This article introduces the paper "Geometrical algorithms for automated design of side actions in injection moulding of complex parts" presented at the Computer-Aided Design

1. Overview:

- Title: Geometrical algorithms for automated design of side actions in injection moulding of complex parts

- Authors: Ashis Gopal Banerjee and Satyandra K. Gupta

- Publication Year: 2007

- Publishing Journal/Academic Society: Computer-Aided Design

- Keywords: Geometric Algorithms, Automated Design, Side Actions, Injection Molding, Undercuts, Cost Function

2. Research Background:

- Social/Academic Context of the Research Topic: Complex injection molded parts frequently incorporate undercuts, which are features inaccessible via the main mold opening directions. Side actions, secondary mold components, are essential for forming these undercuts. However, designing side actions manually is a "challenging task" demanding "considerable expertise". This manual process contributes to increased mold costs due to additional manufacturing, assembly, and longer molding cycle times. Therefore, automating side action design is crucial to reduce mold design lead times and optimize the overall injection molding process.

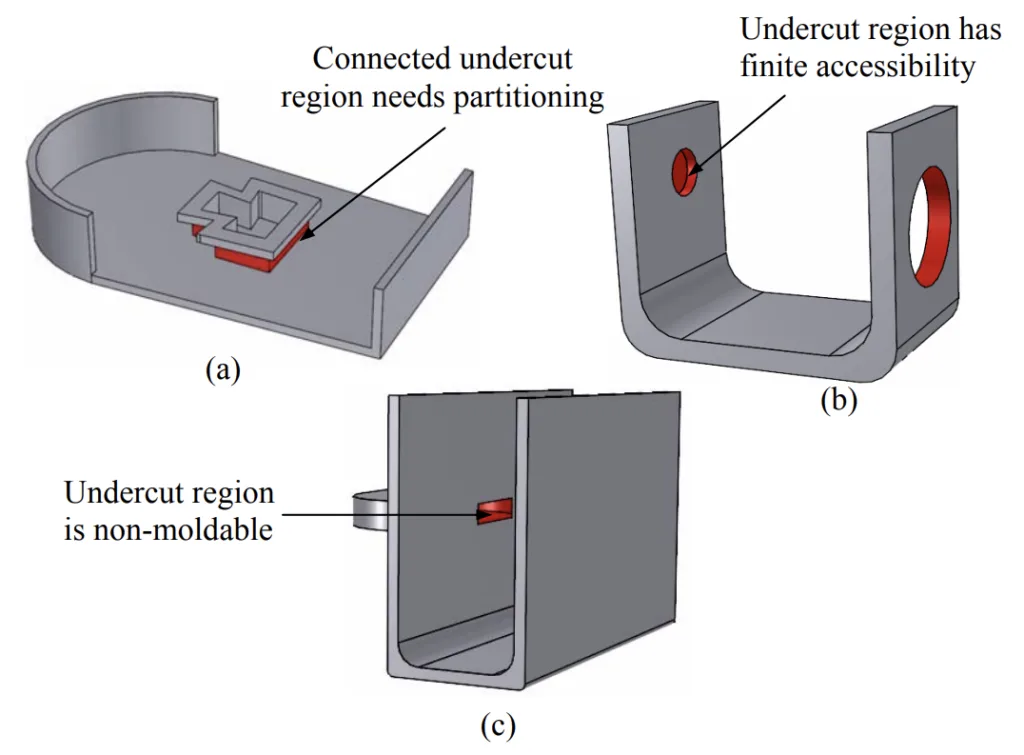

- Limitations of Existing Research: Existing side action design methods often fall short in providing optimal solutions. They "do not always work satisfactorily (i.e. cannot generate an optimal solution from an exhaustive set of feasible solutions) if a complex undercut region (1) needs to be partitioned to generate side actions, or (2) has finite accessibility or (3) is impossible to mold, thereby requiring the part to be redesigned." Many methods rely on "heuristic directions" and may necessitate "post-processing operations (e.g. simulation)" to validate mold piece interference.

