This introduction paper is based on the paper "Design with White Light-Emitting Diodes for an Automotive Low-Beam Projector Headlamp" published by "Sensors and Materials".

1. Overview:

- Title: Design with White Light-Emitting Diodes for an Automotive Low-Beam Projector Headlamp

- Author: Yueh-Ying Chiang, Sheng-Jye Hwang, Huei-Huang Lee, Deng-Yuan Hwang, and Chien-Chih Liao

- Year of publication: 2016

- Journal/academic society of publication: Sensors and Materials, Vol. 28, No. 9 (2016) 1035–1042, MYU Tokyo

- Keywords: LED headlamp, projection headlamp, ECE R112

2. Abstract:

A numerical model was developed to design a new automotive low-beam light-emitting diode (LED) headlamp. First, an existing automotive low-beam projector LED headlamp model with ray-tracing software (TracePro) was simulated. The existing commercially available automobile LED headlamp is a combination of one multi-reflector and two projection systems serving as a low-beam LED headlamp module. The simulated results were compared with the headlamp regulations to prove that the headlamp numerical model and boundary conditions were correct and similar to reality. Finally, the original design was modified into only two projection systems using single-light-output 515 lumen LEDs. Each projection system was improved to make the headlamp light distributions conform to the ECE R112 regulation. It was concluded that using a high power LED could decrease the number of optical systems required for an automotive headlamp.

3. Introduction:

The design of automotive headlamps has evolved alongside light source technology, with halogen bulbs used since 1970 and white LEDs emerging in 1996. LEDs offer advantages like longer lifetime, lower power consumption, short response time, and no mercury pollution compared to conventional sources. However, their different luminescence characteristics necessitate redesigning optical systems. This research utilized computer-aided engineering (CAE) software (TracePro) to simulate the optical performance of an LED headlamp designed to meet ECE R112 standards. Initially, a commercially available LED headlamp (combining one multi-reflector and two projection systems) was studied to understand the software's performance. The study then aimed to modify this design into one using only two projection systems, leveraging higher power LEDs (515 lumens), and ensuring the light distribution conforms to ECE R112 regulations.

4. Summary of the study:

Background of the research topic:

Automotive headlamp technology has advanced with light source development. White LEDs, introduced in 1996, offer significant benefits over traditional sources but require specific optical system designs due to their unique luminescence properties. Ensuring compliance with regulations like ECE R112 is crucial for automotive lighting.

Status of previous research:

