Beyond the Surface: How Severe Plastic Deformation Boosts Biomedical Implant Performance

This technical brief is based on the academic paper "Properties of the nanocrystalline layers obtained by methods of severe plastic deformation in metals and alloys for biomedical applications" by Konrad Skowron, submitted for the Degree of Doctor of Philosophy in Physics (Kraków 2021). It is summarized and analyzed for HPDC and manufacturing professionals by the experts at CASTMAN.

![Figure 2.3 Schematic of a low and high angle grain boundary and the angle of misorientation [8].](https://castman.co.kr/wp-content/uploads/image-2527.webp)

Keywords

- Primary Keyword: Severe Plastic Deformation (SPD)

- Secondary Keywords: Nanocrystalline Layers, Biomedical Implants, Surface Mechanical Attrition Treatment (SMAT), Laser Shock Peening (LSP), Corrosion Resistance, Magnesium, Titanium, 316L Stainless Steel

Executive Summary

- The Challenge: The failure of medical implants, often starting at the surface due to fatigue, wear, or corrosion, is a critical issue, especially with an aging population demanding more durable prosthetics.

- The Method: This research investigates the use of Severe Plastic Deformation (SPD) techniques, specifically Surface Mechanical Attrition Treatment (SMAT) and Laser Shock Peening (LSP), to create gradient nanocrystalline layers on the surface of common biometals like magnesium, titanium, and 316L stainless steel.

- The Key Breakthrough: The study successfully demonstrates that these SPD methods create a dense layer of crystal lattice defects, which significantly improves the material's properties. Notably, SMAT was found to enhance the corrosion resistance of both magnesium and titanium.

- The Bottom Line: By precisely controlling the formation of nanocrystalline structures, SPD surface treatments offer a powerful, data-driven pathway to producing safer, longer-lasting biomedical components without altering the bulk material.

The Challenge: Why This Research Matters for HPDC Professionals

In the face of an increasingly aging society, the demand for safe and durable materials for prosthetics has never been higher. As detailed in the paper's introduction, implant failure is a major clinical concern, and it almost always begins at the surface. The human body is a highly corrosive environment, and the constant stresses of fatigue and wear can compromise an implant's integrity over time (Introduction, p. 17).

While methods like physical vapor deposition (PVD) can create protective surface layers, their bond with the substrate can be a point of failure. This research tackles the problem from a different angle: modifying the inherent structure of the metal's surface itself. The study focuses on biometals like magnesium, titanium, and 316L stainless steel, which are the workhorses of the medical implant industry but each have their own challenges, from magnesium's high corrosion rate to the need for improved wear resistance in titanium and steel (Chapter 1, p. 21). Understanding how to enhance these materials at a microstructural level is key to the next generation of medical devices.

The Approach: Unpacking the Methodology

To generate and analyze these advanced surface layers, the researcher employed a multi-faceted, interdisciplinary approach combining physics, materials science, and electrochemistry.

The core of the study involved two primary SPD methods (Chapter 3, p. 41):

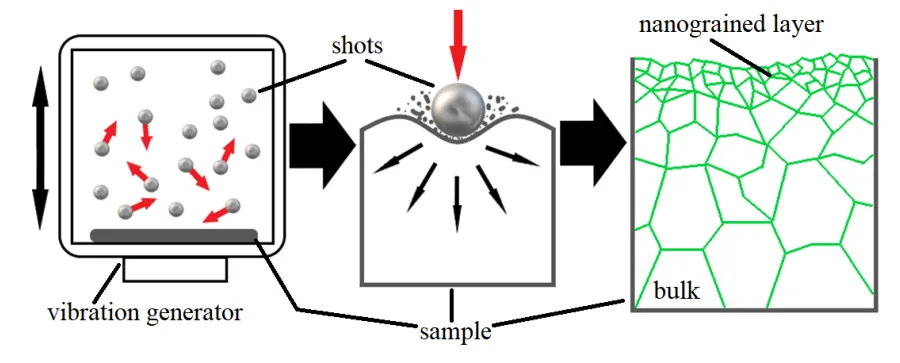

1. Surface Mechanical Attrition Treatment (SMAT): This method uses high-frequency vibrations to propel small spherical shots against the material's surface. This repeated, multidirectional impact induces severe plastic deformation, refining the grain structure into a nanocrystalline state in the top layer (Chapter 3.3.1, p. 45).

