Beyond the Barcode: Embedding Intelligence Directly into Your Die Castings

This technical summary is based on the academic paper "Autonomous Control of Intelligent Products in Beginning of Life Processes" by Karl A. Hribernik, Christoph Pille, Oliver Jeken, Klaus-Dieter Thoben, Katja Windt, and Matthias Busse, published in the International Conference on Product Lifecycle Management.

Keywords

- Primary Keyword: Embedded RFID in Casting

- Secondary Keywords: Intelligent Products, Autonomous Manufacturing, Die Casting Traceability, Product Lifecycle Management (PLM), RFID Integration

Executive Summary

- The Challenge: Conventional part marking methods for metal castings are applied post-production and lack the robustness and data capacity needed for true autonomous control from the moment of creation.

- The Method: Researchers developed a three-part approach: physically embedding RFID transponders into metal parts during the die-casting process, integrating the part's data with IT systems via a semantic mediator, and enabling autonomous decision-making using a "Product Variant Corridor" algorithm.

- The Key Breakthrough: The study successfully demonstrated the practical feasibility of embedding a functional RFID transponder directly into a zinc alloy component during the die-casting process, creating a truly "intelligent" part from birth.

- The Bottom Line: This technology enables item-level traceability and autonomous control right from the casting machine, paving the way for highly flexible, efficient, and self-managing production and assembly lines.

The Challenge: Why This Research Matters for HPDC Professionals

In today's customer-driven market, manufacturers face immense pressure to shorten product lifecycles, increase product variety, and reduce time-to-market without sacrificing quality. A significant barrier to achieving this agility in metal component production is the lack of an efficient and robust method for uniquely identifying parts during manufacture.

Conventional methods like engraved or laser-cut barcodes and data matrix codes are applied after casting. They are susceptible to damage in harsh industrial environments and offer limited data capacity. This fundamental limitation prevents the seamless integration of physical parts with their digital data streams, hindering the implementation of advanced concepts like autonomous logistics and item-level Product Lifecycle Management (PLM) from the very beginning of a product's life. This research directly addresses this critical gap by creating a method to give a metal part its unique identity and decision-making capability the instant it's formed.

The Approach: Unpacking the Methodology

The researchers proposed a comprehensive solution combining hardware innovation, software integration, and advanced decision-making logic.