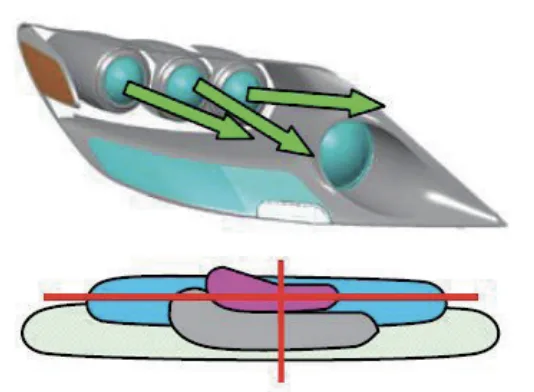

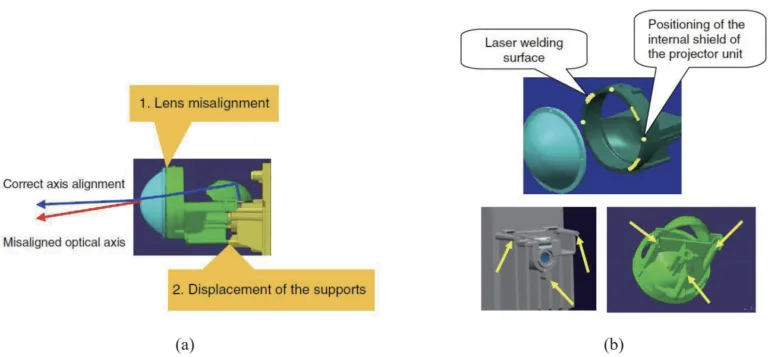

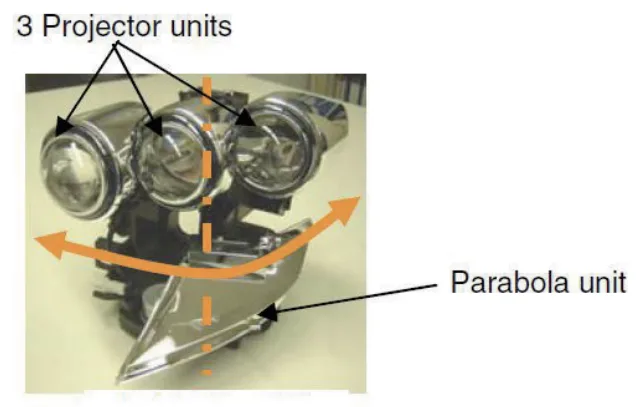

Previous work, such as that by Inaba et al.(2) on the LEXUS LS600H, demonstrated complex LED headlamp systems using multiple projector units (e.g., three swiveling units and a parabola unit). A key challenge identified in such multi-unit systems is achieving accurate alignment of the optical axes for proper beam superposition, influenced by factors like lens misalignment and support displacement. Techniques like precision positioning, laser welding, and 3-point support arrangements were developed to address these alignment issues.

Purpose of the study:

The study aimed to develop and validate a numerical model using CAE software (TracePro) for designing an automotive low-beam LED headlamp. The specific goals were: 1) To simulate an existing commercial LED headlamp to verify the accuracy of the simulation model and boundary conditions against reality and regulations. 2) To design a new, simplified low-beam LED headlamp using only two projection systems by employing high-power (515 lumen) LEDs. 3) To optimize this new design to ensure its light distribution conforms to the ECE R112 regulation.

Core study:

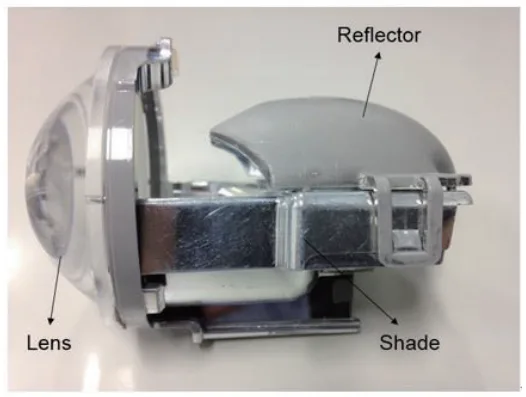

The core study involved two main phases. First, a commercially available LED headlamp, comprising one multi-reflector and two projection systems (using 350 lumen LEDs), was reverse engineered and simulated using TracePro software. The simulation results were compared with regulations to validate the modeling approach. Second, a new headlamp design was developed, simplifying the structure to only two projection systems utilizing higher power (515 lumen) LEDs. This new design underwent iterative modifications within the simulation environment, focusing on optimizing the shutter geometry and optical system alignment (cant angle, axis rotation) to shape the light beam precisely and meet the stringent illumination requirements specified by the ECE R112 standard.

5. Research Methodology

Research Design:

The research employed a simulation-based design and validation methodology. It started with reverse engineering and simulating an existing commercial LED headlamp to establish a baseline and validate the simulation tool (TracePro) and modeling assumptions. Subsequently, a new design featuring fewer optical components and higher-power LEDs was proposed and iteratively refined through simulation until its performance met the target regulatory standards (ECE R112).

Data Collection and Analysis Methods:

