This article introduces the paper['Case-Based Product Development of a High-Pressure Die Casting Injection Subset Using Design Science Research'] presented at the ['FME Transactions']

1. Overview:

- Title: Case-Based Product Development of a High-Pressure Die Casting Injection Subset Using Design Science Research

- Author: Matilde C. Tojal, F. J. G. Silva, R. D. S. G. Campilho, Arnaldo G. Pinto, Luís Pinto Ferreira

- Publication Year: 2022

- Publishing Journal/Academic Society: FME Transactions

- Keywords: Product Development; DSR; Maintenance; Sustainability; Die Casting;Productivity; FMEA; Wear analysis.

2. Research Background:

Background of the Research Topic:

The automotive industry plays a significant role in the modern economic structure and is at the forefront of productive systems technologic development. Organizations are driven to constantly increase research and development activities for innovation and product improvement. Spare part consumption is a major contributor to resource consumption in productive systems. Sustainable manufacturing is a paradigm for viable production considering economic, environmental, and social dimensions. Maintenance is crucial for activity management and long-term results, impacting production volume, cost, availability, and efficiency. Die casting, widely used in metalworking, causes severe wear, especially in components subjected to high temperatures. Specifically, the injection nozzle area in high-pressure die casting requires attention due to constant replacements and productivity losses.

Status of Existing Research:

Existing research emphasizes the importance of data collection for critical spare part selection and root problem characterization, utilizing tools like Pareto's, FMEA, and Ishikawa diagrams. Product development complexity increases conflicting factors, necessitating data-driven decisions. Product data management maintenance systems are seen as adequate for understanding conflicting factors. Innovation and optimal performance/cost ratio are key in product development, alongside effective risk management. Industry 4.0 technologies in maintenance and effective human resource management are also areas of focus in existing research to enhance sustainability. Prior models for optimal spare part management and barriers to sustainable maintenance, such as data collection and maintenance costs, have been identified. Design Science Research (DSR) is recognized as a methodology for developing new products from existing ones, addressing complex and ill-defined problems.

Necessity of the Research:

The injection nozzle area and its connection to the mold in die casting processes still undergo constant replacements, process stoppages, and productivity losses despite some changes in recent years. This highlights the urgent need for research into new concepts for the nozzle and connecting zone to enhance process efficiency, particularly in these critical areas. The current state necessitates improvements in spare part request reduction, spare part lifespan extension, acquisition cost reduction, and reduction in equipment corrective maintenance times within High-Pressure Die Casting Injection systems.

3. Research Purpose and Research Questions:

Research Purpose:

This paper aims to demonstrate how sustainable maintenance can be achieved by focusing resources on analyzing critical problems and mitigating their causes at human, machine/process, or supplier levels within a High-Pressure Die Casting Injection system. The research proposes to show the beneficial results of implementing a new injection subset concept through Design Science Research (DSR).

Key Research:

The key research is the case-based product development of a high-pressure die casting injection subset using Design Science Research (DSR) methodology. This involves an iterative DSR process to develop and implement a new injection subset concept for a Zamak High-Pressure Die Casting Injection Machine (ZHPIM).

Research Hypotheses:

The implementation of the new injection subset concept is hypothesized to bring beneficial results, including:

- Reduction of injection subset consumption.

- Reduction of acquisition cost.

- Reduction of waste generated.

- Reduction of intervention time during maintenance operations.

- Increase in equipment availability time.

4. Research Methodology

Research Design:

The research employed Design Science Research (DSR) as the iterative research methodology, specifically the DSR process developed by Siedhoff [35], which combines design thinking with pre-existing DSR stages. The starting point was the initial design of the product under study, following a case-based reasoning approach. The DSR cycle included exploratory research, problem clarification, solution establishment, and prescriptive research leading to solution recommendations.

Data Collection Method:

Data collection involved:

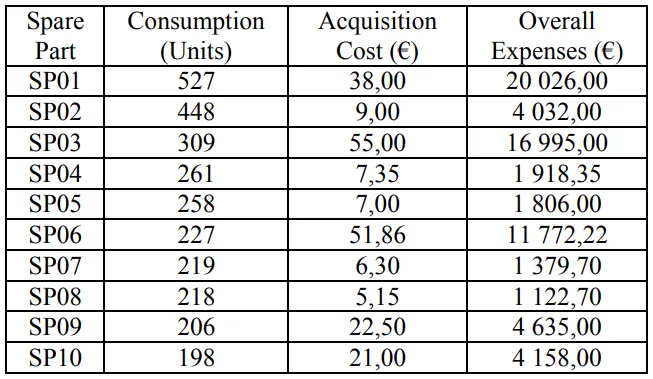

- Creating a classification table of spare parts consumption by quantitative relevance of requests and acquisition costs (Table 1).

