Boosting Durability of SKD61 Die-Casting Steel: A Data-Driven Look at Ti/Cr vs. Ti/Mo PVD Coatings

This technical brief is based on the academic paper "Comparative Analysis on the Surface Property of SKD 61 Die-casting Steel Using Multilayer PVD Coating" by Seung Wook Kim, published in the Journal of the Semiconductor & Display Technology (2021). It is summarized and analyzed for HPDC professionals by the experts at CASTMAN.

Keywords

- Primary Keyword: SKD61 PVD Coating

- Secondary Keywords: Die-casting steel, Plunger sleeve, Thermal fatigue, Surface hardness, Residual stress, Surface roughness, Ti/Cr coating

Executive Summary

- The Challenge: SKD61 steel, a cornerstone material for high-pressure die-casting (HPDC) tools like plunger sleeves, rapidly degrades from thermal fatigue, erosion, and corrosion at operating temperatures exceeding 600°C.

- The Method: Researchers applied multilayer Physical Vapor Deposition (PVD) coatings of Titanium/Chromium (Ti/Cr) and Titanium/Molybdenum (Ti/Mo) at two different thicknesses (1.0 µm and 1.5 µm) onto SKD61 steel samples. They then evaluated surface hardness, roughness, and residual stress after a high-temperature thermal test.

- The Key Breakthrough: The Ti(1.5µm)/Cr(1.5µm) coating combination significantly outperformed all other configurations. It delivered the highest surface hardness, the lowest surface roughness after thermal exposure, and the most beneficial compressive residual stress.

- The Bottom Line: A thick, multilayer Ti/Cr PVD coating is a highly effective and data-supported strategy for enhancing the surface integrity, durability, and operational lifespan of critical SKD61 die-casting components.

The Challenge: Why This Research Matters for HPDC Professionals

In the demanding world of die-casting, the longevity and reliability of tooling are paramount. SKD61 hot-work tool steel is a common choice for molds and critical components like plunger sleeves due to its inherent properties. However, the extreme working environment—characterized by high temperatures (over 600°C), high pressure, and repeated thermal cycling—imposes severe thermal, mechanical, and chemical stresses on the material.

A primary failure mode, especially at the inlet of a plunger sleeve where molten metal is repeatedly injected, is thermal fatigue. This leads to surface erosion and corrosion, which directly compromises the quality of the final cast products and leads to costly downtime for tool replacement. While various surface improvement techniques exist, there is a pressing need for a more effective solution to protect these critical surfaces. This study directly addresses this challenge by systematically evaluating advanced PVD coatings to find an optimal solution.

The Approach: Unpacking the Methodology

To identify the most robust surface treatment, the researcher conducted a rigorous comparative study. The methodology was as follows:

- Base Material: Samples were fabricated from SKD61 die-casting steel, the target material for improvement.

- Coating Application: A multilayer PVD coating was applied using a DC sputtering process. The top layer was always Titanium (Ti) to facilitate deposition and prevent oxidation, while the bottom layer was either Chromium (Cr) or Molybdenum (Mo) to provide key mechanical properties.

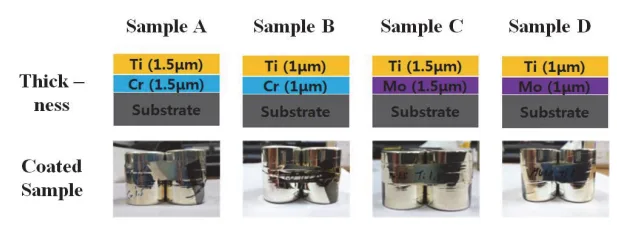

- Sample Groups: Four distinct sample groups were created to compare both material and thickness, as detailed in Figure 1:

- Sample A: Ti (1.5µm) / Cr (1.5µm)

- Sample B: Ti (1.0µm) / Cr (1.0µm)

- Sample C: Ti (1.5µm) / Mo (1.5µm)

- Sample D: Ti (1.0µm) / Mo (1.0µm)

