This article introduces the paper "Castability and Strength of Potassium Chloride-Ceramic Composite Salt Cores" presented at the Journal of Japan Foundry Engineering Society (J.JFS).

1. Overview:

- Title: Castability and Strength of Potassium Chloride-Ceramic Composite Salt Cores (セラミックスを複合した塩化カリウム中子の溶融成形性と強度)

- Authors: Jun Yaokawa, Koichi Anzai, Youji Yamada, Hiroshi Yoshii, and Hiroyuki Fukui (八百川盾, 安斎浩一, 山田養司, 吉井 大, 福井広之)

- Publication Year: 2004

- Publishing Journal/Academic Society: Journal of Japan Foundry Engineering Society (J.JFS)

- Keywords: salt, core, potassium chloride, ceramic, whisker, castability, bending strength, surface fold, shrinkage

2. Research Background:

- Social/Academic Context of the Research Topic: The die casting industry requires high-strength, easily removable cores for manufacturing products with complex undercut shapes, such as closed-deck cylinder blocks. While sand cores and metal cores have been used, they present limitations in terms of shape flexibility, removal ease, and cost-effectiveness. Water-soluble salt cores offer excellent removal properties, but traditionally, sintered salt cores lack sufficient strength for demanding applications.

- Limitations of Existing Research: Sintered salt cores, while water-soluble, do not provide the necessary strength for complex die casting. Melt forming is a potential method to produce stronger salt cores, offering advantages in shape freedom, productivity, and cost. However, research and practical examples of melt-formed salt cores, especially for intricate shapes like closed-deck cylinder blocks, are scarce.

- Necessity of the Research: This research addresses the need for stronger salt cores by exploring melt forming techniques and reinforcing potassium chloride salt cores with ceramic materials. The study aims to overcome the strength limitations of sintered salt cores and improve upon existing core technologies for advanced die casting applications.

3. Research Purpose and Research Questions:

- Research Purpose: The primary purpose of this research is to investigate the feasibility of using melt forming to produce salt cores and to evaluate the impact of ceramic reinforcement on the strength and castability of these cores.

- Key Research Questions:

- Is it possible to manufacture salt cores using a melt forming process?

- How does the incorporation of ceramic particles or whiskers affect the bending strength of potassium chloride salt cores?

- What is the influence of ceramic content on the castability of salt cores, specifically concerning surface roughness and internal solidification shrinkage?

- Research Hypotheses:

- Salt cores can be successfully produced through melt forming.

- The addition of ceramic reinforcement will enhance the bending strength of salt cores.

- The ceramic content will significantly influence the castability of salt cores, requiring optimization to achieve a balance between strength and formability.

4. Research Methodology

- Research Design: This study employs an experimental research design to assess the bending strength and castability of potassium chloride salt cores. The cores were manufactured using melt forming and reinforced with varying types and amounts of ceramic particles and whiskers.

- Data Collection Method:

- 4-Point Bending Test: The strength of the salt cores was evaluated using a 4-point bending test to determine their flexural strength.

- Surface Roughness Observation: The surface quality of the salt cores was assessed through visual observation to evaluate surface roughness and identify any defects.

- X-ray Tests: X-ray radiography was used to examine the internal structure of the salt cores and quantify the extent of internal solidification shrinkage.

- Microscopic Observation: Cross-sections of selected samples were examined microscopically to analyze the dispersion of ceramic reinforcement and the microstructure of the salt cores.

- Ceramic Content Measurement: The actual ceramic content within the salt cores was measured to verify the intended compositions.

- Analysis Method:

- Statistical Analysis: Quantitative data from bending tests were statistically analyzed to determine the relationship between ceramic reinforcement and core strength.

- Qualitative Analysis: Surface roughness and shrinkage observed in visual inspections and X-ray images were qualitatively analyzed to assess castability.

- Calculation of Shrinkage Rate and Curvature: Shrinkage rates were calculated to quantify internal defects, and the curvature of the solidified layer was analyzed to understand surface fold formation.