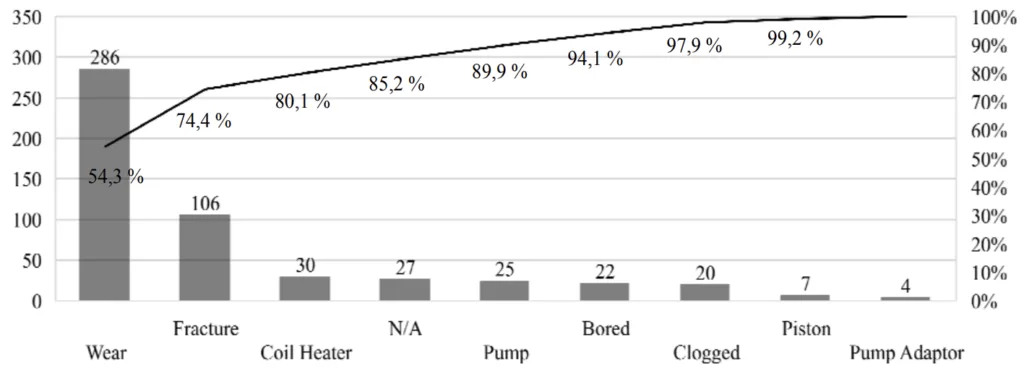

- Pareto's analysis to identify urgent components for study (Figure 1).

- Software-based task assistance data providing problem descriptions, causes, solutions, intervention equipment, and breakdown times.

- Observation and monitorization of the manufacturing process to complement software data.

- Material analysis using SEM and EDS.

- Metallographic and hardness testing.

Analysis Method:

The analysis methods used were:

- Pareto's analysis to prioritize spare parts based on consumption and acquisition costs (Figure 1).

- FMEA to identify failures with the highest breakdowns and intervention times.

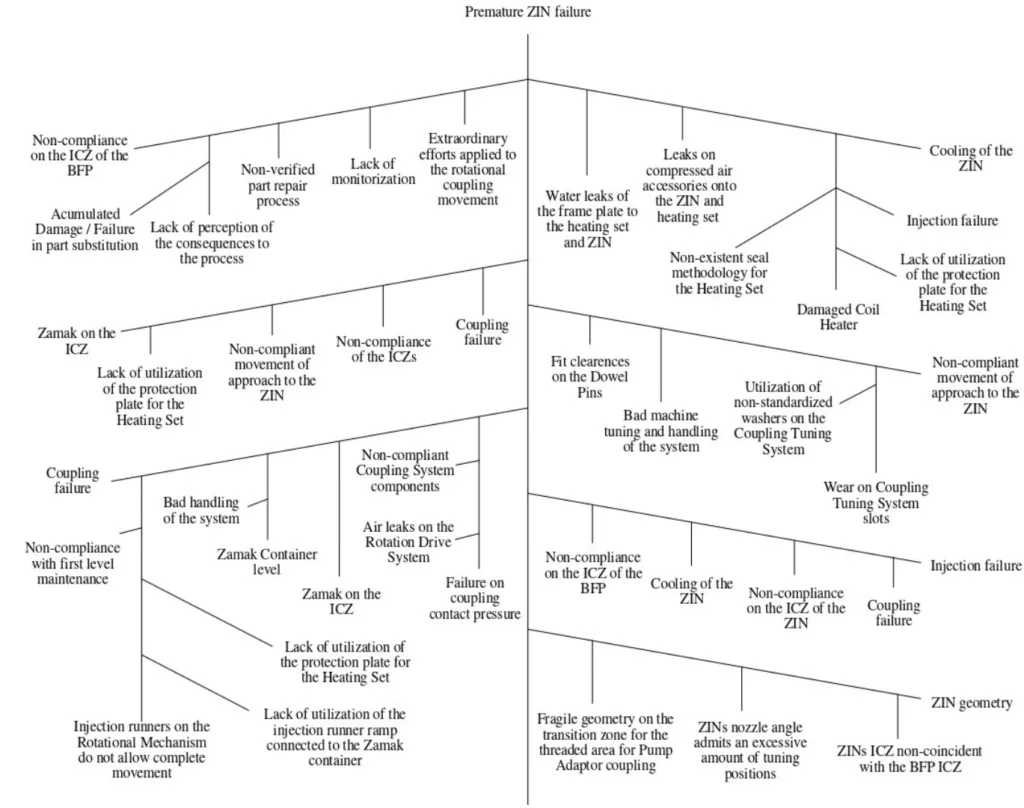

- Ishikawa diagrams to summarize findings and guide development stages (Figure 17).

