This introduction paper is based on the paper "Mechanical properties of homogenized twin-roll cast and conventionally cast AZ31 magnesium alloys" published by "Materials Engineering - Materiálové inžinierstvo".

1. Overview:

- Title: Mechanical properties of homogenized twin-roll cast and conventionally cast AZ31 magnesium alloys

- Author: Mariia Zimina, Přemysl Málek, Jan Bohlen, Dietmar Letzig, Gerrit Kurz, Miroslav Cieslar

- Year of publication: 2015

- Journal/academic society of publication: Materials Engineering - Materiálové inžinierstvo

- Keywords: Magnesium; Twin-roll casting; Tensile tests; Microstructure; Microhardness.

2. Abstract:

The improvement of mechanical properties of magnesium alloys nowadays is very important, because of the variety of industrial applications. For this goal, the number of casting techniques and further treatments were developed. Among the continuous casting techniques, which allow producing long strips of the alloys, is twin-roll casting. Using this process one can get the magnesium alloy with finest microstructure and higher specific strength. In this paper the comparison of tensile properties of conventionally cast and twin-roll cast AZ31 magnesium alloys was made. Tensile tests were carried out with constant strain rate 10⁻³ s⁻¹ at temperatures ranging from 100 to 300 °C. Both materials were tested in as-cast state and after homogenization treatment at 450 °C for 10 hours. The investigation showed that there are no significant changes in ductility of AZ31 conventionally cast alloy even after heat treatment, while the ductility of twin-roll cast alloy increases.

3. Introduction:

Magnesium alloys are well-known structural materials, widely used in the automotive industry due to the trend of reducing car component weight. Mg-Al-based alloys, with high specific strength, stiffness, low density, and good thermal/electrical conductivities, are potential replacements for some steels and copper alloys, and are also used in electronics. The properties of magnesium alloys are crucially influenced by alloying elements, and various casting techniques like die casting and twin-roll casting (TRC) are employed to achieve desired properties. The AZ31 alloy is popular for its good strength, ductility, and low cost. Producing thin sheets from TRC materials is a key area, but challenges like the inhomogeneity of as-cast structures remain. This paper studies the microstructure and mechanical properties of AZ31 prepared by conventional casting (CC) and TRC, examining the effects of inhomogeneous structures and heat treatment.

4. Summary of the study:

Background of the research topic:

The increasing demand for lightweight materials in industries like automotive drives research into magnesium alloys. Improving their mechanical properties is essential for expanding their applications. Twin-roll casting is a promising continuous casting technique for producing magnesium alloy strips with fine microstructures.

Status of previous research:

Previous research has investigated the impact of various alloying elements (Al, Zn, Ca, Sn, Sr, Zr) on the mechanical properties of magnesium alloys. Different casting techniques, including die casting and TRC followed by hot working, are known to influence the texture, microstructure, and consequently, the mechanical properties. AZ31 is a widely studied commercial alloy. The production of thin sheets via TRC has been explored, with as-cast strip thickness going down to 5 mm. However, the role of as-cast structure inhomogeneity on final product properties remains an area of interest.

Purpose of the study:

In this paper the microstucture and mechanical properties of AZ31 prepared by two different cast techniques, conventional casting (CC) and TRC, were studied. In order to examine the effect of the inhomogeneous structure on mechanical properties during heat treatment the specimens in the as-cast and homogenized states were prepared for structural, microhardness and tensile tests.

Core study:

The core of the study involves a comparative analysis of AZ31 magnesium alloys produced by conventional casting (CC) and twin-roll casting (TRC). The study investigates these materials in both as-cast and homogenized states, focusing on their microstructure, microhardness distribution, and tensile properties at various temperatures.

5. Research Methodology

Research Design:

The study involved investigations of AZ31 CC ingot and 5.6 mm thick AZ31 TRC strip. Two sets of samples were used for each casting method: 1) as-cast AZ31 magnesium alloy and 2) alloy after homogenization treatment at 450 °C for 10 hours. Specimens were annealed in an air furnace and quenched in oil.

Data Collection and Analysis Methods:

- Chemical Composition: The chemical composition of the AZ31 magnesium alloy was determined (Table 1).

- Microstructure Analysis: Standard metallographic specimens (10 mm × 10 mm × 5.6 mm) were prepared, etched with 5% picric acid, and examined using an Olympus GX51 optical microscope with NIS-Elements AR 3.0 software. SEM images were also taken for TRC AZ31.

- Microhardness Testing: Vickers microhardness tests were conducted on the same metallographic specimens using a QNess Q10 machine with an applied load of 100 g. Mapping of the 5 mm × 8 mm cross-section for TRC material was performed in the transverse direction (TD).

- Tensile Testing: 1 mm thick dog-bone shaped coupons were machined from both CC ingot and TRC strip (TRC tensile axes parallel to RD, length 6 cm). Tensile tests were performed on an INSTRON 5228 machine at a constant strain rate of 10⁻³ s⁻¹. Samples were heated to 100, 150, 200, 250, and 300 °C, held for 10 minutes at temperature before the test.