Method 1: In-Process RFID Embedding

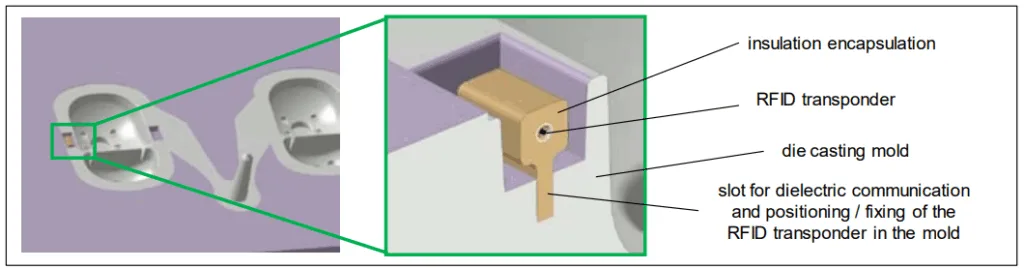

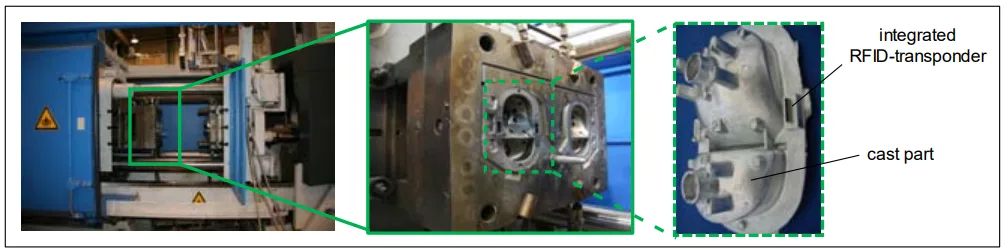

The core challenge was to protect a sensitive RFID transponder from the extreme temperatures and pressures of the die-casting process. The team selected a compact glass transponder ('Sokymat SID153') operating at a low frequency (125 kHz) to minimize interference from the surrounding metal. This transponder was encased in a specially designed insulation layer that provided both thermal protection and mechanical stability, allowing it to be precisely positioned and fixed within the casting mold. The experiment was conducted on a FRECH DAW 315 die-cast unit using a zinc alloy (ZL0410), which, despite a lower melting point than aluminum, presented a comparable thermal challenge due to the part's thin walls and volume.

Method 2: Semantic Data Integration

To connect the physical part to the factory's IT landscape, a semantic mediator architecture was proposed. Since the chosen RFID hardware was not EPCglobal compliant, a custom hardware abstraction layer (HAL) was developed to interface with reader devices, while maintaining compatibility with the FOSSTRAK standard for future scalability. This system links the part's unique ID to a "digital counterpart" or software agent. The mediator uses Web Ontology Language (OWL-DL) to understand and integrate data from various sources (e.g., ERP, MES), making relevant information seamlessly available to the intelligent product's agent.

Method 3: The Product Variant Corridor

To enable autonomous control, the paper introduces the "Product Variant Corridor" as a decision-making methodology. This concept allows the intelligent product itself to decide its next production step. The product's software agent gathers real-time information about available machines, production status (e.g., machine breakdowns, work-in-process levels), and current customer demand. It then evaluates different production paths and resulting final product variants, choosing the optimal route based on a weighted system of targets like minimizing lead time or maximizing capacity utilization. This corridor of possibilities narrows as production progresses but can also expand if new customer orders emerge.

The Breakthrough: Key Findings & Data

The research yielded significant results, demonstrating the viability of the entire concept from physical implementation to autonomous control.

Finding 1: Successful Embedding of RFID in a Die-Cast Part

The experimental work confirmed that the chosen insulation and positioning strategy was effective. As shown in the paper's Figure 4, the encapsulated RFID transponder was successfully integrated into the final cast part—an automobile rear light—and ejected with the casting. The transponder remained functional after the process, which involved teeming molten zinc alloy at 420°C. This demonstrates that with proper thermal and mechanical protection, it is physically possible to embed electronic identification directly into metal components "from the cradle."

Finding 2: A Complete Framework for an Autonomous Intelligent Product

The study established a holistic architecture for an intelligent product. As classified in Figure 6, the resulting product demonstrates "decision making" as its level of intelligence. Because the processing power resides in its external software agent, it exhibits "intelligence through the network." Crucially, this intelligence is applied at the "item level," not just the container or batch level. This framework successfully combines the physical RFID-enabled part with a powerful, flexible, and scalable IT backend, creating a product capable of autonomously navigating its own production and assembly processes.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that integrating RFID embedding into the die-casting process is feasible. It may require mold modifications for positioning and fixing the encapsulated transponder but eliminates downstream marking processes, potentially reducing overall cycle time and handling.

- For Quality Control Teams: The data in the paper illustrates the potential for 100% traceability from the moment of casting. An embedded, protected RFID tag ensures that a part’s identity cannot be lost or damaged, providing an incorruptible link to its production data (e.g., machine parameters, cycle time, quality checks) throughout its lifecycle.

- For Design Engineers: The findings indicate that the location and insulation of the embedded transponder are critical design considerations. Early-phase collaboration between part designers and manufacturing engineers is essential to ensure a suitable location is available that does not compromise the part's structural integrity while ensuring reliable RFID communication.

