Preventing Catastrophic Mold Failure: The Power of High Hardenability Mold Steel in HPDC

This technical summary is based on the academic paper "Development and Applications of High Hardenability Special Quality Die Casting Mold Steels" by K. Namiki, N. Yokoi, A. Sekiya, and T. Yanagisawa, published in NADCA DIE CASTING CONGRESS & TABLETOP (2013). It has been analyzed and summarized for technical experts by CASTMAN.

Keywords

- Primary Keyword: High Hardenability Mold Steel

- Secondary Keywords: Die Casting Mold Life, Gross Cracking, Mold Toughness, DH31-EX, DHA-WORLD, Heat Checking Resistance, Bainitic Transformation

Executive Summary

- The Challenge: Large die casting molds for parts like automotive transmissions are prone to gross cracking originating from water lines, caused by reduced toughness in the mold's core during quenching.

- The Method: Two new high hardenability mold steels, DH31-EX™ and DHA™-WORLD, were developed to delay the formation of brittle bainite structures during the cooling of large molds.

- The Key Breakthrough: These new steels maintain significantly higher toughness in the core of large molds compared to conventional H13 steel, effectively preventing gross cracking.

- The Bottom Line: Adopting high hardenability mold steel is a critical strategy to extend the life of large, complex molds, reduce costly downtime, and enable shorter cycle times through more aggressive cooling designs.

The Challenge: Why This Research Matters for HPDC Professionals

In the automotive industry, the push for lightweighting has led to larger and more complex aluminum die-cast components, such as transmission and crank cases. To meet production demands and reduce costs, die casters are shortening cycle times. A key strategy for this is to increase the number of cooling water lines and place them closer to the mold surface.

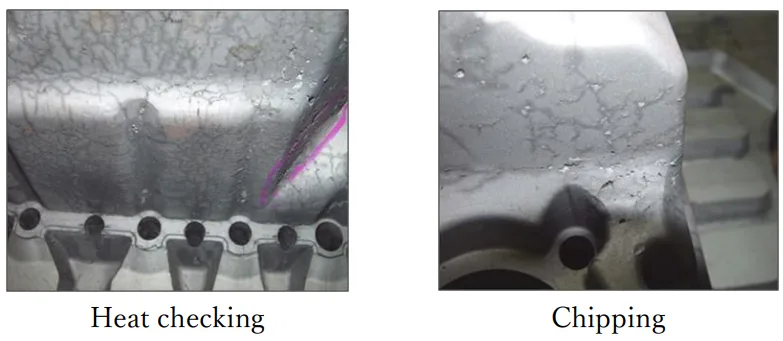

However, this creates a significant engineering challenge. While heat checking can be managed through regular maintenance, a "gross crack" originating from a water line can lead to catastrophic failure, resulting in time-consuming repairs or scrapping the entire mold. This problem is especially acute in large molds, where the thick core cools slowly during the quenching process. This slow cooling promotes the formation of a bainitic microstructure, which dramatically reduces the steel's toughness and makes it susceptible to cracking under stress. Therefore, improving the internal toughness of large molds has become a key property to ensure reliable mold life.

The Approach: Unpacking the Methodology

To address the challenge of low core toughness, researchers developed two new hot work die steels with high hardenability: DH31-EX (a 2367 modified, double-melted, high-Mo steel) and DHA-WORLD (an H11 improved, single-melt steel). The core principle behind their design was to modify the steel chemistry to delay the onset of bainitic transformation during quenching.

The study validated the performance of these steels through a multi-stage methodology:

1. Material Characterization: Continuous Cooling Transformation (CCT) diagrams were generated to map the microstructural changes in the new steels versus conventional H13 steel during cooling.

2. Mechanical Testing: Charpy impact tests were conducted on samples subjected to various cooling rates to quantify the relationship between cooling speed and toughness. Crucially, tests were also performed on large-scale blocks (200mm x 600mm x 300mm and 550mm x 500mm) to simulate the conditions inside a real-world, large-sized mold.

3. Performance Testing: A heat checking test was conducted using a 135-ton die casting machine for 10,000 shots to compare the surface durability of the new steels against H13-ESR.

4. Real-World Application: A large production mold (824mm x 814mm x 404mm, 2.1 tons) for an automotive transmission case was manufactured using DHA-WORLD, heat-treated, and monitored throughout its production life of 150,000 shots.

