Unlocking Stability and Performance: A Deep Dive into Zinc Alloy Ageing for HPDC Professionals

This technical summary is based on the academic paper "Ageing of Zink Alloys" by Lothar H. Kallien and Walter Leis, published in International Foundry Research (2011).

![Figure 1: Phase diagram zinc – aluminum [1]](https://castman.co.kr/wp-content/uploads/image-3162.webp)

Keywords

- Primary Keyword: Zinc Alloy Ageing

- Secondary Keywords: Zinc die casting, artificial ageing, natural ageing, mechanical properties, creep resistance, Z410, Z400, Z430, HPDC

Executive Summary

- The Challenge: Zinc die castings naturally lose mechanical strength and change dimensionally over time, creating performance unpredictability, especially in demanding automotive applications.

- The Method: Researchers produced test castings of three common zinc alloys (ZP0400, ZP0410, ZP0430) under a wide range of controlled production parameters and subjected them to both long-term natural ageing and accelerated artificial ageing treatments.

- The Key Breakthrough: The study established a direct, quantifiable correlation between artificial and natural ageing, proving that a 24-hour heat treatment at 105 °C effectively replicates one full year of natural ageing at room temperature.

- The Bottom Line: A specific, validated artificial ageing process can be implemented to rapidly stabilize the mechanical properties of zinc alloy components, eliminating long-term degradation and ensuring predictable, reliable performance from day one.

The Challenge: Why This Research Matters for HPDC Professionals

For engineers working with zinc alloys like Z410, the material's benefits—high productivity, thin-wall capabilities, and excellent mechanical properties—are well-known. However, a significant drawback lurks beneath the surface: the effects of ageing. Due to zinc's low melting point (below 400 °C), diffusion processes occur even at room temperature. This "natural ageing" causes mechanical properties to degrade over time and can lead to an increased creep rate under load.

For industries like automotive, where components must perform reliably for years within a temperature range of -35 °C to +85 °C, this unpredictability is a major concern. While artificial ageing has been used to compensate, a lack of statistically reliable data correlating it with natural ageing has left a gap in engineering knowledge. This research was initiated to bridge that gap, providing a scientifically-backed methodology to control and predict the long-term behavior of zinc die castings.

The Approach: Unpacking the Methodology

To ensure the findings were robust and industrially relevant, the researchers conducted a comprehensive experimental program under tightly controlled conditions.

Method 1: Controlled Die Casting Production

The study utilized three of the most common die casting zinc alloys: ZP0400 (ZnAl4), ZP0410 (ZnAl4Cu1), and ZP0430 (ZnAl4Cu3). Test plates were produced on a Frech DAW 80 hot chamber die casting machine, with key production parameters systematically varied to cover a wide range of real-world scenarios:

- Wall Thickness: 0.8 mm, 1.5 mm, and 3.0 mm

- Gate Velocity: 25 m/s, 40 m/s, and 55 m/s

- Die Temperature: 120 °C, 160 °C, and 200 °C

Method 2: Systematic Ageing Protocols

After casting, specimens were immediately frozen to -20 °C to halt any initial ageing. They were then subjected to two distinct ageing regimes:

- Natural Ageing: Stored in a climate-controlled room at room temperature, with measurements taken at 3 and 6 weeks, 3 and 6 months, and 1 year.

- Artificial Ageing: Tempered for a fixed 24-hour period at three different temperatures: 65 °C, 85 °C, and 105 °C.

Method 3: Comprehensive Mechanical Testing

Over 3,000 specimens were tested to evaluate a full suite of mechanical properties. Tests were conducted on as-cast, naturally aged, and artificially aged samples at three critical temperatures (-35 °C, room temperature, and +85 °C) to simulate real-world service conditions. The properties investigated included yield strength, tensile strength, elongation, Young's modulus, creep behavior, hardness, and fatigue life.

The Breakthrough: Key Findings & Data

The extensive testing revealed clear, actionable relationships between production, ageing, and final part performance.

Finding 1: A Definitive Correlation Between Artificial and Natural Ageing

The primary goal of the study was achieved: a direct correlation between accelerated artificial ageing and long-term natural ageing was established. The research demonstrated that different artificial ageing treatments correspond to specific periods of natural ageing.