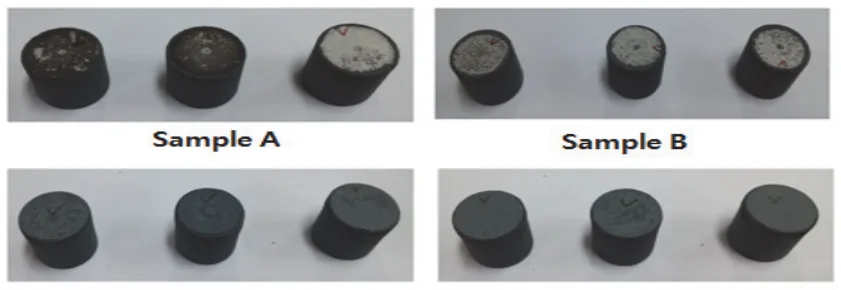

- Simulated Thermal Fatigue: To mimic the harsh conditions of die-casting, all coated samples were subjected to a heat treatment test at 800°C for 24 hours (see Figure 2).

- Performance Analysis: After the thermal test, the samples were analyzed for three critical surface properties:

- Surface Hardness (HRB, HRC): Measured to determine resistance to deformation.

- Surface Roughness (Rsa, Rsq): Measured using a Confocal Laser Scanning Microscope (CLSM) to quantify surface degradation.

- Residual Stress: Measured using an X-ray Diffractometer (XRD) to analyze the internal stresses that influence fatigue life.

The Breakthrough: Key Findings & Data

The study yielded clear and decisive results, pointing to a superior coating strategy for SKD61 steel.

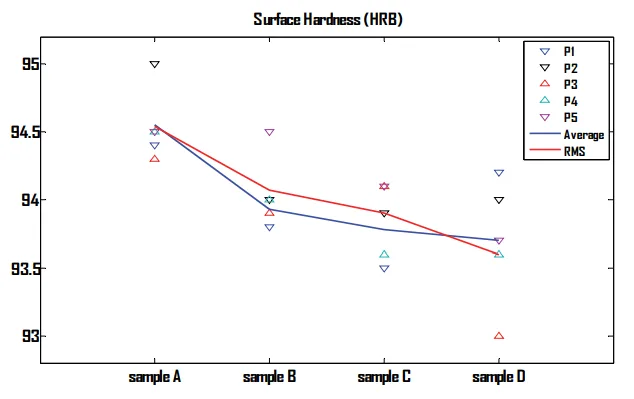

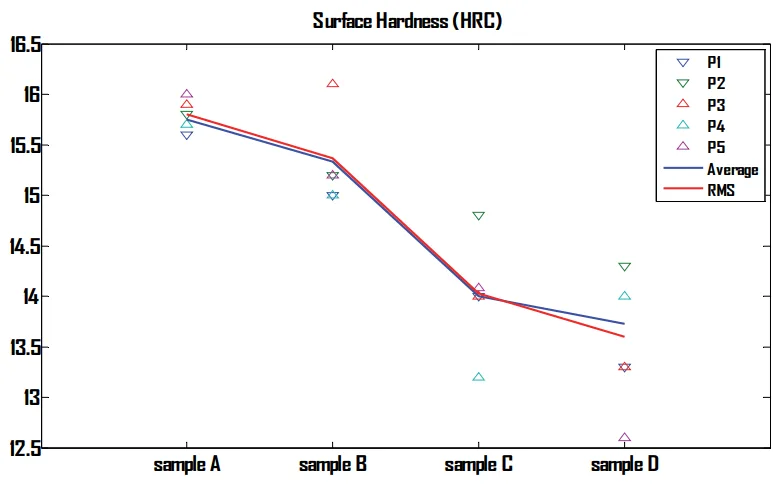

- Finding 1: Ti/Cr Coatings Deliver Superior Hardness The samples coated with Ti/Cr (A and B) consistently demonstrated higher surface hardness (both HRB and HRC) compared to the Ti/Mo coated samples (C and D). Furthermore, the thicker 1.5µm coating (Sample A) provided the highest hardness of all. This is clearly illustrated in the hardness measurement graphs in Figure 4 and Figure 5. The paper attributes this to the higher intrinsic hardness of Cr and its smaller covalent bond radius, which creates a stronger material structure.