- SEM and EDS analysis for ZIN wear characterization (Figure 18).

- Metallographic analysis to assess microstructural alterations.

- Rockwell C hardness testing (ISO 6508-1:2016) to measure hardness.

- Quantitative analysis of intervention categorization by system and failure group (Table 2).

Research Subjects and Scope:

The research subject was a Zamak High-Pressure Die Casting Injection Machine (ZHPIM) used for injecting Zamak 5 on steel cable ends. The scope focused on the injection system of the ZHPIM, specifically the injection subset components, including the Zamak Injection Nozzle (ZIN) and related parts. The study analyzed spare part consumption, failure modes, and developed improvements for these components.

5. Main Research Results:

Key Research Results:

- Pareto analysis highlighted SP01, SP03, SP06, SP09, and SP10 as the most urgent spare parts based on accumulated acquisition cost (Figure 1).

- Injection system interventions constituted 43.4% of total interventions, with the Molding Set accounting for 47.9% (Table 2).

- Within the Injection Set, ZIN failures represented 44.6% of interventions (Table 2).

- Wear and fracture were identified as major ZIN failure modes (Figure 4).

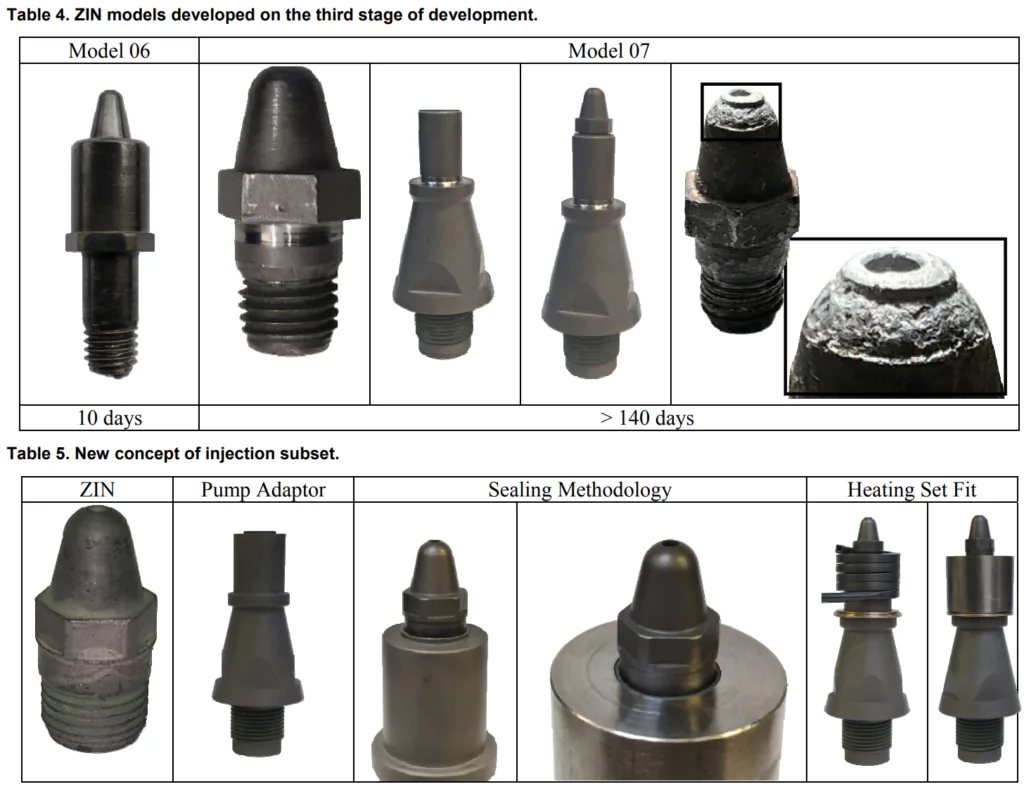

- Design modifications through DSR iterations led to Model 07, which demonstrated wear attributed to excessive plastic deformation, reaching a working time of over 140 days, a significant improvement compared to earlier models (Table 4).

- The new injection subset concept (Model 07) achieved improvements in product efficiency, spare part consumption reduction, an 1100% increase in spare part working time, a 58% reduction in part acquisition cost, and a 55% reduction in corrective maintenance time.

Data Interpretation:

The Pareto analysis effectively directed the research focus to the most cost-intensive spare parts. The categorization of interventions revealed the injection system, particularly the ZIN, as the primary area for improvement. DSR methodology, through iterative design and testing, successfully addressed the premature wear issues of the ZIN. The progression through Models 01 to 07 demonstrates the effectiveness of DSR in developing a significantly improved injection subset, leading to enhanced sustainability and operational efficiency of the ZHPIM. The final Model 07 exhibited a shift in failure mode from brittle fracture to plastic deformation wear, indicating a more predictable and manageable wear process.

