This article introduces the paper "Design of gravity assisted heat exchanger and its application on enhanced waste heat recuperation utilizing organic Rankine and LNG system".

1. Overview:

- Title: Design of gravity assisted heat exchanger and its application on enhanced waste heat recuperation utilizing organic Rankine and LNG system

- Authors: Rizvi Arefin Rinik, Naimul Islam, M. Monjurul Ehsan, Yasin Khan

- Year: 2024

- Journal/Conference: International Journal of Thermofluids

- Keywords: Waste Heat, Gravity heat exchanger, Organic Rankine, Combined cycle, Parametric optimization

2. Research Background:

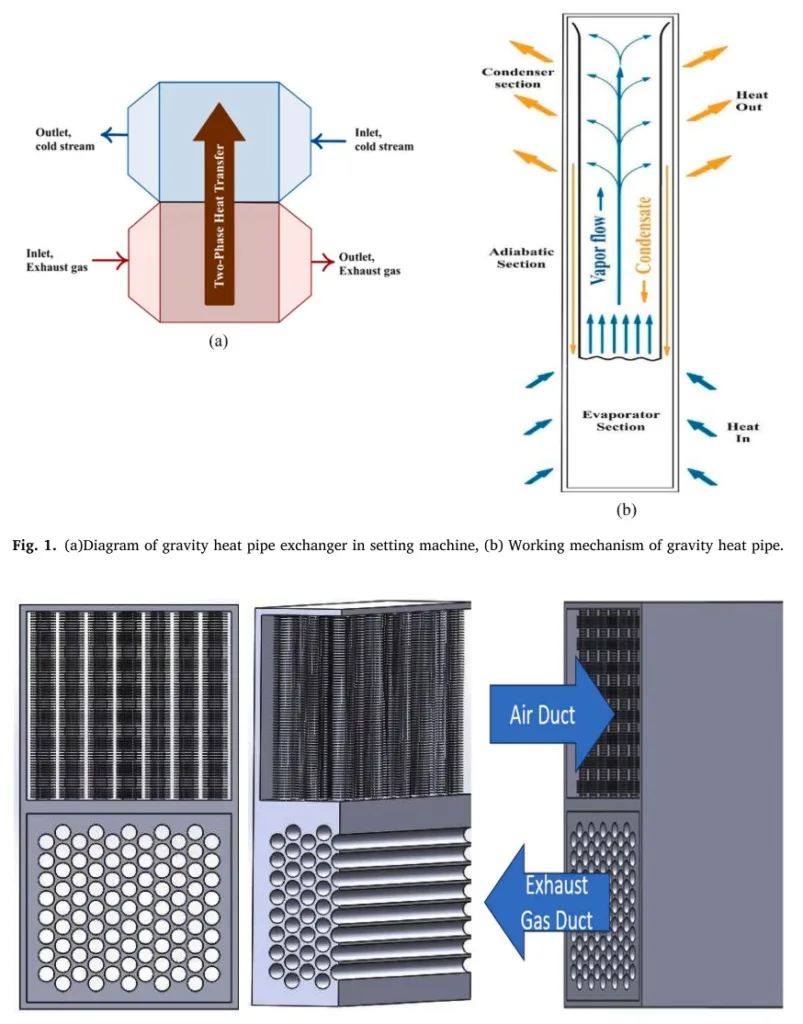

The research addresses the growing global energy demand, projected to increase by 33% by 2050 [1]. A significant portion of energy is wasted as low-grade waste heat in industries like manufacturing and power generation [2, 4]. Conventional waste heat recovery (WHR) methods using heat exchangers often face challenges such as high costs, complexity, and limitations imposed by the temperature of the waste heat source [5]. These limitations hinder widespread adoption, particularly in smaller industries. The research highlights the need for efficient, cost-effective, and easily applicable WHR systems that can handle dirty exhaust gases.

3. Research Objectives and Research Questions:

The primary objective is to design a novel gravity-assisted heat exchanger (GPHE) and integrate it with Organic Rankine Cycle (ORC) and Liquefied Natural Gas (LNG) cycles for enhanced waste heat recuperation. This system aims to overcome the limitations of conventional WHR technologies. The core research questions are implicit but can be inferred as:

- What is the optimal design of a gravity-assisted heat exchanger for maximizing energy recovery from low-grade waste heat streams, particularly those containing contaminants?

- How efficiently can the GPHE, ORC, and LNG cycles be integrated to maximize overall energy recovery and minimize energy losses?

