized as light RE elements (LREE) and heavy RE elements (HREE), but their individual and categorical roles in controlling Mg alloy properties remain unclear. The high cost of RE elements, especially HREE, limits their widespread application, driving research towards low-RE content Mg-RE alloys with excellent mechanical properties.

Status of Existing Research:

High-pressure torsion (HPT) is a severe plastic deformation (SPD) technique capable of processing Mg alloys at room temperature (RT) without cracking due to high hydrostatic pressure. HPT produces bulk ultrafine-grained materials with high-angle boundaries, leading to enhanced mechanical and superplastic properties. Grain refinement in Mg alloys via DRX can reach nano or micro-scale depending on alloy composition, second phases, and processing conditions. Reviews have focused on deformation processing and corrosion behavior of Mg alloys. SPD-induced grain refinement generally improves uniform corrosion due to increased grain boundaries. However, improved strength and formability in Mg-RE alloys can sometimes negatively impact corrosion performance. Increased dislocation density and twins may decrease corrosion resistance, although contradictory results exist, suggesting deformation features can be beneficial.

Necessity of the Research:

HPT generates non-equilibrium ultrafine microstructures with high dislocation and vacancy densities, potentially causing loss of mechanical properties during recovery and grain growth. While HPT in Mg alloys is well-documented, research on thermal stability and its corrosion impact remains limited. This study aims to compare the evolution of deformation, recrystallisation microstructure, and texture in low RE Mg-RE alloys, specifically Mg-1.4Nd (LREE) and Mg-0.6Gd and Mg-0.4Dy (HREE). The research also investigates the correlation between corrosion performance in 3.5% NaCl solution and the effects of RE solute elements and microstructural changes. The alloy compositions were chosen based on phase diagrams to ensure single-phase Mg-RE alloys, and low HREE content was selected due to cost considerations. This study is part of a broader investigation into microstructure and corrosion performance of low RE binary Mg-RE alloys, building upon previous work on Mg-1.4Nd [59] and Mg-0.4Dy [8,9,43,58], and the effect of RE elements on as-cast corrosion behavior [13] and homogenous treatment effects [65]. This research seeks to enhance the understanding of individual RE element effects on Mg alloys and contribute to controlled alloy design.

4. Research Purpose and Research Questions:

Research Purpose:

The primary research purpose is to compare the evolution of deformation and recrystallisation microstructure and texture of three low RE containing Mg-RE alloys: Mg-1.4Nd (wt.%) representing LREE, and Mg-0.6Gd and Mg-0.4Dy (wt.%) representing HREE. A further objective is to correlate the corrosion performance of these Mg-RE alloys in a 3.5% NaCl (wt.%) solution with the influence of RE solute elements and the alterations in deformation and recrystallisation microstructures.

Key Research:

The key research questions addressed in this study are:

- How does HPT processing and subsequent isochronal annealing at 250 °C and 450 °C affect the microstructure and texture evolution in Mg-1.4Nd, Mg-0.6Gd, and Mg-0.4Dy alloys?

- What are the differences in dynamic recrystallisation (DRX) behavior among these alloys during HPT processing?

- How does thermal annealing at different temperatures influence the thermal stability of the microstructure and texture in each alloy?

- How does HPT processing and subsequent annealing affect the corrosion behavior of these Mg-RE alloys in a 3.5% NaCl solution?

- What is the correlation between the observed microstructural and textural changes and the corrosion performance of the Mg-RE alloys?

- How do LREE (Nd) and HREE (Gd, Dy) elements differentially influence the microstructure, texture, thermal stability, and corrosion behavior of Mg-RE alloys processed by HPT?

Research Hypotheses:

While not explicitly stated as formal hypotheses, the research is guided by the expectation that:

- The type of RE element (LREE vs. HREE) will significantly influence the DRX behavior during HPT and the resulting microstructure and texture.

- Thermal annealing will induce different recrystallisation and grain growth behaviors in the alloys, depending on the RE element and initial HPT microstructure.

- The corrosion resistance of HPT-processed Mg-RE alloys will be improved due to grain refinement, but subsequent annealing may alter this depending on grain growth, precipitation, and texture evolution.

- The effect of annealing temperature on corrosion resistance will differ between Mg-1.4Nd and Mg-0.6Gd/Mg-0.4Dy alloys due to variations in precipitation behavior and texture stability.

5. Research Methodology

Research Design:

This study employs an experimental design involving comparative analysis of three Mg-RE alloys (Mg-1.4Nd, Mg-0.6Gd, Mg-0.4Dy) subjected to different thermomechanical processing conditions. The conditions include HPT processing at room temperature and subsequent isochronal annealing at 250 °C and 450 °C for 1 hour. The study compares the microstructural, textural, and corrosion behavior of these alloys under these conditions to evaluate the effects of RE element type and thermal treatments.

Data Collection Method:

- Microstructure and Texture Characterization: Electron Backscatter Diffraction (EBSD) was used to characterize the microstructure and texture of the HPT-processed and annealed samples. EBSD measurements were taken near the centers of the rotation direction-shear direction (RD-SD) plane of the discs. Sample preparation involved grinding with progressively finer SiC papers, mechanical polishing with diamond solution, and ionic polishing using a Gatan PECS II system. A scanning electron microscope (FEG-SEM SUPRA 55 VP) operating at 20 kV was used for EBSD data acquisition.