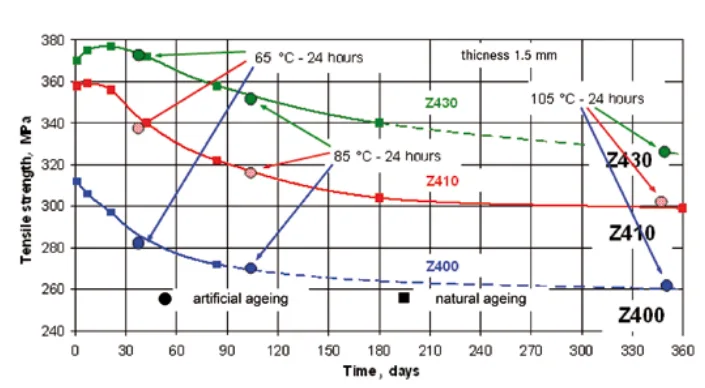

As shown in Figure 47, for the Z410 alloy, an artificial ageing treatment at 105 °C for 24 hours produces a decrease in tensile strength equivalent to one full year of natural ageing at room temperature. Similarly, ageing at 85 °C for 24 hours equates to approximately 120 days of natural ageing, and 65 °C for 24 hours equals 45 days. This provides a practical and highly efficient method to stabilize components and predict their end-of-life properties. The activation energy for this ageing process was calculated to be 67 kJ/mol (Figure 48).

Finding 2: The Critical Role of Copper in Strength and Ageing Rate

The study confirmed that copper content is a key factor in both the initial strength and the ageing behavior of zinc alloys.

Figure 51 provides a direct comparison of the three alloys. Z430, with the highest copper content (2.7-3.3 wt%), exhibits the highest initial tensile strength and ages more slowly, retaining 88% of its as-cast strength after artificial ageing (105 °C / 24 h). In contrast, the copper-free Z400 alloy has the lowest initial strength and ages the fastest, retaining only 83%. Z410 falls in between. This data, combined with hardness measurements (Figure 36), clearly illustrates that increasing copper content enhances strength and improves the alloy's resistance to age-related degradation.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting wall thickness is the most powerful tool for controlling mechanical properties, as it has the largest impact on cooling rate and microstructure. Die temperature and gate velocity have a much smaller, linear effect (Figure 18).

- For Quality Control Teams: The data in Figure 39 and Figure 43 of the paper illustrates the effect of natural and artificial ageing on tensile strength. The finding that completed ageing results in a predictable ~15% strength reduction can be used to establish new quality inspection criteria for heat-treated components, ensuring they meet long-term performance specifications.

- For Design Engineers: The findings indicate that creep behavior is a critical consideration. The data presented in Figure 27 provides maximum allowable stress levels at various temperatures for a design limit of 1% creep per year, offering a valuable guide for designing durable components subjected to constant load.

Paper Details

Ageing of Zink Alloys

1. Overview:

- Title: Ageing of Zink Alloys

- Author: Lothar H. Kallien and Walter Leis

- Year of publication: 2011

- Journal/academic society of publication: International Foundry Research 64 (2011) No. 1

- Keywords: Zinc alloys, die casting, ageing, natural ageing, artificial ageing, mechanical properties, creep, ZP0400, ZP0410, ZP0430

2. Abstract:

The goal of the research was the investigation of the material properties of zinc alloys under natural and artificial ageing to find a correlation between them. As zinc die castings are produced under a variety of production conditions, it was necessary to produce test castings using different parameters under extremely controlled conditions. Test castings of ZP0400, ZP0410, and ZP0430 alloys were produced using a hot chamber die casting machine with varied parameters of wall thickness, gate velocity, and die temperature. Samples were subjected to natural ageing for up to one year and artificial ageing at 65 °C, 85 °C, and 105 °C for 24 hours. Mechanical properties including tensile strength, creep, fatigue, and hardness were evaluated. The results established that artificial ageing at 105 °C for 24 hours corresponds to one year of natural ageing. The activation energy for ageing was determined to be approximately 67 kJ/mol, while for creep it was 94 kJ/mol. The study concludes that artificial ageing is a necessary process to stabilize the mechanical properties of zinc die castings.

