Abstract

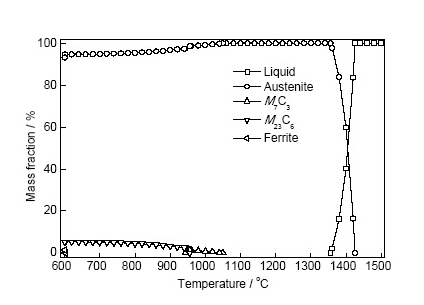

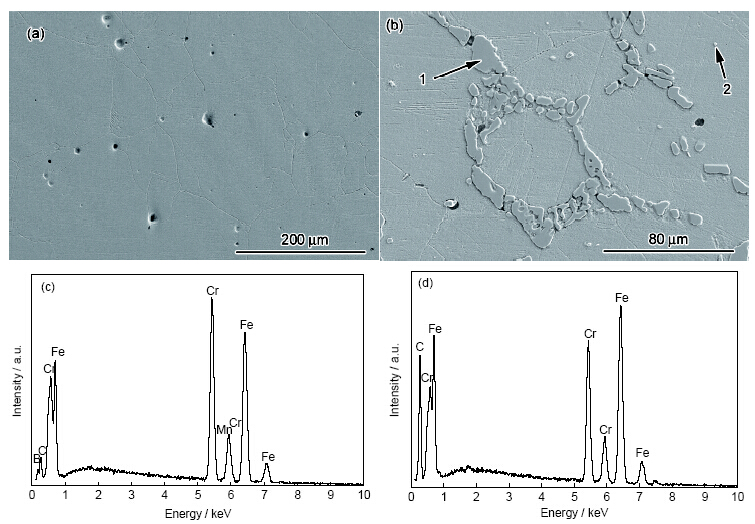

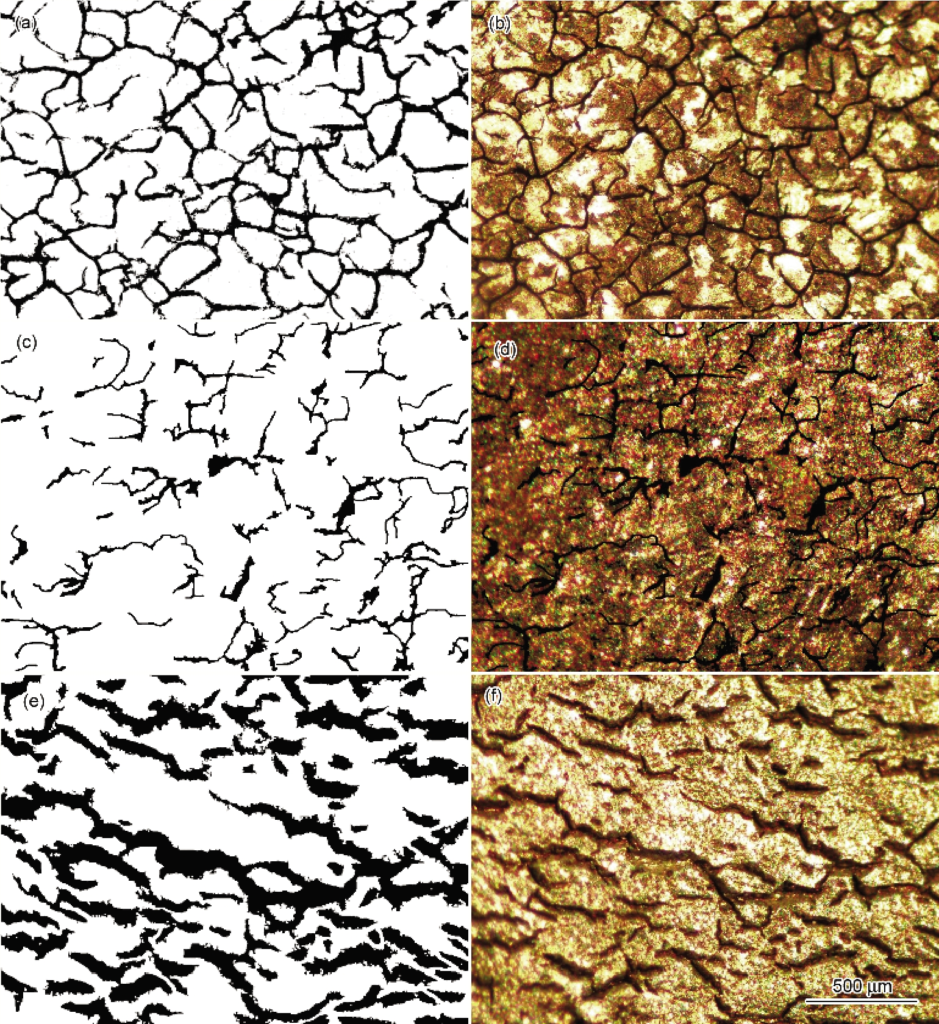

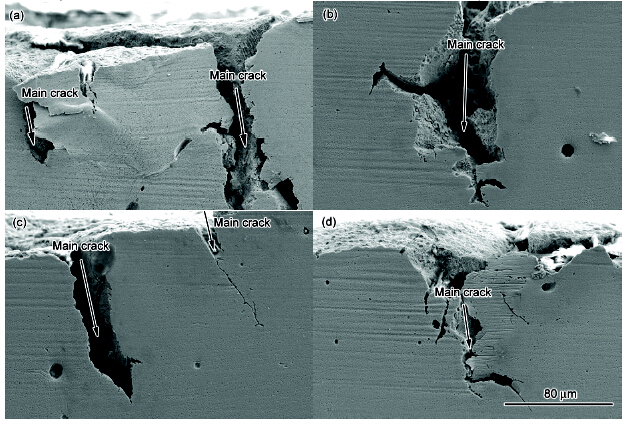

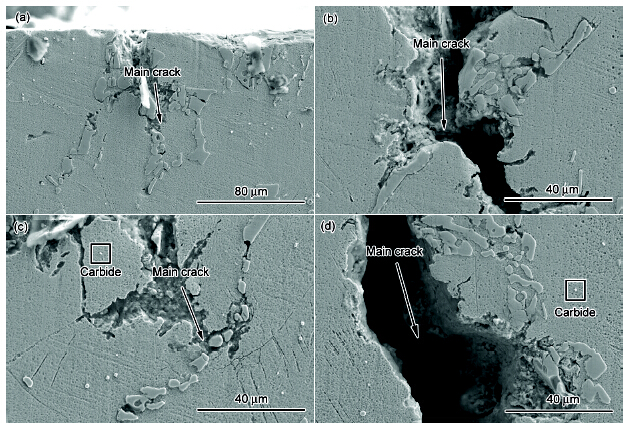

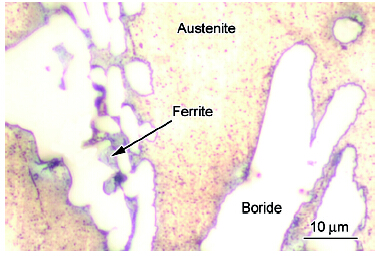

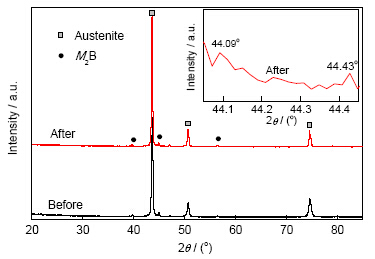

Copper die-casting die steel is usually used in severe rugged environment. Liquid metal flows with high temperature and high pressure during injection and provides rapid filling of the die cavity. The copper die-casting steel should has excellent combination of the properties of high toughness, wear resistance, hardness, thermal fatigue resistance, oxidation resistance and corrosion resistance at high temperature for the cavity surface of die-casting die suffers high pressure, scour, erosion and thermal shock. A new kind of copper alloy die-casting die steel with pure austenitic matrix was conducted in this work, wherein the boride with high thermal stability and high hardness distributes in the austenitic matrix. The mechanical properties of copper alloy die-casting die steel at high temperature of 850 ℃ were studied using dynamic thermal-mechanical simulation testing machine. The thermal fatigue behavior of die steel at room temperature to 800 ℃ was performed using self-restraint Uddeholm thermal fatigue test method, and the depth extension status of surface thermal fatigue cracks and cross-sectional cracks in die steel thermal fatigue specimens was measured using stereo microscope and SEM. The effects of B content on the mechanical properties at room temperature and high temperature and on the thermal fatigue resistance were evaluated. The experimental results showed that boride distributes in austenitic matrix in the form of M2B-type boride (M represents Fe, Cr or Mn) after adding B in the tested steels, and the comprehensive performances of steel at high temperatures were effectively improved, the hardness of the steel at room temperature increased from 200 HV to 302 HV, the tensile yield strength at 850 ℃ increased from 144.3 MPa to 190.3 MPa, and the compressive yield strength increased from 139.7 MPa to 167.9 MPa. Evaluation of the degree of heat checking on 300 cyc of thermal fatigue testing at room temperature to 800 ℃ showed that the die steel containing B was rating 2~3, much better than rating 7~8 of electroslag remelting ESR-H13 steel for comparison, which mainly because the thermal fatigue cracks were blunted or deflected by boride, and then the cracks spread as scattering shapes was avoided.

