This introduction paper is based on the paper "Metal Casting Dies" published by "Indian Foundry Journal".

1. Overview:

- Title: Metal Casting Dies

- Author: Thoguluva Raghavan Vijayaram

- Year of publication: 2011

- Journal/academic society of publication: Indian Foundry Journal (Vol 57 No. 10 October 2011)

- Keywords: Die-casting, die materials, casting dies, die design, heat transfer and fluid flow, die design factors, casting die life, casting die defects.

2. Abstract:

Die-castings are the highest produced engineering components in foundries. These cast products are important components ranging from automotive to playing toys. Die-casting is a versatile process for producing engineered metal parts. The liquid metal or alloy is forced under high pressure into reusable metallic moulds in a casting process. Metallic moulds used in die-casting technology are called as casting dies. In this paper, different types of casting dies are discussed. Parts produced by die-casting can be sharply defined with smooth or textured surfaces and are suitable for a wide variety of attractive and serviceable finishes. Die-casters can produce castings in a variety of shapes, sizes and wall thicknesses that are light-weight, strong, durable and dimensionally precise. Die-casting process has been well-researched and systematically quantified in terms of thermodynamics, heat transfer and fluid flow. Design factors causing thermal fatigue should be identified to extend the die life. In die-casting process, die design and die manufacturing costs are high. The main cause of failure of die-casting dies are due to thermal fatigue cracking. This paper explains about the different types of die materials used for die fabrication. Besides, properties of dies, defects in casting dies and die life are discussed. The basics of die construction design and procedures are presented with their constructional features.

3. Introduction:

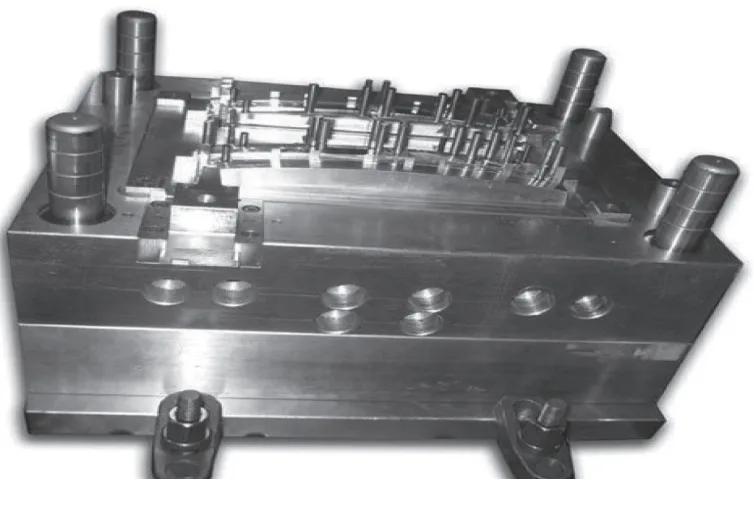

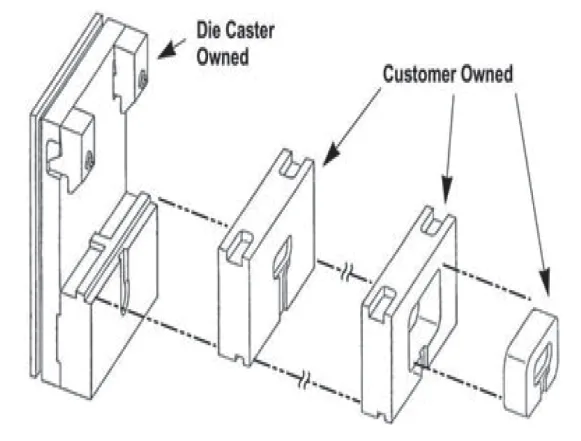

In the die-casting process, liquid metal or alloy is forced under high pressure into reusable metallic moulds. Die-casting dies may be classified as single cavity die, multiple cavity die, combination die, and unit dies. Only one mould cavity is present in the single cavity die. Multiple cavity die will have several identical cavities. Combination cavity die will have several different cavities. Unit dies will have simple small dies that can be combined in two or more units in a master holding die [1,2]. A pressure-casting die is shown in Fig. 1. As per the AICI, the commonly used die materials are tool steels, die steels, hot work die steels, shock-resisting die steels, high speed steels, mould steels, water-hardening steels, and maraging steels. Various types of casting die defects are heat checks, shrinkage of a die, die surface erosion, die surface crack, die breakage, lack of hot hardness, improper and rough surface finish during fabrication and thermal fatigue [3].

Tool steel dies are expensive and high startup costs are involved in setting it. Effective use of advanced die materials and cooling methods extend and increase the die life changes in the dimensions of the die and the location of the water cooling lines in the die will affect the die life.

