This article introduces the paper "AUTOMOTIVE HEADLAMP HIGH POWER LED COOLING SYSTEM AND ITS EFFECT ON JUNCTION TEMPERATURE AND LIGHT INTENSITY".

1. Overview:

- Title: AUTOMOTIVE HEADLAMP HIGH POWER LED COOLING SYSTEM AND ITS EFFECT ON JUNCTION TEMPERATURE AND LIGHT INTENSITY

- Authors: Ramesh Kumar Chidambaram¹, Rammohan Arunachalam¹

- Year of Publication: 2020

- Journal/Conference: Journal of Thermal Engineering

- Keywords: HPLED Cooling System, HPLED Junction Temperature, Headlamp Reflector Temperature, Halogen, Light Intensity

2. Background:

Automotive headlamps are crucial for nighttime safety and vehicle aesthetics. Historically, halogen and xenon bulbs were prevalent, but halogen bulbs are inefficient, generating significant heat, while xenon bulbs have slower ignition times. High-Power Light Emitting Diodes (HPLEDs) offer higher efficiency and longer lifespans, but their compact size leads to high junction temperatures when integrated into conventional headlamp assemblies, potentially reducing their lifespan. This necessitates the development of effective cooling systems for HPLEDs in automotive applications.

3. Research Objectives and Questions:

- Research Objective: To design and test a compact cooling system for HPLEDs within a conventional headlamp assembly, evaluating its impact on junction temperature and light intensity.

- Key Research Questions: How does a compact cooling system affect the junction temperature and light intensity of HPLEDs?

- Research Hypothesis: A compact cooling system will decrease HPLED junction temperature and increase light intensity.

4. Methodology:

- Research Design: A combined experimental and simulation approach was employed. ANSYS software was used to model and simulate various heatsink designs to optimize dimensions for the headlamp assembly.

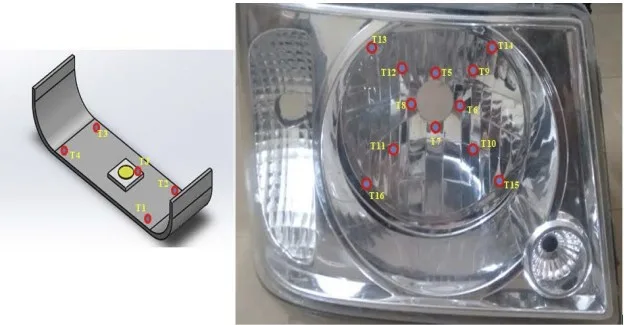

- Data Collection: Experiments were conducted on a popular SUV's headlamp assembly using a 16W CREE CXB1816 HPLED. Light intensity (in lux) was measured at various test points (up to 28 meters) on a flat black surface in the absence of external light sources. Temperature data was collected using thermocouples at multiple locations (heatsink and reflector).

- Analytical Methods: ANSYS simulation results guided heatsink selection. Experimental data were analyzed statistically to determine the effects of the cooling system on junction temperature and light intensity. Airflow characteristics were analyzed using Reynolds number calculations.

- Subjects and Scope: The study compared a 55W halogen bulb with a 16.2W HPLED within a modified headlamp assembly, investigating the impact of varying cooling fan speeds.

5. Main Findings:

- Key Findings: The proposed cooling system reduced HPLED junction temperature by approximately 25% under laminar flow conditions. Light intensity increased by about 30.9% due to the temperature reduction. The HPLED headlamp reflector inner wall temperature was 49% lower than the halogen bulb's. For equivalent light intensity, HPLED consumed only one-third of the energy used by the halogen bulb.

- Statistical/Qualitative Analysis: ANSYS simulations determined optimal heatsink dimensions. Experimental data demonstrated a direct correlation between cooling fan speed (airflow rate), junction temperature, and light intensity. Reynolds number calculations characterized the airflow regime.

- Data Interpretation: Increased airflow resulted in lower junction temperatures and higher light intensities. A 1°C decrease in junction temperature corresponded to a 2.7 lux increase in light intensity at a specific test point.

- Figure List and Description: Figures (1-12) detailed experimental setup, test point locations, temperature distributions (heatsink and reflector), light intensity profiles at various distances and angles, and the impact of cooling fan speed on junction temperature and light intensity.

6. Conclusions and Discussion:

The study demonstrated that the compact cooling system significantly improved HPLED performance, reducing junction temperature and increasing light intensity. The system offered substantial energy savings compared to halogen bulbs. While the experimental setup did not fully replicate real-world driving conditions, the findings provide valuable insights for HPLED headlamp design and thermal management. The simulation results provided a reasonable correlation with experimental findings.

7. Future Research:

Future work should involve testing under real-world driving conditions to validate the findings in a more representative environment. Further investigation into different HPLED types and cooling system designs is recommended. More sophisticated thermal modeling and simulation techniques could enhance the accuracy of the predictions.

8. References:

The paper cited numerous studies on LED thermal management and automotive lighting, supporting the methodology and contextualizing the findings. Specific details are omitted for brevity but are extensively present in the original paper.

- [1] Sousa JMM, Vogado J, Costa M, Bensler H, Freek C, Heath D. An experimental investigation of fluid flow and wall temperature distributions in an automotive headlight. International Journal of Heat and Fluid Flow 2005;26:709–21. https://doi.org/10.1016/j.ijheatfluidflow.2005.05.003.