- Corrosion Behavior Evaluation: Electrochemical tests were conducted in a 3.5% NaCl solution at room temperature using an AUTOLAB PGSTAT302N potentiostat. A standard three-electrode cell setup was used with Mg-RE samples as the working electrode, a platinum plate as the counter electrode, and a saturated calomel electrode (SCE) as the reference electrode. Electrochemical Impedance Spectroscopy (EIS) and potentiodynamic polarization tests were performed to assess corrosion behavior.

Analysis Method:

- Microstructure and Texture Analysis: TSL Orientation Imaging Microscopy (OIM) software was used for EBSD data acquisition and analysis. Grain boundary misorientations were analyzed, categorizing boundaries into very low-angle grain boundaries (VLAGBs), low-angle grain boundaries (LAGBs), and high-angle grain boundaries (HAGBs). Recrystallisation fraction was calculated using the grain orientation spread (GOS) approach. Deformation and recrystallisation textures were evaluated using MATLAB toolbox MTEX [68].

- Electrochemical Data Analysis: Open-circuit potential measurements were taken. Electrochemical impedance spectroscopy (EIS) tests were performed with an amplitude of 10 mV in the frequency range from 10⁵ Hz to 10⁻² Hz. Potentiodynamic polarization curves were recorded with a scan rate of 2 mV.s⁻¹. Corrosion parameters such as corrosion potential (Ecorr), corrosion current density (Icorr), and cathodic slope (βc) were derived from the polarization curves. Equivalent circuit fitting was applied to EIS data to determine parameters like charge transfer resistance (Rct), film resistance (Rf), and capacitances.

Research Subjects and Scope:

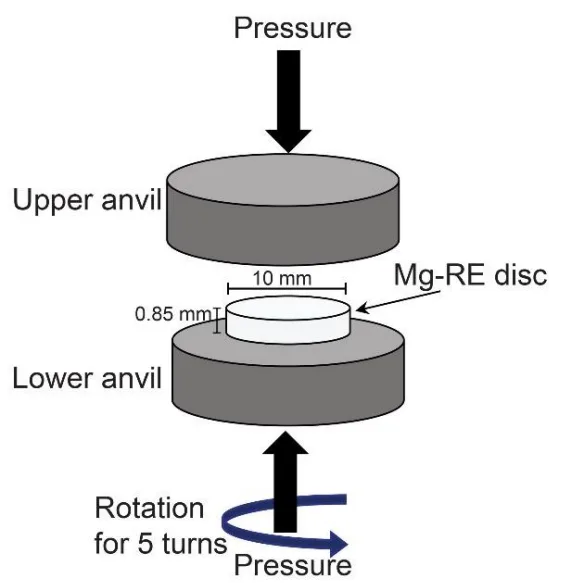

The research focused on three as-cast Mg-RE alloys: Mg-1.4Nd, Mg-0.6Gd, and Mg-0.4Dy (wt.%). These alloys were processed by high-pressure torsion (HPT) at room temperature for 5 turns under 6.0 GPa pressure. Subsequently, HPT-processed samples were annealed in a radiation furnace at 250 °C and 450 °C for 1 hour. The scope of the study was limited to evaluating the microstructure, texture, and corrosion behavior of these specific alloys under these defined processing and annealing conditions.

6. Main Research Results:

Key Research Results:

- Microstructure Evolution:

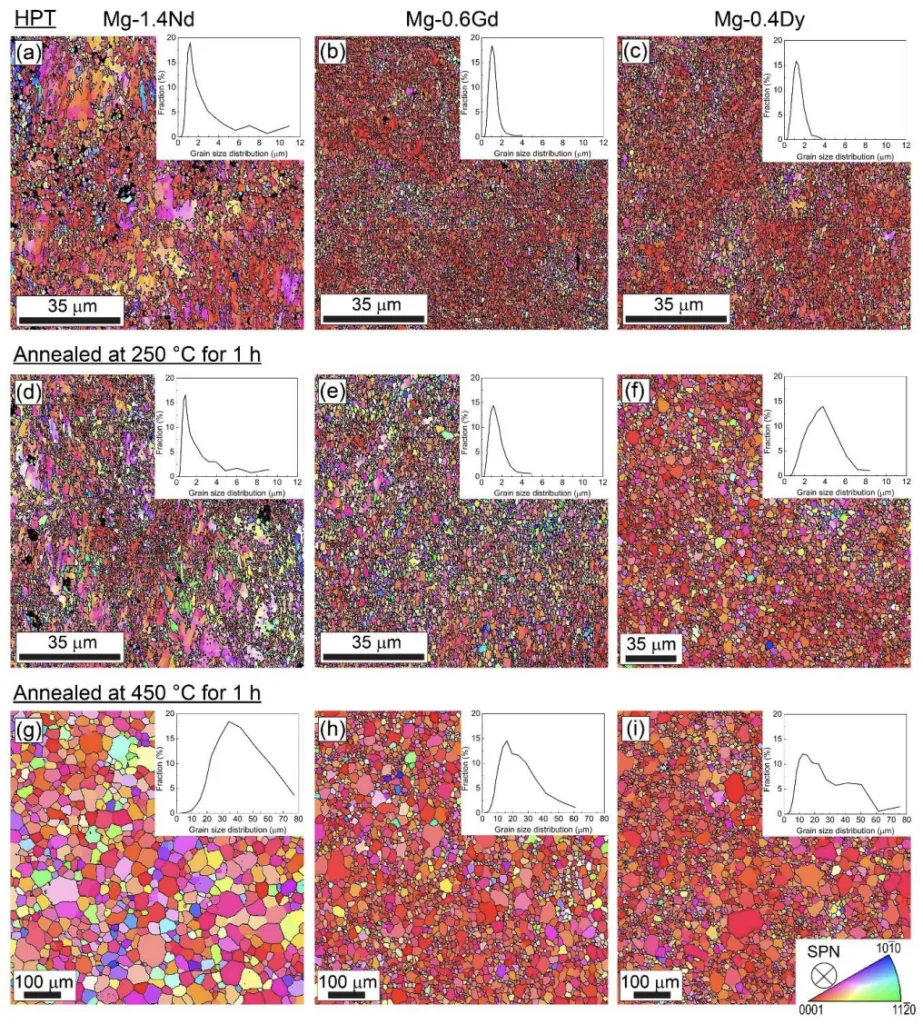

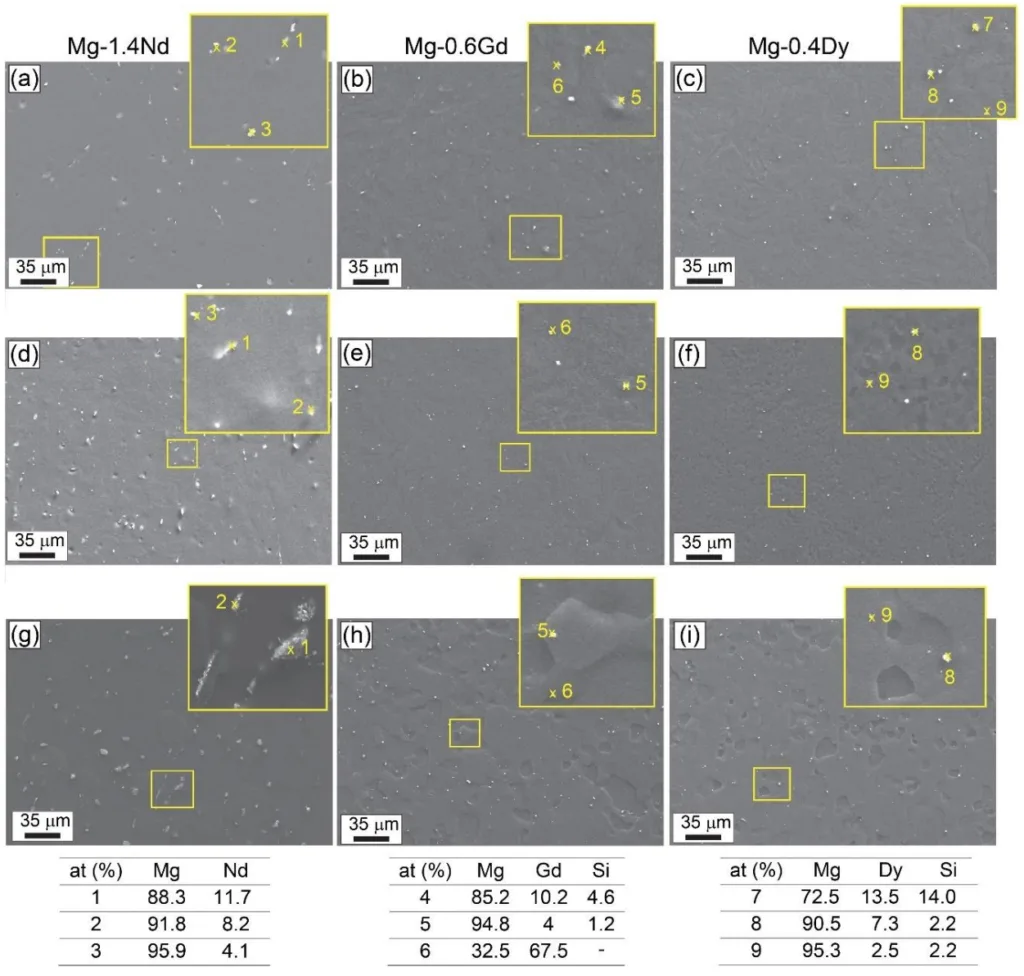

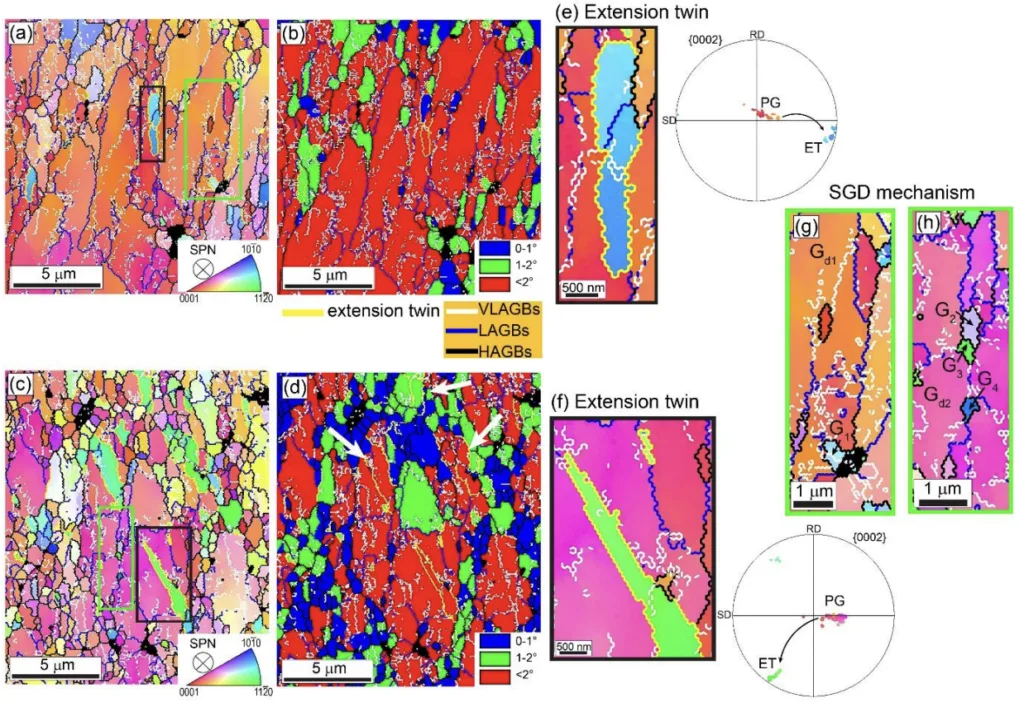

- HPT processing resulted in a heterogenous microstructure in Mg-1.4Nd with large deformed grains and small dynamically recrystallised grains, while Mg-0.6Gd and Mg-0.4Dy exhibited homogenous microstructures of fine, equiaxed DRX grains (Figure 2a-c).