3. Introduction:

Hot chamber die casting is a highly productive technology for high-quality zinc parts used by manufacturers of cars, furniture, and other mechanical parts. Despite their high density, zinc alloys are used in automotive applications due to high mechanical properties, the ability to cast thin walls, and their plating properties. However, the low melting temperature of approximately 390 °C leads to an increased creep rate and ageing effects, where mechanical properties are lost over time. This natural ageing is typically compensated by artificial ageing. The typical service temperature range for automotive applications is between -35 °C and +85 °C, yet until now, few statistically reliable data have been published for these temperature ranges.

4. Summary of the study:

Background of the research topic:

Zinc die casting alloys, due to their low melting point, exhibit ageing phenomena at room temperature. This results in changes to mechanical properties and dimensions over the service life of a component, which is a significant concern for engineering applications requiring long-term stability.

Status of previous research:

Prior literature describes the ageing process as related to the eutectoid phase change of the β-phase and notes that the addition of copper increases the solubility of aluminum. Previous studies have documented dimensional changes and suggested heat treatments to mitigate these effects. However, a comprehensive dataset correlating specific production parameters with the effects of both natural and artificial ageing on a wide range of mechanical properties was not available.

Purpose of the study:

The purpose of this research was to systematically investigate the material properties of zinc alloys under natural and artificial ageing to establish a quantitative correlation between the two processes. A further goal was to determine the influence of key die casting production parameters—specifically wall thickness, gate velocity, and die temperature—on the ageing behavior and final mechanical properties of the alloys ZP0400, ZP0410, and ZP0430.

Core study:

The core of the study was an experimental investigation involving the controlled production of test castings under a Design of Experiments (DOE) framework. These castings were then subjected to systematic natural and artificial ageing protocols. A comprehensive suite of mechanical tests, including tensile, creep, fatigue, and hardness tests, was conducted across a range of service temperatures (-35 °C, RT, +85 °C) to fully characterize the material behavior.

5. Research Methodology

Research Design:

The study employed a Design of Experiments (DOE) methodology using Design-Expert 7 software to efficiently investigate the effects of three key process parameters, each at three levels. Center point conditions were included to ensure statistical robustness.

Data Collection and Analysis Methods:

Test plates of alloys ZP0400, ZP0410, and ZP0430 were cast on a Frech DAW 80 hot chamber machine. The process was monitored using sensors for pressure and temperature. From these plates, probes for tensile testing were machined according to DIN 50125. Mechanical properties were measured using a 100 kN Universal "Schenck" tensile test machine, custom-built creep testing equipment according to DIN 50118, a Russenberger & Müller resonance testing machine for fatigue, and standard hardness testing.

Research Topics and Scope:

The research investigated the influence of the following parameters on the mechanical properties of zinc alloys:

- Alloys: ZP0400 (ZnAl4), ZP0410 (ZnAl4Cu1), ZP0430 (ZnAl4Cu3)

- Production Parameters:

- Wall thickness: 0.8, 1.5, 3.0 mm

- Gate velocity: 25, 40, 55 m/s

- Die temperature: 120, 160, 200 °C

- Ageing Conditions:

- Natural ageing (up to 1 year)

- Artificial ageing (65 °C, 85 °C, 105 °C for 24 hours)

- Testing Temperatures: -35 °C, Room Temperature (RT, 23 °C), +85 °C

6. Key Results:

Key Results:

- A direct correlation was established between artificial and natural ageing: artificial ageing at 105 °C for 24 hours produces mechanical properties equivalent to those after one year of natural ageing at room temperature.

- The total drop in tensile strength and yield strength after the ageing process is completed is approximately 15%.

- The ageing process is thermally activated and follows an Arrhenius law, with a calculated activation energy for ZP0410 of 67 kJ/mol.

- Creep behavior is a self-diffusion process, also thermally activated, with a calculated activation energy of 94 kJ/mol.

