This technical summary is based on the academic paper "Effect of stress on damping capacity of a shape memory alloy CuZnAl" published by N. CIMPOEȘU, S. STANCIU, M. MAYER, I. IONIȚĂ, R. HANU CIMPOEȘU in the Journal of Optoelectronics and Advanced Materials (2010). It was analyzed and summarized for HPDC experts by CASTMAN experts with the help of LLM AI such as Gemini, ChatGPT, and Grok.

Keywords

- Primary Keyword: Shape Memory Alloy Damping Capacity

- Secondary Keywords: CuZnAl Alloy, Internal Friction, Storage Modulus, Vibration Damping Materials, Martensitic Transformation, Passive Structure Control

Executive Summary

- The Challenge: Developing metallic materials with exceptionally high damping capacity is crucial for passively attenuating unwanted noise and vibration in demanding engineering applications, from civil structures to advanced machinery.

- The Method: Researchers synthesized a copper-zinc-aluminum (CuZnAl) shape memory alloy (SMA) and subjected it to deformation (forging) and tension. Its microstructure and thermomechanical properties were then meticulously analyzed using SEM, dilatometry (DIL), calorimetry (DSC), and dynamic mechanical analysis (DMA).

- The Key Breakthrough: The study revealed that the CuZnAl alloy exhibits a significant internal friction (damping) peak associated with its martensitic phase transformation. Crucially, applying mechanical stress (both deformation and tension) not only enhances the magnitude of this damping peak but also shifts its effective temperature range, making it more tunable for practical applications.

- The Bottom Line: Mechanical processing is a powerful tool for engineering the damping characteristics of SMAs. By applying stress, the damping performance of CuZnAl can be significantly improved and tailored for specific operational temperatures, opening new possibilities for passive vibration control.

The Challenge: Why This Research Matters for HPDC Professionals

In modern engineering, controlling unwanted vibration and noise is a persistent challenge. While polymers are often used for amortization, metallic materials with high damping capacity offer superior strength and durability. Among these, shape memory alloys (SMAs) are exceptionally promising candidates due to their unique properties arising from a reversible martensitic phase transition (Ref. [1, 2]).

This internal friction mechanism allows SMAs to dissipate significant amounts of energy, making them ideal for applications in passive structure control, such as dampers for bridges and retrofitting devices for buildings (Ref. [9]). However, to fully exploit this potential, it is critical to understand and control the factors that influence their damping behavior, such as temperature, frequency, and applied stress (Ref. [7, 8]). This research dives deep into how mechanical stress can be used to optimize the damping performance of a CuZnAl SMA, providing insights relevant to any industry seeking advanced materials for vibration attenuation.

The Approach: Unpacking the Methodology

To investigate the alloy's properties, the researchers employed a multi-faceted analytical approach:

- Alloy Synthesis: A CuZnAl shape memory alloy was produced using a classical melting method in a laboratory furnace. The final chemical composition was confirmed via spark spectrometry and EDAX analysis (Table 1).

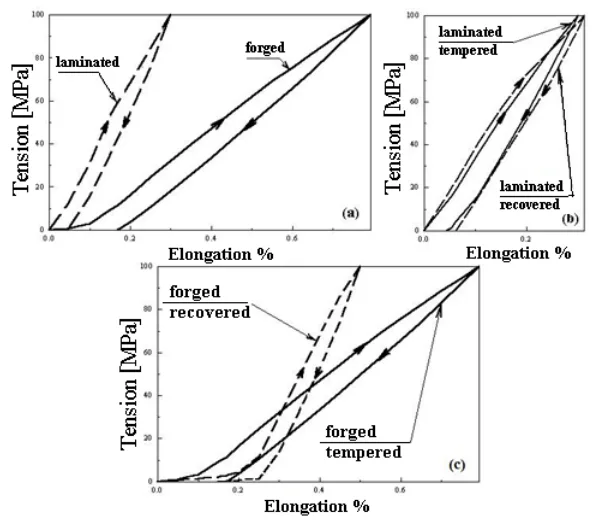

- Sample Preparation: The alloy was studied in two key states: a deformed state achieved by hot forging at 1073 K, and a tensioned state obtained by applying stress to a laminated sample using an INSTRON 3382 tension equipment.

