From Waste to Worth: How Metallurgical Slags Can Refine High-Performance Casting Alloys

This technical summary is based on the academic paper "AN ATTEMPT TO USE VARIOUS METALLURGICAL SLAGS IN THE MODIFICATION PROCESSES OF CASTING ALLOYS" by J. SITKO, published in Arch. Metall. Mater. (2021).

Keywords

- Primary Keyword: Metallurgical Slag Modification

- Secondary Keywords: Casting Alloy Modification, Grain Refinement, IN-713C Superalloy, AlSi7Mg, Microstructure Control, Industrial Waste Upcycling

Executive Summary

- The Challenge: Improving the microstructure and mechanical properties of critical casting alloys, such as AlSi7Mg and IN-713C, while finding a value-added application for abundant industrial slag waste.

- The Method: Introducing specially prepared and ground metallurgical slags (copper and steel) as modifying agents into aluminum alloy melts and as a component in the mould coating for nickel superalloy castings.

- The Key Breakthrough: Ground copper slag effectively refined the coarse eutectic structure of AlSi7Mg into a fine-dispersive morphology, while a slag mixture demonstrated a visible grain refinement effect in IN-713C superalloy castings.

- The Bottom Line: Metallurgical slags, typically considered an industrial waste product, show proven potential as effective, low-cost modifying agents for enhancing the structural properties of high-performance casting alloys.

The Challenge: Why This Research Matters for HPDC Professionals

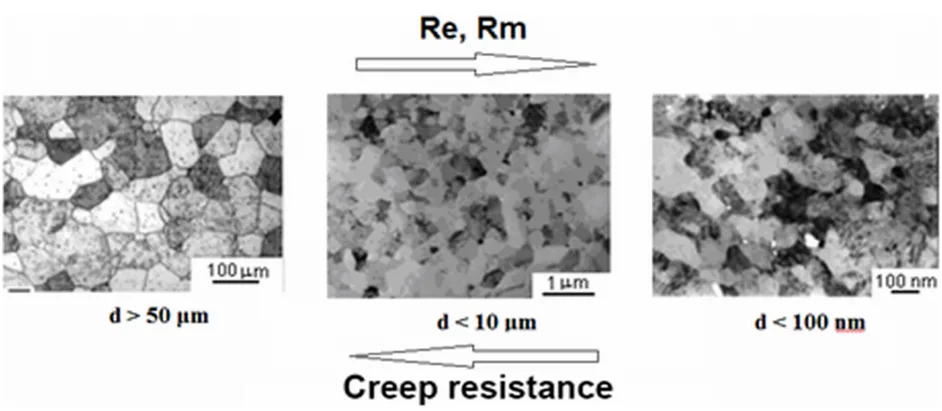

In high-performance casting, controlling the final microstructure is paramount to achieving desired mechanical and operational properties. For alloys like hypoeutectic AlSi7Mg, a coarse-grained eutectic structure can reduce mechanical performance. Similarly, for nickel-based superalloys like IN-713C used in high-temperature applications, grain size is a critical parameter that dictates creep resistance and tensile strength.

Simultaneously, the metallurgical industry generates vast quantities of slag as a byproduct. This material is often treated as waste, despite containing valuable components. This research addresses both challenges head-on by investigating whether these slags can be repurposed as an important raw material—a modifying agent to refine the structure of casting alloys, thereby improving their properties and providing a sustainable, economical use for industrial waste.

The Approach: Unpacking the Methodology

The study conducted two distinct sets of experiments to evaluate the modifying potential of metallurgical slags on two different alloy systems.

Modification of AlSi7Mg Aluminum Alloy:

- Materials: Granulated copper slag and steel slag were ground to a fine powder (granulation below 0.071 mm) and calcined. The base alloy was hypoeutectic AlSi7Mg.

- Process: A 1 kg charge of AlSi7Mg was melted in a silicon carbide crucible under a protective slag cover (NaF and KCl). At approximately 850°C, 30 g of the prepared slag was added to the bath and stirred. The molten alloy was then poured into a QC40-80 probe to register the solidification process via thermal ATD analysis and for subsequent microstructural examination.

Surface Modification of IN-713C Nickel Superalloy:

- Materials: A mixture of copper and steel slag was prepared, along with ground coke breeze as a reducing agent.

- Process: Three types of ceramic moulds were prepared using the lost wax method.