- Research Subjects and Scope: The research focused on potassium chloride salt cores reinforced with six types of ceramic materials: Mullite and Aluminum Borate particles, and Aluminum Borate, Silicon Nitride, Silicon Carbide, Potassium Titanate, and Zinc Oxide whiskers. The volume fraction of ceramic reinforcement was varied to investigate its effect on core properties.

5. Main Research Results:

- Key Research Results:

- Strength Enhancement: The bending strength of potassium chloride salt cores was significantly enhanced by increasing the ceramic content.

- High Strength with Whisker Reinforcement: Potassium chloride cores reinforced with Al18B4O33 whiskers achieved a bending strength of approximately 30 MPa, which is about five times greater than that of conventional sand cores.

- Surface Folds: Surface folds were observed on all salt core specimens, regardless of ceramic type or content.

- Internal Shrinkage: Internal solidification shrinkage was present in all specimens. The amount of shrinkage initially decreased with increasing ceramic content but increased again when the ceramic content became excessive.

- Formability Limits: Excessive ceramic content led to a high apparent viscosity of the molten mixture, resulting in extremely low formability and difficulty in the melt forming process.

- Statistical/Qualitative Analysis Results:

- Figure 9 demonstrates a positive correlation between bending strength and mullite content in the salt cores.

- Figure 7 illustrates that the shrinkage ratio initially decreases with increasing mullite content up to a certain point, after which it starts to increase.

- Figure 10 compares the bending strength achieved with different ceramic materials, showing that whisker reinforcement generally provides a greater strength increase per unit volume fraction compared to particle reinforcement.

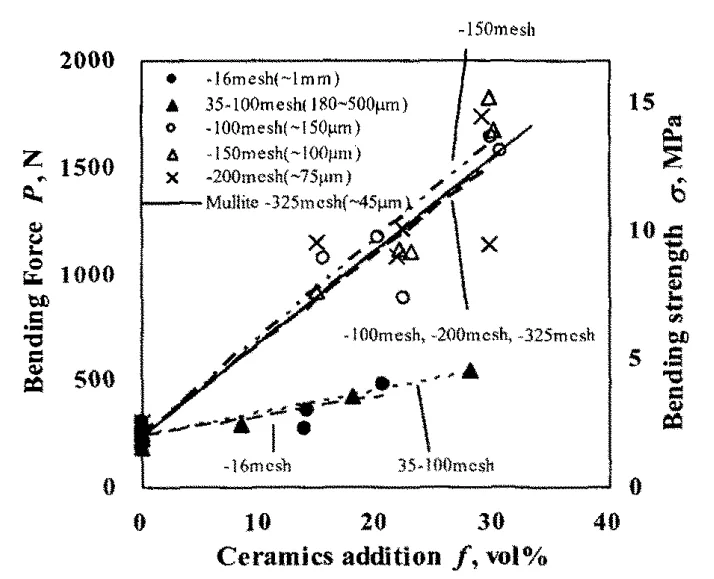

- Figure 12 shows the influence of mullite particle size on bending strength, indicating that finer particles generally lead to better strength, except at very high concentrations where larger particles might hinder formability less.

- Data Interpretation: Ceramic reinforcement is an effective method to enhance the strength of potassium chloride salt cores produced by melt forming. However, achieving optimal castability requires careful control of ceramic content. While increasing ceramic content reduces shrinkage up to a point, excessive amounts can negatively impact formability due to increased viscosity and potentially lead to increased shrinkage again due to processing issues. Surface folds and internal shrinkage remain inherent challenges in the melt forming of these salt cores.

- Figure Name List:

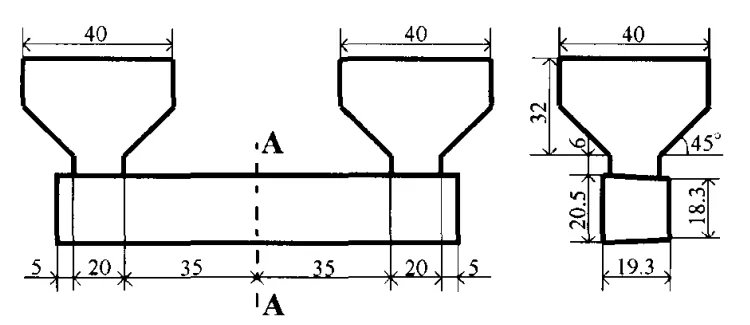

- Fig.1 Schematic drawing of mold design.