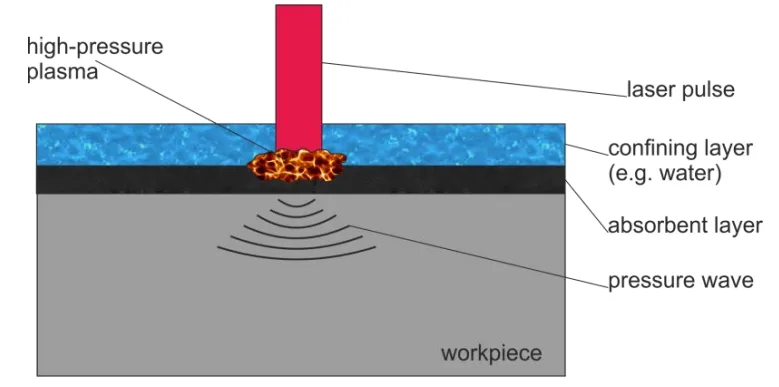

2. Laser Shock Peening (LSP): In this technique, high-energy laser pulses create a rapidly expanding plasma on the material's surface, generating a shockwave that travels into the material. This shockwave also induces intense plastic deformation and creates a gradient of refined grains (Chapter 3.3.2, p. 46).

To measure the resulting changes, a suite of advanced analytical techniques was used:

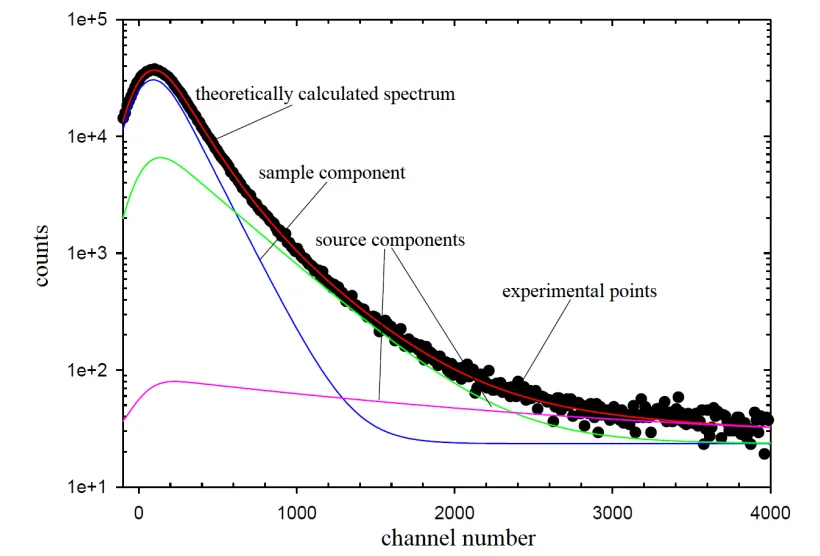

- Positron Annihilation Spectroscopy (PAS): As the main research method, PAS was used to track and distinguish different types of crystal lattice defects, like vacancies and dislocations, providing a unique, non-destructive view into the material's subsurface changes (Chapter 4, p. 51).

- Complementary Analysis: The PAS results were combined with microhardness tests, X-ray Diffraction (XRD), Electron Backscatter Diffraction (EBSD), and electrochemical corrosion tests to build a comprehensive picture of the modified materials' properties (Abstract, p. 7).

The Breakthrough: Key Findings & Data

The research yielded significant insights into the relationship between defect structures created by SPD and the resulting material properties.

Defect-Rich Layers Confirmed: For all materials studied (Mg, Ti, 316L steel), both SMAT and LSP successfully created a gradient microstructure with a high density of defects and a nanocrystalline top layer. PAS measurements allowed for the determination of the total depth of these affected layers, which was found to be over twice as large for magnesium as for titanium under similar SMAT conditions (Thesis Summary, p. 164).

SMAT Enhances Corrosion Resistance: Electrochemical tests showed that the microstructure induced by SMAT improves the corrosion resistance of both magnesium and titanium. The study suggests this is because the high defect concentration promotes the formation of a tighter, more stable, corrosion-resistant barrier layer on the surface (Chapter 9.3.5, p. 140; Chapter 9.4, p. 149). As shown in Figure 7.20, the corrosion behavior of SMATed magnesium was significantly improved compared to the untreated reference sample.