- Mould 1 (Control): No modifying coating.

- Mould 2 (Standard): A coating of zirconium flour with 5% cobalt aluminate (current technology).

- Mould 3 (Experimental): A coating of zirconium silicate (40%), a slag mixture (60%), and 5% ground coke breeze.

- IN-713C alloy was melted in a vacuum induction furnace and cast into the pre-heated moulds. The resulting castings were then analyzed for changes in surface macrostructure and grain size.

The Breakthrough: Key Findings & Data

The research demonstrated a clear and positive, though varied, modifying effect of the slags on both alloys.

Finding 1: Copper Slag Effectively Refines AlSi7Mg Eutectic Structure

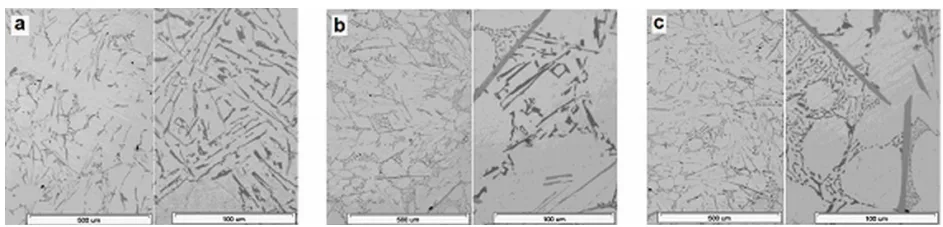

The introduction of ground copper slag into the AlSi7Mg melt had a significant beneficial effect on the alloy's microstructure. As shown in Figure 2, the slag modified the morphology of the eutectic from a coarse, granular form (Fig. 2a) to a more desirable fibrous, fine-dispersive structure (Fig. 2c). Thermal ATD analysis confirmed this effect, showing an increase in the liquidus temperature (Tliq) by 4°C, which indicates the slag particles promoted heterogeneous nucleation, creating additional sites for crystallization to begin.

Finding 2: Slag Mixture Achieves Visible Grain Refinement in IN-713C Superalloy

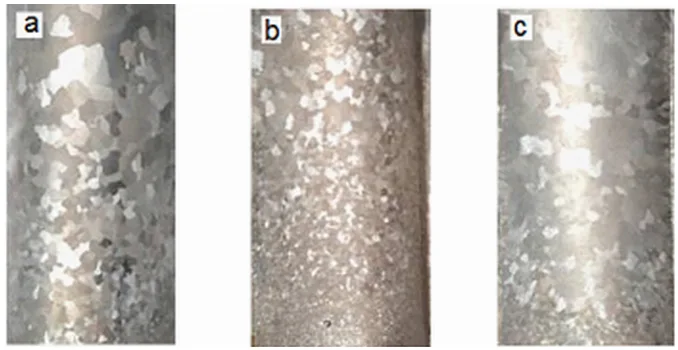

The slag-based mould coating had a clear impact on the grain structure of the IN-713C casting. While not as potent as the standard cobalt aluminate modifier, it produced a notable improvement over the unmodified casting.

- Unmodified Casting (Figure 8a): Exhibited a very coarse grain structure, with an average grain surface area of 27.15 mm² and only 0.036 grains per mm² (Figures 9 & 10).

- Slag Mixture Modified Casting (Figure 8c): Showed a significant refinement, with an average grain surface area of 4.78 mm² and 0.288 grains per mm².

- Cobalt Aluminate Modified Casting (Figure 8b): For comparison, the standard technology produced the finest structure, with an average grain surface area of 0.445 mm² and 2.245 grains per mm².

The results confirm that the slag mixture acts as an effective, if weaker, grain refiner for nickel superalloys.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that incorporating treated metallurgical slag powders into mould coatings or directly into melts may contribute to achieving finer grain structures and improved eutectic morphology, potentially at a lower cost than conventional modifiers.

- For Quality Control Teams: The data in Figures 9 and 10 of the paper illustrates the direct effect of the modifying agent on final grain size, a critical quality metric for superalloys. This reinforces the importance of controlling surface conditions at the mould-metal interface to ensure consistent properties.

- For Design Engineers: The findings indicate that the composition of the mould's surface coating can directly influence the microstructure of the final casting. This suggests that for components with complex or thin-walled sections, specifying a modifying coating could be a valuable consideration in the early design phase to ensure desired mechanical properties.