- Necessity of the Research: The research addresses the necessity for automated side action design to overcome the limitations of manual methods and existing automated approaches. Automated design promises to "significantly reduce mold design lead times" and optimize the process by minimizing a "customizable molding cost function." This research is essential for advancing injection molding technology and enabling efficient manufacturing of complex parts.

3. Research Purpose and Research Questions:

- Research Purpose: The primary research purpose is to "describe algorithms for generating shapes of side actions to minimize a customizable injection molding cost function." The paper aims to present a "new algorithm to handle these types of cases" where existing methods are inadequate for complex undercut regions.

- Key Research Questions: The research seeks to answer:

- How can geometrical algorithms automate the design of side actions for complex injection molded parts with undercuts?

- How can a customizable molding cost function be integrated into the automated design process to optimize side action design?

- How can complex undercut regions, including those requiring partitioning or with limited accessibility, be effectively handled algorithmically?

- Research Hypotheses: While not explicitly stated, the underlying hypothesis is that "the results presented in this paper will provide the foundations for developing fully automated software for designing side actions." The authors propose that geometrical algorithms can be developed to automate side action design, effectively addressing complex undercut geometries and minimizing a customizable molding cost function.

4. Research Methodology

- Research Design: The research employs a computational geometry-based approach, focusing on the development and implementation of geometrical algorithms for automated side action design.

- Data Collection Method: The research utilizes geometric models of polyhedral parts and mold enclosures as input. Computational experiments are conducted to test and validate the developed algorithms.

- Analysis Method: The algorithms are analyzed through computational experiments, evaluating their performance based on metrics such as computation time, the number of nodes in the search space, and branching factors. Methods like "depth-first branch and bound algorithm", "Minkowski sum", "collision detection", and "sweep-based collision polygon" are employed within the algorithms.

- Research Subjects and Scope: The research focuses on the design of side actions for "polyhedral parts" with "undercut facets" in injection molding. The scope is limited to side actions that retract "perpendicular to the main mold opening direction," primarily focusing on "sliders and lifters" as side action mechanisms.

5. Main Research Results:

- Key Research Results: The paper successfully developed and presented algorithms for:

- "generating shapes of side actions to minimize a customizable injection molding cost function."

- "computing candidate retraction space for every undercut facet."

- generating "a discrete set of feasible, non-dominated retractions."

- grouping "undercut facets into undercut regions by performing state space search over such retractions."

- generating "the shapes of individual side actions."

- Statistical/Qualitative Analysis Results: Table 1 in the paper presents the "Results of computational experiments," quantifying the performance of the algorithms across different part models with varying complexities. For instance, for Part A Model #1, the "Candidate retraction space computation time" is reported as "3.5 (in s)," and the "Feasible retraction set generation time" as "5.2 (in s)." Figure 15 visually demonstrates "Alternative designs obtained by modifying the cost function parameters," showcasing the algorithm's adaptability to different cost considerations.

- Data Interpretation: The computational results, as shown in Table 1, indicate the efficiency and feasibility of the proposed algorithms. The paper highlights that "Based upon the given set of cost function parameter values, an optimal set of 2 or 3 side actions were generated for four sample parts in about 30-50s," suggesting a "reasonably good performance." Figure 15 further illustrates the algorithm's capability to produce varied side action designs based on customized cost function parameters, demonstrating its practical applicability.

- Figure Name List:

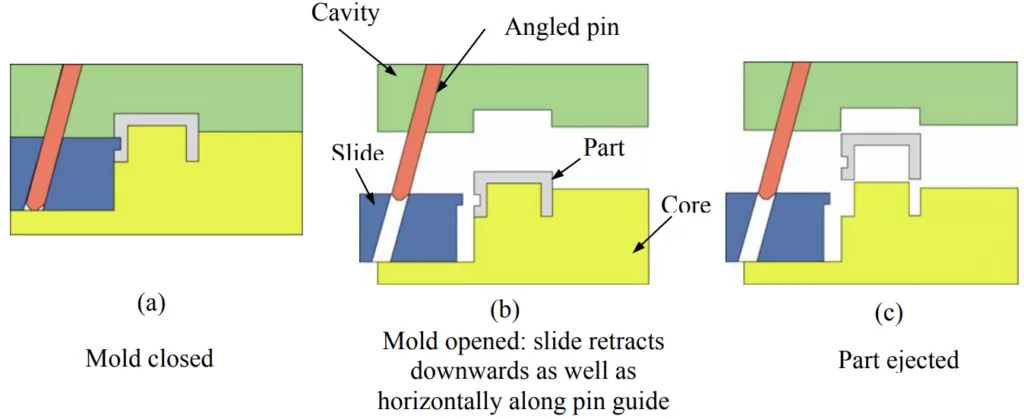

- Figure 1: Side action removal in a direction different from the main mold opening direction

- Figure 2: Steps after part solidification for molding external undercuts using slider

- Figure 3: Steps after part solidification for molding internal undercuts using lifters

- Figure 4: Typical thin-walled plastic parts

- Figure 5: Parts that pose challenges for existing side action design algorithms

- Figure 6: Candidate and non-candidate core retractions

- Figure 7: Candidate core retraction space

- Figure 8: Difference between candidate and feasible core retractions

- Figure 9: Intersection of two candidate retraction spaces

- Figure 10: Maximum error in retraction length

- Figure 11: Constructing collision-free 2D translation space

- Figure 12: Constructing candidate core retraction space

- Figure 13: Five test parts

- Figure 14: Side action solids for 4 different test parts (A, B, C, D) shown in retracted state

- Figure 15: Alternative designs obtained by modifying the cost function parameters

6. Conclusion and Discussion:

- Summary of Main Results: The research successfully introduced novel algorithms for automating side action design in injection molding. These algorithms effectively address complex undercut geometries and minimize a user-defined molding cost function. Key algorithmic steps include candidate retraction space computation, feasible retraction selection, undercut region grouping, and side action shape generation. Computational experiments validate the approach's feasibility and efficiency.

- Academic Significance of the Research: This work makes a significant academic contribution to the field of automated mold design. It provides a robust algorithmic framework for side action design, overcoming limitations of prior methods and offering a more optimized and comprehensive solution.

- Practical Implications: The developed algorithms hold substantial practical implications for the injection molding industry. They pave the way for creating fully automated side action design software, which can drastically reduce mold design lead times, enhance design quality, accelerate product development cycles, and lower manufacturing costs.

- Limitations of the Research: The paper acknowledges that "The current objective function does not account for the orientations of the retractions," suggesting an area for future refinement. Furthermore, the research primarily focuses on "side core" type side actions, indicating that "Further work needs to be done to generalize our method to design other kinds of side actions, namely, split cores, fused cores etc."

7. Future Follow-up Research:

- Directions for Follow-up Research: The paper suggests several avenues for future research, including:

- Generalizing the algorithms to accommodate other types of side actions like "split cores, fused cores etc."

- Enhancing the "edge sub-division scheme" to strengthen theoretical foundations.

- Extending the approach to "directly design side actions from NURBS surfaces" for seamless integration with CAD systems.

- Exploring the "possibility of selecting main mold opening direction concurrently with side action design" for integrated optimization.

- Expanding the algorithms to handle cases where "side actions need not be necessarily retracted in a plane perpendicular to the mold opening directions," potentially involving 3D retraction space analysis.

- Areas Requiring Further Exploration: Further exploration is needed in refining the objective function to incorporate retraction orientation, generalizing the algorithms to diverse side action mechanisms, integrating with NURBS-based CAD environments, concurrently optimizing parting direction and side action design, and extending the approach to 3D retraction space analysis for more complex scenarios.

8. References:

- [1] H. K. Ahn, M. Berg, P. Bose, S. W. Cheng, D. Halperin, J. Matoušek, and O. Schwarzkopf. Separating an Object from Its Cast. Computer Aided Design, Vol. 34, No. 8, pp. 547-559, 2002.