Defect Type and Hardness Correlation: The study successfully correlated the type and depth of defects with mechanical properties. For SMATed magnesium, a plateau of high mean positron lifetime (indicating high defect concentration) extended to a depth of about 200 µm, which coincided with the thickness of the highly deformed layer observed with EBSD and microhardness tests (Figure 7.13 and Figure 7.14).

Thermal Stability Mapped: The study of isochronal annealing revealed two distinct stages of defect recovery in titanium. The first stage, between 150-200 °C, was linked to the disappearance of vacancy clusters, while the second, more gradual stage was related to the recovery of dislocations. This provides a critical thermal processing map for these advanced materials (Chapter 10, Summary, p. 160).

Practical Implications for Your HPDC Operations

The findings presented in this paper, while focused on biomedical applications, have direct and valuable implications for any high-performance manufacturing operation, including high-pressure die casting.

For Process Engineers: This research demonstrates that mechanical surface treatments like SMAT are not just for finishing but are powerful tools for targeted property enhancement. The data shows a clear link between process parameters (e.g., treatment duration, vibration amplitude) and the resulting depth and density of the hardened, defect-rich layer (Chapter 7.3.3). This suggests that such processes can be precisely tuned to achieve desired surface hardness and durability in critical components.

For Quality Control: The use of Positron Annihilation Spectroscopy (PAS) as a tool to quantify defect concentration (Chapter 6) highlights the potential for advanced, non-destructive evaluation (NDE) techniques. The correlation between PAS results and improved material properties suggests that such methods could be used to validate the effectiveness of surface treatments and ensure consistent quality in high-performance parts.

For Die Design and Material Selection: The study reinforces the principle that a material's performance is profoundly influenced by its microstructure. For applications requiring extreme surface durability and corrosion resistance, incorporating a post-casting surface treatment like SMAT or LSP could allow for the use of more cost-effective alloys or enable existing alloys to perform in more demanding environments. The findings on 316L steel (Chapter 8) and titanium (Chapter 9) are particularly relevant for industries where strength and corrosion resistance are paramount.

Paper Details

Properties of the nanocrystalline layers obtained by methods of severe plastic deformation in metals and alloys for biomedical applications

1. Overview:

- Title: Properties of the nanocrystalline layers obtained by methods of severe plastic deformation in metals and alloys for biomedical applications

- Author: Konrad Skowron

- Year of publication: 2021

- Journal/academic society of publication: Thesis submitted for the Degree of Doctor of Philosophy in Physics, The Henryk Niewodniczański Institute of Nuclear Physics Polish Academy of Sciences and Jerzy Haber Institute of Catalysis and Surface Chemistry Polish Academy of Sciences

- Keywords: nanocrystalline materials, severe plastic deformation, SMAT, LSP, positron annihilation spectroscopy, corrosion, biometals

2. Abstract:

Due to the increasing demand for durable materials that can be used in the production of prosthetics, biometals have been attracting much interest in recent years. Implant failure usually begins on its surface as a result of fatigue, wear, or corrosion. The destruction process can be slowed down by the application of appropriate surface modification techniques which lead to the formation of a nanocrystalline structure on the surface of the implant, especially those based on severe plastic deformation. The main objective of the presented thesis is to study how the presence of crystal lattice defects introduced during severe plastic deformation is correlated with the properties of biometals, especially their corrosion resistance. The subject of the present research are gradient microstructures with nanocrystalline top layers generated by surface mechanical attrition treatment (SMAT) and laser shock peening (LSP) in biometals such as magnesium, titanium, and 316L stainless steel. The use of positron annihilation spectroscopy allowed obtaining defect depth distributions in the deformed surface layers which were compared with the observed microstructure, microhardness profiles, and residual stresses. It was demonstrated that SMAT improved corrosion resistance of magnesium and titanium and the correlation between the defect concentration and corrosion resistance of the materials studied was found.