- Thermomechanical Analysis: The material's behavior was characterized using a suite of advanced instruments:

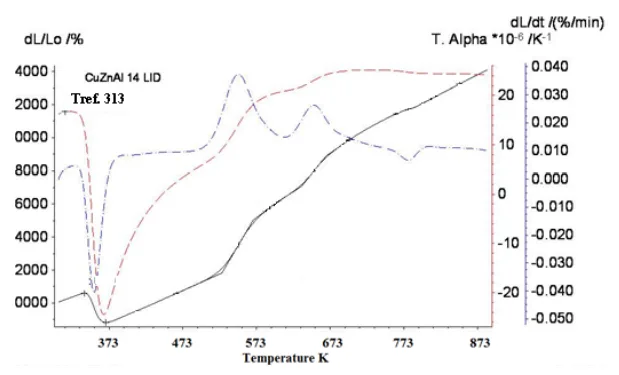

- A DIL 402 dilatometer was used to measure dimensional changes with temperature, identifying the martensitic transformation temperature range (Figure 3).

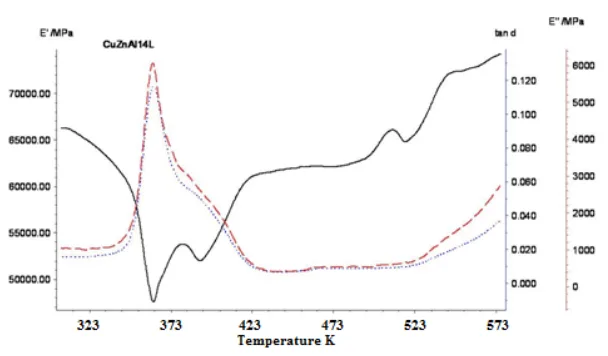

- A DMA 242 C dynamic mechanical analyzer measured the internal friction (tan δ) and storage modulus (E') as a function of temperature, providing a direct assessment of the material's damping capacity and stiffness.

- Differential Scanning Calorimetry (DSC) was used to determine the transformation enthalpies and confirm the transformation temperatures in the tensioned state (Figure 5).

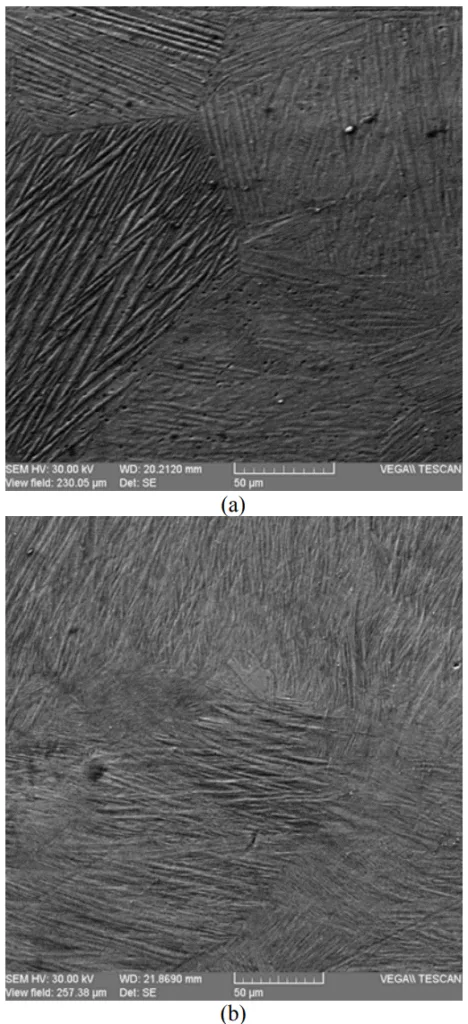

- A Scanning Electron Microscope (SEM) was used to observe the microstructure, revealing the characteristic martensitic variants in both deformed and tensioned states (Figure 2).