- Fig.2 Schematic drawing of bending test.

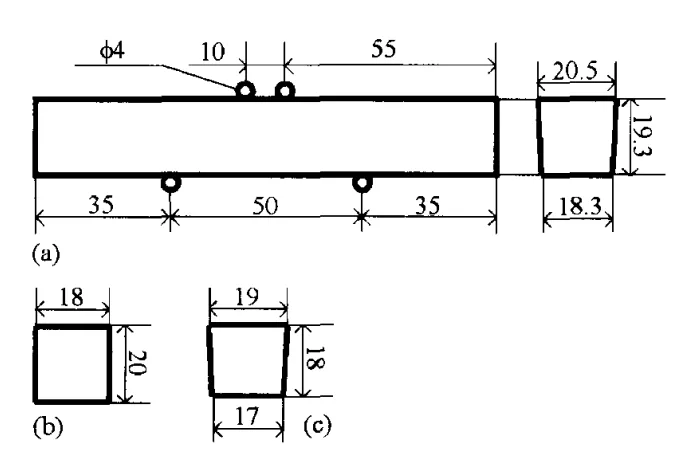

- Fig.3 Schematic drawing of melting.

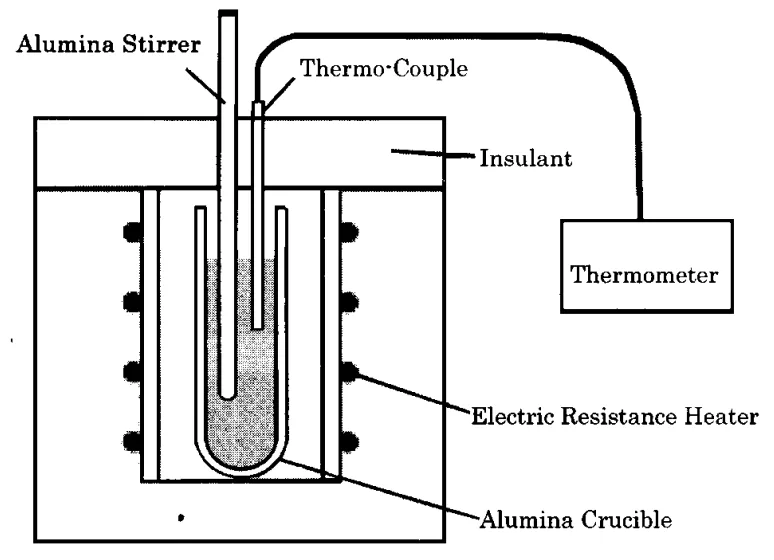

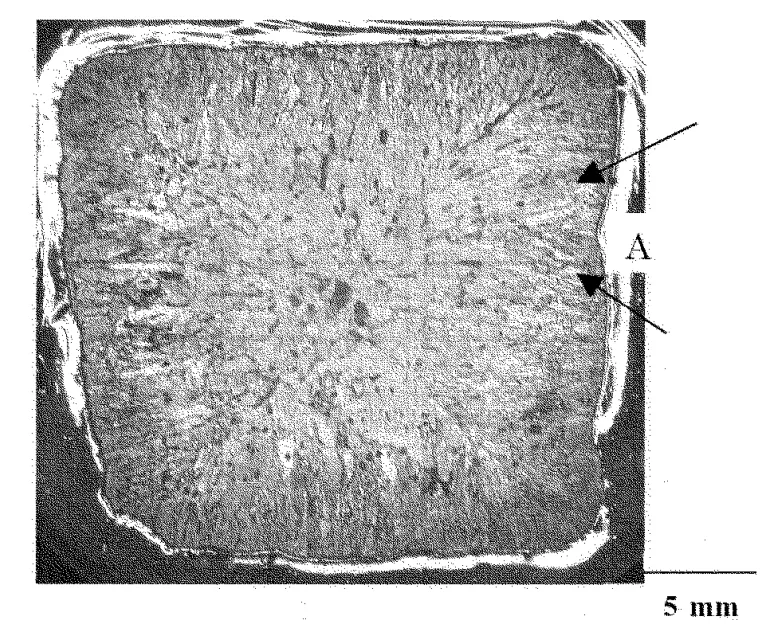

- Fig.4 Typical salt core. Potassium chloride with 36.7 mass% -325 mesh mullite. There were many surface folds.