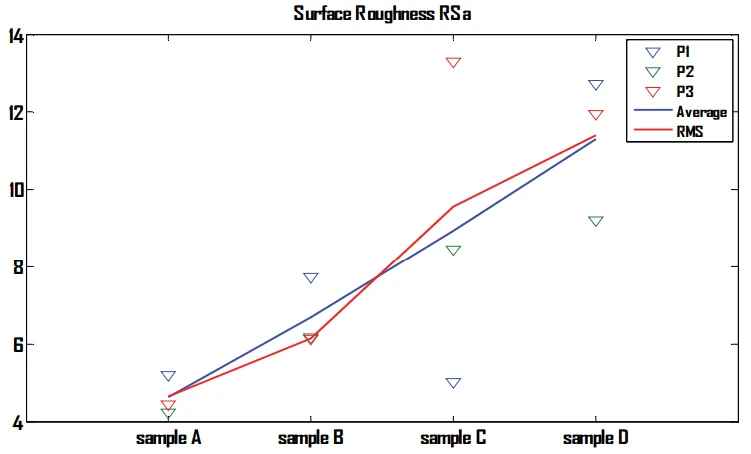

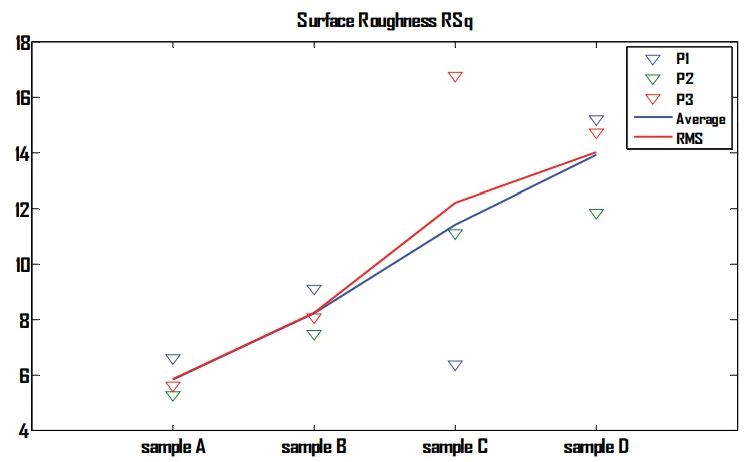

- Finding 2: Ti/Cr Coatings Best Resist Surface Degradation After the 800°C thermal test, the Ti/Cr coated samples exhibited significantly lower surface roughness (Rsa and Rsq) than the Ti/Mo samples. As shown in Figure 6 and Figure 7, Sample A (Ti 1.5µm / Cr 1.5µm) maintained the smoothest surface, indicating the best resistance to thermal degradation and fatigue.

- Finding 3: All Coatings Induce Beneficial Compressive Stress The XRD analysis revealed that all PVD coatings successfully induced compressive residual stress, which is highly desirable for improving fatigue resistance. The Ti/Cr coatings generated higher compressive stress than the Ti/Mo coatings. Critically, Figure 10 shows that Sample A possessed the highest compressive residual stress value (-440.1 MPa), confirming its superior ability to withstand cyclic loading.

Practical Implications for Your HPDC Operations

The conclusions drawn from this research offer actionable insights for manufacturing professionals seeking to improve tool life and product quality.

- For Process Engineers: The findings strongly suggest that specifying a Ti/Cr PVD coating over a Ti/Mo alternative for SKD61 components can significantly enhance resistance to thermal fatigue. Opting for a thicker coating (e.g., 1.5µm) can further maximize this benefit, potentially extending the service life of plunger sleeves and reducing maintenance-related downtime.