Casting dies should have high strength, impact toughness, hot hardness, wear resistance at room and elevated temperatures[4, 5]. Hot work tool steels are used to fabricate dies due to its superior properties like applications at higher temperatures, high toughness and high resistance to wear and cracking. The alloying elements present in steel are tungsten, molybdenum, chromium and vanadium, which greatly influence the mechanical, physical, chemical and manufacturing properties like hardenability, castability, formability, machinability and weldability. In this paper, different types of casting dies, materials for fabricating dies, die life, various die defects, mechanical properties, casting die construction and die design procedure are discussed in detail.

4. Summary of the study:

Background of the research topic:

Die-castings are significant engineering components, produced in large volumes. Die-casting is a versatile manufacturing process where molten metal is forced under high pressure into reusable metallic molds, known as casting dies. This process allows for the production of parts with sharp definitions, smooth or textured surfaces, and a wide range of shapes, sizes, and wall thicknesses, resulting in lightweight, strong, durable, and dimensionally precise components. The die-casting process itself is well-understood in terms of thermodynamics, heat transfer, and fluid flow. However, die design and manufacturing involve high costs, and a primary cause of die failure is thermal fatigue cracking.

Status of previous research:

The field of die casting relies on established knowledge regarding die classification (single cavity, multiple cavity, combination, and unit dies, as detailed in [1,2]). Common materials for die construction, such as various tool steels and hot work die steels, are standardized (e.g., by AICI). Identified die defects include heat checks, shrinkage, and surface erosion [3]. Desirable mechanical properties for dies, such as high strength, impact toughness, hot hardness, and wear resistance, are well-documented [4,5]. Hot work tool steels are frequently chosen for die fabrication due to their superior performance at high temperatures and resistance to wear and cracking, with alloying elements like tungsten, molybdenum, chromium, and vanadium playing crucial roles in determining the steel's overall properties.

Purpose of the study:

This paper aims to:

- Discuss the different types of casting dies.

- Explain the various die materials used for die fabrication.

- Describe the properties of dies, common defects found in casting dies, and factors affecting die life.

- Present the fundamental principles of die construction design and procedures, including their constructional features.

Core study:

The paper covers several key aspects of metal casting dies:

- Classification of Die-Casting Dies: Details on single-cavity, multiple-cavity, combination, and unit dies.

- Engineering Materials for Dies: A list of materials including various steels (Tool Steels, Die Steels, Hot Work Die Steels), cast iron, and other specialized alloys.

- Defects in Casting Dies: An enumeration of common defects such as die wear, heat checks, surface erosion, and thermal fatigue.

- Die Life: Discussion of factors influencing die longevity and typical operational lifespans for dies used with different alloys.

- Properties of Dies: Highlighting essential characteristics like strength, toughness, hot hardness, and wear resistance.

- Basic Rules for Casting Die Design: Guidelines covering taper draft, sprue/runner systems, process automation, and the use of lubricants.

- Casting Die Construction and Design Procedure: Information on die assembly (fixed and ejector halves), the importance of early collaboration with die-casters, adherence to design procedures (e.g., NADCA), and critical aspects like gating system design and fill time.

- Heat Transfer in Die Design: Detailed explanation of heat transfer principles, including equations for calculating maximum filling time, heat available from the molten metal (with contributions from Foster Bennett, Wallace, and Flemings), and heat transfer rates.

5. Research Methodology

Research Design:

The paper is a descriptive and explanatory review of established knowledge, principles, and practices within the field of metal casting die technology. It synthesizes information from existing literature and industry standards.

Data Collection and Analysis Methods:

Information was compiled from published academic works (as cited in references [1]-[6]), industry standards and guidelines (from organizations such as AISI, NADCA, ACDA, SDCE, ADCI), and established engineering principles. The analysis involves structuring this information into logical sections to provide a comprehensive overview of metal casting dies.

Research Topics and Scope:

- Topics Covered: Classification of die-casting dies; materials used for die fabrication; common die defects; factors affecting die life; essential properties of dies; fundamental rules for casting die design; procedures for die construction and design; and the role of heat transfer in die design.

- Scope: The paper addresses the fundamental aspects of metal casting dies, aiming to provide a foundational understanding of their types, materials, design considerations, common operational issues, and service life. It focuses on established theories and practices in the die casting industry.

6. Key Results:

Key Results:

- Classification of Dies: Die-casting dies are categorized as single cavity die, multiple cavity die, combination die, and unit dies. (Refer to Fig. 2 for Unit Die and Fig. 3 for general Die-Casting Dies). A pressure-casting die is shown in Fig. 1.

- Die Parts (as per ACDA): Include Cover Portion, Gate, Sprue Pin, Die Cavity, Ejector Pin, Rack, Ejector Portion, Fixed Ore, Runners, Sprue Hole, Parting Line, Ejector Plate, Pinion, and Cooling Vents.