구리 다이캐스팅 다이 스틸은 일반적으로 가혹한 거친 환경에서 사용됩니다. 액체 금속은 사출 중에 고온 및 고압으로 흐르고 다이 캐비티를 빠르게 채웁니다. 구리 다이캐스팅 강은 다이캐스팅 다이의 캐비티 표면이 고압, 세굴, 침식을 겪기 때문에 고온에서 고인성, 내마모성, 경도, 열피로성, 내산화성 및 내식성의 우수한 조합을 가져야 합니다. 그리고 열충격. 순수한 오스테나이트 기지를 가진 새로운 종류의 구리 합금 다이캐스팅 다이 강이 이 작업에서 수행되었으며, 여기서 높은 열 안정성과 높은 경도를 가진 붕화물이 오스테나이트 기지에 분포합니다. 850℃의 고온에서 동합금 다이캐스팅 다이강의 기계적 성질을 동적 열-기계적 시뮬레이션 시험기를 사용하여 연구하였다. 자체 구속 Uddeholm 열피로 시험법을 이용하여 상온 ~ 800 ℃에서 금형강의 열피로 거동을 수행하였으며, 금형강 열피로 시편의 표면열피로균열 및 단면균열의 깊이 확장 상태를 스테레오로 측정하였다. 현미경 및 SEM. 상온 및 고온에서의 기계적 물성 및 내열피로성에 대한 B 함량의 영향을 평가하였다. 실험 결과, 붕화물은 시험된 강재에 B를 첨가한 후 M2B형 붕화물(M은 Fe, Cr 또는 Mn을 나타냄) 형태로 오스테나이트 기지에 분포하고 고온에서 강의 종합 성능이 효과적으로 향상되었으며 경도 상온에서 강재의 인장강도는 200 HV에서 302 HV로 증가하였고, 850 ℃에서의 인장항복강도는 144.3 MPa에서 190.3 MPa로, 압축항복강도는 139.7 MPa에서 167.9 MPa로 증가하였다. 300 cyc의 실온에서 800 ℃까지의 열피로 시험에 대한 히트 체킹 정도를 평가한 결과, B를 함유한 다이강이 등급 2~3으로, 비교를 위한 일렉트로슬래그 재용해 ESR-H13 강의 등급 7~8보다 훨씬 우수한 것으로 나타났으며, 이는 주로 열피로균열이 붕소화물에 의해 무디거나 편향되어 균열이 산란 형태로 퍼지는 것을 방지했기 때문입니다.

Key words

die-casting die steel thermal fatigue property copper alloy die-casting

References

| [1] | Cui K. Heat Treat Met, 2007; 32(1): 1 (崔 崑. 金属热处理, 2007; 32(1): 1) |

| [2] | Klobcar D, Tusek J, Taliat B. Mater Sci Eng, 2008; A472: 198 |

| [3] | Wallace F J, Schwam D. Die Cast Eng, 2000; 44(3): 50 |

| [4] | Zhu Y L, Schwan D, Wallace J F, Birceanu S. Mater Sci Eng, 2004; A379: 420 |

| [5] | Mesquita R A, Kestenbach H J. Mater Sci Eng, 2011; A528: 4856 |

| [6] | Medvedeva A, Bergstrom J, Gunnarsson S, Andersson J. Mater Sci Eng, 2009; A523: 39 |

| [7] | Li G B, Li X Z, Wu J J. J Mater Process Technol, 1998; 74: 23 |

| [8] | Persson A, Hogmark S, Bergstr?m J. J Mater Process Technol, 2004; 152: 228 |