- What are the optimal operating parameters (temperatures, pressures, mass flow rates) for the combined system?

- What is the economic viability of the proposed GPHE compared to conventional heat exchangers?

Specific hypotheses are not explicitly stated, but the research implicitly hypothesizes that the combined GPHE-ORC-LNG system will achieve higher energy efficiency and economic viability compared to conventional WHR methods.

4. Research Methodology:

The study employed a combined theoretical and experimental approach.

- Research Design: The research involved designing a gravity pipe heat exchanger, developing mathematical models for heat transfer, energy efficiency, and exergy analysis, performing parametric optimization, and conducting an economic analysis. An experimental validation of the GPHE model is mentioned, using data from a prior study [1].

- Data Collection: Experimental data on the performance of the GPHE was apparently drawn from a prior study; details of this methodology are not provided in the given excerpt. Additional data was generated using simulation and modelling.

- Analysis Methods: The analysis involved heat transfer calculations, energy and exergy analysis, mathematical optimization models to determine optimal operating parameters, and economic cost analysis comparing the GPHE to conventional heat exchangers. Specific software (Python and COOLPROP) were used.

- Research Subjects/Scope: The research focused on a specific type of gravity-assisted heat exchanger applied to recover waste heat from a low-temperature, potentially dirty, exhaust gas stream (like that from a heat setting machine). The use of pentane as the ORC working fluid is explored.

5. Major Research Findings:

The excerpt provides limited findings; detailed results would be expected in the complete paper. Based on the available section, preliminary findings include:

- The GPHE demonstrated good effectiveness (close to 52.3%) at an optimum temperature of approximately 275 °C to 280 °C for a 35 kg/s air flow rate.

- The ORC cycle showed maximum efficiency of 36.8% when using pentane (mass flow rate 3.3 kg/s) and a condenser pressure of 0.21 MPa, producing 280 kW of power.

- The system's exergy efficiency decreased by 4.94% with a 7 °C increase in pinch temperature.

- The designed GPHE showed economic viability for waste heat recovery from dirty exhaust gas.

(Note: Figures from the paper were referenced but are not directly available for inclusion in this summary.)

6. Conclusions and Discussion:

The proposed combined GPHE-ORC-LNG system offers a potentially innovative solution for waste heat recovery, particularly from low-grade, dirty streams. The gravity-assisted heat exchanger design addresses the challenges of conventional heat exchangers by enabling efficient heat transfer even in the presence of contaminants. Integration with ORC and LNG cycles enhances energy recovery and provides flexibility in applications. The economic analysis suggests viability. However, the conclusions are limited by the absence of full results data.

7. Future Research:

Future research should include a more comprehensive experimental validation of the entire system’s performance under various operating conditions. Further optimization of the system’s design and operating parameters using advanced optimization techniques could be pursued. The economic analysis could be expanded to include a wider range of scenarios and uncertainties.

8. References :

- [1] M.A. Islam, H.S. Che, M. Hasanuzzaman, N.A. Rahim, Energy demand forecasting. Energy for Sustainable Development, Elsevier, 2020, pp. 105–123, https://doi.org/ 10.1016/B978-0-12-814645-3.00005-5.

- [2] D.M. Arias, O. García-Valladares, G. Besagni, C.N. Markides, A vision of renewable thermal technologies for drying, biofuels production and industrial waste, gas or water recovery, Appl. Therm. Eng. 223 (2023) 120022, https://doi.org/10.1016/j. applthermaleng.2023.120022.

- [3] S.S. Siwal, et al., Recovery processes of sustainable energy using different biomass and wastes, Renew. Sustain. Energy Rev. 150 (2021) 111483, https://doi.org/ 10.1016/j.rser.2021.111483.

- [4] S. Nallathambi, K. Ramasamy, Prediction of electricity consumption based on DT and RF: an application on USA country power consumption, in: 2017 IEEE International Conference on Electrical, Instrumentation and Communication Engineering (ICEICE), IEEE, 2017, pp. 1–7, https://doi.org/10.1109/ ICEICE.2017.8191939.

- [5] D. Pashchenko, Natural gas reforming in thermochemical waste-heat recuperation systems: a review, Energy 251 (Jul. 2022) 123854, https://doi.org/10.1016/j. energy.2022.123854.

- [6] Y. Zhao, et al., A comparative study of energy consumption and efficiency of Japanese and Chinese manufacturing industry, Energy Policy 70 (2014) 45–56, https://doi.org/10.1016/j.enpol.2014.02.034.