Figure Name List:

- Figure 1. Pareto's analysis on spare part consumption by accumulated acquisition cost (Overall expenses).

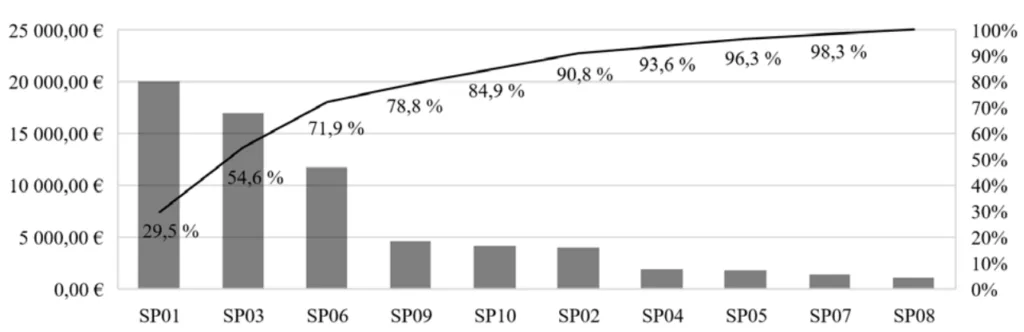

- Figure 2. ZHPIM equipment structure by main systems, sets and working groups.