| [9] | Kang J W, You R, Nie G, Hao X K, Long H M, Wang T J, Huang T Y. J Mech Eng, 2012; 48(12): 63 (康进武, 游 锐, 聂 刚, 郝小坤, 龙海敏, 王天骄, 黄天佑. 机械工程学报, 2012; 48(12): 63) |

| [10] | Persson A, Hogmark S, Bergstr M J. J Mater Process Technol, 2004; 148: 108 |

| [11] | Khader I, Renz A, Kailer A, Haas D. J Eur Ceram Soc, 2013; 33: 593 |

| [12] | Norstrom L. Scand J Metall, 1982; 11: 33 |

| [13] | Kariofillis G K, Kiourtsidis G E, Tsipas D N. Surf Coat Technol, 2006; 201: 19 |

| [14] | Chen Y W, Wu X C. J Iron Steel Res, 2010; 22(7): 42 (陈英伟, 吴晓春. 钢铁研究学报, 2010; 22(7): 42) |

| [15] | Cui K. Mater Mech Eng, 2001; 25(1): 1 (崔 崑. 机械工程材料, 2001; 25(1): 1) |

| [16] | Jiang Q C, Sui H L, Guan Q F. ISIJ Int, 2004; 44: 1103 |

| [17] | Sui H L. PhD Dissertation, Jilin University, Changchun, 2006 (隋鹤龙. 吉林大学博士学位论文, 长春, 2006) |

| [18] | Chen X, Zheng S, Yuan J Y. Procedia Eng, 2012; 27: 1780 |

| [19] | Chen X, Li Y X, Zhang H M. J Mater Sci, 2011; 46: 957 |

| [20] | Chen X, Li Y X. Mater Sci Eng, 2010; A528: 770 |

| [21] | Liu Z L, Li Y X, Chen X, Hu K H. Acta Metall Sin, 2007; 43: 477 (刘仲礼, 李言祥, 陈 祥, 胡开华. 金属学报, 2007; 43: 477) |

| [22] | Liu Z L, Li Y X, Chen X. China Foundry, 2012; 9: 313 |

| [23] | Chen X, Li Y X. Mater Sci Eng, 2007; A444: 298 |

| [24] | Li Y X, Liu Z L, Chen X. Int J Cast Met Res, 2008; 21: 67 |

| [25] | Liu Z L, Chen X, Li Y X. J Iron Steel Res Int, 2009; 16(3): 37 |

| [26] | Liu Z L, Li Y X, Chen X. Mater Sci Eng, 2008; A486: 112 |

| [27] | Liu Z L. PhD Dissertation, Tsinghua University, Beijing, 2007 (刘仲礼. 清华大学博士学位论文, 北京, 2007) |

| [28] | Chen X, Li Y X. China Foundry, 2013; 10: 155 |

| [29] | Benxi 1st Steelworks enxi 1st Steelworks. Boron Steel. Beijing: Metallurgical Industry Press, 1977: 39 (本溪钢铁公司第一炼钢厂. 硼钢. 北京: 冶金工业出版社, 1977: 39) |

| [30] | Guo C, Kelly P M. Mater Sci Eng, 2003; A352: 40 |

| [31] | Ma S Q, Xing J D, Liu G F, Yi D W, Fu H G, Zhang J J, Li Y F. Mater Sci Eng, 2010; A527: 6800 |

| [32] | Guo C Q. PhD Dissertation, The University of Queensland, Brisbane, 2002 |

| [33] | Chu Y Y, He X L, Tang L, Xu T D, Ke J. Acta Metall Sin, 1987; 23: 169 (褚幼义, 贺信莱, 唐 立, 徐庭栋, 柯 俊. 金属学报, 1987; 23: 169) |

| [34] | He X L, Chu Y Y, Ke J. Acta Metall Sin, 1983; 19: 459 (贺信莱, 褚幼义, 柯 俊. 金属学报, 1983; 19: 459) |

| [35] | Jahazi M, Jonas J J. Mater Sci Eng, 2002; A335: 49 |

| [36] | He X L, Chu Y Y, Tang L, Zhou Z X, Ke J. Acta Metall Sin, 1987; 23: 291 (贺信莱, 褚幼义, 唐 立, 周振新, 柯 俊. 金属学报, 1987; 23: 291) |

| [37] | Persson A, Hogmark S, Bergstr?m J. Int J Fatigue, 2004; 26: 1095 |