- [7] B. Liu, M. Lu, B. Shui, Y. Sun, W. Wei, Thermal-hydraulic performance analysis of printed circuit heat exchanger precooler in the Brayton cycle for supercritical CO2 waste heat recovery, Appl. Energy 305 (2022) 117923, https://doi.org/10.1016/j. apenergy.2021.117923.

- [8] S.M. Hosseinnia, M. Sorin, A systematic pinch approach to integrate stratified thermal energy storage in buildings, Energy Build. 232 (2021) 110663, https://doi. org/10.1016/j.enbuild.2020.110663.

- [9] Z. Zhang, L. Zhang, Y. Yuan, Numerical simulation of turbulent natural convection heat transfer in an MW-class offshore wind turbine nacelle based on a multi-feature acquisition meshing technique, Sustain. Energy Technol. Assess. 57 (2023) 103249, https://doi.org/10.1016/j.seta.2023.103249.

- [10] D. Brough, J. Ramos, B. Delpech, H. Jouhara, Development and validation of a TRNSYS type to simulate heat pipe heat exchangers in transient applications of waste heat recovery, Int. J. Thermofluids 9 (2021) 100056, https://doi.org/ 10.1016/j.ijft.2020.100056.

- [11] E. Tian, Y.-L. He, W.-Q. Tao, Research on a new type waste heat recovery gravity heat pipe exchanger, Appl. Energy 188 (2017) 586–594, https://doi.org/10.1016/ j.apenergy.2016.12.029.

- [12] L.Y. Zhang, et al., Experimental investigation and economic analysis of gravity heat pipe exchanger applied in communication base station, Appl. Energy 194 (2017) 499–507, https://doi.org/10.1016/j.apenergy.2016.06.023.

- [13] X. Liu, X. Han, Z. Wang, G. Hao, Z. Zhang, Y. Chen, Application of an anti-gravity oscillating heat pipe on enhancement of waste heat recovery, Energy Convers. Manage 205 (2020) 433–444, https://doi.org/10.1016/j.enconman.2019.112404.

- [14] Z. Guo, J. Yang, Z. Tan, X. Tian, Q. Wang, Numerical study on gravity-driven granular flow around tube out-wall: Effect of tube inclination on the heat transfer, Int. J. Heat. Mass Transf. 174 (2021) 121296, https://doi.org/10.1016/j. ijheatmasstransfer.2021.121296.

- [15] H. Jouhara, N. Nieto, B. Egilegor, J. Zuazua, E. Gonz´alez, I. Yebra, A. Igesias, B. Delpech, S. Almahmoud, D. Brough, J. Malinauskaite, A. Vlasopoulos, M. Hill, B. Axcell, Waste heat recovery solution based on a heat pipe heat exchanger for the aluminium die casting industry, Energy 266 (2023), https://doi.org/10.1016/j. energy.2022.126459.

- [16] M. Imran, R. Pili, M. Usman, F. Haglind, Dynamic modeling and control strategies of organic Rankine cycle systems: methods and challenges, Appl. Energy 276 (2020) 115537, https://doi.org/10.1016/j.apenergy.2020.115537.

- [17] P.R. Gupta, A.K. Tiwari, Z. Said, Solar organic Rankine cycle and its polygeneration applications – a review, Sustain. Energy Technol. Assess. 49 (2022) 101732, https://doi.org/10.1016/j.seta.2021.101732.

- [18] R. Loni, et al., A critical review of power generation using geothermal-driven organic Rankine cycle, Therm. Sci. Eng. Progr. 25 (2021) 101028, https://doi.org/ 10.1016/j.tsep.2021.101028.

- [19] C. Wieland, et al., Innovations for organic Rankine cycle power systems: current trends and future perspectives, Appl. Therm. Eng. 225 (2023) 120201, https://doi. org/10.1016/j.applthermaleng.2023.120201.

- [20] S. Hu, J. Li, F. Yang, Z. Yang, Y. Duan, Multi-objective optimization of organic Rankine cycle using hydrofluorolefins (HFOs) based on different target preferences, Energy 203 (2020) 117848, https://doi.org/10.1016/j. energy.2020.117848.

- [21] X. Li, et al., Organic Rankine cycle systems for engine waste-heat recovery: Heat exchanger design in space-constrained applications, Energy Convers. Manage 199 (2019) 111968, https://doi.org/10.1016/j.enconman.2019.111968.