- For Quality Control: The clear correlation shown in this study between the Ti(1.5µm)/Cr(1.5µm) coating and superior surface properties provides a robust, data-backed specification for sourcing or applying coatings to critical die-casting tools. This can help ensure higher, more consistent performance.

- For Die Design & Material Selection: When designing new tools from SKD61 steel that will face severe thermal cycling, this research implies that incorporating a Ti(1.5µm)/Cr(1.5µm) PVD coating into the initial design is a cost-effective strategy to build in longevity and superior resistance to erosion and corrosion.

Paper Details

Comparative Analysis on the Surface Property of SKD 61 Die-casting Steel Using Multilayer PVD Coating

1. Overview:

- Title: Comparative Analysis on the Surface Property of SKD 61 Die-casting Steel Using Multilayer PVD Coating

- Author: Seung Wook Kim

- Year of publication: 2021

- Journal/academic society of publication: Journal of the Semiconductor & Display Technology, Vol. 20, No. 2. June 2021.

- Keywords: Thermal fatigue, PVD, Plunger sleeve, Surface hardness, Surface roughness, Residual stress, XRD

2. Abstract:

The properties of materials which are widely used in industry fields like automobile, shipbuilding, casting, and electronics are strongly needed to have higher surface hardness, lower surface roughness, and higher compressive residual stress. As mentioned above, for the purpose of satisfying three factors, a variety of researches with respect to surface improvement have been actively studied and applied to every industry. SKD61 which is mostly used for die casting process of cold chamber method must meet a countless number of problems which are thermal, mechanical and chemical from highly specific working environment at high temperature over 600°C. Above all, in case of plunger sleeves used for die casting process, thermal fatigue has a bad effect on the surface of an inlet where molten metal is repeatedly injected. On account of it, plunger sleeves cause manufacturers to deteriorate quality of products. Therefore, in this paper, to improve the surface of an inlet of plunger sleeve, multilayer PVD coating using Ti, Cr and Mo is suggested. Furthermore, The surface characteristics such as surface roughness(Rsa, Rsq), surface hardness(HRB, HRC) and residual stress using XRD(X-ray diffractometer) of coated samples and specimens are studied and discussed.

3. Introduction:

SKD61 tool steel is a primary material for hot press, hot forging, and die-casting molds, as well as high-temperature tools. The harsh working environment of high temperature and pressure demands that SKD61 possess high hardness, toughness, and resistance to deformation. Plunger sleeves, a critical component in die-casting, are primarily made from SKD61 and face a combination of mechanical, thermal, and chemical challenges. At temperatures exceeding 600°C, the repeated injection of molten metal leads to erosion and corrosion, primarily caused by thermal fatigue. This degradation compromises product quality. While various methods like ion nitriding, EDM, and PVD coatings have been researched, an efficient method for improving the surface of the plunger sleeve inlet has remained elusive.

4. Summary of the study:

Background of the research topic:

The study is grounded in the industrial need to improve the performance of SKD61 steel used in high-temperature die-casting applications. The material's surface properties—specifically hardness, roughness, and residual stress—are critical factors that determine its resistance to wear, friction, and fatigue, directly impacting tool life and product quality.

Status of previous research:

The paper acknowledges that various surface improvement methods are actively being researched, including ion nitriding, Electrical Discharge Machining (EDM), and PVD coatings. However, it notes that despite these efforts, the surface performance of the plunger sleeve inlet, a particularly vulnerable area, has not been effectively improved.

Purpose of the study:

The primary goal of this research was to identify an optimal multilayer PVD coating to improve the surface properties of the SKD61 plunger sleeve inlet. The study aimed to systematically compare coatings made of Titanium (Ti), Chromium (Cr), and Molybdenum (Mo) and analyze their effects on surface roughness, surface hardness, and residual stress.