3. Introduction:

The introduction highlights the growing need for durable biomaterials for prosthetics in an aging society. It establishes that implant failure typically originates at the surface from corrosion, fatigue, or wear. It proposes that surface modification methods, particularly those based on severe plastic deformation (SPD), can create nanocrystalline layers that enhance durability. Unlike deposition methods (PVD, CVD), SPD layers are better bonded to the substrate. The paper focuses on two SPD methods, Surface Mechanical Attrition Treatment (SMAT) and Laser Shock Peening (LSP), to create these gradient nanocrystalline microstructures. The primary goal is to use Positron Annihilation Spectroscopy (PAS) and other techniques to study the resulting defect structures and their effect on material properties, especially corrosion resistance.

4. Summary of the study:

Background of the research topic:

The research is set against the backdrop of biomedical engineering, where metallic materials like titanium alloys, stainless steels, and magnesium are used for implants. A key challenge is that these implants must survive in the highly corrosive environment of the human body while maintaining their mechanical integrity. Traditional materials often have properties (e.g., Young's modulus) that are mismatched with human bone, leading to issues like stress shielding and eventual failure. Furthermore, the release of toxic ions from corrosion is a major concern. This has driven research into surface modification techniques to improve biocompatibility, durability, and corrosion resistance.

Status of previous research:

Previous research has established various methods for creating nanocrystalline surfaces. These include deposition techniques like PVD and CVD, but these can suffer from poor adhesion. Severe Plastic Deformation (SPD) methods have gained popularity as they modify the material itself, creating a well-bonded, integral surface layer. Methods like SMAT and LSP are known to induce nanocrystalline structures and compressive residual stresses, which are beneficial for fatigue life and hardness. However, the paper notes that despite these efforts, the specific impact of the induced crystal lattice defects on the corrosion process is "still not understood completely" (Abstract, p. 7), indicating a gap in the knowledge that this study aims to fill.

Purpose of the study:

The main objective of the thesis is to investigate the correlation between the presence of crystal lattice defects, introduced by SPD methods (SMAT and LSP), and the properties of biometals, with a special focus on their corrosion resistance. The study aims to characterize the gradient microstructures and defect distributions in magnesium, titanium, and 316L stainless steel and link these physical changes to measurable improvements in performance.

Core study:

The core of the study involves subjecting samples of magnesium, titanium, and 316L stainless steel to SMAT and LSP under various parameters. The resulting surface and subsurface layers are then meticulously analyzed. Positron Annihilation Spectroscopy (PALS and VEP) is used to determine the type, concentration, and depth profile of defects like vacancies and dislocations. These results are then correlated with data from microhardness tests, EBSD, XRD (for microstructure and residual stress), and electrochemical tests (for corrosion resistance). The study also examines the thermal stability of the created nanocrystalline structures through isochronal annealing experiments.

5. Research Methodology

Research Design:

The research was designed as a comparative experimental study. Samples of commercial purity magnesium, grade 2 titanium, and AISI 316L stainless steel were first annealed to create a baseline reference state. Then, they were subjected to different surface treatments:

- SMAT: Performed on Mg and Ti with varying durations (60s, 120s) and vibration amplitudes (13 µm, 27 µm).

- LSP: Performed on 316L stainless steel.

- Control Groups: Untreated annealed samples and samples deformed by simple compression were used for comparison.

Data Collection and Analysis Methods:

A comprehensive suite of characterization techniques was employed:

- Positron Annihilation Spectroscopy (PAS): PALS and VEP beam techniques were the primary methods for defect analysis, measuring positron lifetimes and S/W-parameters to identify vacancies, dislocations, and their clusters. Depth profiling was achieved by combining PAS with sequential chemical etching of the sample surface.

- Microscopy and Diffraction: Optical Microscopy, SEM, and EBSD were used to visualize the microstructure, grain size, and grain orientation. XRD was used to determine crystallite size, lattice strain (Williamson-Hall method), and residual stresses (sin²ψ and MGIXD methods).

- Mechanical and Surface Testing: Microhardness profiles were measured to quantify the hardening effect. An optical profilometer was used to measure surface roughness (Ra).

- Electrochemical Testing: Corrosion behavior was evaluated using Open Circuit Potential (OCP), Linear Sweep Voltammetry (LSV), and Electrochemical Impedance Spectroscopy (EIS) in saline solutions simulating physiological conditions.