- Engineering Materials for Fabricating Casting Dies (as per AISI, NADCA, AND ACDA):

- Tool Steels (specially alloyed steels)

- Die Steels (specially alloyed steels)

- Hot Work Die Steels (H1 to H19 chromium-base, H20 to H39 tungsten-base, H40 to H59 molybdenum-base)

- Shock-Resisting Die Steel

- High Speed Steel (Tungsten-base and Cobalt-base)

- Mould Steels (P1 to P19 Low carbon, P20 to P39)

- Special Purpose Steels (Low Alloy, Carbon-Tungsten)

- Water Hardening Steel (W code)

- Pearlitic Cast Iron and Martensitic Cast Iron

- High Tungsten –Chromium Steel (Die-cast Tool Steel)

- Maraging Steels

- Copper, Steel, Graphite, Ceramic Composite Materials, Refractory Metal Alloys.

- List of Defects in Casting Dies:

- Die Wear, Heat Checks, Die Surface Erosion, Die Surface Crack, Die Breakage and Failure, Lack of Hot Hardness, Improper and Rough Surface Finish during Fabrication, Die Shrink, Die becoming Softer, Thermal Fatigue Cracking.

- Die Life (Table-1): Depends on casting temperature and alloy.

- Zinc (420°C): 1,000,000 castings

- Magnesium (670°C): 300,000 castings

- Aluminium (700°C): 100,000 castings

- Brass (950°C): 20,000 castings

- Properties of Dies: High Strength, Impact Toughness, Hot Hardness, Wear Resistance at room and elevated temperatures. Hot-work tool steels are noted for these properties.

- Basic Rules for Casting Die Design:

- Include taper draft for casting removal.

- Sprues and runners removable manually or by trim dies.

- Process can be highly automated.

- Lubricants (e.g., water-based with graphite) applied as thin coatings.

- Water-based lubricants also aid in keeping die temperature low.

- Casting Die Construction and Design Procedure:

- Dies are made of alloy steels in at-least 2 sections (fixed/cover half and ejector die half).

- Early collaboration with die-casters is recommended.

- Design follows procedures by NADCA (USA, Canada), SDCE, and ADCI (Australia).

- Gating system design and ideal filling time are crucial.

- The filling time is a function of casting characteristics or process/equipment.

- Heat Transfer in Die Design:

- Maximum Filling Time Equation (1):

Maximum Filling Time = (Amount of Heat Available / Heat Transfer Rate) - Processing conditions (Plunger Diameter and Speed, Gate and Runner Sizes, Die Temperature, Metal Temperature, Amount and Type of Release Spray, Cycle Timing, Clamping Tonnage) are determined from filling time.

- Heat Available Equations:

- Foster Bennett (1966) - Equation (2): Heat Available = {[(Tg – Tliq). Cp] + Lf}

(Where Tg = metal temp at gate, Tliq = liquidus temp, Cp = specific heat, Lf = latent heat of solidification).

Bennett's assumption (Table-2): Superheat (10.10%), Latent heat of fusion (70.10%), Heat of solid cooling (19.80%). - Wallace and Linday (1968) - Equation (3): Heat Available = {(Tg – Tliq). Cp}. M

(Where M = mass of casting). - For "Thixotropic" metals (Flemings) - Equation (4): Heat Available = {([Tg – T] + [c.Z]). Cp}. M

(Where T = min. flow temp, c = % solid allowed, Z = coefficient to convert latent heat to equivalent temp).

- Foster Bennett (1966) - Equation (2): Heat Available = {[(Tg – Tliq). Cp] + Lf}

- Heat Transfer Rate Equation (5):

Heat Transfer Rate = {[Coefficient]. [Temp 1 – Temp 2]. [Surface Area]}

(Where Temp 1 = Metal Temperature, Temp 2 = Die Surface Temperature). - Final Gating Equation for Filling Time (6):

Filling Time = [ K. t {(Tg −T) +( C.Z)}] / (Tg −Td)

(Where K = combination of all coefficients, t = typed thickness of casting, Td = die temperature).

- Maximum Filling Time Equation (1):

Figure Name List:

- Fig. 1: Pressure Die-Casting Die.

- Fig. 2: Unit Die.

- Fig. 3: Die-Casting Dies.

- Table-1: Die Life

- Table-2: Bennett's Assumption

7. Conclusion:

Various aspects on the die-casting dies are discussed.

The die life and casting die defects are also discussed.

8. References:

- [1] Viarcik, E.J, "High Integrity Die Casting", Wiley, USA, 2002.

- [2] The Metallurgy of Die Castings", Society of Die Casting Engineers, USA, 1986.

- [3] Bralla, J.G, "Design for Manufacturability Handbook", McGraw Hill, USA, 1999.

- [4] Cardelli, F, "Materials Handbook: A Concise Desk Reference", 2nd Edition, Springer, USA, 2008.

- [5] "Fundamentals of Tool Design", 5th Edition, Society of Manufacturing Engineers, 2003.

- [6] Serope Kalpakjian and Schmid, Mnaufacturing Engineering Technology, Prentice Hall, 2007.

9. Copyright:

- This material is a paper by "Thoguluva Raghavan Vijayaram". Based on "Metal Casting Dies".

- Source of the paper: https://www.researchgate.net/publication/267823207

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.