- [2] B. Aronov, and M. Sharir. On Translational Motion Planning of a Convex Polyhedron in 3-Space. Siam Journal of Computing, Vol. 26, No. 6, pp. 1785-1803, 1997.

- [3] A. G. Banerjee. Computer Aided Design of Side Actions for Injection Molding of Complex Parts. Master of Science Thesis, University of Maryland, College Park, 2006.

- [4] Cgal.org. Computational Geometry Algorithms Library. http://www.cgal.org, 2004.

- [5] L.L. Chen, S.Y. Chou, and T.C. Woo. Parting Directions for Mould and Die Design. Computer Aided Design, Vol. 25, No. 12, pp. 762-768, 1993.

- [6] L.L. Chen, S. Y. Chou, and T. C. Woo. Partial Visibility for Selecting a Parting Direction in Mould and Die Design. Journal of Manufacturing Systems, Vol. 14, No. 5, pp. 319-330, 1995.

- [7] X. Chen and S. McMains. Finding All Undercut-free Parting Directions for Extrusions. Geometric Modeling and Processing, 2006, Lecture Notes in Computer Science, Vol. 4077, pp. 514-527, 2006.

- [8] Y. Chen, and D.W. Rosen. A Region Based Method to Automated Design of Multi-Piece Molds with Application to Rapid Tooling, Journal of Computing and Information Science in Engineering, Vol. 2, No. 2, pp. 86-97, 2002.

- [9] Y. Chen, and D.W. Rosen. A reverse glue approach to automated construction of multi-piece molds, Journal of Computing and Information Science in Engineering, Vol. 3, No. 3, pp. 219-230, 2003.

- [10] Y. H. Chen. Determining parting direction based on minimum bounding box and fuzzy logics. International Journal of Machine Tools and Manufacture, Vol. 37, No. 9, pp. 1187-1199, 1997.

- [11] T. H. Cormen, C. E. Leiserson, R. L. Rivest, and C. Stein. Introduction to Algorithms, The MIT Press, 2001.

- [12] M. de Berg, M. van Kreveld, M. Overmars, and O. Schwarzkopf. Computational geometry: algorithms and applications, Second Edition. Springer-Verlag, Berlin, 2000.

- [13] S. Dhaliwal, S.K. Gupta, J. Huang, and A. Priyadarshi. Algorithms for Computing Global Accessibility Cones. Journal of Computing and Information Science in Engineering, Vol. 3, No. 3, pp. 200-209, 2003.

- [14] G. Elber, X. Chen, and E. Cohen. Mold Accessibility via Gauss Map Analysis. Journal of Computing and Information Science in Engineering, Vol. 5, No. 2, pp. 79-85, 2005.

- [15] G. Fowler. Cost and Performance Evaluation Models For Comparing Traditional and Multi-Shot Injection Molding. Master of Science Thesis, University of Maryland, College Park, 2004.

- [16] M. W. Fu, J. Y. H. Fuh, and A. Y. C. Nee. Generation of optimal parting direction based on undercut features in injection molded parts. IIE Transactions Vol. 31, pp. 947-955, 1999.

- [17] M. W. Fu, J. Y. H. Fuh, and A. Y. C. Nee, Undercut Feature Recognition in an Injection Mould Design System. Computer Aided Design, Vol. 31, No. 12, pp. 777-790, 1999.

- [18] M. A. Ganter, and P. A. Skoglund. Feature extraction for casting core development. Journal of Mechanical Design, Vol. 115, No. 4, pp. 744-750, 1993.

- [19] S. K. Gupta, A. G. Banerjee, X. Li, and G. Fowler. Development of a Manufacturability Analysis Framework for Injection Molded Multi-Material Objects. In NSF Design, Service, and Manufacturing Grantees and Research Conference, St. Louis, MO, 2006.

- [20] J. Huang, S. K. Gupta, and K. Stoppel. Generating sacrificial multi-piece molds using accessibility driven spatial partitioning. Computer Aided Design, Vol. 35 No. 3, pp. 1147-1160, 2003.

