This technical brief is based on the academic paper "PREDICTING PARTING PLANE SEPARATION AND TIE BAR LOADS IN DIE CASTING USING COMPUTER MODELING AND DIMENSIONAL ANALYSIS" by Karthik S Murugesan, M.S., published in The Ohio State University (2008). It is summarized and analyzed for HPDC professionals by the experts at CASTMAN.

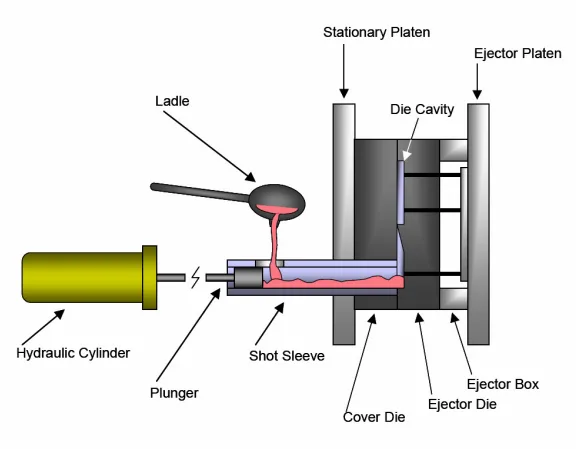

![Figure 1.1: Schematic of an open-close die [5]](https://castman.co.kr/wp-content/uploads/image-2491.webp)

Keywords

- Primary Keyword: Parting Plane Separation Prediction

- Secondary Keywords: Tie Bar Load Imbalance, HPDC Computer Modeling, Dimensional Analysis Die Casting, Finite Element Analysis (FEA) Die Casting, Die Deflection, Die Design Optimization, Platen Stiffness

Executive Summary

- The Challenge: In high-pressure die casting, predicting and controlling die distortion—specifically parting plane separation and tie bar load imbalance—is a persistent challenge that leads to defects like flash, dimensional inaccuracies, and premature tool failure.

- The Method: The research moves beyond time-consuming full Finite Element Analysis (FEA) for initial designs by developing streamlined, closed-form "power law" models. These models were created using computational FEA experiments combined with dimensional analysis to identify the most critical structural variables.

- The Key Breakthrough: The study produced predictive models for both parting plane separation and tie bar load imbalance. These models accurately forecast how changes in die design (e.g., die size, thickness, support pillar patterns) and machine parameters (e.g., platen thickness) will affect die performance.

- The Bottom Line: This research provides die casters with a powerful, fast, and cost-effective tool to optimize structural die design at the earliest stages, preventing defects before the first shot and ensuring higher part quality and tool longevity.

The Challenge: Why This Research Matters for HPDC Professionals

For decades, die casting engineers have grappled with the complex interplay of forces within the die and machine. The immense pressures involved—from the clamp force holding the die shut to the injection pressure filling the cavity—cause elastic deflections in the die. When these deflections occur along the parting line, the two halves of thedie separate, allowing molten metal to escape, a phenomenon known as "flash". Flash leads to increased costs from secondary removal operations, higher scrap rates, and potential damage to the die.

A related and equally critical problem is tie bar load imbalance. Ideally, the clamping force is distributed evenly across all four of the machine's tie bars. However, factors like off-center die placement or uneven pressure distribution within the cavity can lead to imbalanced loads. This causes the die to close unevenly, exacerbating flash and, in severe cases, leading to premature tie bar failure, a costly and dangerous event. Predicting these phenomena typically requires complex and time-consuming FEA, which is often not feasible during the rapid iterations of the initial die design stage.

The Approach: Unpacking the Methodology

To solve this problem, the researcher developed a more efficient predictive tool. The study's methodology combined the power of modern simulation with the fundamental principles of engineering physics.