The Breakthrough: Key Findings & Data

The research yielded definitive data demonstrating the superiority of the new high hardenability steels for large die casting molds.

Finding 1: Dramatically Improved Core Toughness in Large Molds

The fundamental advantage of the new steels is their ability to resist bainitic transformation. The CCT diagrams in Figures 4 and 5 show the bainitic transformation starting point for DHA-WORLD and DH31-EX is approximately 2 hours, significantly longer than for H13. This delay ensures that even the slowly cooled core of a large mold can achieve a tougher martensitic structure.

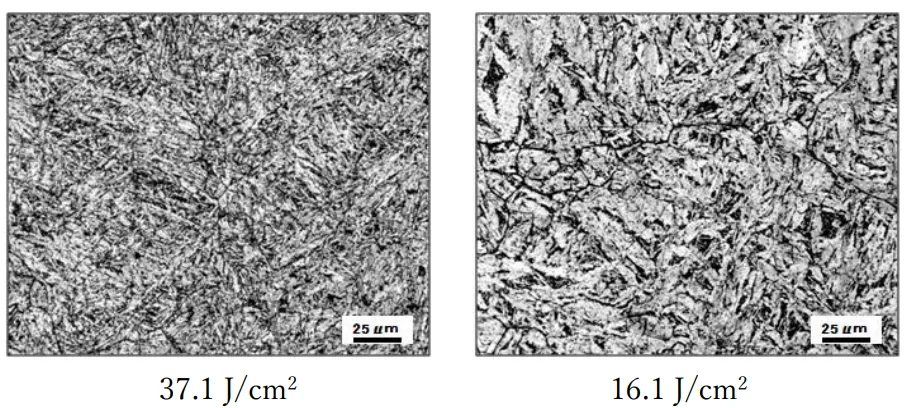

This directly translated to superior mechanical properties. In a large test block simulating a mold core, the toughness of H13 steel dropped to just 10 J/cm² in the center. In contrast, as shown in Figure 13, DHA-WORLD maintained a high toughness of 30 J/cm² in the center, three times that of H13. The micrographs in Figure 14 clearly show the difference: a desirable tempered martensite structure in DHA-WORLD versus the brittle tempered bainite in H13.

Finding 2: Superior Heat Checking Resistance

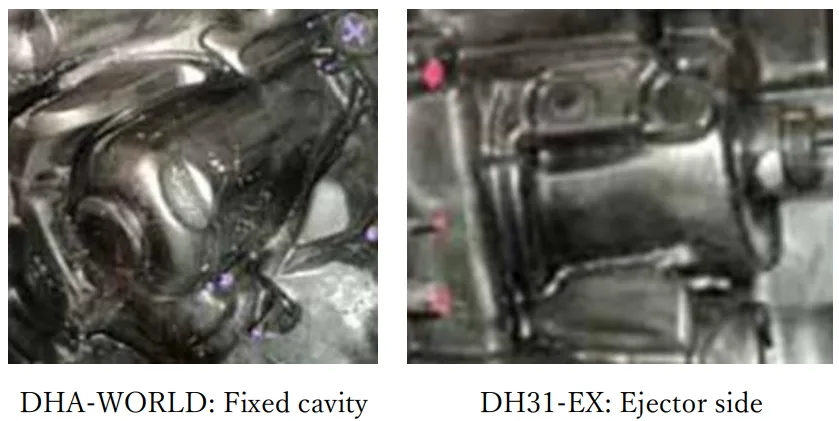

In addition to preventing gross cracks, the new steels also exhibited better resistance to surface-level heat checking. After a 10,000-shot die casting test, the conventional H13-ESR mold showed noticeable heat checking. As seen in Figure 8, both the DH31-EX and DHA-WORLD specimens showed significantly less heat checking, with almost no cracks visible on the central surface between the projections. This indicates a longer service life before surface repairs are needed.