Core study:

The core of the study involved fabricating four sets of SKD61 samples with different PVD coatings: Ti(1.5µm)/Cr(1.5µm), Ti(1.0µm)/Cr(1.0µm), Ti(1.5µm)/Mo(1.5µm), and Ti(1.0µm)/Mo(1.0µm). These samples were then subjected to a high-temperature test to simulate thermal fatigue. Following the test, a comparative analysis of their surface characteristics was performed to determine the most effective coating combination and thickness.

5. Research Methodology

Research Design:

The experiment was designed as a comparative study. SKD61 steel was selected as the substrate material. Four sample types were prepared by applying multilayer PVD coatings using a DC sputtering technique. The variables were the bottom layer material (Cr or Mo) and the coating thickness (1.0 µm or 1.5 µm for each layer).

Data Collection and Analysis Methods:

- Surface Hardness: Measured using a Wilson hardness tester. HRB tests were conducted with a 100 kgf load, and HRC tests used a 10 kgf preload and 150 kgf main load.

- Surface Roughness: Analyzed using a Confocal Laser Scanning Microscope (CLSM, Calz Zeiss, Germany) to determine the arithmetic mean roughness (Rsa) and root mean square roughness (Rsq).

- Residual Stress: Measured using an X-ray Diffractometer (XRD, X'pert PRO-MRD, PHILIPS, Netherland). The sin²ψ method was employed, focusing on the (211) lattice plane, to calculate the compressive or tensile residual stress in the coatings.

Research Topics and Scope:

The research focused exclusively on SKD61 steel. The scope was limited to comparing the effects of multilayer PVD coatings composed of Ti, Cr, and Mo on three key surface properties: hardness, roughness, and residual stress. The analysis was conducted after a simulated thermal fatigue test to assess performance under conditions relevant to die-casting.

6. Key Results:

Key Results:

The experimental results demonstrated a clear hierarchy of performance among the tested coatings.

- Hardness: The Ti/Cr coated samples (A and B) were significantly harder than the Ti/Mo coated samples (C and D). The thickest Ti/Cr coating (Sample A) exhibited the highest average hardness values (Figures 4 and 5).

- Roughness: After the 800°C thermal test, the Ti/Cr coatings maintained a much smoother surface. Sample A had the lowest roughness values (Rsa and Rsq), indicating superior resistance to thermal degradation (Figures 6 and 7).

- Residual Stress: All coatings successfully introduced beneficial compressive residual stress. The Ti/Cr coatings showed higher compressive stress values than the Ti/Mo coatings. Sample A, with the thickest Ti/Cr coating, registered the highest compressive stress of -440.1 MPa, indicating the greatest potential for improved fatigue life (Figure 10).

Figure Name List:

- Fig. 1. Thin film thickness and actual features of the coated samples.

- Fig. 2. Sample to measure and analyze surface roughness and surface hardness after the test at 800°C for a day(24 h) by using heat treatment furnace.

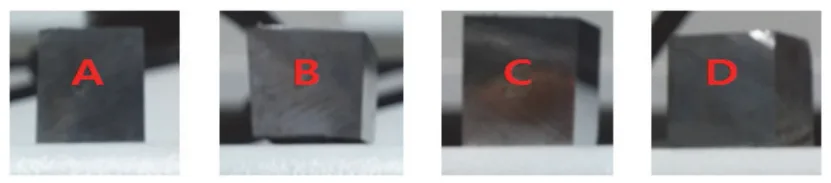

- Fig. 3. The specimens to measure and analyze residual stress using XRD.

- Fig. 4. Surface Hardness(HRB).

- Fig. 5. Surface Hardness(HRC).

- Fig. 6. Surface roughness (RSa).

- Fig. 7. Surface roughness (RSq).

- Fig. 8. Pretest results to determine planes for the purpose of measuring residual stress.

- Fig. 9. Diffracted intensity versus 20 in terms of the lattice plane(211) from the X-ray incidence angles(ψ) : 0°, 18.22°, 26.25°, 32.80°, 38.72°, 43.37° and 50° respectively.

- Fig. 10. The measured and calculated compressive residual stress on the lattice plane (211) by XRD software.