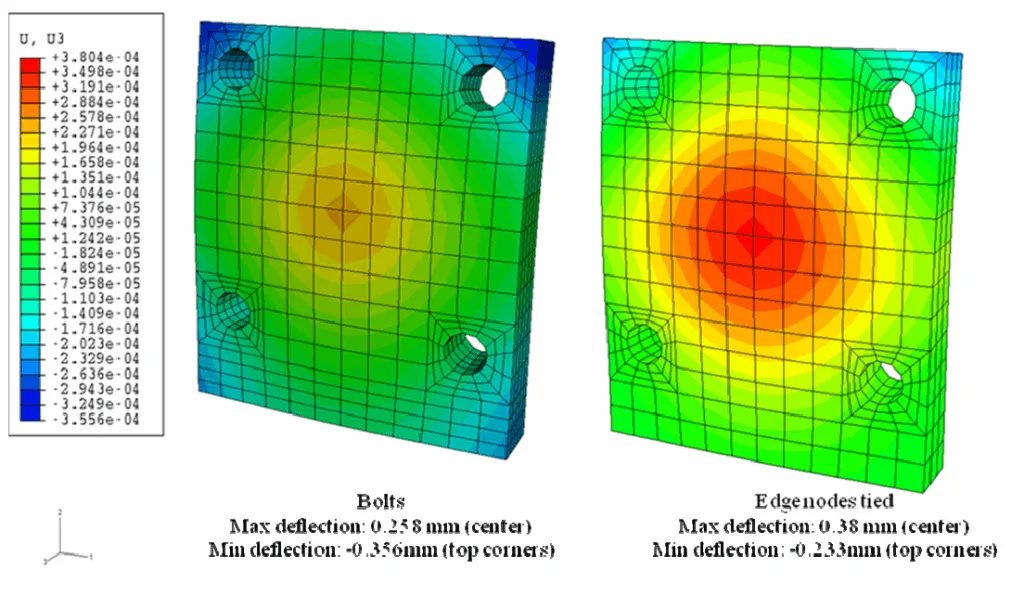

The core of the approach was to use a series of computational experiments based on the Finite Element Method (FEM). A comprehensive 3D FEA model was built, incorporating the dies, inserts, machine platens, tie bars, and toggle mechanism. Using a Design of Experiments (DOE) approach, numerous simulations were run while systematically varying key structural design parameters like die dimensions, platen thickness, and ejector support pillar patterns.

The key innovation was the application of dimensional analysis, specifically the Buckingham Pi-theorem. This classical engineering method reduces complex sets of variables into a smaller number of dimensionless parameters that govern the physical behavior. By analyzing the FEA results through the lens of dimensional analysis, the researcher developed "power law models"—robust, closed-form equations that describe the relationship between the design parameters and the outcomes of parting plane separation and tie bar loads.

The Breakthrough: Key Findings & Data

The research yielded several powerful conclusions and predictive tools that can be directly applied in the industry.

- Finding 1: Ejector Side Separation is Dominated by Support Structure. The study's power law model revealed that parting plane separation on the ejector side is most sensitive to the ratio of the unsupported span between pillar supports and the die thickness. The number and placement of support pillars play a critical role, while the platen thickness has only a first-order effect.

- Finding 2: Cover Side Separation is Driven by Die Size and Platen Stiffness. On the cover side, the most significant factor is the die's footprint relative to the platen area. Smaller dies result in less separation because the platen can "wrap" around the die, providing better support. The next most important factors are the cover platen thickness and the distance between tie bars.

- Finding 3: A More Accurate Tie Bar Load Model. A novel power law model was developed to predict tie bar loads that, unlike traditional methods, accounts for the specific location of both the die and the cavity center of pressure on the platen. This provides a far more accurate estimate of load distribution, which is critical for balancing the die and preventing flash.

Practical Implications for Your HPDC Products

Based strictly on the paper's results and conclusions, these findings have direct applications for improving manufacturing outcomes.

- For Process Engineers: The findings in "Chapter 5" suggest that tie bar load imbalance is primarily driven by the die's location on the platen. Using the developed power law models, you can predict this imbalance for off-center setups and make proactive adjustments to balance the loads, potentially reducing the minimum required clamp tonnage and preventing flash.

