The content of this introduction paper is based on the article "A Performance Evaluation of Three-Phase Induction Electric Motors between 1945 and 2020" published by "MDPI".

1. Overview:

- Title: A Performance Evaluation of Three-Phase Induction Electric Motors between 1945 and 2020

- Author: Danilo Ferreira de Souza, Francisco Antônio Marino Salotti, Ildo Luís Sauer, Hédio Tatizawa, Aníbal Traça de Almeida, and Arnaldo Gakiya Kanashiro

- Year of publication: 2022

- Journal/academic society of publication: Energies

- Keywords: three-phase induction motor; squirrel-cage rotor; energy efficiency; motor performance

2. Abstract:

In the late 19th century, the three-phase induction motor was the central element of productivity increase in the second industrial revolution in Europe and the United States. Currently, it is the main load on electrical systems in global terms, reaching approximately 70% of electrical energy consumption in the industrial sector worldwide. During the 20th century, electric motors underwent intense technological innovations that enabled significant performance gains. Thus, this work analyses the performance changes in squirrel-cage rotor three-phase induction electric motors (SCIMs) with mechanical powers of 3.7 kW, 37 kW, and 150 kW and speed ranges corresponding to two poles and eight poles, connected to a low voltage at a frequency of 60 Hz and tested between 1945 and 2020. The study confirms accumulated performance gains of above 10% in some cases. Insulating materials for electrical conductors have gone through several generations (cotton, silk, and currently, varnish). Improvements to the housing for cooling, the bearings, the quality of active materials, and the design were the elements that enabled the high gains in performance. The first commercial two-pole SCIM with a shaft power of 4.4 kW was marketed in 1891, with a weight/power ratio of 86 kg/kW, and until the 2000s, this value gradually decreased, eventually reaching 4.8 kg/kW. Between 2000 and 2020, this ratio showed a reversed trend based on improvements in the performance of SCIMs. More active materials were used, causing the weight/power ratio to reach 8.6 kg/kW. The MEPS (minimum energy performance standards) of SCIMs had an essential role in the performance gain over the last three decades. Data collection was via tests at the Electrical Machines Laboratory of the Institute of Energy and Environment of the University of São Paulo. The laboratory has a history of tests on electrical equipment dating from 1911.

3. Introduction:

The three-phase induction motor (SCIM) has been pivotal in driving industrial revolutions since the late 19th century, currently consuming approximately 70% of industrial electrical energy worldwide. This paper highlights the historical progression of mechanical force production, from animal domestication to steam engines and finally to electric motors, emphasizing the superior efficiency and economy of electric motors over earlier methods. As illustrated in Figure 1, electric motors rapidly replaced steam power as the preferred means of motive power after their introduction in the 1880s. The advent of electric motors, particularly SCIMs, revolutionized industrial organization by enabling flexible factory layouts and improved process control, as depicted in Figure 2. While various electric motor technologies exist, SCIMs have become the predominant choice in industrial applications due to their advantages summarized in Table 1, including low cost, simple construction, reliability, and ease of maintenance. Despite perceptions of limited evolution, this research investigates the significant changes SCIMs have undergone, focusing on performance, design, and volume evolution over time.

4. Summary of the study:

Background of the research topic:

Three-phase induction motors are critical components in modern industry, consuming a significant portion of global electrical energy. Understanding their performance evolution is crucial for optimizing energy efficiency and industrial productivity. Despite the perception that SCIM technology has remained static, continuous advancements in materials, design, and manufacturing processes have likely led to performance improvements. This study addresses the need to quantify these improvements and understand the factors driving them.

Status of previous research:

Previous research acknowledges the historical development of electric motors and the increasing importance of energy efficiency. Existing literature, as cited in the paper, documents the early innovations in SCIM technology and the impact of standardization and material improvements on motor design and mass reduction. However, a comprehensive quantitative analysis of long-term performance trends based on empirical test data was needed to validate these qualitative observations and measure the actual performance gains over several decades.