Paper Details

AN ATTEMPT TO USE VARIOUS METALLURGICAL SLAGS IN THE MODIFICATION PROCESSES OF CASTING ALLOYS

1. Overview:

- Title: AN ATTEMPT TO USE VARIOUS METALLURGICAL SLAGS IN THE MODIFICATION PROCESSES OF CASTING ALLOYS

- Author: J. SITKO

- Year of publication: 2021

- Journal/academic society of publication: Arch. Metall. Mater. 66 (4), 1067-1074

- Keywords: Surface modification, metallurgical slags, cobalt aluminate, nickel and aluminium alloys, free enthalpy, microstructure

2. Abstract:

The paper presents preliminary results of research on the use of certain smelting slags in the process of modification of casting alloys, leading to a change in the structure of these alloys and improvement of their mechanical and operational properties. The positive effect of ground copper slag with a fraction below 0.1 mm on the effect of modifying the hypoeutectic silumin AlSi7Mg towards changing the morphology of coarse-grained eutectic to fine-dispersive was demonstrated. The modifying effect also applies to the pre-eutectic α phase and results in the formation of additional crystallization sites (nucleation process), which was demonstrated by the thermal ATD solidification analysis, showing an increase in the temperature Tliq and Te max. The positive and noticeable influence of the mixture of copper and steel slag on the surface modifying effect of fragmentation of the structure was demonstrated in casting nickel superalloy IN-713C. Based on the results of research conducted so far on the modifying effect of cobalt aluminate, a hypothetical model of the impact of reduced metallic components of the applied metallurgical slags on the nucleation process and shaping of the microstructure of nickel alloys was developed.

3. Introduction:

Metallurgical slag is the largest group among the total amount of industrial waste. The processes of smelting pig iron and steel produce large amounts of blast furnace and steel-converter slag. A significant amount of slags is produced in the metallurgical processes of smelting copper (copper slag) as well as nickel and zinc. The availability, chemical composition and physicochemical properties of some metallurgical slags as well as economic and ecological considerations constitute the basis for research on the possibility of their use in various industries. Thus, slags can be regarded, on the one hand, as waste from various metallurgical processes, and as an important raw material and output product in other processes, on the other hand. Metallurgical slags are more and more often the object of interest in terms of the possibility of their development. The analysis of the chemical composition of some metallurgical slags (copper slag and steel slag) shows that they contain many valuable components. These slags, after appropriate mechanical and chemical treatment, can be components of refining and modifying preparations used in the foundry of metal alloys.

4. Summary of the study:

Background of the research topic:

The study is based on the premise that metallurgical slags, a major industrial waste product, contain valuable chemical components that could be used to modify the structure and properties of casting alloys. This offers a potential solution to both waste management and materials engineering challenges.

Status of previous research:

Previous studies have confirmed the presence of modifying elements (Na, Mg, Ca, Ti, P) and main alloy components (Si, Al, Cu, Mn, Fe) in copper and steel slags. Research exists on using slags for refining processes, but data on their use for volume and surface modification of casting alloys is lacking.

Purpose of the study:

The paper aims to present preliminary research results on using prepared slag mixtures to modify the structure of two distinct alloys: the AlSi7Mg aluminium alloy and the IN-713C nickel superalloy.

Core study:

The core of the study involved two main experiments. The first tested the effect of adding ground copper and steel slag to liquid AlSi7Mg on its solidification behavior and final microstructure. The second tested the effect of a mould coating containing a mixture of copper and steel slag on the surface grain structure of a cast IN-713C nickel superalloy, comparing it to an unmodified casting and one made with a standard cobalt aluminate modifier.

5. Research Methodology

Research Design:

The research was designed as a comparative experimental study. For the AlSi7Mg alloy, the microstructures of the base alloy were compared with those modified by steel slag and copper slag. For the IN-713C alloy, three casting conditions were compared: unmodified, modified with a standard technology (cobalt aluminate), and modified with the experimental slag mixture.

Data Collection and Analysis Methods:

Data was collected through metallographic observation using a light microscope, thermal ATD solidification analysis for the AlSi7Mg alloy, and stereological analysis of macrostructure images for the IN-713C alloy to calculate the number of grains per unit area and the average grain area. Thermodynamic calculations were also performed using HSC Chemistry software to predict the feasibility of chemical reactions.