- Annealing at 250 °C maintained a heterogenous microstructure in Mg-1.4Nd, but increased grain size in Mg-0.6Gd and Mg-0.4Dy (Figure 2d-f).

- Annealing at 450 °C led to a homogenous, fully recrystallised microstructure in Mg-1.4Nd, but bimodal grain distributions in Mg-0.6Gd and Mg-0.4Dy (Figure 2g-i).

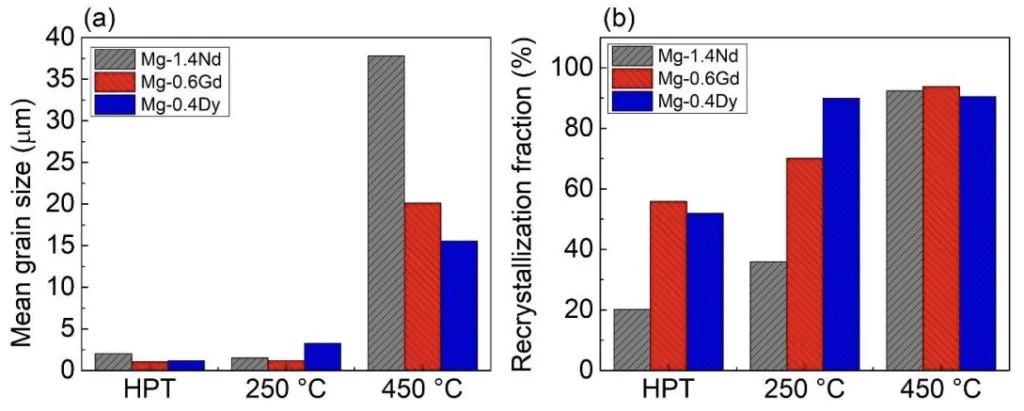

- DRX fraction in HPT-processed Mg-1.4Nd was significantly lower (20.2%) compared to Mg-0.6Gd (55.8%) and Mg-0.4Dy (51.9%) (Figure 3).