- [22] M.A. Chatzopoulou, S. Lecompte, M. De Paepe, C.N. Markides, Off-design optimisation of organic Rankine cycle (ORC) engines with different heat exchangers and volumetric expanders in waste heat recovery applications, Appl. Energy 253 (2019) 113442, https://doi.org/10.1016/j.apenergy.2019.113442.

- [23] Z. Zheng, J. Cao, W. Wu, M.K.H. Leung, Parallel and in-series arrangements of zeotropic dual-pressure Organic Rankine Cycle (ORC) for low-grade waste heat recovery, Energy Rep. 8 (2022) 2630–2645, https://doi.org/10.1016/j. egyr.2022.01.057.

- [24] J. Song, X. Li, K. Wang, C.N. Markides, Parametric optimisation of a combined supercritical CO2 (S-CO2) cycle and organic Rankine cycle (ORC) system for internal combustion engine (ICE) waste-heat recovery, Energy Convers. Manage 218 (Aug. 2020) 112999, https://doi.org/10.1016/j.enconman.2020.112999.

- [25] Ł. Witanowski, P. Klonowicz, P. Lampart, T. Suchocki, Ł. Jędrzejewski, D. Zaniewski, P. Klimaszewski, Optimization of an axial turbine for a small scale ORC waste heat recovery system, Energy 205 (2020) 118059, https://doi.org/ 10.1016/j.energy.2020.118059. ISSN 0360-5442.

- [26] W. Qiang, L. Yanzhong, W. Jiang, Analysis of power cycle based on cold energy of liquefied natural gas and low-grade heat source, Appl. Therm. Eng. 24 (4) (2004) 539–548, https://doi.org/10.1016/j.applthermaleng.2003.09.010.

- [27] T. He, Z.R. Chong, J. Zheng, Y. Ju, P. Linga, LNG cold energy utilization: prospects and challenges, Energy 170 (2019) 557–568, https://doi.org/10.1016/j. energy.2018.12.170.

- [28] K.A. Al-attab, Z.A. Zainal, Externally fired gas turbine technology: a review, Appl. Energy 138 (2015) 474–487, https://doi.org/10.1016/j.apenergy.2014.10.049.

- [29] M. Hou, Z. Wu, G. Yu, J. Hu, E. Luo, A thermoacoustic stirling electrical generator for cold exergy recovery of liquefied nature gas, Appl. Energy 226 (2018) 389–396, https://doi.org/10.1016/j.apenergy.2018.05.120.

- [30] X. Shi, D. Che, A combined power cycle utilizing low-temperature waste heat and LNG cold energy, Energy Convers. Manage. 50 (3) (2009) 567–575, https://doi. org/10.1016/j.enconman.2008.10.015.

- [31] M. Mehrpooya, B. Golestani, S.M. Ali Mousavian, Novel cryogenic argon recovery from the air separation unit integrated with LNG regasification and CO2 transcritical power cycle, Sustain. Energy Technol. Assess. 40 (2020) 100767, https://doi.org/10.1016/j.seta.2020.100767.

- [32] D.S. Ayou, V. Eveloy, Energy, exergy and exergoeconomic analysis of an ultra lowgrade heat-driven ammonia-water combined absorption power-cooling cycle for district space cooling, sub-zero refrigeration, power and LNG regasification, Energy Convers. Manage 213 (2020) 112790, https://doi.org/10.1016/j. enconman.2020.112790.

- [33] B. Ghorbani, A. Ebrahimi, M. Ziabasharhagh, Novel integrated CCHP system for generation of liquid methanol, power, cooling and liquid fuels using Kalina power cycle through liquefied natural gas regasification, Energy Convers. Manage 221 (2020) 113151, https://doi.org/10.1016/j.enconman.2020.113151.

- [34] H. Yu, T. Gundersen, E. Gençer, Optimal liquified natural gas (LNG) cold energy utilization in an Allam cycle power plant with carbon capture and storage, Energy Convers. Manage. 228 (2021) 113725, https://doi.org/10.1016/j. enconman.2020.113725.

- [35] J. Bao, T. Yuan, L. Zhang, N. Zhang, X. Zhang, G. He, Comparative study of liquefied natural gas (LNG) cold energy power generation systems in series and parallel, Energy Convers. Manage. 184 (2019) 107–126, https://doi.org/10.1016/ j.enconman.2019.01.040.