Research Topics and Scope:

The research focused on the modifying effects of copper and steel slags on a hypoeutectic aluminum-silicon alloy (AlSi7Mg) and a nickel-based superalloy (IN-713C). The scope included material preparation (grinding, sieving, calcining), experimental casting, and micro/macrostructural analysis.

6. Key Results:

Key Results:

- Ground copper slag demonstrated a beneficial effect on modifying AlSi7Mg, changing the eutectic morphology from granular to fibrous and fragmenting pre-eutectic α dendrites.

- Thermal analysis of the AlSi7Mg modification with copper slag showed a 4°C increase in Tliq temperature, indicating an effect of heterogeneous nucleation.

- A mixture of copper and steel slag used in a mould coating resulted in a "small but visible grain refinement effect" on the IN-713C nickel superalloy casting compared to an unmodified casting.

- The grain refinement effect of the slag mixture (average grain size of 4.78 mm²) was significant compared to the unmodified state (27.15 mm²) but weaker than the effect of the standard cobalt aluminate modifier (0.445 mm²).

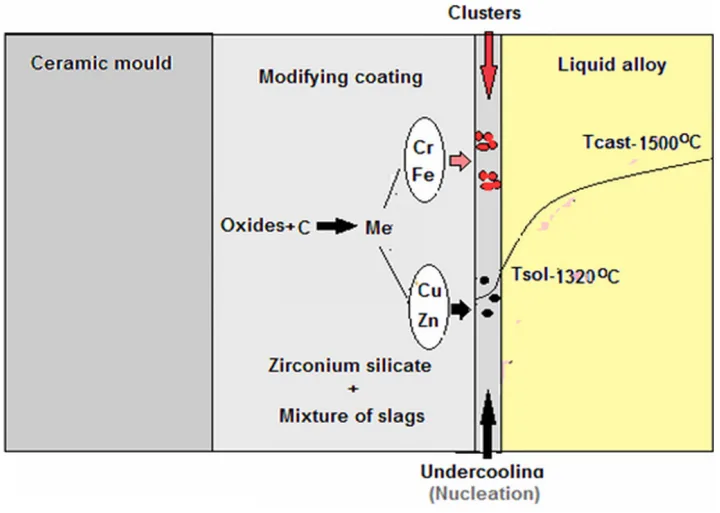

- Thermodynamic calculations supported a hypothetical model where carbon reduces metallic oxides (Cr2O3, Fe2O3, Cu2O) in the slag at casting temperatures, releasing metallic elements that act as crystallization nuclei.

Figure Name List:

- Fig. 1. Alloy cast into the QC40-80 probe

- Fig. 2. Microstructure of the AlSi7Mg alloy: initial state (a), modification – steel slag (b), modification – copper slag (c)

- Fig. 3. The influence of grain size on the properties of nickel superalloys castings

- Fig. 4. Average change of the free enthalpy ΔG as a function of temperature for the considered reactions of oxides with carbon

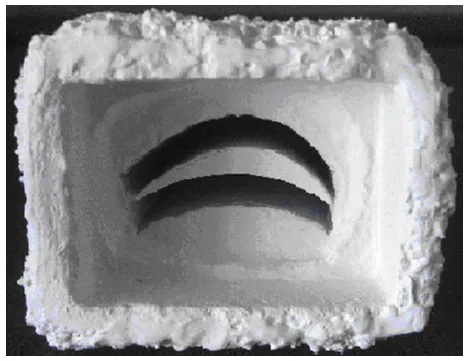

- Fig. 5. The cavity of the ceramic mould

- Fig. 6. Cast from experiment no. 2

- Fig. 7. Change of the surface structure at the height of the castings: unmodified (a)

- Fig. 8. Microstructure of castings: unmodified (a), current technology (b), slag mixture in the modifying coating (c)

- Fig. 9. Influence of technological conditions of casting on the number of grains per mm² of the casting surface

- Fig. 10. Influence of technological conditions of casting on the average grain surface

- Fig. 11. Hypothetical model of the modifying effect of a coating containing zirconium silicate, a mixture of slags and coke breeze

7. Conclusion:

Metallurgical slag, treated as a waste and a by-product, can be used successfully in many industries, including in the refining and modification of casting alloys. It has been shown that a properly prepared copper slag, introduced in a small amount into the liquid hypoeutectic aluminium alloy, shows noticeable modifying properties. In the case of the IN-713C nickel alloy, the presence of the slag mixture in the modifying coating modifies the grain refinement. This effect is however less than that of cobalt aluminate. But in some cases a significant grain size reduction is not required. Although the obtained results are not fully satisfactory, in the author's opinion, they constitute an incentive to conduct further research on the use of a wider range of slags.