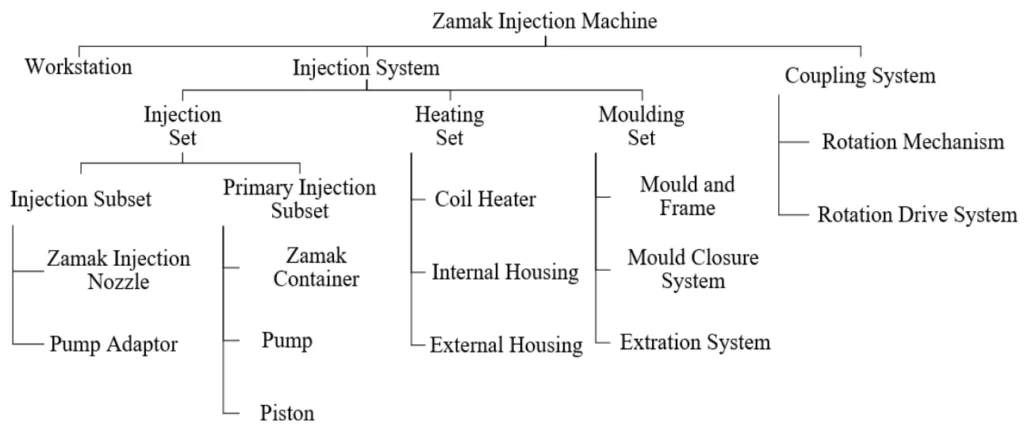

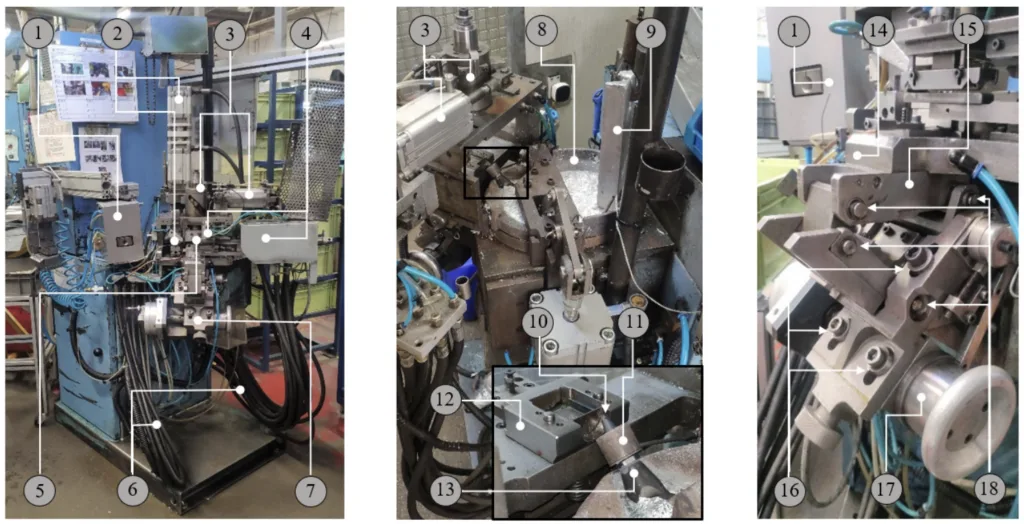

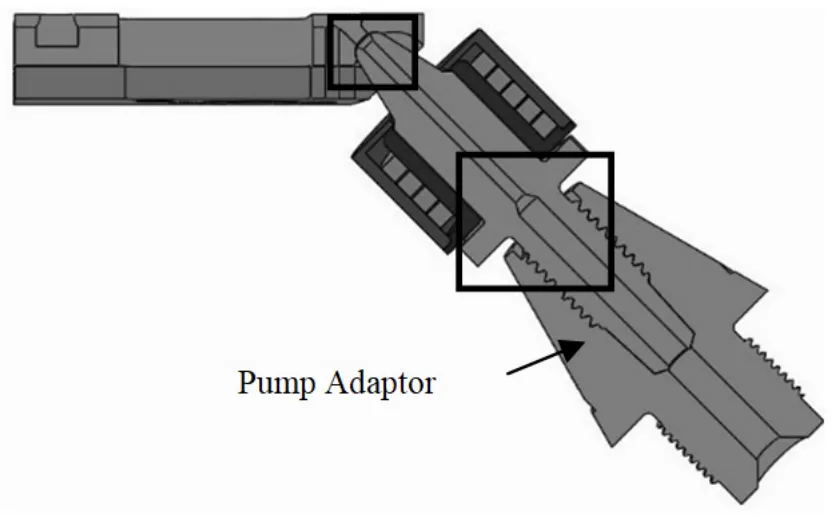

- Figure 3. Workstation, Injection System and Coupling System and corresponding main components and location.

- Figure 4. Pareto's analysis for ZIN failure mode count for the period under study.

- Figure 5. Injection failure caused by technical problems on the coupling system elements.

- Figure 6. Location of the protection plates of the heating set and the internal parts of the moulding set

- Figure 7. Extreme wear on the coupling system tunning slots.

- Figure 8. Clearances on the dowel pins that connect to the coupling system and group of washers found on the ΖΗΡΙΜ.

- Figure 9. Intervention process impact on premature coupling and tunning system wear.

- Figure 10. Technical problems with the seal of the contact between the heating set and the ZIN.

- Figure 11. Failure mode by excessive corrosion of the heating set incapacitating the coil heater.

- Figure 12. Bottom frame plate interaction with the ZIN.

- Figure 13. Contact points between BFP and the ZIN injection contact zones.

- Figure 14. Geometric issues function as a major contributor to failure mode by fracture.

- Figure 15. ICZ from BFP compliant with the required working state.

- Figure 16. Non-compliance of ICZs for the BFP due to abrasion and impact.

- Figure 17. Ishikawa diagram for ZINs premature failure

- Figure 18. SEM analysis to the ZIN.

- Figure 19. Failure mode of the ZIN injection contact zone by pitting.

- Figure 20. Failure mode of the ZIN injection contact zone by spalling.

- Figure 21. Feed marks impact on nucleation and propagation of premature failure.

6. Conclusion:

Summary of Main Results:

The research successfully developed a new injection subset concept for a ZHPIM through Design Science Research. This development resulted in significant improvements, including reduced spare part consumption, acquisition costs, waste, and maintenance intervention time, alongside increased equipment availability and safer intervention processes. The new Model 07 ZIN demonstrated a substantial increase in working time and a shift to a more predictable wear mode.

Academic Significance of the Research:

This research demonstrates the effective application of Design Science Research methodology in the context of die casting product development and sustainable maintenance. It contributes to the body of knowledge by providing a detailed case study of DSR implementation for improving a critical component in a high-pressure die casting system. The study also highlights the importance of iterative design, data-driven analysis, and a maintenance-focused approach to product development.

Practical Implications:

The practical implications of this research are significant for the die casting industry. The developed injection subset concept offers a tangible solution for reducing costs associated with spare parts, maintenance, and downtime in high-pressure die casting operations. The increased lifespan of the ZIN and the optimized maintenance procedures contribute to more sustainable and efficient manufacturing processes. The systematic approach employed can be adapted for improving other components and processes within die casting and similar industries.

Limitations of the Research

The paper does not explicitly state limitations of the research.

7. Future Follow-up Research:

- Directions for Follow-up Research:

The paper suggests further pursuing the advantages obtained on Model 05 regarding the optimization of the intervention process. A more specific analysis of the premature wear of the ICZ is recommended. Further investigation into the material behavior in relation to the selected steel properties is also suggested. - Areas Requiring Further Exploration:

Further exploration could focus on applying the DSR methodology and the developed injection subset concept to other critical components within the ZHPIM or similar die casting machines. Investigating different materials and manufacturing processes for the ZIN and pump adaptor to further enhance wear resistance and performance could also be explored.