- [36] Z. Tian, Z. Qi, W. Gan, M. Tian, W. Gao, A novel negative carbon-emission, cooling, and power generation system based on combined LNG regasification and waste heat recovery: Energy, exergy, economic, environmental (4E) evaluations, Energy 257 (2022) 124528, https://doi.org/10.1016/j.energy.2022.124528.

- [37] A.H. Farajollahi, et al., Waste heat recovery of an UAV propulsion system based on PEM fuel cell by a novel transcritical CO 2 - LNG hybrid cycle; thermodynamic and multiple linear regression analyses, Energy Sources Part A Recov. Utiliz. Environ. Effects 44 (4) (2022) 8694–8717, https://doi.org/10.1080/ 15567036.2022.2123574.

- [38] Z. Tian, W. Zeng, B. Gu, Y. Zhang, X. Yuan, Energy, exergy, and economic (3E) analysis of an organic Rankine cycle using zeotropic mixtures based on marine engine waste heat and LNG cold energy, Energy Convers. Manage. 228 (2021) 113657, https://doi.org/10.1016/j.enconman.2020.113657.

- [39] Z. Yu, C. Feng, F. Bian, D. Wang, Investigation and optimization of a two-stage cascade ORC system for medium and low-grade waste heat recovery using liquefied natural gas cold energy, Int. J. Refriger. 135 (2022) 97–112, https://doi.org/ 10.1016/j.ijrefrig.2021.12.025.

- [40] J. Ma, X. Song, B. Zhang, N. Mao, T. He, Optimal design of dual-stage combined cycles to recover LNG cold energy and low-temperature waste thermal energy for sustainable power generation, Energy Convers. Manage. 269 (2022) 116141, https://doi.org/10.1016/j.enconman.2022.116141.

- [41] L.-H. Zhi, P. Hu, L.-X. Chen, G. Zhao, Thermodynamic analysis of an innovative transcritical CO2 parallel Rankine cycle driven by engine waste heat and liquefied natural gas cold, Energy Convers. Manage. 209 (2020) 112583, https://doi.org/ 10.1016/j.enconman.2020.112583.

- [42] S. Yao, C. Li, Y. Wei, Design and optimization of a zero carbon emission system integrated with the utilization of marine engine waste heat and LNG cold energy for LNG-powered ships, Appl. Therm. Eng. 231 (2023) 120976, https://doi.org/ 10.1016/j.applthermaleng.2023.120976.

- [43] T. Hai, et al., Optimization next to environmental analysis of harvesting waste heat from a biomass-driven externally-fired gas turbine cycle for sub-zero cooling and production of hydrogen, freshwater, and hot water, Appl. Therm. Eng. 223 (2023) 119884, https://doi.org/10.1016/j.applthermaleng.2022.119884.

- [44] O. Konur, C.O. Colpan, O.Y. Saatcioglu, A comprehensive review on organic Rankine cycle systems used as waste heat recovery technologies for marine applications, Energy Sources Part A Recov. Utiliz. Environ. Effects 44 (2) (2022) 4083–4122, https://doi.org/10.1080/15567036.2022.2072981.

- [45] C. Tian, C. Su, C. Yang, X. Wei, P. Pang, J. Xu, Exergetic and economic evaluation of a novel integrated system for cogeneration of power and freshwater using waste heat recovery of natural gas combined cycle, Energy 264 (2023) 126227, https:// doi.org/10.1016/j.energy.2022.126227.

- [46] S.-H. Cha, S.-I. Na, Y.H. Lee, M.S. Kim, Thermodynamic analysis of a gas turbine inlet air cooling and recovering system in gas turbine and CO2 combined cycle using cold energy from LNG terminal, Energy Convers. Manage 230 (2021) 113802, https://doi.org/10.1016/j.enconman.2020.113802.

- [47] B. Peris, J. Navarro-Esbrí, F. Mol´es, A. Mota-Babiloni, Experimental study of an ORC (organic Rankine cycle) for low grade waste heat recovery in a ceramic industry, Energy 85 (2015) 534–542. ISSN 0360-5442.

- [48] H. Jouhara, D. Bertrand, B. Axcell, L. Montorsi, M. Venturelli, S. Almahmoud, M. Milani, L. Ahmad, A. Chauhan, Investigation on a full-scale heat pipe heat exchanger in the ceramics industry for waste heat recovery, Energy 223 (2021) 120037. ISSN 0360-5442.