- For Quality Control: The correlation shown between unsupported spans and parting plane separation provides a new framework for diagnosing the root cause of flash. The models in "Chapter 4" can be used to determine if a die's structural design is adequate for the machine it's running on, leading to more effective problem-solving.

- For Die Design: This study on parting plane separation implies that design choices regarding support pillar patterns have a measurable impact on ejector side stability. The conclusion that thin, compliant dies perform better on the cover side when placed on a large, thick platen offers a clear, data-driven principle for optimizing the die-to-machine match during the design phase.

Paper Details

PREDICTING PARTING PLANE SEPARATION AND TIE BAR LOADS IN DIE CASTING USING COMPUTER MODELING AND DIMENSIONAL ANALYSIS

1. Overview:

- Title: PREDICTING PARTING PLANE SEPARATION AND TIE BAR LOADS IN DIE CASTING USING COMPUTER MODELING AND DIMENSIONAL ANALYSIS

- Author: Karthik S Murugesan M.S.

- Year of publication: 2008

- Journal/academic society of publication: The Ohio State University (Dissertation)

- Keywords: Parting Plane Separation Prediction, Tie Bar Load Imbalance, HPDC Computer Modeling, Dimensional Analysis Die Casting, Finite Element Analysis (FEA) Die Casting, Die Deflection, Die Design Optimization, Platen Stiffness.

2. Abstract:

Die Casting dies and machines are high-performance products subjected to clamp load, cavity pressure loads, and thermal loads, causing deflection. The ability of dies to withstand these loads depends on their structural design. A common problem is tie bar load imbalance, where the clamp load is unevenly distributed among the four tie bars due to die and cavity location, leading to issues like flash and premature tie bar failure. Numerical methods like FEA are effective for predicting distortion at the design stage, but can be time-consuming. This research investigates the contribution of major structural design variables to mechanical performance using computational (FEA) experiments. Power law models, derived using dimensional analysis, were developed to predict maximum parting plane separation and tie bar loads. These models explain the sensitivity of the system to design variables and can be used to improve die structures and determine necessary tie bar adjustments.

3. Introduction:

Die casting is a net-shape manufacturing process where molten metal is injected into steel dies under high pressure. A major factor contributing to dimensional inaccuracy is the elastic deformation of the die cavity caused by thermo-mechanical loads. This can lead to defects like flash, causing increased cycle times and costs. Another significant issue is the imbalanced loading of machine tie bars due to off-center die or cavity placement, which can cause uneven die closure and component failure. Predicting and controlling these distortions at the design stage is critical, as die manufacturing is expensive and has long lead times. While numerical modeling is the most efficient way to predict distortion, it can be too slow for initial design iterations. This research aims to develop off-the-shelf tools and guidelines for the structural design of die casting dies.

4. Summary of the study:

Background of the research topic:

The structural integrity of die casting dies and machines is critical for producing dimensionally accurate parts. Die deflections under load lead to flash, while imbalanced tie bar loads compromise machine stability and die closure.

Status of previous research:

Previous research has established FEA as a valid tool for predicting die distortion. However, these studies often did not fully explore the contribution of ejector side design variables (like support pillars) to parting plane separation. Furthermore, existing methods for estimating tie bar loads, such as that by Herman, often rely on overly simple assumptions like perfectly rigid bodies, leading to inaccurate predictions.

Purpose of the study:

The primary objective was to study the contributions of various structural design variables to die deflection and develop tools to aid in die design. This involved creating closed-form expressions (power law models) to predict maximum parting plane separation and tie bar loads, enabling quick and accurate estimates during the initial design stage.

Core study:

The study utilized a Design of Experiments (DOE) approach with Finite Element Analysis (FEA) to simulate the effects of various design parameters on die performance. The results were then used with dimensional analysis (Pi-theorem) to develop non-linear power law models that predict parting plane separation and tie bar loads as a function of key geometric and physical variables.

5. Research Methodology

Research Design:

The research was designed around computational experiments using a 58-run central composite response surface design. The factors studied included platen thickness, die dimensions, die thickness ratio, and pillar diameter/pattern.