Research Topics and Scope:

The research scope covers the generation and characterization of nanocrystalline surface layers on three key biometals. The topics investigated include:

1. The effect of SMAT and LSP parameters on surface morphology, microstructure, and hardness.

2. The type, concentration, and depth distribution of defects created by these SPD processes.

3. The correlation between defect structure and corrosion resistance.

4. The thermal stability of the induced nanocrystalline structures in Ti and 316L steel.

6. Key Results:

Key Results:

- SMAT and LSP successfully created gradient nanocrystalline layers in all tested materials, significantly reducing crystallite size (e.g., from 2735 nm to 24 nm in LSP-treated steel, p. 124).

- SMAT increased the surface roughness and microhardness of both Mg and Ti. The depth of the hardened layer was found to be approximately 800-900 µm for Mg and 200-400 µm for Ti, depending on the process parameters.

- PAS analysis revealed the creation of a high density of defects, primarily dislocations and vacancy clusters (containing 3-4 vacancies in Ti). The depth profile of these defects was successfully mapped.

- A direct correlation was found between SMAT parameters, defect concentration, and corrosion resistance. Longer SMAT duration and higher amplitude in titanium resulted in a higher defect density and superior corrosion resistance (Chapter 9.4, p. 149).

- For magnesium, SMAT increased the material's reactivity, which promoted the formation of a more protective hydroxide layer, leading to an apparent improvement in corrosion resistance (Chapter 7.3.6, p. 116).

- The thermal stability studies on titanium identified two distinct annealing stages for defects, with vacancy clusters annealing out at lower temperatures (100-200 °C) than dislocations (stable up to ~350 °C).

Figure Name List:

- Figure 1.1: [Not provided in source]

- Figure 2.1: Point defects in a crystal lattice: a) an intrinsic defect – a vacancy, b) an extrinsic defect – an interstitial atom.

- Figure 2.2: Schematic diagram of an: a) an edge dislocation in 2D in a simple cubic structure, the dotted plane is a slip plane, b) a screw dislocation in 3D in a cubic structure.

- Figure 2.3: Schematic of a low and high angle grain boundary and the angle of misorientation.

- Figure 3.1: Surface nanocrystallization methods.

- Figure 3.2: A conceptualization of the SMAT method.

- Figure 3.3: A schematic diagram of the mechanism of the LSP procedure.

- Figure 4.1: 22Na isotope decay scheme.

- Figure 4.2: Positron-electron pair annihilation in a) the center of mass reference frame, b) in the laboratory frame of reference.

- Figure 4.3: Schematic representation of the positron interaction potential with positively charged ions, and defects of the crystal lattice.

- Figure 4.4: Scheme of positron lifetime measurement.

- Figure 4.5: Scheme of a positron lifetime spectrometer.

- Figure 4.6: Positron lifetime spectrum in a logarithmic scale in a function of time, the channel number corresponds to the time.

- Figure 4.7: Schematic illustration of the detector setup used for DB spectroscopy.

- Figure 4.8: DB of the annihilation line. The marked areas denote the intervals used to calculate the S- and W-parameter.

- Figure 4.9: The scheme of positron injector at the VEP facility.

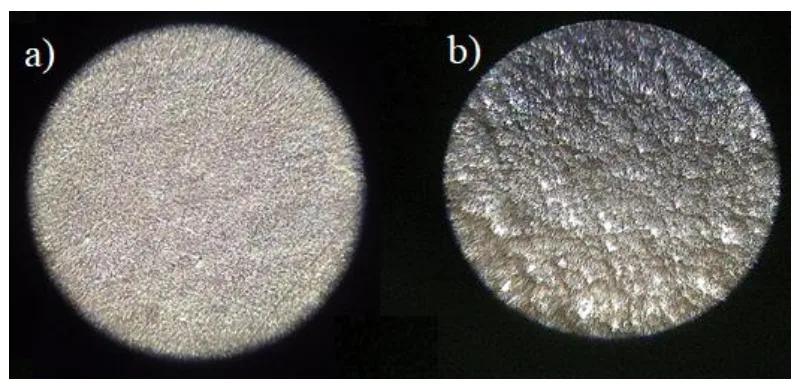

- Figure 6.1: Optical microscope image of the reference sample (a) and the one sandblasted under 5 bar for 1 minute (b).

- Figure 6.2: Values of the S-parameter as the function of the depth from the Cu surfaces exposed to sandblasting.