8. References:

- [1] R. J. S. Costa, F. J. G. Silva, R. D. S. G. Campilho, "A novel concept of agile assembly machine for sets applied in the automotive industry," Int. J. Adv. Manuf. Technol., Vol. 91, pp. 4043-4054, 2017. doi: 10.1007/s00170-017-0109-4

- [2] W. Araújo, F. J. G. Silva, R. Campilho, "Manufacturing cushions and suspension mats for vehicle seats: A novel cell concept," Int. J. Adv. Manuf. Tech., Vol. 90, pp. 1539-1545. 2017, doi: 10.1007/s00170-016-9475-6

- [3] A. Gritsenko, V. Shepelev, E. Zadorozhnaya, K. Shubenkova, "Test Diagnostics of Engine Systems in Passenger Cars," FME Trans., Vol. 48, pp. 46-52, 2020, doi: 10.5937/fmet2001046G.

- [4] F. J. G. Silva, R. M. Gouveia, Cleaner Production - Towards a Better Future. Cham, Switzerland: Springer International Publishing, 2020.

- [5] J. Malek and T. N. Desai, "A systematic literature review to map literature focus of sustainable manufacturing,” J. Clean. Prod., Vol. 256, p. 120345, 2020, doi: 10.1016/j.jclepro.2020.120345.

- [6] M. Siladić, B. Rašuo, "On-Condition Maintenance for Nonmodular Jet Engines: An Experience," J Eng Gas Turbine Power, Vol. 131(3), p. 032502, May 2009, doi: 10.1115/1.3019104.

- [7] B. Rašuo, G. Djuknić, "Optimization of the aircraft general overhaul process," Aircr. Eng. Aerosp. Technol., Vol. 85(5), pp. 343-354. 2013, doi: 10.1108/AEAT-02-2012-0017.

- [8] C. Franciosi, A. Voisin, S. Miranda, S. Riemma, and B. Iung, “Measuring maintenance impacts on sustainability of manufacturing industries: from a systematic literature review to a framework proposal," J. Clean. Prod., Vol. 260, p. 121065, 2020, doi: 10.1016/j.jclepro.2020.121065.

- [9] S. Ferreira, L. Martins, F. J. G. Silva, R. B. Casais, R. D. S. G. Campilho, and J. C. Sá, “A novel approach to improve maintenance operations," Procedia Manuf., Vol. 51, pp. 1531-1537, 2020, doi: 10.1016/j.promfg.2020.10.213.

- [10] L. Silvestri, A. Forcina, V. Introna, A. Santolamazza, and V. Cesarotti, “Maintenance transformation through Industry 4.0 technologies: A systematic literature review," Comput. Ind., Vol. 123, p. 103335, 2020, doi: 10.1016/j.compind.2020.103335.

- [11]L. Morgado, F. J. G. Silva, and L. M. Fonseca, "Mapping occupational health and safety management systems in Portugal: Outlook for ISO 45001:2018 adoption," Procedia Manuf., Vol. 38, pp. 755-764, 2019, doi: 10.1016/j.promfg.2020.01.103.

- [12] M. Jasiulewicz-Kaczmarek and P. Żywica, “The concept of maintenance sustainability performance assessment by integrating balanced scorecard with non-additive fuzzy integral," Eksploat. Niezawodn., Vol. 20(4), pp. 650–661, 2018, doi: 10.17531/ein.2018.4.16.

- [13] S. Ferreira, F. J. G. Silva, R. B. Casais, M. T. Pereira, and L. P. Ferreira, "KPI development and obsolescence management in industrial maintenance," Procedia Manuf., Vol. 38, pp. 1427–1435, 2019, doi: 10.1016/j.promfg.2020.01.145.

- [14] C. Franciosi, A. Lambiase, C. Franciosi, A. Lambiase, S. Alfredo, "Sustainable Maintenance: a Maintenance: a Periodic Maintenance: Sustainable Maintenance: a Periodic Preventive Spare Parts Sustainable Spare Parts Management,” IFAC-PapersOnLine, Vol. 50(1), pp. 13692–13697, 2017, doi: 10.1016/j.ifacol.2017.08.2536.

- [15]T. Santos, F. J. G. Silva, S. F. Ramos, R. D. S. G. Campilho, and L. P. Ferreira, “Asset priority setting for maintenance management in the food industry," Procedia Manuf., Vol. 38, pp. 1623-1633, 2019, doi: 10.1016/j.promfg.2020.01.122.