- Texture Evolution:

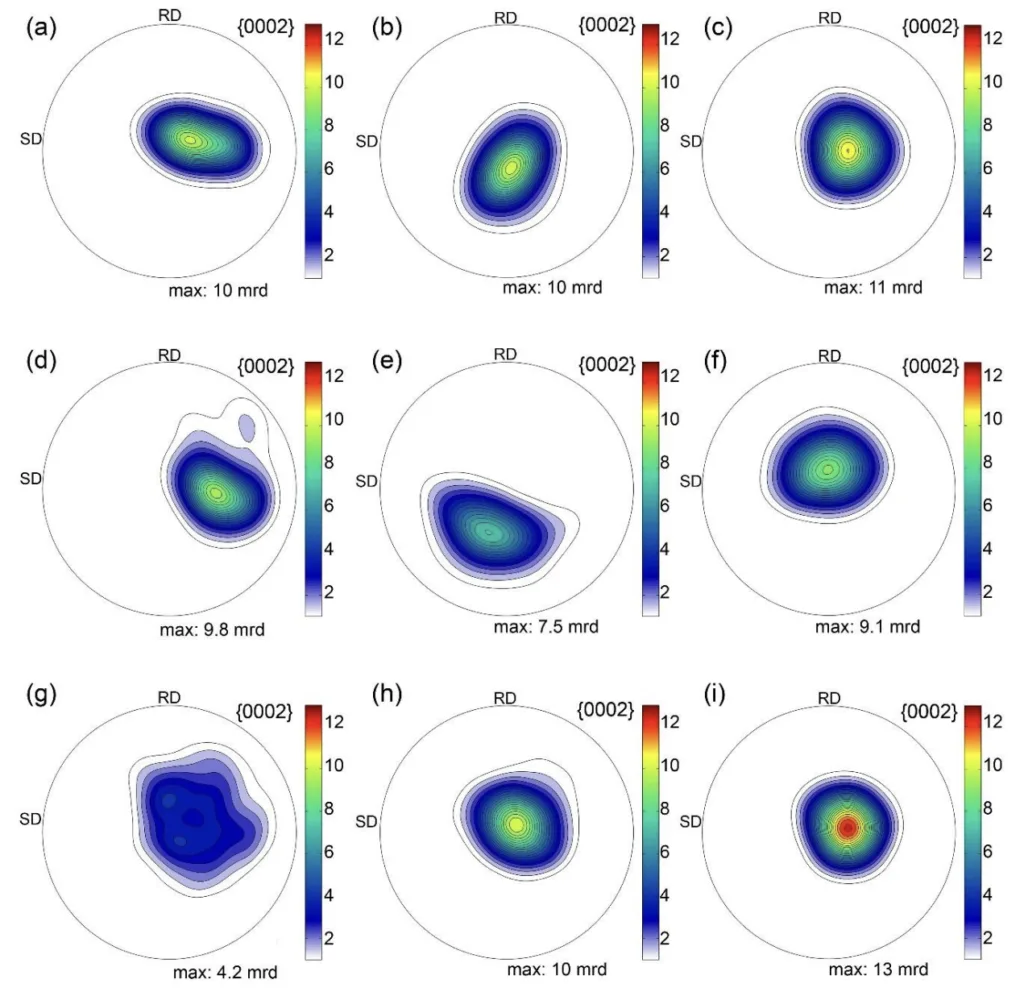

- HPT processing developed a deviated basal texture in all three alloys (Figure 6a-c).

- Annealing at 450 °C weakened the texture in Mg-1.4Nd, but the basal texture remained stable in Mg-0.6Gd and Mg-0.4Dy (Figure 6g-i).

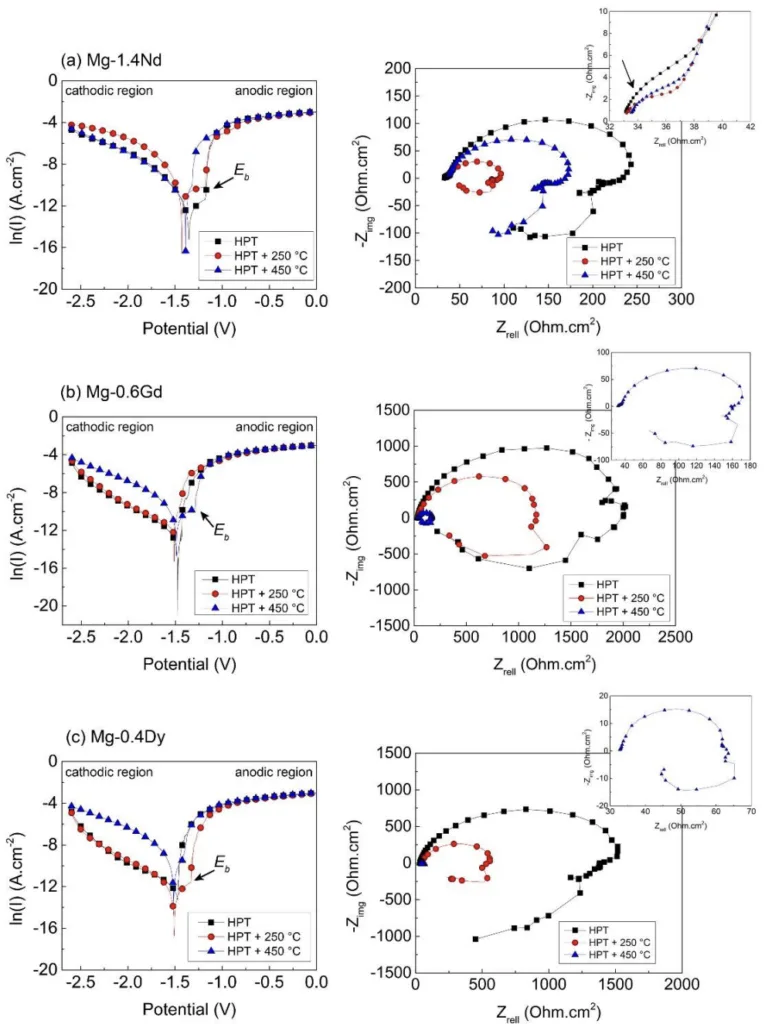

- Corrosion Behavior:

- HPT processing improved corrosion resistance in all alloys due to grain refinement.