- [21] K. C. Hui, and S. T. Tan. Mould design with sweep operations-a heuristic search approach. Computer Aided Design, Vol. 24, No. 2, pp. 81-91, 1992.

- [22] K C. Hui. Geometric Aspects of the Mouldability of Parts. Computer Aided Design, Vol. 29, No. 3, pp. 197-208, 1997.

- [23] L. Kettner. Software Design in Computational Geometry and Contour-Edge Based Polyhedron Visualization. Ph.D. Thesis, ETH Zurich, Switzerland, 1999.

- [24] R. Kharderkar, G. Burton, and S. McMains. Finding feasible mold parting directions using graphics hardware. Computer Aided Design, Vol. 38, No. 4, pp. 327-341, 2006.

- [25] W. T. Liou, J. J-M. Tan, and R. C. T. Lee. Minimum Rectangular Partition Problem for Simple Rectilinear Polygons. IEEE Transactions on Computer-Aided Design, Vol. 9, No. 7, pp. 720-733, 1990.

- [26] H. Y. Lu, and W. B. Lee. Detection of Interference Elements and Release Directions in Die-cast and Injection-moulded Components. Proceedings of the Institution of Mechanical Engineers, Part B Journal of Engineering Manufacture, Vol. 214, No. 6, pp. 431-441, 2000.

- [27] S. McMains and X. Chen. Finding Undercut-Free Parting Directions for Polygons with Curved Edges. Journal of Computing and Information Science in Engineering, Vol. 6, No. 1, pp. 60-68, 2006.

- [28] C. Poli. Design for Manufacturing, A Structured Approach. Butterworth-Heinemann: Boston, Massachusetts, 2001.

- [29] A. K. Priyadarshi, and S. K. Gupta. Geometric algorithms for automated design of multi-piece permanent molds. Computer Aided Design, Vol. 36, No. 3, pp. 241-260, 2004.

- [30] A. K. Priyadarshi, and S. K. Gupta. Finding Mold-Piece Regions Using Computer Graphics Hardware. Geometric Modeling and Processing, 2006, Lecture Notes in Computer Science, Vol. 4077, pp. 655-662, 2006.

- [31] D. Rappaport, and A. Rosenbloom. Moldable and castable polygons. Computational Geometry: Theory and Applications, Vol. 4, No. 4, pp. 219-233, 1994.

- [32] B. Ravi, and M. N. Srinivasan. Decision criteria for computer-aided parting surface design. Computer Aided Design, Vol. 22, No. 1, pp. 11-18, 1990.

- [33] K. H. Shin, and K. Lee. Design of Side Cores of Injection Mold from Automatic Detection of Interference Faces. Journal of Design and Manufacturing, Vol. 3, No. 4, pp. 225-236, 1993.

- [34] T. Wong, S.T. Tan, and W.S. Sze. Parting line formation by slicing a 3D CAD model. Engineering with Computers, Vol. 14, No. 4, pp. 330-343, 1998.

- [35] X. G. Ye, J. Y. H. Fuh, and K. S. Lee. A hybrid method for recognition of undercut features from moulded parts. Computer Aided Design, Vol. 33, No. 14, pp. 1023-1034, 2001.

- [36] X. G. Ye, J. Y. H. Fuh, and K. S. Lee. Automatic Undercut Feature Recognition for Side Core Design of Injection Molds. Journal of Mechanical Design, Vol. 126, pp. 519-526, 2004.

- [37] Z. Yin, H. Ding, and Y. Xiong. Virtual Prototyping of Mold Design: Geometric Mouldability Analysis for Near-net-shape Manufactured Parts by Feature Recognition and Geometric Reasoning. Computer Aided Design, Vol. 33, No. 2, pp. 137-154, 2001.

9. Copyright:

This material is Ashis Gopal Banerjee and Satyandra K. Gupta's paper: Based on Geometrical algorithms for automated design of side actions in injection moulding of complex parts.

Paper Source: https://www.researchgate.net/publication/222301183

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.