Paper Details

Autonomous Control of Intelligent Products in Beginning of Life Processes

1. Overview:

- Title: Autonomous Control of Intelligent Products in Beginning of Life Processes

- Author: Karl A. Hribernik, Christoph Pille, Oliver Jeken, Klaus-Dieter Thoben, Katja Windt, Matthias Busse

- Year of publication: The paper is from the International Conference on Product Lifecycle Management; a specific year is not listed in the provided text.

- Journal/academic society of publication: International Conference on Product Lifecycle Management

- Keywords: PLM, item-level PLM, closed loop, intelligent products, product variant corridor, embedded RFID, casting, RFID integration

2. Abstract:

Current research into integrating RFID into metal parts has shown the practical feasibility of embedding transponders directly into aluminum during the casting process. This introduces the possibility of augmenting parts with decision making capabilities immediately after casting. Along with concepts from the field of Intelligent Products and models of autonomous control in production such as the Product Variant Corridor and Multi-Agent Systems, the potential for optimizing the Beginning-of-Life phase of the lifecycles of products with such cast RFID are immense. This paper explores these potentials and introduces concepts and methods for the autonomous control of cast-RFID-based Intelligent Products in production and assembly processes.

3. Introduction:

Intelligent Products are defined as items with a unique identifier capable of information processing and decision-making. While their potential in the product lifecycle is well-documented, significant barriers prevent widespread adoption, especially for products made of metal parts. This paper addresses three of these barriers: 1) the lack of an efficient method for attaching unique identification to metal parts during manufacture, for which it presents research on embedding RFID transponders during casting; 2) the seamless integration of these products into IT infrastructure, for which it discusses hardware abstraction and semantic data integration; and 3) the design of suitable decision algorithms, for which it proposes the Product Variant Corridor concept. The paper aims to outline an approach that combines these three components to enable autonomous, Intelligent Products in beginning-of-life processes.

4. Summary of the study:

Background of the research topic:

The manufacturing industry is shifting from a supplier-driven to a customer-driven market, requiring shorter product lifecycles, increased product variety, and faster demand satisfaction. This necessitates managing products at an individual item level from the very beginning of their lifecycle (BOL). Intelligent Products, which can process information and make decisions, are a key enabler for this shift. However, their application to metal components has been hindered by technological barriers.

Status of previous research:

Previous research has established the concept of Intelligent Products and their classification based on dimensions like level of intelligence (information handling, decision making), location of intelligence (at the object, through the network), and aggregation level (item, container). Technologies like RFID have been identified as Product Embedded Information Devices (PEIDs), but their application to cast metal parts has been limited by cost and the harsh manufacturing environment. Existing approaches for synchronizing physical products with their digital counterparts include concepts like ID@URI and standards like the EPCglobal Architecture Framework. For data integration in complex IT landscapes, semantic mediators are a known approach. However, existing decision methodologies for production control do not fully cover autonomous logistic processes where a part can dynamically alter its variant and production path based on real-time conditions.

Purpose of the study:

The purpose of this study is to explore the potential of cast-RFID-based Intelligent Products and introduce concepts and methods for their autonomous control in production and assembly processes. The paper aims to present an integrated approach that overcomes the key barriers by combining a novel method for embedding RFID during casting, a flexible data integration architecture, and an autonomous decision-making algorithm.

Core study:

The core of the study is the development and integration of three conceptual components. First, it details the technological methodology for embedding a protected RFID transponder into a metal part during the die-casting process. Second, it proposes a data integration concept using a semantic mediator to link the physical product to its digital counterpart and the wider IT environment. Third, it introduces the Product Variant Corridor as a decision-making framework that allows the intelligent product to autonomously control its path through the manufacturing and assembly process based on logistical and technological criteria. The combination of these three components is presented as a holistic solution for creating autonomous Intelligent Products in their BOL phase.

5. Research Methodology

Research Design:

The research followed a constructive design, developing and integrating three distinct technological and conceptual components: a physical embedding process, a data integration architecture, and a decision-making methodology. The feasibility of the physical component was validated through experimental work, while the overall integrated concept was explored through a prototypical demonstrator.