7. Conclusion:

The study concludes that the surface condition of metallic materials is critical, with surface roughness, hardness, and residual stress being decisive factors. The research aimed to improve the SKD61 surface for die-casting applications by comparing multilayer PVD coatings. The selection of Ti for the top layer was to facilitate deposition and prevent oxidation, while Cr was chosen for its high hardness and Mo for its corrosion resistance and high melting point.

The results conclusively show that the sample coated with Ti(1.5µm)/Cr(1.5µm) (Sample A) exhibited the most superior surface characteristics. It had the highest surface hardness, the lowest surface roughness after thermal testing, and the largest compressive residual stress. Therefore, the paper concludes that the DC sputtered PVD coating of Ti(1.5µm)/Cr(1.5µm) is the most effective treatment among those tested for enhancing the surface properties of SKD61 steel.

8. References:

- Gyujin Park, Min-Woo Kang, Jae-Gil Jung, Young-Kook Lee, Byung-Hoon Kim, "The Effects of Homogenization, Hot-Forging, and Annealing Condition on Microstructure and Hardness of a Modified STD61 Hot-Work Tool Steel", J. of the Korean Society for Heat Treatment, Vol. 26, No. 2, pp. 72-79, 2013.

- S. W. Kim, S. R. Lee, Y. K. Kim, W. K. Lee, D. Y. Lee, "Development of Die-casting Plunger Sleeve for Separation and Structure Analysis via Tread Joint", Conf of KSPE, pp.596-597,

- F. Miglierina, B. Vianello, “Shot Sleeve With Integral Thermal Regulation", Proceedings of 6th Tooling int. Conf. on The use of Tool Steels, Vol. 2. pp. 1317-1341, 2002.

- Yucong Wang, "A study of PVD coatings and die materials for extended die-casting die life", Surface and Coatings Technology, Vol .94-95, pp. 60-63, 1997.

- R.Shivpuri, M. Yu, K.Venkatesan, Y.-L Chu, “A study of erosion in die casting dies by a multiple pin accelerated erosion test", Journal of Materials Engineering and Performance, Vol. 4, Issue 2, pp. 145-153, 1995.

- Banh Tien Long, Ngo Cuong, Nguyen Huu Phan and Vijay Kumar S. Jatti, "Surface improvement of SKD61 die steel material after electrical discharge machining with graphite electrode", Jounal of Chemical and Pharmaceutical Research, 2015,7(7):1204-1211.

- R. Shivpuri, Y. L. Chu, K. Venkatesan, J. R. Conrad, K. Sridhara, M. Shamim, R. P. Fetherston, "An evaluation of metallic coatings for erosive wear resistance in die casting applications", Wear, Vol. 192, Issues 1-2, pp. 49-55, 1996.

- C. M. Seo and S. Y. Oh, "Fatigue and Fracture Mechanics", Won Chang, pp. 50-61, 2009.

- Shu-Hung Yeh, Liu-Ho Chiu, Tao-Liang Chuang, Cheng-Yen Wu, "Thermal Fatigue Behavior Evaluation of Shot-Peened JIS SKD61 Hot-Work Mold Steel", Material Transactions, Vol.54, No.6, pp.1053-1056, 2013.

- https://www.dcu.ie/mechanicalengineering/technical/undergrad/millingguide.shtml.

- http://serc.carleton.edu/research_education/geochemsheets/techniques/XRD.html.

- J.P. Nobre, M.Kornmeier, A.M. Dias, B. Scholtes, "Use of the hole-drilling method for measuring residual stresses in highly stressed shot-peened surface", Experimental Mechanics, Vol.40, Issue 3, pp 289-297, 2000.

- Dong-Woo Lee and Seok-Swoo Cho, “Comparison of X-ray residual stress measurements for rolled steels", International Journal of precision Engineering and Manufacturing December, Vol. 12, Isssue 6, pp. 1001-1008, 2011.