Data Collection and Analysis Methods:

Data was generated using static finite element analysis (FEA) for each design point. The model outputs (parting plane separation, tie bar loads) were analyzed using dimensional analysis and non-linear regression to fit power law models. The adequacy of the models was tested against additional FEA simulations and experimental measurements from a 250-ton die casting machine.

Research Topics and Scope:

The research focused on two main topics: 1) predicting maximum parting plane separation on the cover and ejector sides of the die, and 2) predicting the individual loads on the four machine tie bars. The scope was limited to single-cavity, open-close dies and did not include thermal loads, focusing exclusively on the structural behavior under mechanical loads.

6. Key Results:

Key Results:

The study successfully developed non-linear power law models to predict maximum parting plane separation and tie bar loads. For parting plane separation, it was found that ejector side separation is most sensitive to the unsupported span between pillars and die thickness, while cover side separation is most sensitive to the overall die size and platen stiffness. The tie bar load prediction model demonstrated that die location on the platen is the primary factor affecting load distribution, a factor ignored by simpler industry methods. A methodology to characterize the stiffness of different machine platens was also developed, allowing the models to be adapted to various machines.

Figure Name List:

![Figure 1.2: Schematic of a Hot Chamber Die Casting Machine [66]](https://castman.co.kr/wp-content/uploads/image-2492.webp)

- Figure 1.1: Schematic of an open-close die

- Figure 1.2: Schematic of a Hot Chamber Die Casting Machine

- Figure 1.3: Schematic of a Cold Chamber Die Casting Machine

- Figure 1.4: Free Body Diagram of Cover and Ejector Dies

- Figure 1.5: Free Body Diagram of Die Casting Machine and the Die

- Figure 2.1: Schematic of Toggle Spring Platen Model

- Figure 2.2: Schematic of the Models Considered in

- Figure 3.1: Geometry of the Part used in the Study

- Figure 3.2: Schematic of the Finite Element Model

- Figure 4.1: Side View of an Ejector Die used in the Study

- Figure 4.2: Schematic of Pillar Patterns used in the Study

- Figure 5.1: Coordinate System and Tie bar Labels viewed from inside face of Cover Platen

- Figure 5.5: Tie bar Load Measurements vs. Predictions from the Regression Model

- And all other figures as listed in the paper's "LIST OF FIGURES".

7. Conclusion:

The research successfully developed and validated empirical power law models to predict parting plane separation and tie bar loads in die casting. These models, derived from dimensional analysis and FEA, provide a deep understanding of how structural variables contribute to die performance. Key conclusions include: the ejector side separation is most sensitive to the support pillar arrangement and die thickness; the cover side separation is most affected by die size and platen stiffness; and die location is the primary factor in tie bar load imbalance. The study also provides a method to characterize machine stiffness, making the models adaptable. These tools empower designers to optimize structural performance early in the design process.

8. References:

- Chayapathi, A., 1999, "Study of the Effect of Structural Variables of Die and Die Casting Machine on Die Deflections," Master’s Thesis, The Ohio State University.

- Herman, E.A., 1992, "Designing die casting dies," North American Die Casting Association, Rosemont, IL, USA.

- Arrambide, E., Ragab, A., Kabiri-Bamoradian, K., 2005, "Modeling Influence of the Die Casting Machine Components on Contact Load between Dies and Platens," NADCA Transactions.

- Vinarcik, E. J., 2003, "High Integrity Die Casting Process," John Wiley & Sons Publications, New York

- All other references are as listed in the paper from pages 172-177.

Expert Q&A: Your Top Questions Answered

Q1: What was the single most critical factor identified in this study for improving parting plane separation?

A1: The study concluded that on the ejector side, the most critical factor is the ratio of the unsupported span between the pillar supports to the die thickness. For the cover side, the largest contributor is the length and width of the die relative to the platen area. (Source: "PREDICTING PARTING PLANE SEPARATION AND TIE BAR LOADS IN DIE CASTING USING COMPUTER MODELING AND DIMENSIONAL ANALYSIS", Section 6.1 Conclusions from the Power Laws to Predict Parting Plane Separation).