- [16]T.G. Chondros, "The Development of Mechanics and Engineering Design and Machine Theory since the Rennaissance," FME Trans., Vol. 49, pp. 291-307, 2021, doi: 10.5937/fme2102291C.

- [17] F. Schönberg and M. Messer, "Decision data model in virtual product development,” Comput. Ind. Eng., Vol. 122, pp. 106-124, 2018, doi: 10.1016/j.cie.2018.05.047.

- [18]S. Altuntas, E. B. Özsoy, and Şi. Mor, “Innovative new product development: A case study," Procedia Comput. Sci., Vol. 158, pp. 214–221, 2019, doi: 10.1016/j.procs.2019.09.044.

- [19]M. Riesener, C. Doelle, M. Mendl-Heinisch, and N. Klumpen, "Identification of evaluation criteria for algorithms used within the context of product development," Procedia CIRP, Vol. 91, pp. 508-515, 2020, doi: 10.1016/j.procir.2020.02.207.

- [20] G. Bastchen, F. Silva, and M. Borsato, "Risk management analysis in the product development process," Procedia Manuf., Vol. 17, pp. 507-514, 2018, doi: 10.1016/j.promfg.2018.10.090.

- [21]J. G. Persson, “Current Trends in Product Development," Procedia CIRP, Vol. 50, pp. 378-383, 2016, doi: 10.1016/j.procir.2016.05.088.

- [22]R. G. Cooper, “The drivers of success in new-product development,” Ind. Mark. Manag., Vol. 76, pp. 36-47, 2019, doi: 10.1016/j.indmarman.2018.07.005.

- [23] V. Nunes, F. J. G. Silva, M. F. Andrade, R. Alexandre, A. P. M. Baptista, "Increasing the lifespan of high-pressure die cast molds subjected to severe wear," Surf Coat Tech, Vol. 332, pp. 319-331, 2017. doi: 10.1016/j.surfcoat.2017.05.098.

- [24]B.M.D.N. Moreira, R.M. Gouveia, F.J.G. Silva, R. D. S. G. Campilho, "A Novel Concept Of Production And Assembly Processes Integration," Procedia Manuf., Vol. 11, pp. 1385-1395. 2017, doi: 10.1016/j.promfg.2017.07.268.

- [25] V.F.C. Sousa, F.J.G. Silva, L.P. Ferreira, R.D.S.G. Campilho, T. Pereira, E. Braga, "Improving the Design of Nozzles Used in Zamak High-Pressure Die-Casting Process," FME Trans., Vol. 49, pp. 1005-1013, 2021. doi: 10.5937/fme2104005S.

- [26] O.I. Abdullah, W.T. Abbood, H.K. Hussein, "Development of Automated Liquid Filling System Based on the Interactive Design Approach," FME Trans., Vol. 48, pp. 938-945, 2020. doi: 10.5937/fme2004938A.

- [27] S. Tamada, M. Chandra, P. Patra, S. Mandol, D. Bhattacharjee, P.K. Dan, " Modeling for Design Simplification and Power-Flow Efficiency Improvement in an Automotive Planetary Gearbox: A Case Example," FME Trans., Vol. 48, pp. 707-715, 2020. doi: 10.5937/fme2003707T.

- [28] J. Grenha Teixeira, L. Patrício, K. H. Huang, R. P. Fisk, L. Nóbrega, and L. Constantine, “The MINDS Method: Integrating Management and Interaction Design Perspectives for Service Design," J. Serv. Res., Vol. 20(3), pp. 240-258, 2017, doi: 10.1177/1094670516680033.

- [29] Richard Baskerville & Vijay Vaishnavi, 2020. "A Novel Approach to Collectively Determine Cybersecurity Performance Benchmark Data," Progress in IS, in: Jan vom Brocke & Alan Hevner & Alexander Maedche (ed.), Design Science Research. Cases, pages 17-41, Springer.

- [30] V. K. Vaishnavi and W. K. Jr., “Introduction to Design Science Research in Information and Communication Technology," Des. Sci. Res. Methods Patterns Innov. Inf. Commun. Technol., 2nd edition, pp. 7-30, Boca Raton, FL, USA, CRC Press, 2015. ISBN: 9780429172205.

- [31]F. Devitt and P. Robbins, “Design, Thinking and Science," Commun. Comput. Inf. Sci., Vol. 388, pp-38-48, 2013, doi: 10.1007/978-3-319-04090-5.

- [32] K. Peffers, T. Tuunanen, M. A. RotUhenberger, and S. Chatterjee, "A design science research methodology for information systems research,” J. Manag. Inf. Syst., Vol. 24(3), pp. 45–77, 2007, doi: 10.2753/MIS0742-1222240302.