Purpose of the study:

This study aims to evaluate the performance evolution of squirrel-cage rotor three-phase induction electric motors (SCIMs) from 1945 to 2020. The research seeks to answer the following key questions:

I. What are the most significant changes that SCIMs have undergone throughout their history?

II. Has the performance of SCIMs changed since their development?

III. Has the volume of SCIMs changed over time?

Core study:

The core of this study involves a detailed analysis of historical test reports from the Electrical Machines Laboratory of the Institute of Energy and Environment (IEE) of the University of São Paulo (USP). The research focuses on SCIMs with specific power ratings (3.7 kW, 37 kW, and 150 kW) and speeds (2, 4, 6, and 8 poles) tested at 60 Hz. By analyzing 359 technical reports spanning from 1945 to 2020, the study quantifies the changes in motor performance and mass/power ratio over this period, providing empirical evidence of the technological advancements in SCIM technology.

5. Research Methodology

Research Design:

This research employs a quantitative, longitudinal study design, analyzing historical data to assess trends in SCIM performance over a 75-year period. It utilizes a data-driven approach, relying on standardized performance test reports to ensure data reliability and consistency. The study categorizes SCIMs by power output and number of poles to facilitate comparative analysis across different motor types and performance characteristics.

Data Collection and Analysis Methods:

Data was collected from the Technical Test Reports of the Laboratory of Electrical Machines of IEE-USP, which holds approximately 21,000 technical reports and is accredited by INMETRO. Reports from 1945-1996 were digitized, while reports from 1997-2020 were already in digital format. The analysis focused on reports meeting specific criteria: three-phase SCIMs, new SCIMs, tests according to regulations, manufacturer-provided nameplate data, low voltage operation (up to 600V), 60 Hz operation, and continuous operation. Statistical methods, including averaging and linear regression, were used to analyze performance trends over time, particularly in years with multiple data points or data gaps.

Research Topics and Scope:

The research focuses on the performance evaluation of SCIMs, specifically examining:

- Changes in motor performance (efficiency) over time for different power ratings and pole configurations.

- Evolution of the mass/power ratio of SCIMs, particularly for 2-pole motors.

- The impact of technological innovations, material improvements, and minimum energy performance standards (MEPS) on SCIM performance.

- Analysis of performance trends for SCIMs with 2, 4, 6, and 8 poles across low (3.7 kW), medium (37 kW), and high (150 kW) power categories.

![Figure 18. Stator temperature measurement points (A, B, C, D and E). Adapted from [87].](https://castman.co.kr/wp-content/uploads/image-1844-png.webp)

![Figure 19. Efficiency levels in the IEC 60034-30-1 (2014) classification standard curves for 50 Hz,

4-pole SCIMs. Source: [88,90].](https://castman.co.kr/wp-content/uploads/image-1842-1024x500.webp)

![Figure 20. Timeline of global minimum performance standards for SCIMs. Source: [91–97].](https://castman.co.kr/wp-content/uploads/image-1843-1024x447.webp)

6. Key Results:

Key Results:

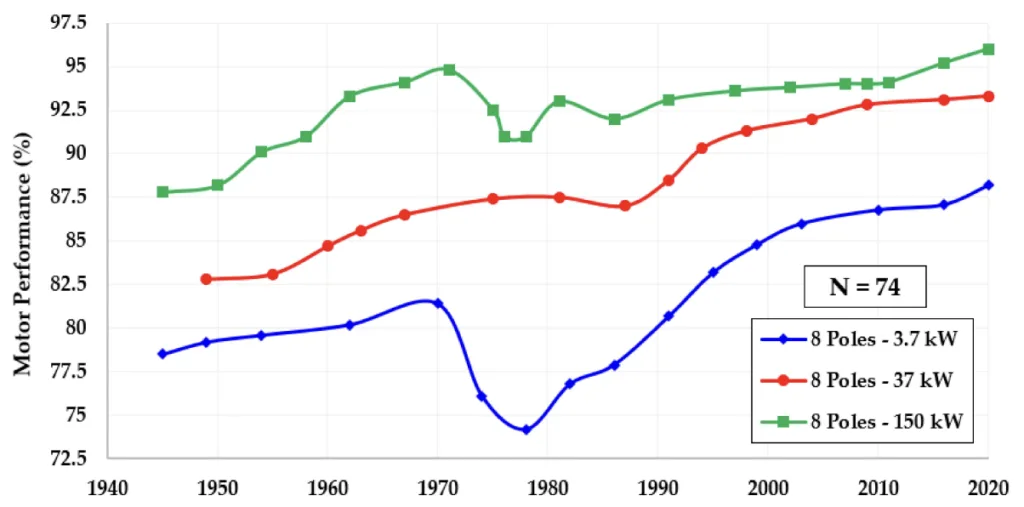

The study revealed significant performance gains in SCIMs between 1945 and 2020, with accumulated gains exceeding 10% in some cases. Loss reductions were substantial, ranging from approximately 45% to 73% depending on the motor power and pole configuration. Key findings include:

- Performance Improvement: Continuous performance gains were observed, particularly between 1945 and the mid-1960s and again from the 1980s to 2020. A temporary performance drop occurred between the 1960s and 1980s, attributed to a focus on cost reduction during an energy crisis.

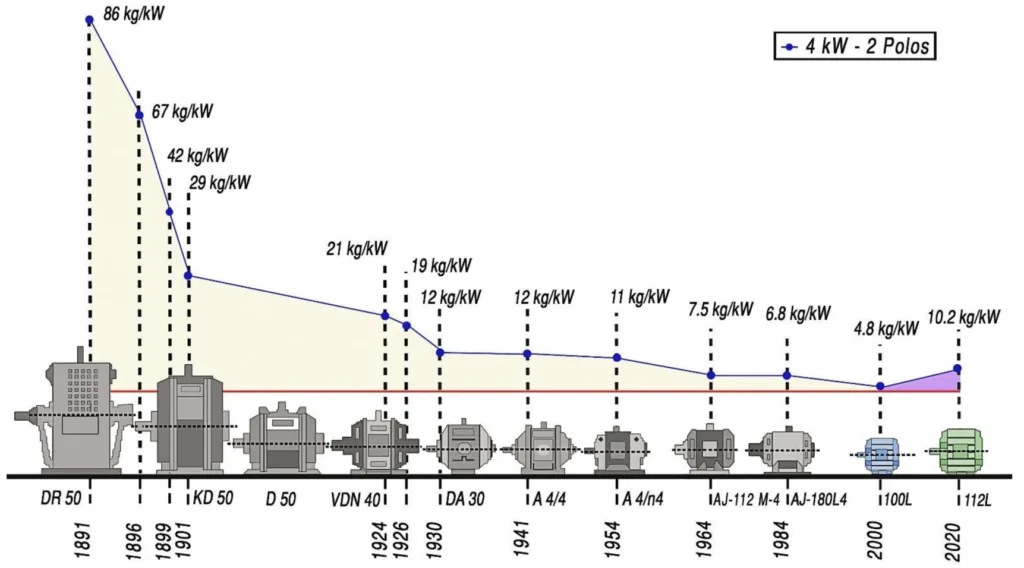

- Mass/Power Ratio Evolution: The mass/power ratio decreased dramatically from 86 kg/kW in 1891 to 4.8 kg/kW by 2000, reflecting technological advancements. However, from 2000 to 2020, this ratio increased to 8.6 kg/kW, indicating a shift towards higher performance and efficiency, even at the cost of increased mass. This trend reversal is illustrated in Figure 21.

- Impact of MEPS: Minimum Energy Performance Standards (MEPS) played a crucial role in driving performance improvements, particularly in the last three decades of the study period.

- Technological Drivers: Improvements in insulating materials (from cotton to varnish), bearings (from plain to ball bearings), active materials, cooling methods, and manufacturing processes were key enablers of performance gains. Figure 5 and Figure 7 visually represent the impact of these innovations on motor design and volume reduction.

Figure Name List:

- Figure 1. Percentage of mechanical drive manufacturing from hydraulic power, steam engines, and electric motors per year. Source: adapted from [7,8].

- Figure 2. An industrial organization based on: (a) mechanical drive from hydraulic energy; (b) steam engines; and (c) electric motors. Source: [13-16].

- Figure 4. Improvements in SCIM mass/power ratio between 1891 and 1984. Source: [61-63].

- Figure 5. Chronology of 0.75 kW SCIM mass reduction between 1900 and 1990. Source: [65-68].

- Figure 7. Dimension trends and housing changes of 11 kW 4-pole SCIMs between 1903 and 1974. (a,b): the changes in appearance and frame dimensions of SCIMs of different powers from the open construction of 1904 to those used in the 1970s. Source adapted from: [28,53].

- Figure 9. Density of the magnetic flux in the air gap and the volume of SCIMs.