- Wall thickness was found to be the most influential production parameter on mechanical properties. Die temperature had a lesser, linear effect, while gate velocity had a minimal influence.

- Increasing copper content in the alloy increases the initial tensile strength and hardness and decelerates the ageing process.

- The fatigue strength (at R=-1) for 10 million cycles is approximately 85 MPa for as-cast specimens and decreases to 80 MPa after artificial ageing.

Figure Name List:

- Figure 1: Phase diagram zinc – aluminum [1]

- Figure 2: Ternary system Zn – Al – Cu and positions of zinc die casting alloys [2]

- Figure 3: Usage of zinc [4]

- Figure 4: Dimensional stability of zinc die casting parts at room temperature (ageing time: 5.5 years; die temperature: 180 °C; quenching: air) [7]

- Figure 5: Natural ageing (left) and artificial ageing (right) as a function of copper content

- Figure 6: Typical creep curve

- Figure 7: Homologue temperature for zinc and aluminum

- Figure 8: Varied process parameters

- Figure 9: Position of the thermocouple 2 mm under the surface

- Figure 10: Position of the ejector pins with load sensors

- Figure 11: Geometry of the specimens for static tensile tests

- Figure 12: Boxes for the specimens for natural ageing (23 °C, room air conditioned)

- Figure 13: Upgraded tensile testing machine

- Figure 14: Stress-strain-curve run 23 (3 mm; 160 °C; 40 m/s) measured in as cast condition at RT (23 °C)

- Figure 15: Stress-strain-curve measured in as cast condition (sample thickness 3 mm)

- Figure 16: Stress-strain-curve run 26 (3 mm; 200 °C; 55 m/s) measured in as cast condition at -35 °C

- Figure 17: Stress-strain-curve run 26 (3 mm; 200 °C; 55 m/s) measured in as cast condition at 85 °C

- Figure 18: Tensile strength as a function of wall thickness and die temperature (left) and as a function of die temperature and gate velocity (right) as cast condition

- Figure 19: Tensile strength as a function of wall thickness and test temperature as cast condition

- Figure 20: Tensile strength as a function of wall thickness and die temperature (left) and as a function of testing temperature and wall thickness (right) artificially aged at 105 °C for 24 hours

- Figure 21: Tensile strength as a function of wall thickness and testing temperature, artificially aged at 105 °C for 24 hours

- Figure 22: Creep testing equipment with 12 temperature controlled test stations

- Figure 23: Creep elongation as a function of time and stress of Z410 at room temperature

- Figure 24: Primary and secondary creep rate of Z410

- Figure 25: Creep elongation as a function of time and stress of Z410 at +85 °C

- Figure 26: Stress exponent and activation energy for secondary creep of Z410 measured at 1% creep elongation

- Figure 27: Maximum of stress under creep exposure as a function of temperature, Z410

- Figure 28: Stress exponent for secondary creep of Z400, Z410 and Z430 measured at 1% creep elongation

- Figure 29: Mikroton 654 resonant testing machine for fatigue tests (20 kN)

- Figure 30: Shape of the utilized specimens for fatigue tests

- Figure 31: S/N-curves (extended fatigue test) at R = -1 (compression and tension) of specimens in as cast condition and after artificial ageing (over ageing)

- Figure 32: S/N-curves at R = -1 of artificially aged Z400 in comparison of 20 year naturally aged Z410 specimens from Umicore

- Figure 33: Hardness as a function of processing parameters of Z410 as cast condition, thickness and die temperature show strong influence on hardness. Gate velocity has no influence on the hardness.

