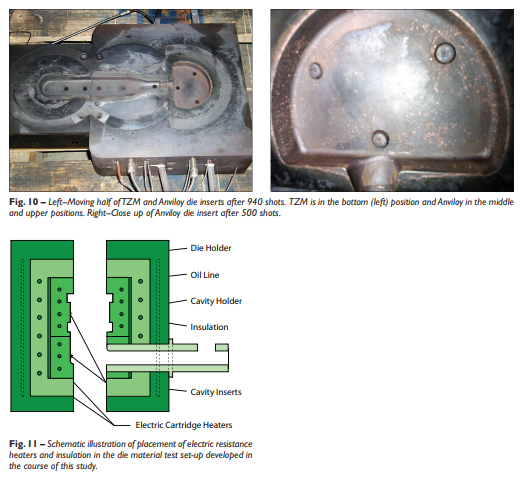

Fig. 10 – Left--Moving half of TZM and Anviloy die inserts after 940 shots. TZM is in the bottom (left) position and Anviloy in the middle and upper positions. Right--Close up of Anviloy die insert after 500 shots. Fig. 11 – Schematic illustration of placement of electric resistance heaters and insulation in the die material test set-up developed in the course of this study