Finding 3: Validated Performance in a High-Volume Production Environment

The ultimate test was the application in a large transmission case mold. The mold, made from DHA-WORLD, was run in mass production. After 140,000 shots, only small, shallow heat checks were observed, with no signs of the large, deep cracks that could cause water leakage (Figure 17). The mold successfully reached its planned life of 150,000 shots without any gross cracking. Post-production analysis of samples from the mold's center confirmed a Charpy impact value of 35.1 J/cm² (Table 2), well above the empirically deduced 20 J/cm² threshold required to prevent gross cracking.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that using high hardenability steels like DHA-WORLD provides a larger process window. It may contribute to reducing cycle times by allowing for the design of more aggressive cooling channels without the high risk of premature mold failure from gross cracking.

- For Quality Control Teams: The data in Figure 13 and Table 2 of the paper illustrates the direct link between a material's hardenability and its final toughness in a large block. This suggests that specifying a minimum core toughness value (e.g., >20 J/cm² U-notch) could become a critical quality inspection criterion for new large-format molds.

- For Design Engineers: The findings indicate that the superior toughness of these steels provides a greater safety margin against crack initiation, especially at the intersection of water lines. This allows for more freedom in designing complex molds with intricate cooling systems essential for modern, thin-walled components.

Paper Details

Development and Applications of High Hardenability Special Quality Die Casting Mold Steels

1. Overview:

- Title: Development and Applications of High Hardenability Special Quality Die Casting Mold Steels

- Author: K. Namiki, N. Yokoi, A. Sekiya (Daido Steel Co., Ltd.); T. Yanagisawa (Daido DM Steels Solutions Co., Ltd.)

- Year of publication: 2013

- Journal/academic society of publication: NADCA DIE CASTING CONGRESS & TABLETOP, Transaction No. T13-052

- Keywords: Toughness, Heat checking, Gross cracking, Water lines, Hardenability, Bainitic transformation, DH31-EX, DHA-WORLD, H13

2. Abstract:

Toughness is becoming more important for die casting mold steels as well as heat checking resistance. High toughness is required to prevent gross cracking from water lines, especially from the crossing of these in large size mold such as transmission and crank cases of automobiles. The cause of decrease in toughness in large molds is Bainitic transformation during quenching. To prevent this high quenching cooling rate is required. But, the tradeoff is dimensional change. The right answer from mold steel design is highly hardenable mold steels. Based on these back grounds two die casting mold steels have been developed: DH31-EX™ and DHA™-WORLD. The former is 2367 modified double melted high Mo steel and the latter is H11 improved type steel. In spite of single melt steel, DHA-WORLD shows much higher toughness than H13 double melted steel even in large mold. These two steels have been applied to large automobile transmission cases in these three years, the largest one of which weighs 1700 lbs. These molds run in actual service without any gross cracking from water lines. This report will describe the features of these steels and the details of application.

3. Introduction:

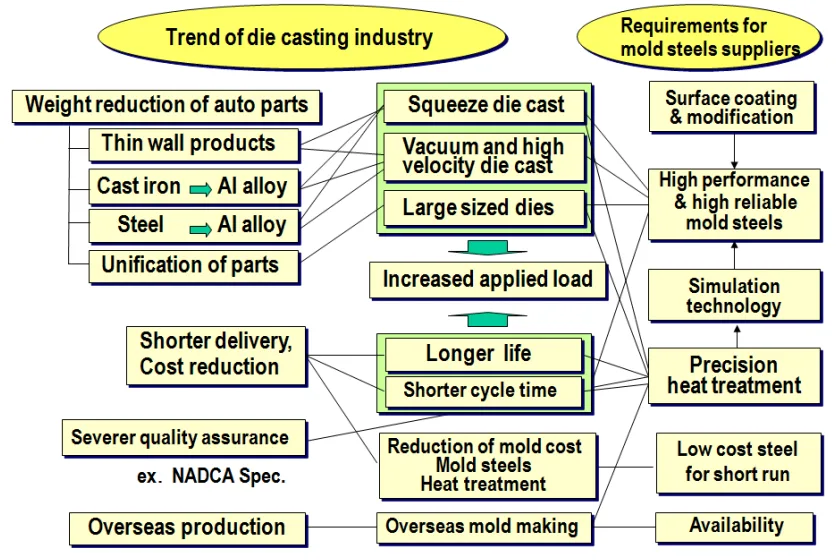

The trend in die casting industries, particularly automotive, is toward lighter vehicles for fuel economy, driving the use of aluminum die casts. To reduce costs, shorter cycle times are essential, which requires high-performance and reliable mold steels. The main failure modes are heat checking, gross crack, and soldering. Gross cracks, which often initiate from water lines, are a major issue as they can lead to catastrophic failure and costly repairs. Measures to shorten cycle time, such as increasing the number of water lines and decreasing the distance to the mold surface, place greater demands on the internal toughness of the mold. Therefore, toughness, especially in large molds, becomes the key property that determines mold life.