Data Collection and Analysis Methods:

For the physical embedding component, experimental work was conducted using a ‘FRECH DAW 315’ die-cast unit. A zinc alloy (ZL0410) was used to cast an automobile rear light part with an embedded, encapsulated RFID transponder. The process parameters (e.g., closing force, melt temperature, die temperature) were controlled and documented. The success of the embedding was determined by the physical integrity and subsequent functionality of the RFID transponder. The data integration and decision methodology components were conceptual and architectural in nature, based on existing standards (e.g., OWL-DL, SPARQL) and novel concepts (Product Variant Corridor).

Research Topics and Scope:

The research scope covers the Beginning-of-Life (BOL) phase of die-cast metal products. The main topics are:

1. Cast RFID: The technological challenge and methodology of embedding RFID transponders into metal parts during the casting process.

2. Data Integration: The design of an IT architecture for seamlessly linking RFID-enabled physical products with their digital counterparts and heterogeneous IT systems.

3. Autonomous Decision-Making: The development of a decision methodology (Product Variant Corridor) to enable intelligent products to autonomously control their own manufacturing and assembly processes.

6. Key Results:

Key Results:

- The practical feasibility of embedding a glass RFID transponder directly into a zinc alloy part during a die-casting process was successfully demonstrated. The transponder was protected by an insulation layer and remained functional after casting.

- A comprehensive conceptual framework for an autonomous Intelligent Product was developed. This framework combines the physically embedded RFID with a "digital counterpart" (software agent) that operates through the network.

- The proposed architecture, utilizing a semantic mediator and a hardware abstraction layer, allows for seamless integration with production logistics IT environments.

- The Product Variant Corridor was introduced as a suitable decision algorithm, enabling the Intelligent Product to make autonomous choices about its production path, thereby increasing flexibility.

- The combined concept results in an Intelligent Product characterized by "decision making" intelligence, located "through the network," and operating at the "item level," as per the classification by Meyer, et al.

Figure Name List:

- Figure 1: Classification of Intelligent Products according to Meyer, et al. [2]

- Figure 2: RFID cast part with integrated RFID transponder (left) and design of a glass transponder (right)

- Figure 3: Positioning and Fixing the RFID Transponder with Insulation in the Die Casting Mold

- Figure 4: Die-cast unit FRECH DAW 315 (left), die casting mold (center) and final cast part with integrated RFID transponder (right)

- Figure 5: Product Variant Corridor

- Figure 6: Characteristics of the Intelligent Product according to Meyer, et al. [2]

- Figure 7: Die-cast rear light with embedded RFID

7. Conclusion:

The concepts and technologies discussed in the paper demonstrate a possible and viable approach to implementing Intelligent Products in the BOL phase of die-cast metal products. The research exemplifies the technology required to provide unique identification from the moment of creation, methods for linking physical parts to digital counterparts, a decision algorithm for autonomous control, and a data integration approach for access to relevant data. Future work will focus on enhancing castings for autonomous routing in intralogistics, developing data integration concepts for sensors, and further refining the Product Variant Corridor for assessing different decision strategies. The combination of these concepts provides a basis for autonomous, Intelligent Products throughout the entire product lifecycle.

8. References:

- 1 D. McFarlane, S. Sarma, J. L. Chirn, C. Y. Wong, K. Ashton, Auto ID systems and intelligent manufacturing control, Engineering Applications of Artificial Intelligence 16 (4) (2003) pp. 365-376.

- 2 G. G. Meyer, K. Främling, J. Holmström, Intelligent Products: A Survey, Computers in Industry 60 (3) (2009) pp. 137-148

- 3 Ventä, Olli. Intelligent Products and Systems. Technology Theme - Final Report. VTT, Espoo: VTT Publications, 2007, 304 s.