- Corrosion resistance of Mg-0.6Gd and Mg-0.4Dy decreased with increasing annealing temperature.

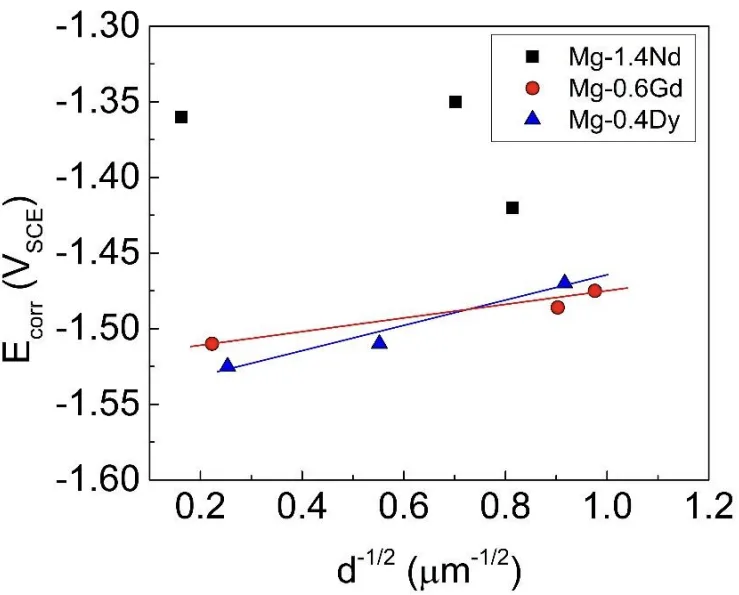

- Corrosion resistance of Mg-1.4Nd improved after annealing at 450 °C compared to 250 °C and HPT-processed condition (Figure 7, Table 1, Table 2).

- Nyquist plots indicated similar corrosion mechanisms across all conditions, with changes in loop diameters reflecting different corrosion rates (Figure 7).

Analysis of presented data:

- Grain Size and Recrystallisation: Figure 3a shows that the mean grain size of HPT-processed Mg-1.4Nd (~2.0 µm) is larger than Mg-0.6Gd (~1.0 µm) and Mg-0.4Dy (~1.2 µm). After annealing at 450 °C, Mg-1.4Nd grain size significantly increased to ~37.8 µm, while Mg-0.6Gd and Mg-0.4Dy reached ~20.1 µm and ~15.5 µm, respectively. Figure 3b illustrates the low recrystallisation fraction in HPT-processed Mg-1.4Nd (20.2%) compared to Mg-0.6Gd (55.8%) and Mg-0.4Dy (51.9%).

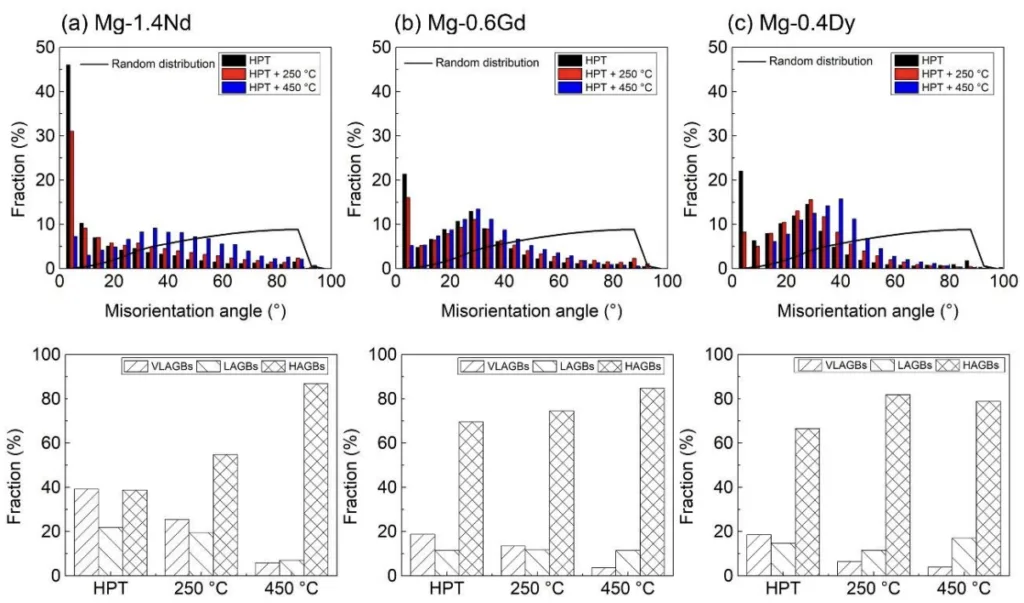

- Grain Boundary Misorientation: Figure 4 shows that HPT-processed Mg-1.4Nd has similar fractions of VLAGBs (39.3%) and HAGBs (38.8%). In contrast, HPT-processed Mg-0.6Gd and Mg-0.4Dy are dominated by HAGBs. Annealing at 450 °C in Mg-1.4Nd drastically reduces VLAGBs and increases HAGBs, while Mg-0.6Gd and Mg-0.4Dy show a slight increase in HAGBs with annealing.