- Figure 34: Hardness of Z410 as a function of natural ageing time

- Figure 35: Hardness of Z400 (a) and Z430 (b), as cast condition

- Figure 36: Hardness (average values) as a function of copper content

- Figure 37: Density of the parts as a function of processing parameters

- Figure 38: Decrease of tensile strength at RT for Z410 as a function of time and wall thickness through the ageing process

- Figure 39: Tensile strength as a function of testing temperature and wall thickness through the natural ageing process of Z410

- Figure 40: Tensile strength as a function of testing temperature and wall thickness through the natural ageing process of Z400

- Figure 41: Tensile strength as a function of testing temperature and wall thickness through the natural ageing process of Z430

- Figure 42: Yield strength as a function of testing temperature and wall thickness through the natural ageing process of Z410

- Figure 43: Tensile strength as a function of testing temperature and wall thickness through the artificial ageing processes of Z410

- Figure 44: Tensile strength as a function of testing temperature and wall thickness through the artificial ageing processes of Z400

- Figure 45: Tensile strength as a function of testing temperature and wall thickness through the artificial ageing processes of Z430

- Figure 46: Yield strength as a function of testing temperature and wall thickness through the artificial ageing processes of Z410

- Figure 47: Ageing behaviour (decreas of tensile strength) in comparison of natural and artificial ageing of Z410 as a function of wall thickness

- Figure 48: Arrhenius plot of time ln(t) versus influence of temperature 1/T during ageing for calculation of the activation energy

- Figure 49: Required time as a function of temperature for artificial ageing to build up a natural ageing of 1 year at RT of Z410

- Figure 50: Additional value of tensile strength (average value of 25 specimens with 1.5 mm wall thickness, unknown process parameters) after 20 years natural ageing (Umicore)

- Figure 51: Ageing behavior (decrease of tensile strength) in comparison of natural and artificial ageing of Z400, Z410 and Z430 as a function of time, broken lines represents expected values

- Figure 52: Influence of copper on tensile strength (referring to Z410 as 100 %) at RT after artificial ageing 24 hours / 105 °C

7. Conclusion:

The ageing behavior of zinc die casting alloys is activated at room temperature and is caused by the low solubility of aluminum in zinc at room temperature. The process is diffusion-controlled and begins immediately after the part is ejected from the die. For Z410, the ageing process at room temperature is substantially finished after one year. The total reduction in tensile and yield strength after completed ageing is approximately 15%.

This natural ageing process can be effectively simulated by an artificial ageing treatment at 105 °C for 24 hours. This treatment terminates the diffusion processes, resulting in stable material properties over time. The creep behavior of these alloys is caused by the self-diffusion of zinc and is thermally activated according to an Arrhenius law. Artificial ageing is a necessary step for zinc alloy components to finish the diffusion processes and ensure stable, predictable mechanical properties for their service life.

8. References:

- [1] Gottstein, G.: Physikalische Grundlagen der Materialkunde. Springer, 2007. ISBN 978-3-540-71104-9.

- [2] Coster, L.: Oner, M.; Rollez, D.: Giesserei-Praxis (1996) no. 21/22, pp. 458-460.

- [3] www.zinc-diecasting.info. Engineering database (access 10.03.2009).

- [4] www.ilzsg.org. International Lead and Zinc Study Group (access 10.03.2009).

- [5] www.pressebox.de. BoxID 85023, 29.11.2006 (access 11.03.2009).

- [6] Opitz, H.: Allgemeine Werkstoffkunde für Ingenieurschulen. VEB Fachbuchverlag, Leipzig, 1971.

- [7] Johnen, H. J.: Gießen mit Zink. Zinkberatung Düsseldorf 1982. ISBN 3-88754-002-6.

- [8] Hänsel, G.: Zinklegierungen – Zusammensetzung und Eigenschaften. Metall 42 (1988) no. 9, pp. 871-874.

- [9] Goodwin, F. E.; Ponikwar, A. L.: Engineering properties. International Lead Zinc Research Organisation.

- [10] Gebhard, E.: Über den Aufbau des Systems Zink-Aluminium-Kupfer und die Volumenänderung der Gusslegierung. Giesserei 29 (....) no. 24, pp. 397-403.

- [11] Klein, F.; Roos, G.: Maßänderungen der Zinkdruckgusslegierungen in Abhängig-keit vom Kupfergehalt. 4. Aalener Giesserei-Symposium 1983, Aalen, Germany.

- [12] Schumann, H.: Metallographie. Deutscher Verlag für Grundstoffindustrie, Leip-zig, VLN: 152-915/3/91.

- [13] Klein, F.: ---. Aalener Giesserei-Symposium 1984.