- [49] T.G.C. Veloso, C.A.R. Sotomonte, CJ.R. Coronado, MA.R. Nascimento, Multiobjective optimization and exergetic analysis of a low-grade waste heat recovery ORC application on a Brazilian FPSO, Energy Convers. Manage. 174 (2018) 537–551. ISSN 0196-8904.

- [50] Dwivedi, A. and Mishra, R.S., Analysis of organic Rankine cycle with waste heat recovery from gas power plant using loop heat pipes. J. Mech. Eng. Res. Dev., ISSN, pp.1024-1752.

- [51] Z. Tian, Y. Yue, B. Gu, W. Gao, Y. Zhang, Thermo-economic analysis and optimization of a combined Organic Rankine Cycle (ORC) system with LNG cold

- energy and waste heat recovery of dual-fuel marine engine, Int. J. Energy Res. 44 (2020) 9974–9994.

- [52] B. Jiang, D. Xia, H. Zhang, H. Pei, X. Liu, Effective waste heat recovery from industrial high-temperature granules: a moving bed indirect heat exchanger with embedded agitation, Energy 208 (2020) 118346. ISSN 0360-5442.

- [53] A.M. Alsayah, JJ. Faraj, AA. Eidan, The augmentation of the heat recovery by using evaporative cooling in HVAC applications: experimental study, Int. J. Thermofluids 22 (2024) 100671. ISSN 2666-2027.

- [54] D. Brough, J. Ramos, B. Delpech, H. Jouhara, Development and validation of a TRNSYS type to simulate heat pipe heat exchangers in transient applications of waste heat recovery, Int. J. Thermofluids 9 (2021) 100056. ISSN 2666-2027.

- [55] A.I. Turja, K.N. Sadat, Y. Khan, M. Monjurul Ehsan, Cascading the transcritical CO2 and organic Rankine cycles with supercritical CO2 cycles for waste heat recovery, Int. J. Thermofluids 20 (2023) 100508. ISSN 2666-2027.

- [56] A.S. Chowdhury, M.M. Ehsan, A critical overview of working fluids in organic Rankine, supercritical rankine, and supercritical brayton cycles under various heat grade sources, Int. J. Thermofluids 20 (2023) 100426. ISSN 2666-2027.

- [57] A.E. Elahi, T. Mahmud, M. Alam, J. Hossain, B.N. Biswas, Exergy analysis of organic Rankine cycle for waste heat recovery using low GWP refrigerants, Int. J. Thermofluids 16 (2022) 100243. ISSN 2666-2027.

- [58] M. Mahmoud, S. Naher, M. Ramadan, M.A. Abdelkareem, H. Jaber, A.-G. Olabi, Investigation of a ground-cooled organic Rankine cycle for waste heat recovery, Int. J. Thermofluids 18 (2023) 100348. ISSN 2666-2027.

- [59] AR. Imre, AM. Ahmed, Effect of the working fluids critical temperature on thermal performance for trilateral flash cycle and organic Rankine cycle, Int. J. Thermofluids 20 (2023) 100417. ISSN 2666-2027.

- [60] Xu Zheng, Y. Li, Ji Zhang, Z. Zhang, C. Guo, N. Mei, Design and multi-objective optimization of combined air separation and ORC system for harnessing LNG cold energy considering variable regasification rates, Int. J. Hydrogen. Energy 57 (2024) 210–223. ISSN 0360-3199.

- [61] Y.A.A. Laouid, C. Kezrane, Y. Lasbet, Apostolos Pesyridis, Towards improvement of waste heat recovery systems: A multi-objective optimization of different organic Rankine cycle configurations, Int. J. Thermofluids 11 (2021) 100100. ISSN 26662027.

- [62] M. Taal, I. Bulatov, J. Klemes, P. Stehlik, Cost estimation and energy price forecasts for economic evaluation of retrofit projects, Appl. Therm. Eng. 23 (2003) 1819–1835.

- [63] A.C. Caputo, P.M. Pelagagge, P. Salini, Heat exchanger design based on economic optimization, Appl. Therm. Eng. 28 (2008) 1151–1159.

- [64] M.A.A Sadreddini, M. Fani, A. Mohammadi, Thermodynamic analysis of a new cascade ORC and transcritical CO2 cycle to recover energy from medium temperature heat source and liquefied natural gas, Energy Convers. Manage 167 (2018) 9–20, https://doi.org/10.1016/j.enconman.2018.04.093.

Copyright and Source Material:

https://doi.org/10.1016/j.ijft.2024.100822

Copyright © 2025 CASTMAN. All rights reserved.