- Figure 6.3: The dependence of the S-parameter in the function of the depth from the surface for the specimens subjected to cutting and 72% compression.

- Figure 7.1: Mg specimen after the SMAT.

- Figure 7.2: Surfaces of the magnesium specimen subjected to SMAT.

- Figure 7.3: Orientation of the scattering vector K is defined by the φ and ψ angles.

- Figure 7.4: Penetration depth of X-ray radiation in the function of sin²ψ for the single-angle measurement.

- Figure 7.5: Knoop hardness indenter imprint.

- Figure 7.6: Photography of the glass-and-PTFE cell with a platinum foil as the CE and the SCE as the RE.

- Figure 7.7: Optical profiler images of Mg samples surface SMATed for (a) 60 s and (b) 120 s.

- Figure 7.8: The SEM-EDS spectrum for the a) reference sample, b) region of interest.

- Figure 7.9: The EDS spectrum for the a) sample SMATed for 120s, b) region of interest.

- Figure 7.10: Image quality microstructure reconstructed from EBSD of the cross-sectioned specimen of Mg SMATed for 60 s.

- Figure 7.11: a) Optical microscopy image of a typical microstructure on the cross-section of the sample SMATed for 120 s; (b) the Image Quality Microstructure reconstructed from EBSD measurements...

- Figure 7.12: Dependencies of lattice spacing in the function of sin²ψ for a) sample SMATed for 60 s and b) SMATed for 120 s.

- Figure 7.13: The relative microhardness of magnesium samples SMATed for 120 s and 60 s versus depth.

- Figure 7.14: The mean positron lifetime profiles.

- Figure 7.15: Mean positron lifetime values as a function of thickness reduction for the Mg specimen deformed using the uniaxial-hydraulic press.

- Figure 7.16: The S-parameter as a function of incident positron energy (mean implantation depth).

- Figure 7.17: Wr-parameter as a function of S-parameter.

- Figure 7.18: EEC applied in the interpretation of the data from electrochemical impedance spectroscopy measurements.

- Figure 7.19: An example of the fit of the EEC showed in Fig. 7.18 to the impedance data.

- Figure 7.20: Linear sweep voltammetry on the Mg sample not subjected to any treatment (reference sample), the samples SMATed for 60 s and 120 s...

- Figure 8.1: Schematic illustration of LSP procedure; θ = 0.64 mm.

- Figure 8.2: X-ray patterns of 316L samples.

- Figure 8.3: Mean positron lifetime profile.

- Figure 8.4: Positron lifetime components τ₁ and τ₂ and intensity I₂ of the longer component versus depth.

- Figure 8.5: a) The S-parameter as a function of the incident positron energy... b) The W-parameter as a function of the incident positron energy.

- Figure 9.1: Optical profiler images of Ti specimens surface SMATed for (a) 60 s and (b) 120 s, and (c) the reference sample.

- Figure 9.2: EBSD orientation mapping of the cross-section of the Ti SMATed for 120 s.

- Figure 9.3: W-H analysis using PANalytical software.

- Figure 9.4: The microhardness measured on the cross-section of Ti samples SMATed for 120 and 60 s versus the distance from the surface.

- Figure 9.5: Depth profiles of the mean positron lifetime for Ti samples SMATed for 60 s and 120 s.

- Figure 9.6: Evolution of the OCP in time.

- Figure 9.7: Impedance spectra of the as-received SMATed and reference samples.

- Figure 9.8: Impedance spectra for the polished SMATed and reference samples.

- Figure 9.9: Logarithm of modulus of impedance Z versus the logarithm of frequency f in the range of low frequencies for polished SMATed and the reference samples.

- Figure 9.10: Logarithm of modulus of impedance Z versus the logarithm of frequency f in the range of low frequencies for the as-received SMATed and the reference sample.

- Figure 9.11: EEC applied in the interpretation of the data from electrochemical impedance spectroscopy measurements.

- Figure 9.12: Example of the fit to the measured data for the as-received SMAT 120 s sample – Nyquist plot.

- Figure 9.13: Example of the fit to measured data – Bode plots.

- Figure 10.1: Temperature profiles of the S-parameter measured for the HE and the compressed specimens of Ti.

- Figure 10.2: Mean positron lifetime in the function of temperature during isochronal annealing measured for SMATed specimens of Ti.