- 4 Wong, C Y, Duncan McFarlane, A Ahmad Zaharudin, and V Agarwal. "The Intelligent Product Driven Supply Chain." Proceedings of IEEE International Conference on Systems, Man and Cybernetics, 2002. Tunisia: IEEE, 2002.

- 5 Goossenaerts, J., Ranta, M., Ranke, A. A. M., Wognum, P. M., Gibbons, W. M., Büchner, A. G., Kerssens-van Drongelen, I. C., Thoben, K. D., Pels, H. J.:Product related Data and Knowledge Management in the Intelligent Enterprise. Proceedings of the first International Workshop on Intelligent Manufacturing Systems, EPFL, Lausanne, Switzerland (1998): 15-17.

- 6 Hong-Bae Jun, Dimitris Kiritsis, Paul Xirouchakis, Research issues on closed-loop PLM, Computers in Industry, Volume 58, Issues 8-9, December 2007, pp. 855-868

- [And so on for all 36 references as listed in the paper]

Expert Q&A: Your Top Questions Answered

Q1: Why was a zinc alloy used in the experiment instead of aluminum, which is more common in many HPDC applications?

A1: The paper states that while the zinc alloy (ZL0410) has a lower processing temperature than aluminum (approx. 420°C vs. 710°C), the experimental part had a thin wall thickness of approximately 1 mm. This design resulted in a volume that is comparable to aluminum concerning heat capacity. Therefore, the total heat energy impacting the embedded electronics was comparable, and this was confirmed by numerical calculations, making the experiment a valid proof of concept for higher-temperature alloys.

Q2: The paper mentions the chosen RFID transponder is not EPC compliant. What is the practical implication of this?

A2: The lack of EPC compliance means the hardware cannot be used out-of-the-box with standard EPCglobal Architecture Framework middleware. To overcome this, the researchers had to develop an alternative hardware abstraction layer (HAL). While this HAL was designed to expose an interface compatible with the FOSSTRAK project's HAL definition, it represents a custom solution. For industrial deployment, using EPC-compliant hardware would be preferable to leverage industry-standard software and ensure broader interoperability.

Q3: How does the "Product Variant Corridor" differ from traditional production planning and control systems?

A3: Traditional systems typically follow a more rigid, top-down planning approach where the production sequence and final product configuration are determined in advance. The Product Variant Corridor enables decentralized, autonomous decision-making at the individual product level. The product itself, via its digital agent, dynamically decides its next step based on real-time factory conditions and demand, allowing it to change its planned production path or even its final variant configuration during the process to optimize for current logistical goals.

Q4: What are the main challenges in protecting the RFID transponder during casting?

A4: The paper identifies two primary challenges. First is the extreme thermal load from the molten metal. Second is the high compression load during the die-casting and redensification process. The solution requires an insulation material that not only resists high temperatures but is also mechanically robust enough to prevent the transponder from being crushed and to hold it securely in a fixed position within the mold.

Q5: Is the "intelligence" actually inside the cast part?

A5: No, and this is a key point in the paper's architecture. The intelligence is located "through the network." The physical cast part only carries the unique identifier within the embedded RFID transponder. All information processing, data storage, and decision-making are handled by its external "digital counterpart," which is a software agent running on the factory's IT infrastructure. This approach is necessary due to the current limitations of embedding complex electronics and power sources directly into a cast metal part.

Conclusion: Paving the Way for Higher Quality and Productivity

The fundamental challenge of achieving true item-level traceability and control from the very start of a component's life has long been a barrier to next-generation manufacturing. This research provides a powerful breakthrough by demonstrating a viable method for Embedded RFID in Casting. By giving a metal part a unique, incorruptible identity at the moment of its creation, we can unlock immense potential for autonomous, self-managing production systems that are more flexible, efficient, and responsive to market demands.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Autonomous Control of Intelligent Products in Beginning of Life Processes" by "Karl A. Hribernik, et al.".

Source: The paper was presented at the International Conference on Product Lifecycle Management.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.