- Texture Analysis: Figure 6a shows the recalculated {0002} pole figure of HPT-processed Mg-1.4Nd indicating a typical basal texture. Annealing at 450 °C weakens this texture (Figure 6g). Mg-0.6Gd and Mg-0.4Dy maintain a stable basal texture throughout HPT and annealing, with Mg-0.6Gd texture shifting towards RD after annealing at 250 °C (Figure 6b,e,h and 6c,f,i).

- Corrosion Parameters: Table 1 shows that Icorr values for Mg-0.6Gd and Mg-0.4Dy are lower than Mg-1.4Nd in HPT condition, indicating better corrosion resistance. Table 2 shows that Rct values for HPT-processed Mg-0.6Gd (3825 Ω.cm²) and Mg-0.4Dy (1713 Ω.cm²) are higher than Mg-1.4Nd (251.4 Ω.cm²), confirming better corrosion resistance. For Mg-1.4Nd, Rct increases after annealing at 450 °C (162.6 Ω.cm²) compared to 250 °C (61.2 Ω.cm²), suggesting improved corrosion resistance at 450 °C annealing.

Figure Name List:

- Figure 1. Schematic illustration showing the HPT processing.

- Figure 2. SPN-IPF maps and grain size distributions of HPT-processed: (a) Mg-1.4Nd, (b) Mg-0.6Gd, (c) Mg-0.4Dy, annealed at 250 °C for 1 h: (d) Mg-1.4Nd, (e) Mg-0.6Gd, (f) Mg-0.4Dy and annealed at 450 °C for 1 h: (g) Mg-1.4Nd, (h) Mg-0.6Gd, and (i) Mg-0.4Dy alloys. The HAGBs are indicated by a black line. SPN denotes the shear plane normal direction.

- Figure 3. Evolution of: (a) mean grain size and (b) recrystallisation fraction of HPT-processed and annealed Mg-1.4Nd, Mg-0.6Gd, and Mg-0.4Dy alloys at 250 and 450 °C for 1 h, respectively.

- Figure 4. Grain boundary misorientation angle distributions and fractions of VLAGBs, LAGBs, and HAGBs of samples HPT-processed and annealed at 250 and 450 °C for 1 h: (a) Mg-1.4Nd, (b) Mg-0.6Gd, and (c) Mg-0.4Dy alloys.

- Figure 5. SEM photos of HPT-processed: (a) Mg-1.4Nd, (b) Mg-0.6Gd, (c) Mg-0.4Dy, annealed at 250 °C for 1 h: (d) Mg-1.4Nd, (e) Mg-0.6Gd, (f) Mg-0.4Dy and annealed at 450 °C for 1 h: (g) Mg-1.4Nd, (h) Mg-0.6Gd, and (i) Mg-0.4Dy alloys.

- Figure 6. Evolution of texture presented by the recalculated {0002} pole figures of the HPT-processed: (a) Mg-1.4Nd, (b) Mg-0.6Gd, (c) Mg-0.4Dy, annealed at 250 °C for 1 h: (d) Mg-1.4Nd, (e) Mg-0.6Gd, (f) Mg-0.4Dy and annealed at 450 °C for 1 h: (g) Mg-1.4Nd, (h) Mg-0.6Gd, and (i) Mg-0.4Dy alloys.

- Figure 7. Polarisation curves and Nyquist plots in a 3.5% NaCl solution of deformed and recrystallised samples of: (a) Mg-1.4Nd, (b) Mg-0.6Gd, and (c) Mg-0.4Dy alloys. The Nyquist plots of the HPT-processed and annealed Mg-1.4Nd (250 and 450 °C), annealed Mg-0.6Gd at 450 °C, and Mg-0.4Dy at 450 °C are placed at the upper right with a small scale for further visibility.

- Figure 8. Equivalent electric circuit used to fit the Nyquist plots of HPT-processed and annealed Mg-RE samples.

- Figure 9. IPF and GOS maps of selected regions from the microstructures of: (a,b) HPT-processed (from Figure 2) and (c,d) annealed Mg-1.4Nd at 250 °C for 1 h (from Figure 2) showing the presence of (e,f) an extension twin (black box) and corresponding {0002} pole figure and (g,h) a sub-grain development mechanism (green box).

- Figure 10. Evolution of Ecorr as a function of d-1/2 for HPT-processed and annealed Mg-1.4Nd, Mg-0.6Gd, and Mg-0.4Dy samples.