8. References:

- [1] A. Konstanciak, W. Sabela, Odpady w hutnictwie żelaza i ich wykorzystanie, Hutnik-Wiadomości Hutnicze 12, 572-580 (1999).

- [2] P. Sobczyński, Żużle hutnicze – ich natura i przydatność gospodarcza, Odpady przemysłowe i komunalne, powstawanie i możliwości ich wykorzystania. Kraków (1999).

- [3] J. Sitko, Modernizacja technologii zagospodarowania odpadów hutniczych, Systemy Wspomagania w Inżynierii Produkcji. Inżynieria systemów technicznych: E. Milewska (Red.), P.A. NOVA, 2 (14), 287-294 (2016).

- [4] J. Sitko, Problem utylizacji odpadów, Zeszyty Naukowe Politechniki Śląskiej 73, 531-540 (2014).

- [5] T. Stefanowicz, Otrzymywanie i odzysk metali oraz innych surowców ze ścieków i odpadów pogalwanicznych, Wydawnictwo Politechniki Poznańskiej 167-172 (1992).

- [6] H. Byrdziak, A. Mizera, J. Piątkowski, KGHM Polska Miedź S.A. - Biuletyn (2000).

- [7] D. Krupka, A. Chmielarz, A. Bojanowski, J. Sitko, Polskie srebro. Osiągnięcia produkcyjne i badawcze, III KN „Metale Szlachetne", Zakopane - Kościelisko (2002).

- [8] Z. Bonderek, S. Rzadkosz, Problemy uszlachetniania ciekłych stopów aluminium. Krzepnięcie Metali i Stopów, PAN Katowice 41-49 (1999).

- [9] H. Postołek, C. Adamski, Wpływ napięć międzyfazowych na rafinujące oddziaływanie żużli, Archiwum Hutnictwa 38, 4 (1981).

- [10] T. Kargul, Opracowanie hybrydowego modelu procesu pozapiecowej rafinacji stali do oceny wybranych technologii metalurgicznych, 2009 AGH, Kraków.

- [11] D. Krupka, J. Sitko, B. Ochab i inni, Development of zinc production at the Boleslaw Zinc Plant, The IV International Conference Zinc '2006, Plovdiv, Bułgaria, 197-207 (2006).

- [12] D. Krupka, J. Sitko, J. Dutrizac, G.E. James, Zakład Elektrolizy Cynku - BIG RIVER ZINC, Sauget w USA, Rudy Metale 46, 10, 461-469 (2001).

- [13] S. Pietrowski, Siluminy, 2001 Wydawnictwo Politechniki Łódzkiej, Łódź.

- [14] F. Binczyk, Konstrukcyjne stopy odlewnicze, 2003 Wydawnictwo Politechniki Śląskiej, Gliwice.

- [15] J. Sitko, Procesy zagospodarowania odpadów hutniczych, Monografia habilitacyjna, 2019 P.A.NOVA, Gliwice.

- [16] A. Hernas, Żarowytrzymałość Stali i Stopów, 2000 Wydawnictwo Politechniki Śląskiej, Gliwice.

- [17] L.A. Dobrzański, Podstawy nauki o materiałach i metaloznawstwo materiały inżynierskie z podstawami projektowania materiałowego, 2002 Wydawnictwa Naukowo-Techniczne, Warszawa.

- [18] C.N. Wei, H.Y. Bor, C.Y. Ma, T.S. Lee, A study of IN-713LC superalloy grain refinement effects on microstructure and tensile properties, Materials Chemistry and Physics 80, 89-93 (2003).

- [19] L. Liu, R. Zhang, L. Wang, S. Pang, B. Zhen, A new method of fine grained casting for nickle-base superalloys, Journal of Materials Processing Technology 77, 300-304 (1998).

- [20] P. Gradoń, Procesy fizykochemiczne w układzie forma – modyfikator-ciekły stop kształtujące makro- i mikrostrukturę wybranych nadstopów niklu, Rozprawa doktorska, 2014 Politechnika Śląska, Katowice.