The Breakthrough: Key Findings & Data

The study yielded several critical findings that demonstrate the powerful effect of stress on the alloy's damping properties.

- Finding 1: High Damping in the Deformed State: The dynamic mechanical analysis of the forged (deformed) sample revealed a prominent internal friction peak with a high value of 0.11635 at a temperature of 362.7 K. This peak corresponds directly to the martensitic transformation range identified by dilatometry, confirming the transformation is the source of the high damping (Figure 4).

- Finding 2: Stress Shifts the Transformation Window: Applying tension to the alloy caused the martensitic transformation temperature range to decrease, moving it closer to room temperature. DSC analysis on a 4% tensioned sample showed a transformation range of 313-350 K, compared to 339-369 K in the deformed state (Figure 5).

- Finding 3: Tension Enhances Damping Performance: In the tensioned state, the internal friction peak became even more significant, reaching a value of 0.1607 at a lower temperature of approximately 333.8 K. This demonstrates that tension not only shifts the operating window but also increases the maximum damping capacity (Figure 6).

- Finding 4: Correlated Modulus Softening: In both deformed and tensioned states, the high internal friction peak was accompanied by a sharp drop, or "softening," in the storage modulus (E'). This behavior is a classic signature of a martensitic transformation and is directly linked to the mechanisms that produce the high damping effect (Figure 4, Figure 6).

Practical Implications for HPDC Products

While this study focuses on a classically melted SMA, the principles uncovered have significant implications for the broader field of advanced materials, including those relevant to HPDC.

- For Process Engineers: The research clearly shows that mechanical processing post-casting is not just for shaping but is a critical tool for engineering material properties. The fact that forging and tension can dramatically alter the damping behavior of this alloy (as seen in Figure 4 and Figure 6) suggests that similar post-casting treatments could be explored to enhance the functional performance of advanced HPDC components.

- For R&D and Product Development: The exceptional damping values achieved (tan δ > 0.16) highlight the potential of SMA-type alloys for creating components with built-in passive vibration control. This could inspire the development of new, high-damping alloys specifically designed for the HPDC process, targeting applications in automotive (e.g., brackets, mounts), aerospace, or sensitive electronics enclosures where vibration is a critical failure mode.

- For Quality Control: The distinct and correlated signatures of the internal friction peak and the storage modulus dip provide a powerful method for quality assurance. DMA testing could be implemented to verify that a component possesses the required damping characteristics within a specific temperature range, ensuring it meets functional performance specifications.

Paper Details

Effect of stress on damping capacity of a shape memory alloy CuZnAl

1. Overview:

- Title: Effect of stress on damping capacity of a shape memory alloy CuZnAl

- Author: N. CIMPOEȘU, S. STANCIU, M. MAYER, I. IONIȚĂ, R. HANU CIMPOEȘU

- Year of publication: 2010

- Journal/academic society of publication: JOURNAL OF OPTOELECTRONICS AND ADVANCED MATERIALS Vol. 12, No. 2

- Keywords: shape memory effect, damping capacity, internal friction, storage modulus

2. Abstract:

A copper based shape memory alloy was obtained by classical melting method. Chemical analyze beside copper, zinc and aluminum reveal small amounts of other chemical elements like iron, lead or nickel that can improve the damping capacity of shape memory alloy. Starting from chemical composition the material was analyzed in deformed and tensioned state by microstructure (SEM), dilatometry (DIL) or calorimetry (DSC) and mechanical-dynamic (DMA) point of view. Results present a nice internal friction peak, in both cases, in transformation temperatures domain with possible practical applications.