- Figure 10.3: Temperature dependencies of the positron lifetime components, τ₂(a), τ₁(b), and intensity I₂(c), of the longer component...

- Figure 10.4: Mean positron lifetime in the function of temperature during isochronal annealing measured for SMATed specimens of AISI 316L stainless steel.

7. Conclusion:

The thesis successfully demonstrated that SPD methods like SMAT and LSP are effective in creating gradient nanocrystalline layers on biometals. The main conclusions are:

- SMAT increases dislocation density and refines grains in magnesium, which increases hardness. The process parameters (duration, amplitude) influence the depth and profile of the defect distribution.

- The induced microstructure in magnesium increases its susceptibility to anodic oxidation, which paradoxically leads to better corrosion resistance through the formation of a more robust passivating hydroxide layer.

- LSP on 316L steel creates clusters of vacancies and a high density of dislocations near the surface, along with deformation-induced martensite.

- SMAT on titanium also creates a defect-rich layer of dislocations and vacancy clusters, and its corrosion resistance is improved. The defect distribution is directly correlated with the improved corrosion performance.

- The thermal stability of defects in titanium was characterized, showing two distinct annealing stages for vacancy clusters and dislocations.

- Overall, the final results show a clear correlation between the defect concentration induced by surface nanocrystallization methods and the improved corrosion resistance of magnesium and titanium.

8. References:

[A comprehensive list of 165 references is provided in the original thesis across pages 28-30, 38-39, 48-50, 67-68, 76-77, 85, 119-121, 128, 149-150, and 161. These are omitted for brevity but are available in the source document.]

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the surface integrity and performance of critical metallic components. The findings offer a clear, data-driven path toward improving quality and durability by engineering the material's microstructure. The strong correlation between defect concentration and corrosion resistance is a particularly powerful insight for developing next-generation products.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting and manufacturing problems. If the issues of surface durability and corrosion discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Expert Q&A: Your Top Questions Answered

Q1: What was the single most critical factor identified in this study for improving the corrosion resistance of titanium?

A1: The study concluded that the improved corrosion resistance was due to the microstructure created in the sample surface layer, which promotes the formation of a tight, corrosion-resistant barrier layer. This is directly correlated with a higher dislocation density induced by the SMAT process, as stated in the summary of Chapter 9 (p. 149).

Q2: What specific types of defects were created by the SMAT process in titanium?

A2: The PALS measurements identified two main types of defects. The shorter positron lifetime component was attributed to positrons trapped at dislocations, while the longer component indicated the presence of vacancy clusters containing approximately 3 or 4 vacancies, as detailed in the Chapter 9 Summary (p. 148).

Q3: How deep did the SMAT treatment affect the titanium samples?

A3: The total depth of the SMAT-affected layer in titanium was determined to be about 250 µm for the 60s treatment and about 400 µm for the 120s treatment, as determined by positron lifetime depth profiles shown in Figure 9.5 and discussed in the Chapter 9 Summary (p. 148).

Q4: What specific measurement technique allowed the researchers to map these defect profiles?

A4: The researchers primarily used Positron Annihilation Spectroscopy (PAS), combining it with a sequential chemical etching procedure. This allowed them to perform measurements at different depths and construct a detailed profile of the defect distribution, as explained in the methodology of Chapter 6 (p. 81).

Q5: According to the paper, what is a key area for future research regarding these materials?

A5: The paper suggests that while a correlation between vacancy clusters and corrosion resistance is observed, "the confirmation of the influence of vacancy clusters in plastically deformed titanium on corrosion resistance requires further research," as noted in the discussion of thermal stability in Chapter 10 (p. 158).

Q6: What is the direct, practical takeaway from this paper for a manufacturing facility?

A6: The core takeaway, based on the paper "Properties of the nanocrystalline layers obtained by methods of severe plastic deformation...", is that mechanical surface treatments like SMAT can be precisely controlled to create a surface with a higher defect density, which in turn significantly improves the corrosion resistance and hardness of the final component.

Copyright

- This material is an analysis of the paper "Properties of the nanocrystalline layers obtained by methods of severe plastic deformation in metals and alloys for biomedical applications" by Konrad Skowron.

- Source of the paper: The Henryk Niewodniczański Institute of Nuclear Physics Polish Academy of Sciences.

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 CASTMAN. All rights reserved.