- [14] Schaller, Y.: Zink-Druckguss – Neue Legierungen, neue Anwendungen. VDI Bericht 1173.

- [15] Birch, J.: Computerized properties data for zinc casting alloys. Die Casting Engineer 20.

Expert Q&A: Your Top Questions Answered

Q1: Why was 105 °C for 24 hours identified as the optimal artificial ageing treatment?

A1: This specific time-temperature combination was identified as optimal because it provides the most efficient way to achieve the properties of a fully stabilized part. As shown in Figure 47 and Table 10, this treatment reliably simulates one full year of natural ageing in just one day. The paper also concludes that temperatures over 120 °C should be avoided to prevent other, undesirable phase transformations from occurring.

Q2: What is the primary metallurgical mechanism that causes this ageing phenomenon in zinc alloys?

A2: The ageing is driven by diffusion. The paper explains that the maximum solubility of aluminum in zinc is extremely low at room temperature (around 0.05 wt%). During the rapid cooling of die casting, a supersaturated solid solution is formed. Over time, this unstable state resolves itself as aluminum segregates from the zinc matrix to form a stable, cubic face-centered phase, which reduces the material's overall strength.

Q3: How significantly does copper content influence the choice of alloy for a specific application?

A3: Copper content is a critical factor. The results in Figure 51 show a clear trend: higher copper content leads to higher initial strength and a slower rate of ageing. For an application requiring maximum strength and long-term stability, an alloy like Z430 (~3% Cu) would be superior. For applications where these factors are less critical, the lower-cost, copper-free Z400 may be sufficient, but its properties will change more rapidly.

Q4: Of all the casting process parameters studied, which one should engineers focus on the most to control part quality?

A4: The study unequivocally identifies wall thickness as the most dominant process parameter affecting mechanical properties. As stated in the results, its influence is significantly stronger than that of die temperature or gate velocity. This is because wall thickness directly controls the cooling rate, which in turn dictates the microstructure of the final casting. Therefore, controlling wall thickness and ensuring its consistency is paramount for achieving repeatable mechanical performance.

Q5: Does the ageing process in zinc alloys ever truly stop, or does it continue indefinitely?

A5: The research suggests that the process reaches a stable endpoint. The data collected over one year of natural ageing shows a leveling-off of properties. This is strongly supported by the analysis of 20-year-old naturally aged Z410 samples provided by Umicore (Figure 50), which fit perfectly with the one-year data. This indicates that the natural ageing process is effectively complete after approximately one year.

Q6: What is the practical impact of the different activation energies for ageing (67 kJ/mol) and creep (94 kJ/mol)?

A6: The different activation energies indicate that ageing and creep are driven by different diffusion mechanisms. Ageing is caused by the diffusion of solute atoms (aluminum and copper), while creep is caused by the self-diffusion of the base metal atoms (zinc). The higher activation energy for creep means it is more sensitive to temperature changes than the ageing process. This is a crucial insight for designing components that will be under load at elevated temperatures.

Q7: Can the findings for Z410 be applied to the other alloys like Z400 and Z430?

A7: While the specific values and rates differ, the fundamental behavior is similar across all alloys. The paper shows that all three alloys follow the same trend of decreasing strength with ageing (Figure 51). The correlation between artificial and natural ageing established for Z410 provides a strong model for the other alloys, with the understanding that the rate of ageing will be faster for Z400 and slower for Z430 due to the influence of copper.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of property degradation in zinc die castings has long been a hurdle for engineers seeking long-term, predictable performance. This research effectively demystifies the Zinc Alloy Ageing process, providing a clear, data-driven roadmap to stability. The key breakthrough—that a 24-hour heat treatment at 105 °C can reliably stabilize a component—transforms ageing from an uncontrolled variable into a controlled process step.

By understanding the dominant influence of wall thickness and the strengthening effect of copper, engineers can now make more informed decisions in both design and production. This knowledge empowers the HPDC industry to deliver zinc components with guaranteed, stable, and reliable mechanical properties for the entire product lifecycle.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Ageing of Zink Alloys" by "Lothar H. Kallien and Walter Leis".

Source: International Foundry Research 64 (2011) No. 1

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.