3. Introduction:

Damping materials have wide applications for amortization and energy dissipation. High damping capacity is a critical property for engineering structures where noise and vibration must be attenuated. Shape memory alloys (SMAs) are highly promising candidates due to their high damping capacity, which arises from the reversible martensitic phase transition (MT) and the stress-induced reorientation of martensite variants. This study investigates the influence of factors like temperature and strain amplitude on the damping capacity of a CuZnAl SMA, which has potential uses in devices like braces, dampers, and connection elements for structures.

4. Summary of the study:

Background of the research topic:

SMAs are special materials known for the shape memory effect and superelasticity. A less exploited but highly valuable property is their damping capacity. It is generally accepted that micro-structural features play a dominant role in the damping response of materials. This research builds on previous work by investigating how stress, through deformation and tension, affects these micro-structural features and, consequently, the damping performance.

Status of previous research:

Previous research has established SMAs as high-damping materials and has explored their use in passive structure control devices. Studies have systematically investigated the effects of temperature change rate, frequency, and strain amplitude on damping capacity. This paper extends that work by focusing specifically on the effect of applied stress (forging and tension) on the thermomechanical behavior and damping properties of a CuZnAl alloy.

Purpose of the study:

The study aims to analyze a copper-based SMA in both deformed and tensioned states to understand the effect of stress on its damping capacity. The goal is to characterize the material's microstructure, transformation temperatures, and dynamic mechanical properties to evaluate its potential for practical applications in vibration damping.

Core study:

The core of the study involves a comparative analysis of a CuZnAl alloy under two conditions: hot-forged (deformed) and 4% tensioned. The researchers used dilatometry and DSC to identify the martensitic transformation temperatures for each state. They then used DMA to measure the internal friction (tan δ) and storage modulus (E') across these temperature ranges. The key objective was to quantify how the damping peak's magnitude and temperature position change as a result of the applied stress.

5. Research Methodology

Research Design:

The research was designed as a comparative experimental study. An alloy was first synthesized and its composition was verified. Samples were then prepared into two distinct states: deformed via hot forging and subsequently tensioned. The properties of samples from both states were then characterized using a standardized set of analytical techniques to allow for direct comparison.

Data Collection and Analysis Methods:

- Chemical Composition: Determined by spark spectrometry and EDAX analysis (Table 1).

- Microstructure: Imaged using a Vega Tescan SEM with a secondary electron detector (Figure 2).

- Thermal Expansion & Transformation Range: Measured with a DIL 402 dilatometer on a cylindrical sample (Figure 3).

- Dynamic Mechanical Properties: Internal friction (tan δ) and storage modulus (E') were measured using a DMA 242 C analyzer on a rectangular sample at a frequency of 1 Hz (Figure 4, Figure 6).

- Calorimetry: Transformation temperatures and enthalpy for the tensioned sample were determined using DSC (Figure 5).

Research Topics and Scope:

The research focuses on a single copper-based shape memory alloy (Cu54.9Zn26.5Al6.44). The scope is limited to analyzing the effects of two specific stress states—hot forging and static tension—on the material's damping capacity and related thermomechanical properties. The temperature range of investigation was primarily between 303 K and 573 K.

6. Key Results:

Key Results:

- The CuZnAl alloy contains small amounts of Fe, Pb, and Ni, which can contribute to modifying its thermal and mechanical behavior.

- In the deformed (forged) state, the alloy exhibits a significant internal friction peak (tan δ) of 0.11635 at 362.73 K, which is within the martensitic transformation range.

- This damping peak is accompanied by a minimum in the storage modulus (E'), which drops from ~67000 MPa to ~47554 MPa.

- In the 4% tensioned state, the transformation temperature range shifts to lower temperatures (peak at 313.1 K on heating, from DSC).

- The tensioned sample shows an even higher internal friction peak of 0.1607 during the second heating cycle, occurring at a lower temperature of 333.8 K.