- Figure 11. Changes to performance of 4-pole SCIMs between 1935 and 1996. Source: adapted from [65,66].

- Figure 14. The average performance of 2-pole SCIMs between 1945 and 2020.

- Figure 21. Changes to SCIMs in the mass/power ratio between 1891 and 2020.

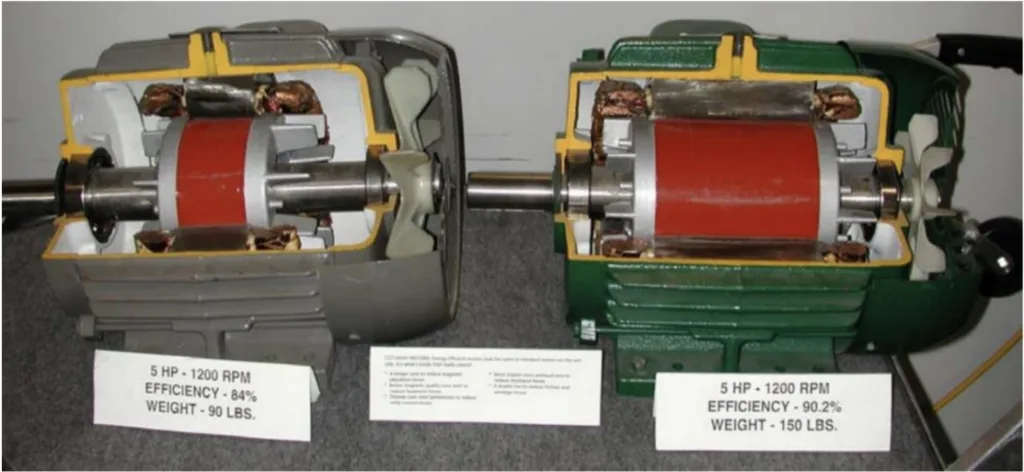

- Figure 22. The difference in the material quantity between Standard SCIM and High-Efficiency SCIM. Source: [98].

7. Conclusion:

This study demonstrates that contrary to the notion of static SCIM technology, significant advancements have occurred in SCIM performance between 1945 and 2020. Accumulated performance gains of over 10% and substantial loss reductions are confirmed through empirical data analysis. Technological innovations, material improvements, and the implementation of MEPS have been crucial drivers of this evolution. The research highlights three distinct periods: continuous performance gains (1945-mid 1960s), performance reduction due to cost optimization (1960s-1980s), and renewed performance improvement driven by legislation and technological advancements (1980s-2020). The increase in mass/power ratio after 2000 signifies a shift towards prioritizing efficiency over size and cost. These findings underscore the dynamic nature of SCIM technology and the ongoing pursuit of higher efficiency and performance in electric motors.

8. References:

- [7] Baldwin, S.F. The Materials Revolution and Energy-Efficient Electric Motor Drive Systems. Annu. Rev. Energy 1988, 13, 67-94.

- [28] Alger, P.L.; Arnold, R.E. The History of Induction Motors in America. Proc. IEEE 1976, 64, 1380-1383.

- [66] Sjöberg, S. Motor Developments and Energy Efficiency. In Energy Efficiency Improvements in Electric Motors and Drives; Springer: Berlin/Heidelberg, Germany, 1997; pp. 102–112.

- [85] McCoy, G.A.; Douglass, J.G. Advanced Manufacturing Office Premium Efficiency Motor Selection and Application Guide—A Handbook for Industry Premium Efficiency Motor Selection and Application Guide Disclaimer; Washington State University Energy Program: Washington, DC, USA, 2014.

- [98] De Castro, R.A. Feasibility Analysis of Replacement of Oversized Electric Motors and the Influence of Reactive Energy. Master's Thesis, University of Campinas-UNICAMP, Sao Paulo, Brazil, 2008.

9. Copyright:

- This material is a paper by "Danilo Ferreira de Souza, Francisco Antônio Marino Salotti, Ildo Luís Sauer, Hédio Tatizawa, Aníbal Traça de Almeida, and Arnaldo Gakiya Kanashiro". Based on "A Performance Evaluation of Three-Phase Induction Electric Motors between 1945 and 2020".

- Source of the paper: https://doi.org/10.3390/en15062002

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.