Research Topics and Scope:

The research focused on AZ31 magnesium alloy. The scope included:

- Comparison of conventional casting (CC) versus twin-roll casting (TRC).

- Evaluation of as-cast versus homogenized (450 °C for 10 hours) states.

- Characterization of microstructure (grain size, phase distribution, segregation).

- Measurement of microhardness and its distribution.

- Assessment of tensile properties (yield strength, ultimate tensile strength, ductility) at temperatures ranging from 100 °C to 300 °C.

6. Key Results:

Key Results:

Microstructure:

- AZ31 magnesium alloys contain mainly α-Mg phase and secondary β-Al₁₂Mg₁₇ phase.

- As-cast TRC material has smaller secondary phase particles and a bulk grain size of about 200 µm, with finer grains (approx. 50 µm) near the surface, compared to CC alloy (grain size ~300 µm).

- After homogenization (450 °C for 10 h):

- CC alloy: Slight coarsening of microstructure, partial dissolution of β-Al₁₂Mg₁₇ phase.

- TRC alloy: Significant microstructure refinement (grain size down to 50 µm) due to full recrystallization, and dissolution of β-phase.

- TRC AZ31 exhibits a central segregation zone, potentially containing pores and defects, attributed to Mn and other impurities. The dendritic structure typical for Mg-Al alloys in as-cast TRC is almost eliminated after homogenization.

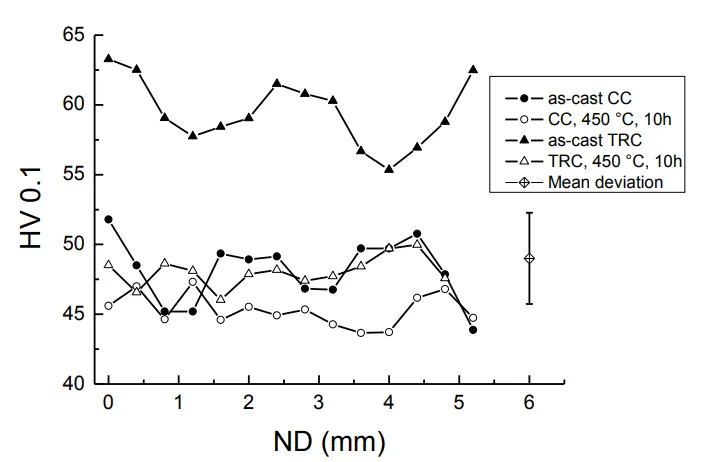

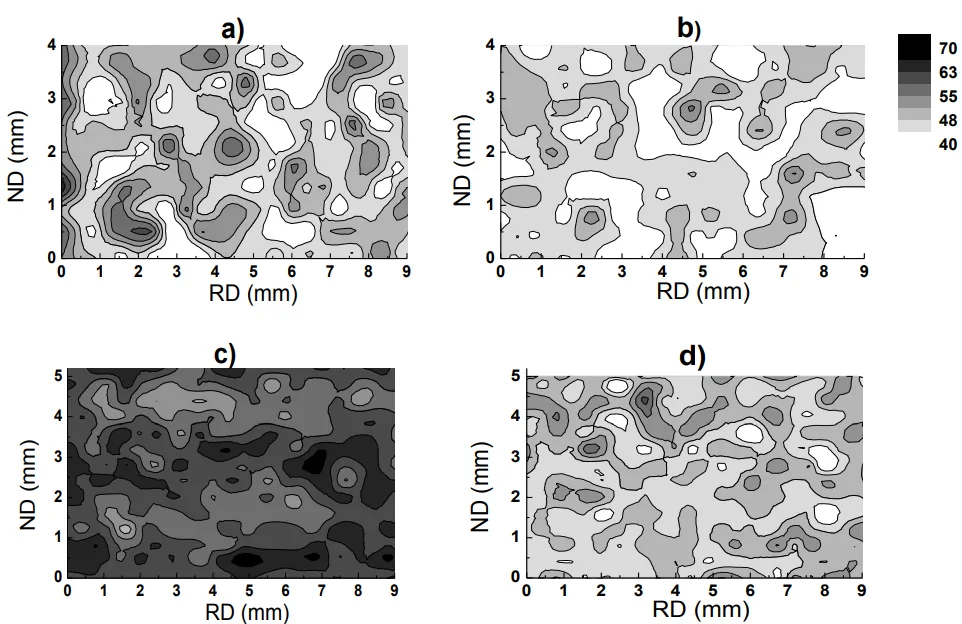

Microhardness:

- As-cast TRC AZ31 strip shows inhomogeneous hardness, being harder in the middle and near the surfaces. The central zone's elevated hardness is linked to finer grains and Al/Mn supersaturation.