- Sung-Youn Chun, Ji-Won Baek, "A Comparative Study of CrN Coatings Deposited by DC and Asymmetric Bipolar Pulsed DC Sputtering", J. Kor. Inst. Surf. Eng. Vol.47, No.2. pp 86-92, 2014.

- Yang-Soon Park, Sun-Ho Han and Kyuseok Song, "Oxidation behavior on the surface of titanium metal specimens at high temperatures (300~1000°C)", Analytical Sciencce & Technology Vol. 22, No.6, 464-470, 2009.

- J. Winiarski, W. Tylus, K. Winiarska, B. Szczygiel, "The influence of molybdenum on the corrosion resistance of ternary Zn-Co-Mo alloy coatings deposited from citrate-sulphate bath", Corrosion Science February, Vol.91, pp. 330-340, 2015.

- Confocal Laser Scanning Microscopy operating manual, ZEISS.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the durability of SKD61 steel in demanding HPDC applications. The findings offer a clear, data-driven path toward improving tool quality, reducing defects, and optimizing production through the strategic application of advanced PVD coatings.

CASTMAN is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the problem discussed in this white paper aligns with your research goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your research.

Expert Q&A:

- Q1: Which PVD coating combination provided the best overall performance for SKD61 steel in this study? A: The Ti(1.5µm)/Cr(1.5µm) multilayer coating (Sample A) demonstrated the most superior surface properties. It achieved the highest surface hardness (HRB and HRC), the lowest surface roughness (Rsa and Rsq) after thermal testing, and the largest beneficial compressive residual stress. This is detailed in the paper "Comparative Analysis on the Surface Property of SKD 61 Die-casting Steel Using Multilayer PVD Coating" and supported by the data across Figures 4, 5, 6, 7, and 10.

- Q2: Why did the Ti/Cr coatings perform better than the Ti/Mo coatings in terms of hardness? A: The paper suggests two reasons for the superior hardness of the Ti/Cr coatings. First, Chromium (Cr) has a higher Mohs hardness value (8.5) compared to Molybdenum (Mo) (5.5). Second, the covalent bond radius of Cr (139±5 pm) is smaller than that of Mo (154±5 pm), leading to a stronger interatomic bond in the Cr crystals, which results in higher surface hardness. This is explained in section 4.1 of the paper.

- Q3: Does the thickness of the PVD coating matter? A: Yes, the study clearly shows that for the same coating materials, a thicker coating resulted in better surface properties. For example, the 1.5µm Ti/Cr coating (Sample A) had higher hardness and lower roughness than the 1.0µm Ti/Cr coating (Sample B). The same trend was observed for the Ti/Mo coatings. The conclusion states that "in case of the same coating materials, the thicker the coating thickness, the better the surface characteristics of the SKD61 base material."

- Q4: What is residual stress, and why is compressive stress important for die-casting tools? A: Residual stress is the stress that remains in a material after the original cause of the stress has been removed. In this study, the researchers measured it using XRD. Compressive residual stress is beneficial for components subjected to fatigue because it counteracts the tensile stresses that cause cracks to form and grow. The paper confirms that all tested coatings induced compressive residual stress, with the Ti/Cr coatings showing higher values, which is advantageous for improving the fatigue life of SKD61 steel components. This is shown in the d-spacing vs. sin²ψ plots in Figure 10, where a negative slope indicates compressive stress.

- Q5: How was the effect of thermal fatigue simulated in this experiment? A: To simulate the harsh thermal environment of die-casting, the coated samples were subjected to a heat treatment test. As described in the "3. Fabrication of Samples and Specimen" section, the samples were placed in a heat treatment furnace at 800°C for 24 hours. The surface properties were then measured after this thermal exposure to evaluate their resistance to degradation, as shown in Figure 2.

Copyright

- This material is an analysis of the paper "Comparative Analysis on the Surface Property of SKD 61 Die-casting Steel Using Multilayer PVD Coating" by Seung Wook Kim.

- Source of the paper: Journal of the Semiconductor & Display Technology, Vol. 20, No. 2. June 2021.

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 CASTMAN. All rights reserved.