- The storage modulus (E') in the tensioned state shows a very large decrease in the transformation range, from 45000 MPa to approximately 2000 MPa.

Figure Name List:

- Fig. 1 Summary of elongation-tension variation of the copper based material a) for forged and laminated states, b) laminated and c) forged with different heat treatments applied like recovered or water quenched.

- Fig. 2. SEM realized microstructure of shape memory alloy Cu54.9Zn26.5Al6.44; (a) deformed by forging state; (b) tensioned state.

- Fig. 3 Variations with temperature of relative thermal expansion (dL/ Lo with solid line), relative thermal expansion in time d(dL/Lo) dt) and thermal expansion coefficient (α), on the dilatometry recorded during heating to 600 K of a lamella cut from as-cast SMAS alloy Cu69.57Zn15.09Al5.35.

- Fig. 4. Internal friction tanδ, storage modulus E'and amortization modulus E'' variations with temperature.

- Fig. 5. DSC thermogram recorded during a heating cooling cycle up to 473 K of fragments cut from tensioned 4% sample of CuZnAl shape memory alloy.

- Fig. 6. Variation diagram of internal friction, tanδ and storage elasticity modulus E' of a shape memory alloy type Cu68,1 Zn13,2 Al4,85, with temperature first heating cycle being represented with black color, cooling with blue and second heating cycle with red.

7. Conclusion:

The study successfully demonstrated that a classically melted CuZnAl shape memory alloy possesses good shape memory effect and excellent damping properties. The key conclusions are:

- The alloy exhibits a high internal friction peak in its martensitic state, with values of 0.11635 in the deformed state and 0.1607 in the tensioned state, making it suitable for practical damping applications.

- Applying deformation and tension effectively shifts the critical transformation temperature domain to the left (lower temperatures), "taking" the internal friction peak with it. This allows for tuning the material's optimal damping range.

- The variation in storage modulus is inversely related to the internal friction, with the modulus reaching a minimum where damping is at its maximum, confirming the connection to the martensitic transformation.

8. References:

- [1] J. V. Humbeeck, J. Alloys Comp. 355, 58 (2003).

- [2] J. San Juan, J. M. L. Nó, J. Alloys Comp. 355, 65 (2003).

- [3] M. Vogelsang, R. Arsenadet, R. Fisher, Metall. Mater. Trans., A Phys.Metall. Mater. Sci. 17, 379 (1986).

- [4] T. Christman, S. Suresh, Acta Metall. Mater. 36, 1691 (1988).

- [5] D. C. Dunand, A. Mortensen, Acta Metall. Mater. 39, 1405 (1991).

- [6] F. S. Shieu, S. L. Sass, Acta Metall. Mater. 39, 539 (1991).

- [7] F. Ddeborde, V. Pelosin, A. Rivi´ere, Scripta Mater. 33, 1993 (1995).

- [8] S. Golyandin, S. Kustov, K. Sapozhnikov, M. Parlinska, R. Gotthardt, J. van Humbeeck, J. Alloy Compd. 310, 312 (2000).

- [9] G. Song, N. Ma, H.-N. Li, Engineering Structures 28 1266 (2006).

- [10] G. Guenin, Memoire de forme et alliages cuivreux, Traitement thermique, 234, 21 (1990).

- [11] I. L. Pelegrina, M. Chandrasekaran, M. S. Andrade, Acta metall. 36, 1111 (1988).

- [12] W. De Jonghe, R. De Batist, L. Delaey, M. De Bonte, Internal Friction Measurements onCopper - Zinc Based Martensite, în " Shape Memory Effects in Alloys" - editată de Jeff Perkins. Plenum Press, New York - London, 1975.

- [13] N. Cimpoeşu, S. Stanciu, D. Achiței, V. Manole, R. Hanu Cimpoeșu, J. Optoelectron. Adv. Mater. -Symposia, 1(6), 1149 (2009).