- [21] Monografia KGHM Polska Miedź S.A. 2007 Lubin.

- [22] HSC Chemistry Software – http://www.outotec.com/en/Products-services/HSC-Chemistry/2013

- [23] Dokumentacja techniczna programu HSC Chemistry (v. 4.1).

- [24] J. Szala, Program komputerowy Met-Ilo, Katowice (2011).

- [25] M. Zielińska, J. Sieniawski, M. Wierzbińska, Effect of modification on microstructure and mechanical properties of cobalt casting superalloy, Archives of Metallurgy and Materials 53, 3, 887-893 (2008).

- [26] F. Binczyk, J. Śleziona, P. Gradoń, Modification of macrostructure of nickel superalloys with cobalt nanoparicles, Kompozyty 11:1. Polskie Towarzystwo Materiałów Kompozytowych 49-54 (2011).

- [27] F. Binczyk, J. Śleziona, Effect of modification on the mechanical properties of IN-713C alloy, Archives of Foundry Engineering, Issue Special 1, 195-198 (2010).

- [28] Existence of the Hexagonal Modification of Nickel, American Physical Society 10, 1140-1150 (1965).

Expert Q&A: Your Top Questions Answered

Q1: Why was carbon, in the form of coke breeze, chosen as the reducing agent for the slag mixture in the IN-713C experiment?

A1: Carbon was selected based on thermodynamic calculations, the results of which are shown in Figure 4. The calculations of free enthalpy (ΔG) confirmed that at the high temperatures of nickel superalloy casting (above 1350°C), carbon is an effective agent for reducing key metal oxides present in the slag, such as Fe2O3, Cu2O, and Cr2O3. This reduction process is crucial as it releases pure metallic elements, which can then act as nuclei for grain formation.

Q2: The grain refinement from the slag mixture in IN-713C was much weaker than with cobalt aluminate. Does this make the method practically useless?

A2: Not necessarily. The paper explicitly states, "in some cases a significant grain size reduction is not required." While the slag mixture is less potent than the conventional cobalt aluminate method, it still provides a "small but visible grain refinement effect" compared to an unmodified casting. This could make it a viable, lower-cost alternative for applications where moderate grain refinement is sufficient, while also providing a sustainable use for industrial waste.

Q3: How exactly does copper slag modify the AlSi7Mg alloy?

A3: The paper suggests a heterogeneous nucleation mechanism. The finely dispersive compounds present in the copper slag, based on silicon, copper, and calcium, act as "foreign" bodies or substrates within the molten aluminum. These particles serve as preferential sites for the pre-eutectic α dendrites and, subsequently, the eutectic structure to crystallize upon, leading to a finer and more distributed microstructure. This is supported by the observed 4°C increase in the liquidus temperature during the ATD analysis.

Q4: What is the proposed mechanism for grain refinement in the IN-713C alloy using the slag mixture?

A4: The hypothetical model presented in Figure 11 proposes that the added coke breeze reduces metal oxides within the slag at the mould-alloy interface. This reaction forms fine metallic particles of elements like Cr, Fe, and Cu. The paper highlights chromium as a particularly effective nucleant, as its crystal lattice (A3) at temperatures above 1350°C is identical to that of nickel, with similar parameters. These chromium particles act as seeds for crystallization, leading to grain refinement.

Q5: The paper mentions that slags can be used for refining and purification. Did this study investigate that aspect?

A5: This study focused specifically on modification—the process of altering the alloy's structure during solidification. While the introduction notes that slags can be used for refining (i.e., removing impurities from the liquid metal), the experiments presented here were designed exclusively to test their effect on nucleation and grain morphology. The refining properties of these specific slag preparations were not evaluated in this research.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides compelling preliminary evidence that metallurgical slags can be successfully repurposed from industrial waste into a valuable material for casting process enhancement. The study demonstrates that a targeted Metallurgical Slag Modification can lead to significant microstructural improvements, such as refining the eutectic in AlSi7Mg and reducing grain size in IN-713C superalloys. While the effects may be more moderate than those of highly specialized conventional modifiers, the economic and ecological benefits present a strong case for continued investigation.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "AN ATTEMPT TO USE VARIOUS METALLURGICAL SLAGS IN THE MODIFICATION PROCESSES OF CASTING ALLOYS" by "J. SITKO".

- Source: https://doi.org/10.24425/amm.2021.136426

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.