4. Summary of the study:

Background of the research topic:

Low toughness in the core of large die casting molds is caused by bainitic transformation during quenching. This has been a long-standing problem that leads to premature mold failure via gross cracking.

Status of previous research:

Conventional approaches to improve mold toughness included using fast quenching or applying standard premium steels like H13. However, fast quenching can cause unacceptable dimensional changes, and standard steels like H13 still suffer from toughness loss in the slowly cooled sections of large molds.

Purpose of the study:

The study aimed to develop and validate new high hardenability die casting mold steels that could maintain high toughness even in the center of large-sized molds, thereby preventing gross cracking and extending mold life.

Core study:

The core of the study involved the characterization and application of two newly developed steels, DH31-EX and DHA-WORLD. Their properties (hardenability, toughness, heat checking resistance) were compared against the industry standard H13 steel through laboratory tests, large block simulations, and a full-scale production trial of a large automotive transmission case mold.

5. Research Methodology

Research Design:

The research employed a comparative study design, evaluating the properties of the two new steels (DH31-EX, DHA-WORLD) against the benchmark steel (H13). The evaluation progressed from fundamental material characterization to simulated large-scale testing and finally to a real-world industrial application.

Data Collection and Analysis Methods:

Data was collected through CCT diagrams, Charpy impact testing (U-notch) on specimens from various locations within large blocks, optical microscopy to analyze microstructures, and visual inspection of mold surfaces after production runs. Hardness testing was also performed.

Research Topics and Scope:

The research focused on improving the toughness of large die casting molds to prevent gross cracking. The scope included alloy design, steel production, heat treatment response, mechanical property testing, and a case study on a large automotive transmission mold, demonstrating the practical application and benefits of the developed steels.

6. Key Results:

Key Results:

- The bainitic transformation starting points for DHA-WORLD and DH31-EX are around 2 hours, much longer than for H13, indicating significantly higher hardenability.

- In large quenched blocks, DHA-WORLD (a single-melt steel) demonstrated toughness equivalent to or better than ESR-melted H13, maintaining high Charpy values (>30 J/cm²) even in the center, where H13 dropped to 10 J/cm².

- Both DHA-WORLD and DH31-EX showed superior heat checking resistance compared to H13-ESR after 10,000 shots.

- A large transmission case mold made of DHA-WORLD successfully completed its planned life of 150,000 shots without any gross cracking from water lines. The toughness in the mold center was measured at 35.1 J/cm², exceeding the empirical safety threshold of 20 J/cm².

Figure Name List:

- Figure 1 Trend of die casting industries and requirements for mold steel suppliers in Japan.

- Figure 2 Change in die casting mold steels.

- Figure 3 Optical micrographs taken from the thin part (left) and the thick part (right) of a transmission case mold.

- Figure 4 CCT diagram of DHA-WORLD.

- Figure 5 CCT diagram of DH31-EX.

- Figure 6 Effect of quenching cooling rate on Charpy Impact values (U notch).

- Figure 7 Charpy impact values of the specimens taken from vacuum quenched and tempered large block.

- Figure 8 Heat checking test result: The appearance of test specimens after 10,000 shots.

- Figure 9 Examples of heat checking and chipping.

- Figure 10 An example of gross crack.

- Figure 11 Fracture surface from water line

- Figure 12 Optical micrograph taken from the cross section of water line

- Figure13 Charpy impact values distribution in large test blocks tempered to 43 HRC.

- Figure 14 Optical micrographs taken from the center part of the test blocks.

- Figure15 Hardness obtained by tempering.

- Figure 16 Optical micrograph taken from the center of the mold.

- Figure 17 Examples of mold surfaces of the molds.

- Figure Appendix-1 Correlation between V and U notch absorbed energy.

7. Conclusion:

Two hot work die steels, DH31-EX and DHA-WORLD, were developed to prevent gross cracking in large die casting molds by increasing toughness. The key feature of these steels is high hardenability, which provides high toughness even in large size molds. These two mold steels have been successfully applied to automotive transmission cases and are running well.