- [14] E. Patoor, M. Berveiller (coordonnateurs), – Technologie des alliages à mémoire de forme. Comportement mécanique et mise en oeuvre, Hermès, Paris, 1994, ISBN 2-86601-426-X, 228.

- [15] S. H. Chang, S. K. Wu, Key Eng. Mater. 319, 9 (2006).

- [16] S. H. Chang, S. K. Wu, Scripta Mater. 55, 311 (2006).

- [17] S. H. Chang, S. K. Wu, J. Alloys Compd. 437, 120 (2007).

- [18] S. H. Chang, S. K. Wu, Mater. Sci. Eng. A 454-455 379 (2007).

- [19] N. Cimpoesu S. Stanciu, Shape memory alloys type CuZnAl and CuMnAl comparison of their energy dissipation capacity, Proceedings of International Conference Tehnomus XIV, 2009, Suceava.

Expert Q&A: Your Top Questions Answered

Q1: What is the primary benefit of the CuZnAl alloy investigated in this paper? A1: The primary benefit is its exceptionally high damping capacity (also called internal friction). The study shows it can achieve internal friction (tan δ) values as high as 0.1607, which allows it to effectively dissipate vibrational energy, making it a promising material for passive damping applications (Source: Figure 6, Conclusions).

Q2: How does applying stress, like forging or tension, affect the alloy's performance? A2: Applying stress has two major positive effects. First, it increases the peak damping capacity of the material. Second, it shifts the temperature at which this peak damping occurs to a lower, often more practical, range. For example, tension increased the peak from 0.11635 to 0.1607 and lowered its effective temperature (Source: Conclusions, comparison of Figure 4 and Figure 6).

Q3: What is the underlying physical mechanism that causes this high damping? A3: The high damping capacity is a direct result of the reversible martensitic phase transition and the stress-induced reorientation of martensite variants within the alloy's microstructure. This process is inherently energy-dissipative (Source: Introduction, Ref. [1, 2]).

Q4: What is the practical significance of the internal friction peak observed at 363 K (90°C) in the deformed state? A4: This peak, with a value of 0.11635, demonstrates that the material has very high damping properties in a temperature range relevant to many industrial and engineering applications. It confirms that the material can be processed (forged) to exhibit strong damping at specific elevated temperatures (Source: Figure 4).

Q5: Why is it important that tension shifts the transformation range closer to room temperature? A5: Shifting the high-damping transformation range to lower temperatures (e.g., peak at 333.8 K or 60.8°C in the tensioned state) makes the material's superior properties accessible in more common operating environments without requiring significant external heating. This greatly expands its potential for direct use in various structures and devices (Source: Section 5, Figure 5, Figure 6).

Q6: Can this specific CuZnAl alloy be used in High-Pressure Die Casting? A6: The paper does not investigate HPDC; it uses a "classical melting method" in a laboratory setting. While this specific alloy may not be directly suitable for HPDC, the research provides a critical insight: the principles of enhancing damping through alloy composition and, most importantly, post-casting mechanical stress, are extremely valuable. This study serves as a blueprint for developing future advanced HPDC alloys with engineered, high-performance damping characteristics.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing vibration damping in metallic components. The findings offer a clear, data-driven path toward optimizing material performance by demonstrating that mechanical stress is a powerful lever for tuning both the magnitude and effective temperature range of a material's damping capacity.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues of vibration control and material performance discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement advanced material principles in your components.

Copyright

- This material is a paper by "N. CIMPOEȘU, S. STANCIU, M. MAYER, I. IONIȚĂ, R. HANU CIMPOEȘU". Based on "Effect of stress on damping capacity of a shape memory alloy CuZnAl".

- Source of the paper: JOURNAL OF OPTOELECTRONICS AND ADVANCED MATERIALS Vol. 12, No. 2, February 2010, p. 386 - 391.

This material is for informational purposes only. Unauthorized commercial use is prohibited. Copyright © 2025 CASTMAN. All rights reserved.