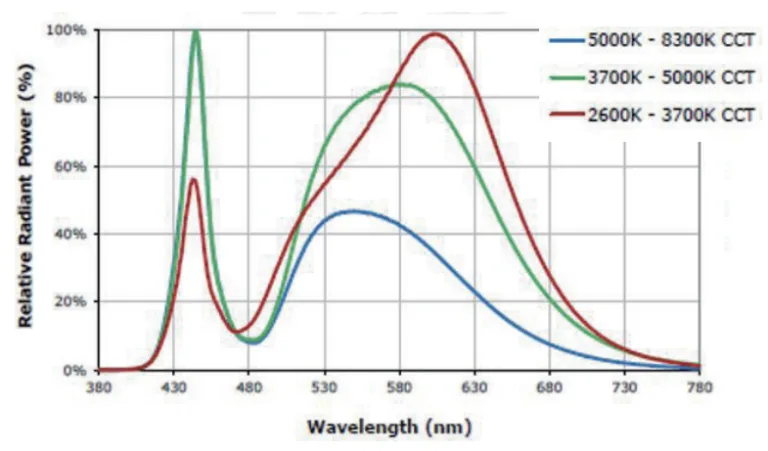

Computer-aided engineering (CAE) software, specifically TracePro ray-tracing software, was the primary tool. Input data included the geometry of the headlamp components (obtained via reverse engineering for the initial model, and designed for the new model), material properties (e.g., Schott BK7 for lens, with wavelength-dependent refractive indices as per Fig. 7), and LED characteristics (Lambertian source model with 350 lumens for the original simulation, Fig. 6; spectral and spatial distribution data for the 515 lumen high-power LED in the new design, Figs. 8, 9, 10, Table 1). Surface properties like reflectivity were defined (assumed 100% for reflector/shade initially). Analysis involved simulating the light distribution on a virtual screen and evaluating illuminance values at specific check points and zones defined by the ECE R112 standard (Table 2). The simulated light shapes (Figs. 12-18) were visually inspected and quantitatively compared against the standard's requirements.

Research Topics and Scope:

The research focused on the optical design and simulation of an automotive low-beam projector headlamp using white LEDs. The scope included:

- Validating a CAE simulation approach for LED headlamps.

- Investigating the feasibility of reducing the number of optical systems in an LED headlamp by using higher-power LEDs.

- Designing and optimizing a two-projector LED headlamp system.

- Ensuring the final design's compliance with the ECE R112 regulation for low-beam light distribution.

The study did not include thermal analysis or experimental prototyping of the new design.

6. Key Results:

Key Results:

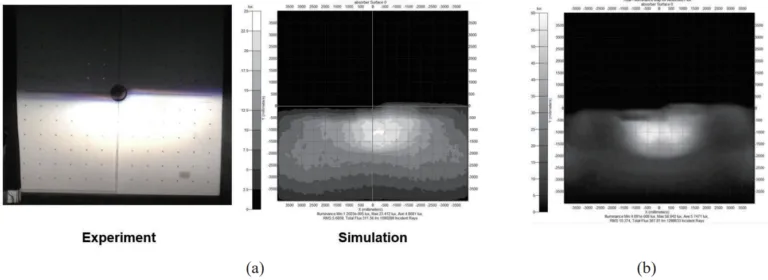

- The simulation of the existing commercial LED headlamp using TracePro produced light shape results (Fig. 12a) similar to reality, validating the numerical model and simulation setup as appropriate for LED headlamp design.

- A new low-beam headlamp design using only two projection systems was successfully developed by employing high-power LEDs (515 lumens each, Table 1).

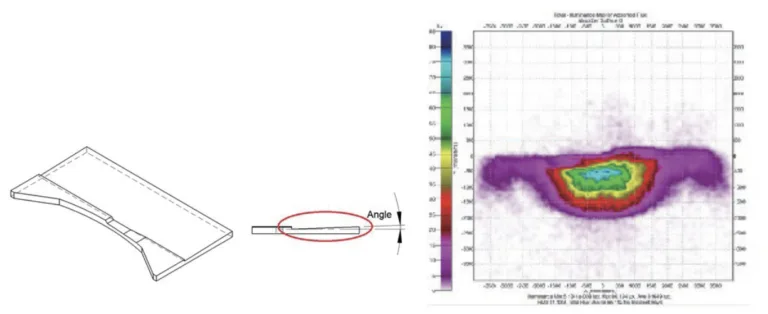

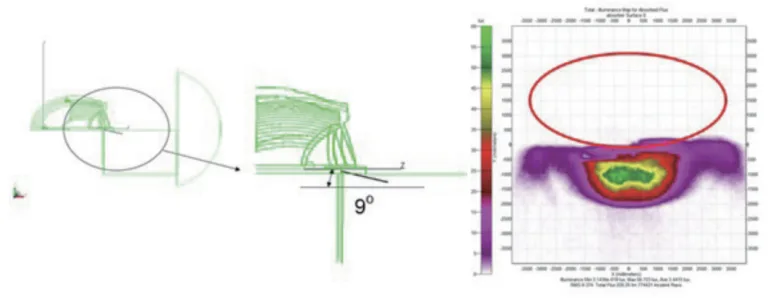

- Through iterative modifications of the optical system components, particularly the shutter geometry (Figs. 13, 14, 15) and the orientation/cant of the LED systems (Figs. 16, 17), the light distribution of the new design was optimized.