- Fig.5 Macro structure of pure potassium chloride core.

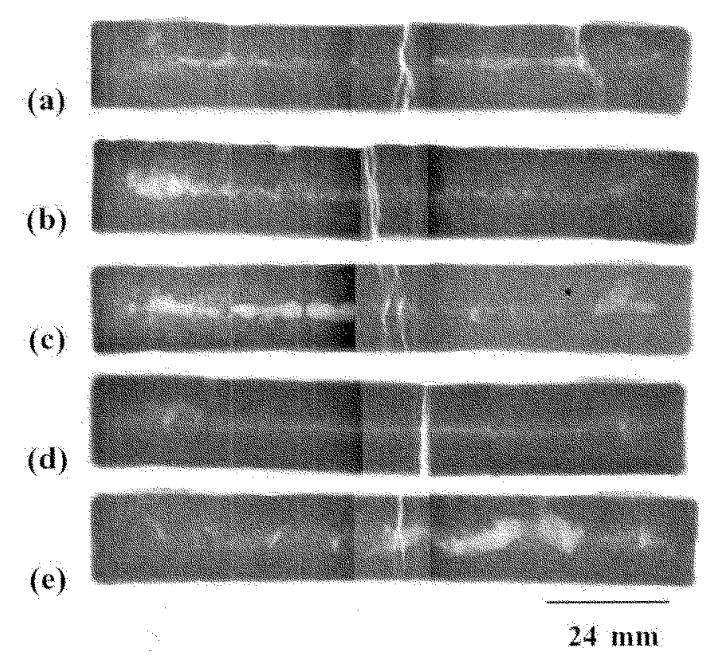

- Fig.6 X-ray photos of potassium chloride with -325 mesh mullite cores.

- Fig.7 Shrinkage ratio of potassium chloride with -325 mesh mullite cores.

- Fig.8 Position - bending force curves of typical potassium chloride with -325 mesh mullite cores.

- Fig.9 Bending strength of potassium chloride with -325 mesh mullite cores.

- Fig.10 Effect of ceramic materials on bending strength of salt cores.