8. References:

- 1) N. Uehara, K. Namiki, K. Takahashi: Denki-Seiko (Electric Furnace Steel), vol.81, No.3, p.165 (1981)

- 2) K. Namiki: Netsu-shori (Journal of the Japan Society for Heat Treatment), vol.50, No.6, p.556 (2010)

- 3) H. Morikawa: Denki- Seiko (Electric Furnace Steel), vol.81, No.1, p.47 (2010)

- 4) NADCA #207-2011, NADCA Publication #229 (2011)

- 5) N. Yokoi, M. Kawano, K. Inoue: Denki- Seiko (Electric Furnace Steel), Vol.81, No.1, p.25 (2010)

- 6) M. Kawano and K. Inoue: Materia Japan, vol.48, p32 (2009)

Expert Q&A: Your Top Questions Answered

Q1: Why is toughness in the center of a large mold so critical? Isn't surface hardness more important?

A1: While surface properties are crucial for wear and heat checking, the core toughness is vital for preventing catastrophic failure. As the paper explains, gross cracks often initiate from internal stress risers like water line intersections. In large molds, the center cools much slower than the surface during heat treatment, leading to the formation of brittle bainite. This low-toughness core cannot arrest a growing crack, leading to complete mold failure.

Q2: The paper uses U-notch Charpy tests, which are common in Japan, but V-notch is the standard in the US. How can I compare these results to my own data?

A2: The authors anticipated this and included a very helpful correlation in the appendix. Figure Appendix-1 shows a direct comparison between V-notch and U-notch test results for these types of steels. The data establishes an approximate conversion formula: V-notch (J) ≈ 0.43 * U-notch (J). This allows engineers in the US to translate the paper's findings into the more familiar V-notch values for direct comparison.

Q3: What makes DHA-WORLD notable compared to other premium steels like double-melted H13?

A3: The key distinction highlighted in the paper is its performance-to-cost potential. DHA-WORLD is a single-melt steel, which typically implies a lower production cost than double-melted (ESR) steels. Despite this, Figure 7 and Figure 13 show that DHA-WORLD delivers toughness that is equivalent to or even better than ESR-melted H13 in large sections. It achieves this through advanced alloy design and clean steel-making technology, offering premium performance without the full cost of a double-melt process.

Q4: The CCT diagrams (Figures 4 & 5) show the bainitic transformation is shifted to 2 hours. Why is this specific duration significant for large molds?

A4: The 2-hour mark is significant because it surpasses the time it takes for the core of a very large mold block to cool through the critical transformation temperature range (around 500-300°C). For standard H13, this transformation happens much faster. By pushing the "nose" of the CCT curve out to 2 hours, the steel can cool slowly through this range without forming brittle bainite, ensuring a tougher martensitic microstructure is achieved throughout the entire mold, not just at the surface.

Q5: What is the single most important takeaway from the real-world transmission case mold test?

A5: The test provides definitive proof that the principles of high hardenability translate directly to production reliability. The mold made from DHA-WORLD not only survived its planned 150,000-shot life but did so without the gross cracking that plagues large molds made from conventional steels. The key takeaway is the validation of an empirical toughness threshold: the measured core toughness of over 35 J/cm² (Table 2) confirms that maintaining a core toughness above 20 J/cm² is a successful strategy for preventing gross cracking.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of preventing gross cracking in large, high-performance die casting molds is a critical barrier to improving productivity and reducing operational costs. This research demonstrates that the root cause—low core toughness from bainitic transformation—can be overcome through advanced material science. By utilizing a High Hardenability Mold Steel like DHA-WORLD or DH31-EX, die casters can ensure that even the largest and most complex molds maintain the internal toughness required to resist catastrophic failure. This not only extends mold life and reduces downtime but also empowers engineers to design more efficient cooling systems for faster cycle times.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

- This content is a summary and analysis based on the paper "Development and Applications of High Hardenability Special Quality Die Casting Mold Steels" by "K. Namiki, N. Yokoi, A. Sekiya, T. Yanagisawa".

- Source: NADCA DIE CASTING CONGRESS & TABLETOP, (2013), Transaction No. T13-052

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.