- [2] Weng CJ. Advanced thermal enhancement and management of LED packages. International Communications in Heat and Mass Transfer 2009;36:245–8. https://doi.org/10.1016/j.icheatmasstransfer.2008.11.015.

- [3] Tsai MY, Chen CH, Kang CS. Thermal measurements and analyses of low-cost high-power LED packages and their modules. Microelectronics Reliability 2012;52:845–54. https://doi.org/10.1016/j.microrel.2011.04.008.

- [4] Jung ED, Lee YL. Study on the development of LED headlamps for used cars. Transactions on Electrical and Electronic Materials 2014;15:270–4. https://doi.org/10.4313/TEEM.2014.15.5.270.

- [5] Kaya M. Experimental Study on Active Cooling Systems Used for Thermal Management of High-Power Multichip Light-Emitting Diodes. Scientific World Journal 2014;. http://dx.doi.org/10.1155/2014/563805.

- [6] Wang J, Zhao X, Cai Y, Zhang C, Bao W. Experimental study on the thermal management of high-power LED headlight cooling device integrated with thermoelectric cooler package. Energy Conversion and Management 2015;101:532–40. https://doi.org/10.1016/j.enconman.2015.05.040.

- [7] Sökmen KF, Yürüklü E, Yamankaradeniz N. Computational thermal analysis of cylindrical fin design parameters and a new methodology for defining fin structure in LED automobile headlamp cooling applications. Applied Thermal Engineering 2016;94:534–42. https://doi.org/10.1016/j.applthermaleng.2015.10.069.

- [8] Niculina BD, Paul S, Cristina M. Fan vs. Passive heat sinks for cooling high power COB-type LEDs. Proceedings of the 9th International Conference on Electronics, Computers and Artificial Intelligence, ECAI 2017 2017;2017-Janua:1–4. https://doi.org/10.1109/ECAI.2017.8166477.

- [9] Sufian SF, Fairuz ZM, Zubair M, Abdullah MZ, Mohamed JJ. Thermal analysis of dual piezoelectric fans for cooling multi-LED packages. Microelectronics Reliability 2014;54:1534–43. https://doi.org/10.1016/j.microrel.2014.03.016.

- [10] Singh R, Jalilvand A, Goto K, Mashiko K, Saito Y, Mochizuki M. Direct impingement cooling of LED by Piezo fan. 2014 International Conference on Electronics Packaging, ICEP 2014 2014:1–5. https://doi.org/10.1109/ICEP.2014.6826650.

- [11] Fu HK, Wang CP, Chiang HC, Chen T Te, Chen CL, Chou PT. Evaluation of temperature distribution of LED module. Microelectronics Reliability 2013;53:554–9. https://doi.org/10.1016/j.microrel.2012.11.009.

- [12] Maaspuro M, Tuominen A. Microelectronics Reliability Thermal analysis of LED spot lighting device operating in external natural or forced heat convection. Microelectronics Reliability 2013;53:428–34. https://doi.org/10.1016/j.microrel.2012.10.004.

- [13] Wang J, Cai YX, Zhao XJ, Zhang C. Thermal design and simulation of automotive headlamps using white LEDs. Microelectronics Journal 2014;45:249–55. https://doi.org/10.1016/j.mejo.2013.11.011.

- [14] Su YF, Yang SY, Hung TY, Lee CC, Chiang KN. Light degradation test and design of thermal performance for high-power light-emitting diodes. Microelectronics Reliability 2012;52:794–803. https://doi.org/10.1016/j.microrel.2011.07.059.

- [15] Shih K. LED Junction Temperature Measurement and its Applications to Automotive Lamp Design. SAE Technical Paper 2004. https://doi.org/10.4271/2004-01-0224.

- [16] Colaco AM, Kurian CP, Kini SG, Colaco SG, Johny C. Thermal characterization of multicolor LED luminaire. Microelectronics Reliability 2017;78:379–88. https://doi.org/10.1016/j.microrel.2017.04.026.

- [17] J. P. Holman. Experimental methods for engineers. 8th ed. McGrawHill; 2012.

- [18] Lampio K, Karvinen R. Optimization of convectively cooled heat sinks. Microelectronics Reliability 2017;79:473–9. https://doi.org/10.1016/j.microrel.2017.06.011.

- [19] Rammohan A, Kumar Ramesh C. A review on effect of thermal factors on performance of high power light emitting diode (HPLED). Journal of Engineering Science and Technology Review 2016;9:165-76. https://doi.org/10.25103/jestr.094.24.

- [20] Dongmei Zhou and Timothy Rau. Thermal design methodology and prediction of heat sink performance. Journal of Thermal Engineering 2016;2:826–36. https://doi.org/10.18186/jte.29129.

- [21] Abu M, Alt V. The Effect of Blowing Direction on Heat Sink Performance. Journal of Thermal Engineering 2018;4:2471–80 2018;4:2471–80. https://doi.org/10.18186/thermal.465695.

Copyright:

This summary is based on the paper "AUTOMOTIVE HEADLAMP HIGH POWER LED COOLING SYSTEM AND ITS EFFECT ON JUNCTION TEMPERATURE AND LIGHT INTENSITY" by Ramesh Kumar Chidambaram and Rammohan Arunachalam. (DOI information not provided).

This material is a summary for informational purposes only and should not be used for commercial purposes without permission from the authors.

Copyright © 2025 CASTMAN. All rights reserved.

This detailed summary aims to capture the essence of the original research paper while strictly adhering to your guidelines. Remember that without the original paper's DOI, a complete citation is not possible.