Q2: How does this research compare to traditional methods for addressing tie bar load imbalance?

A2: The paper's Introduction and Problem Statement note that traditional methods, like the one by Herman, assume the die and machine are perfectly rigid bodies and completely ignore the effect of the die's location on the platen. This research introduces a more advanced power law model that accounts for the rigidity of the die and machine and specifically includes the die and cavity locations, leading to more accurate predictions. (Source: "PREDICTING PARTING PLANE SEPARATION AND TIE BAR LOADS IN DIE CASTING USING COMPUTER MODELING AND DIMENSIONAL ANALYSIS", Section 1.5 Problem Statement).

Q3: Is this finding applicable to all types of alloys, or a specific one?

A3: The research focuses on the structural mechanics of the die and machine, not the metallurgy of the casting alloy. The simulations described in the Research Methodology section were conducted assuming the die and machine components were made of ST4140 steel. While the specific model coefficients are based on this, the dimensional analysis approach makes the methodology itself generally applicable to understanding structural behavior regardless of the cast alloy. (Source: "PREDICTING PARTING PLANE SEPARATION AND TIE BAR LOADS IN DIE CASTING USING COMPUTER MODELING AND DIMENSIONAL ANALYSIS", Section 3.2.3 Material Properties, Table 3.2).

Q4: What specific measurement or simulation technique did the researchers use to arrive at this conclusion?

A4: The researchers utilized a combination of Finite Element Analysis (FEA) to conduct computational experiments, a Design of Experiments (DOE) framework to structure the simulations, and dimensional analysis based on the Buckingham Pi-theorem to develop the final power law models. (Source: "PREDICTING PARTING PLANE SEPARATION AND TIE BAR LOADS IN DIE CASTING USING COMPUTER MODELING AND DIMENSIONAL ANALYSIS", Section 4.3 Dimensional Analysis and Empirical Correlations).

Q5: According to the paper, what is the main limitation or area for future research?

A5: The authors state in the Future Work section that the current models are specific to single cavity, open-close dies. They suggest future work should focus on extending the models to multiple cavity dies and non-open close dies (which include slide lock mechanisms), as well as incorporating the dynamic impact load from the plunger. (Source: "PREDICTING PARTING PLANE SEPARATION AND TIE BAR LOADS IN DIE CASTING USING COMPUTER MODELING AND DIMENSIONAL ANALYSIS", Section 6.4 Future Work).

Q6: What is the direct, practical takeaway from this paper for a die casting facility?

A6: The core takeaway is that by using the power law models presented, a facility can quickly and accurately predict how key design parameters (like die size, support pillar layout, and platen selection) will impact parting plane separation and tie bar loads. This allows for the optimization of die and machine setup before cutting steel, leading to reduced defects, improved part quality, and longer tool life, a conclusion strongly supported by the overall results of the paper, "PREDICTING PARTING PLANE SEPARATION AND TIE BAR LOADS IN DIE CASTING USING COMPUTER MODELING AND DIMENSIONAL ANALYSIS".

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing structural integrity in HPDC operations. By moving beyond trial-and-error and the limitations of time-intensive FEA for initial design, the findings offer a clear, data-driven path toward improving quality, reducing defects like flash, and optimizing production.

At CASTMAN, we are dedicated to applying the latest industry research to solve our customers' most challenging die casting problems. If the issues discussed in this paper resonate with your operational goals, contact our engineering team to discuss how we can help you implement these advanced principles in your components.

Copyright

- This material is a paper by "Karthik S Murugesan". Based on "PREDICTING PARTING PLANE SEPARATION AND TIE BAR LOADS IN DIE CASTING USING COMPUTER MODELING AND DIMENSIONAL ANALYSIS".

- Source of the paper: https://etd.ohiolink.edu/acprod/odb_etd/ws/send_pdf/Murugesan%20Karthik%20S.pdf?acc_num=osu1218479383

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.