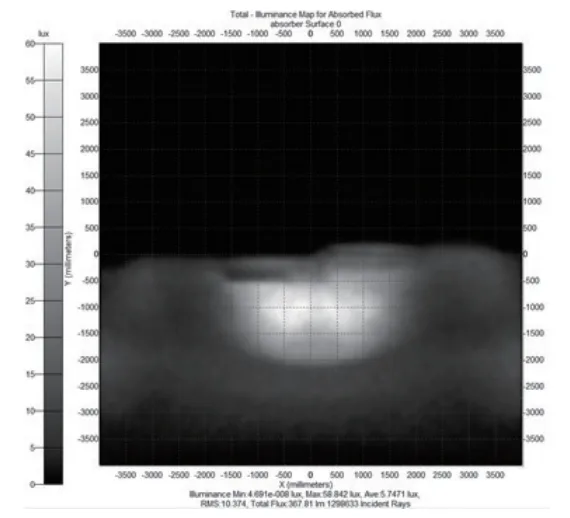

- The final simulated light distribution of the new two-projector design (Fig. 18) was shown to conform to the ECE R112 standard, meeting the illuminance requirements at all specified check points and zones (Table 2).

- The study concluded that using high-power LEDs with higher luminescence efficiency allows for a reduction in the number of optical systems required in a headlamp (from three in the original model to two in the new design).

- The volume of the newly designed headlamp was 40% smaller than the original commercial headlamp studied.

Figure Name List:

- Fig. 1. (Color online) Low-beam unit.(2)

- Fig. 2. (Color online) Misaligned optical axes.(2)

- Fig. 3. (Color online) (a) Factors contributing to optical axis misalignment. (b) The method for solving misaligned optical axes.(2)

- Fig. 4. (Color online) Original LED headlamp.

- Fig. 5. (Color online) Optical projection system.

- Fig. 6. (Color online) Spatial distribution of the Lambertian source.

- Fig. 7. (Color online) BK7 indices of refraction.

- Fig. 8. (Color online) Spectral power distribution of LEDs.(3)

- Fig. 9. (Color online) Spatial distribution of LEDs.(3)

- Fig. 10. (Color online) Spatial distribution of LED.(3)

- Fig. 11. (Color online) New low-beam LED headlamp design.

- Fig. 12. (Color online) (a) The shape of the light in the original LED headlamp experiment and simulation. (b) The shape of the light in the new LED headlamp design for the simulation.

- Fig. 13. (Color online) Light shape of LED 3 after modification of the front parts of the shutter.

- Fig. 14. (Color online) Light shape of LED 3 after modification of the rear parts of the shutter.

- Fig. 15 (a) The final design of part A of the shutter of LED 3. (b) The final design of part B of the shutter of LED 3.

- Fig. 16. (Color online) LED 2 light shape after modification of the lower parts of the shutter.

- Fig. 17. (Color online) LED 3 light shape after modification.

- Fig. 18. (Color online) LED headlamp light shape with the new design.

7. Conclusion:

This study utilized TracePro simulation software to assess and design an LED automotive headlamp, ensuring the light shape met regulatory requirements. The key conclusions are:

(1) The simulation software proved appropriate for validating LED headlamp designs.

(2) Utilizing LEDs with higher luminescence efficiency can effectively reduce the number of optical systems needed within a headlamp assembly.

(3) It is feasible to create an LED headlamp using only two projection systems, provided that a single LED's light output exceeds 500 lumens.

(4) The newly developed design achieved a significant reduction in size, being 40% smaller in volume compared to the original headlamp model studied.

8. References:

- [1] B. Kang, K. Park, B. Yong, and H. Kim: SAE International, Paper (2007) No. 2007-01-3516.

- [2] T. Inaba, S. Watanaba, and Y. Yamada: SAE International, Paper (2008) No. 2008-01-0339.

- [3] CREE: Cree®XLamp®XP-G2 LEDs, Product Family Data Sheet (CREE, Durham, U.S., 2012).

9. Copyright:

- This material is a paper by "Yueh-Ying Chiang". Based on "Design with White Light-Emitting Diodes for an Automotive Low-Beam Projector Headlamp".

- Source of the paper: https://doi.org/10.18494/SAM.2016.1265

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.