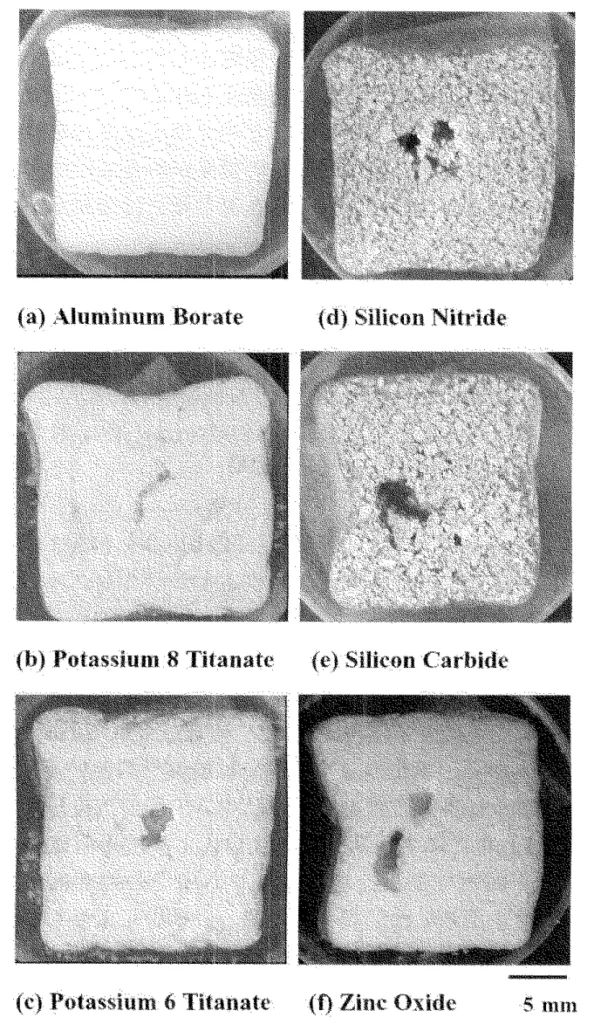

- Fig.11 Macro structure of potassium chloride cores show effect of whisker materials on dispersion.

- Fig.12 Effect of particle size on bending strength of potassium chloride with mullite cores.

6. Conclusion and Discussion:

- Summary of Main Results: This research successfully demonstrated that melt forming can be used to produce potassium chloride salt cores, and that reinforcing these cores with ceramic materials significantly increases their bending strength. Al18B4O33 whisker reinforcement yielded the highest strength, reaching approximately 30 MPa. Castability, however, is sensitive to ceramic content, requiring a balanced approach to optimize strength while minimizing surface defects and shrinkage.

- Academic Significance of the Research: This study contributes to the fundamental understanding of salt core production for die casting by demonstrating the viability of melt forming and ceramic reinforcement. The research provides valuable data on the relationship between ceramic reinforcement, core strength, and castability, advancing the knowledge base for salt core technology. It also sheds light on the solidification behavior of salt materials in casting processes.

- Practical Implications: The findings suggest that melt-formed, ceramic-reinforced potassium chloride salt cores are a promising alternative to conventional sand cores and sintered salt cores. Their enhanced strength and water solubility make them particularly attractive for manufacturing complex die-cast components requiring easy core removal and high structural integrity.

- Limitations of the Research: Surface folds and internal shrinkage remain persistent challenges in melt-formed salt cores. The formability of the salt-ceramic mixture is limited by high ceramic content due to increased viscosity. Further research is needed to optimize ceramic types, content levels, and forming processes to overcome these limitations.

7. Future Follow-up Research:

- Directions for Follow-up Research:

- Investigate methods to mitigate surface fold formation and internal solidification shrinkage in melt-formed salt cores, potentially through mold design modifications or process parameter optimization.

- Optimize the type and volume fraction of ceramic reinforcement to further enhance strength and improve castability, exploring a wider range of ceramic materials and combinations.

- Explore alternative melt forming processes and mold designs to improve the formability of highly filled ceramic-salt mixtures and achieve more complex core geometries.

- Conduct further research into the effect of ceramic particle size distribution and morphology on the strength and castability of salt cores.

- Areas Requiring Further Exploration: Future research should focus on controlling the deformation of the initial solidification shell, managing the viscosity of the ceramic-salt mixture during melt forming, and assessing the feasibility of scaling up the production process for industrial applications.

8. References:

- 1) リョービ(株): 会報ダイカスト No.118(日本ダイカスト協会) (2003)27

- 2) R. Izawa et al.: Report of Japan Die Casting Association JD02 (2002)35

- 3) A. D. Ackerman et al. U.S. Patent 4446906

- 4) Y. Kawabata et al.: U. S. Patent 4776075

- 5) 日本熱物性学会:熱物性ハンドブック(養賢堂) (1990)106

- 6) 日本金属学会:金属データブック改定3版(丸善) (1995)

- 7) Dong: Cast Metals 6 (1993)115

- 8) Dong: 東北大学学位論文(1995)

- 9) Touloukian, Y. S. et al. Thermal Conductivity nonmetallic solid (New York)

- 10) 日本学術振興会先端材料技術第156委員会:複合材料の強度(共立出版) (1997)354

9. Copyright:

*This material is Jun Yaokawa, Koichi Anzai, Youji Yamada, Hiroshi Yoshii, and Hiroyuki Fukui's paper: Based on Castability and Strength of Potassium Chloride-Ceramic Composite Salt Cores.

*Paper Source: J.JFS, Vol.76, No.10 (2004) pp.823~829

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.