7. Conclusion:

Summary of Key Findings:

- DRX during HPT was restricted in Mg-1.4Nd, leading to heterogeneous microstructure, while Mg-0.6Gd and Mg-0.4Dy exhibited homogenous DRX microstructures.

- Annealing at 250 °C provided thermal stability for all alloys. Annealing at 450 °C resulted in homogenous equiaxed grains and texture weakening in Mg-1.4Nd, but bimodal microstructures and stable basal textures in Mg-0.6Gd and Mg-0.4Dy.

- HPT processing improved corrosion resistance in all alloys. Corrosion resistance decreased with annealing temperature for Mg-0.6Gd and Mg-0.4Dy due to grain growth. Mg-1.4Nd showed improved corrosion resistance after annealing at 450 °C, attributed to precipitation and texture weakening.

- HREE (Gd, Dy) elements generally provided better corrosion resistance than LREE (Nd), but precipitation in Mg-1.4Nd at 450 °C altered this trend.

Academic Significance of the Study:

This study contributes to the fundamental understanding of the differential effects of LREE (Nd) and HREE (Gd, Dy) elements on the microstructure evolution, texture development, thermal stability, and corrosion behavior of Mg-RE alloys processed by HPT. It highlights the contrasting DRX behavior and thermal stability between Mg-1.4Nd and Mg-0.6Gd/Mg-0.4Dy alloys under HPT and annealing conditions. The research also elucidates the complex interplay between grain refinement, precipitation, texture weakening, and corrosion resistance in these alloys.

Practical Implications:

The findings offer valuable insights for designing high-performance Mg-RE alloys for structural and biomedical applications. HPT processing is confirmed as an effective method to enhance corrosion resistance through grain refinement. The study suggests that for Mg-0.6Gd and Mg-0.4Dy alloys, HPT processing or low-temperature annealing (250 °C) is preferable to maintain high corrosion resistance. For Mg-1.4Nd, annealing at 450 °C can improve corrosion resistance, potentially due to precipitation strengthening and texture modification, despite grain coarsening. The choice of RE element and subsequent thermal treatments should be carefully considered to optimize the balance between mechanical properties, thermal stability, and corrosion resistance.

Limitations of the Study and Areas for Future Research:

This study is limited to isochronal annealing at two specific temperatures (250 °C and 450 °C) for a fixed duration (1 hour). Further research could explore the effects of varying annealing times and temperatures to comprehensively map the thermal stability and corrosion behavior. The role of grain boundary character distribution and its evolution during annealing, particularly in Mg-1.4Nd, warrants further investigation to understand its influence on recrystallisation kinetics and corrosion resistance. Future studies could also focus on detailed characterization of the precipitates formed in Mg-1.4Nd during annealing at 450 °C and their precise contribution to corrosion resistance improvement. Additionally, investigating the mechanical properties in conjunction with corrosion behavior would provide a more complete picture for alloy design optimization.

8. References:

- [1] Song, J.; Chen, J.; Xiong, X.; Peng, X.; Chen, D.; Pan, F. Research advances of magnesium and magnesium alloys worldwide in 2021. J. Magnes. Alloy. 2022, 10, 863–898. [CrossRef]

- [8] Guerza-Soualah, F.; Azzeddine, H.; Baudin, T.; Helbert, A.-L.; Brisset, F.; Bradai, D. Microstructural and textural investigation of an Mg-Dy alloy after hot plane strain compression. J. Magnes. Alloy. 2020, 8, 1198–1207. [CrossRef]

- [13] Azzeddine, H.; Hanna, A.; Dakhouche, A.; Rabahi, L.; Scharnagl, N.; Dopita, M.; Brisset, F.; Helbert, A.-L.; Baudin, T. Impact of rare-earth elements on the corrosion performance of binary magnesium alloys. J. Alloys Compd. 2020, 829, 154569. [CrossRef]

- [26] Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893-979. [CrossRef]

- [58] Hanna, A.; Azzeddine, H.; Huang, Y.; Bradai, D.; Cabrera, J.M.; Langdon, T.G. An investigation of the thermal stability of an MgDy alloy after processing by high-pressure torsion. Mater. Charact. 2019, 151, 519-529. [CrossRef]

- [59] Tighiouaret, S.; Lachhab, R.; Hanna, A.; Azzeddine, H.; Huang, Y.; Baudin, T.; Helbert, A.-L.; Brisset, F.; Bradai, D.; Langdon, T.G. Thermal Stability of an Mg-Nd Alloy Processed by High-Pressure Torsion. Adv. Eng. Mater. 2019, 21, 1900801. [CrossRef]

- [68] Hielscher, R.; Schaeben, H. A novel pole figure inversion method: Specification of the MTEX algorithm. J. Appl. Cryst. 2008, 41, 1024-1037. [CrossRef]

9. Copyright:

- This material is "Azzeddine, H.; Hanna, A.; Dakhouche, A.; Baudin, T.; Brisset, F.; Huang, Y.; Langdon, T.G." 's paper: Based on "Evaluation of Thermal Stability and Its Effect on the Corrosion Behaviour of Mg-RE Alloys Processed by High-Pressure Torsion".

- Paper Source: https://doi.org/10.3390/cryst13040662

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.