- [33]J. Q. Azasoo and K. O. Boateng, "A Retrofit Design Science Methodology for Smart Metering Design in Developing Countries," Proc. - 15th Int. Conf. Comput. Sci. Its Appl. ICCSA 2015, pp. 1–7, 2015, doi: 10.1109/ICCSA.2015.23.

- [34] Jan vom Brocke & Alan Hevner & Alexander Maedche, "Introduction to Design Science Research," Progress in IS, in: Jan vom Brocke & Alan Hevner & Alexander Maedche (ed.), Design Science Research. Cases, pages 1-13, 2020, Springer. doi: 10.1007/978-3-030-46781-4_1.

- [35] S. Siedhoff, "Design science research,” Seizing Bus. Model Patterns Disruptive Innov., pp. 29-43, Spinger, 2019. ISBN: 978-3658263355.

- [36] S. Gregor and A. R. Hevner, “Positioning and presenting design science research for maximum impact," MIS Q., Vol. 37(2), pp. 337–355, 2013, doi: 10.2753/MIS0742-1222240302.

- [37] K. Lepenioti, A. Bousdekis, D. Apostolou, and G. Mentzas, “Prescriptive analytics: Literature review and research challenges,” Int. J. Inf. Manage., Vol. 50, pp. 57–70, 2020, doi: 10.1016/j.ijinfomgt. 2019.04.003.

- [38] M. Relich and P. Pawlewski, “A case-based reasoning approach to cost estimation of new product development,” Neurocomputing, Vol. 272, pp. 40-45, 2018, doi: 10.1016/j.neucom.2017.05.092.

- [39] H. Saranga, et al. "Resource configurations, product development capability, and competitive advantage: An empirical analysis of their evolution," J. Bus. Res., Vol. 85, pp. 32-50, 2018, doi: 10.1016/j.jbusres.2017.11.045.

- [40] G. Pinto, F. J. G. Silva, A. Baptista, R. D. S. G. Campilho, and F. Viana, “Investigations on the Oxidation of Zn-coated Steel Cables," FME Trans., Vol. 49(3) pp. 587-597, 2021, doi: 10.5937/fme2103587P.

- [41]N. Martins, F. J. G. Silva, R. D. S. G. Campilho, and L. P. Ferreira, "A novel concept of Bowden cables flexible and full-automated manufacturing process improving quality and productivity,” Procedia Manuf., Vol. 51, pp. 438-445, 2020, doi: 10.1016/j.promfg.2020.10.062.

- [42] R. Ribeiro, F. J. G. Silva, A. G. Pinto, R. D. S. G. Campilho, and H. A. Pinto, “Designing a novel system for the introduction of lubricant in control cables for the automotive industry," Procedia Manuf., Vol. 38, pp. 715-725, 2019, doi: 10.1016/j.promfg.2020.01.096.

- [43]H. A. Pinto, F. J. G. Silva, R. P. Martinho, R. D. S. G. Campilho, and A. G. Pinto, “Improvement and validation of Zamak die casting moulds," Procedia Manuf., Vol. 38, pp. 1547–1557, 2019, doi: 10.1016/j.promfg.2020.01.131.

- [44] H. Pinto, F. J. G. Silva, “Optimisation of Die Cast-ing Process in Zamak Alloys," Procedia Manuf., Vol. 11, pp. 517–525, 2017, doi: 10.1016/j.prom fg.2017.07.145.

- [45]B. Arh, B. Podgornik, and J. Burja, "Electroslag remelting: A process overview,” Mater. Tehnol., Vol. 50(6), pp. 971-979, 2016, doi: 10.17222/mit.2016.108.

- [46] A. Pribulová, P. Futaš, M. Bartošová, “Cleanness and mechanical properties of steel after remelting under different slags by ESR," Key Eng. Mater., Vol. 635, pp. 112-117, 2015, doi: 10.4028 /www.scientific.net/KEM.635.112.

- [47]Y. Pan, C. Chen, S. Wang, “Properties Evaluation of a H13 ESR Hot Work Tool Steel Produced Using a Continuous Casting Electrode," China Steel Technical Report, Vol. 29, pp. 49-55, 2016.

9. Copyright:

- This material is "Matilde C. Tojal, F. J. G. Silva, R. D. S. G. Campilho, Arnaldo G. Pinto, Luís Pinto Ferreira"'s paper: Based on "Case-Based Product Development of a High-Pressure Die Casting Injection Subset Using Design Science Research".

- Paper Source: doi: 10.5937/fme2201032T

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.