- After homogenization, TRC alloy softens (microhardness drops to ~50 HV0.1) and becomes more homogeneous due to recrystallization and removal of deformed substructure.

- As-cast CC alloy showed no significant changes in microhardness or grain structure along the cross-section. Homogenized CC material showed a slight 10% decrease in microhardness.

- The mean standard deviation in microhardness for TRC material indicates inhomogeneity not only through the thickness but also along the rolling direction (RD).

Tensile Properties:

- CC alloy: Tensile tests showed no significant changes or improvement in mechanical properties after homogenization. Ductility remained less than 15% and slightly decreased after homogenization, while yield stresses were almost unchanged. This is attributed to coarser, less uniform grain structure and dissolution of secondary phase particles.

- TRC alloy: Ductility significantly increased at all deformation temperatures after homogenization, especially at 300 °C (reaching 36%). Yield strength was significantly reduced by ~50%. These changes are linked to full recrystallization, formation of a homogeneous fine-grained structure, and elimination of dislocation substructure.

- Yield stresses and ultimate tensile strengths decrease with increasing temperature for all specimens. Homogenized TRC strip annealed at 300 °C shows the largest drop in ultimate strength (about 80%).

Figure Name List:

- Fig. 1. Microstructure of AZ31 magnesium alloys: a) CC as-cast, b) CC after homogenization annealing at 450 °C for 10 hours, c) TRC as-cast, d) TRC after homogenization annealing at 450 °C for 10 hours.

- Fig. 2. SEM images of the dendritic structure and central segregation zone in TRC AZ31 magnesium alloy: a) as-cast, b) after aging at 450 °C for 10 h and c) image made by light microscope after aging at 450 °C for 10 h.

- Fig. 3. Evolution of inhomogeneity in AZ31 magnesium alloys during heat treatment.

- Fig. 4. Microhardness mapping (in MPa) of the cross-section of AZ31 magnesium alloys: a) as-cast CC AZ31 alloy, b) CC alloy after homogenization annealing at 450 °C for 10 h, c) as-cast TRC alloy, d) TRC alloy after homogenization annealing at 450 °C for 10 h.

- Fig. 5. Stress-strain curves for AZ31 magnesium alloys during annealing at temperature range from 100 °C – 300 °C: a) as-cast CC, b) CC after homogenization annealing at 450 °C for 10 hours, c) as-cast TRC, d) TRC at 450 °C for 10 hours (note the scale on the figure 5d).

- Fig.6. Temperature dependence of the yield (a) and ultimate (b) strengths of the conventionally cast and twin-roll cast AZ31 magnesium alloys before and after aging at 450 °C for 10 h.

7. Conclusion:

The microstructure and mechanical properties of AZ31 magnesium alloys prepared by different casting techniques (conventional casting and twin-roll casting) were studied in the as-cast and aged (homogenized at 450 °C for 10 h) states.

- In the TRC magnesium alloy, there are smaller secondary phase particles distributed within the α-Mg matrix compared to the CC material.

- After homogenization, β-phase dissolves in both materials, with only a small amount of β-phase particles remaining inside grains.

- The microstructure of the TRC material is more significantly affected by heat treatment; its originally coarse-grained non-uniform structure is replaced by a fine-grained and homogeneous one, except for central segregation particles that remain.

- The originally inhomogeneous structure of the as-cast TRC material, which exhibited significant microhardness variations (near the surface and in the center), was replaced by a softer and much more homogeneous structure after homogenization. HV values become similar for both alloys after homogenization.

- Tensile tests at a relatively low strain rate (10⁻³ s⁻¹) revealed improving ductility of the TRC magnesium alloy after homogenization.

- No significant changes in tensile properties of the CC cast alloy in the as-cast and aged states were observed.

8. References:

- [1] B.L. Mordike, T. Ebert: Mater. Sci. Eng. A 302 (2001) 37-45.

- [2] S. Schumann, H. E. Friedrich: Mater Sci Forum. 419-422 (2003) 51-56.

- [3] H. Zhao, Z. Zhou, X. Liu, S. Guan: J Cent South Univ T. 15(4) (2008) 459-462

- [4] A.W. El-Morsy, A. Abouel-Kasem: J Tribol 133(4) (2011) 603-610.

- [5] E.F. Emley: Principles of Magnesium Technology, Pergamon Press, London 1966.

- [6] M. Avedesian, H. Bakert: ASM specialty handbook: Magnesium and magnesium alloys, New York: ASM International 1999.

- [7] R. Schmid-Fetzer, Grobner: J Adv Eng Mat 3(12) (2001) 947-961.

- [8] F.S. Pan, M.B. Yang, Y.L. Ma.: Mater Sci Forum 191 (2007) 561-565.

- [9] H.K. Lim, D.H. Kim, J.Y. Lee, W.T. Kim, D.H. Kim: J Alloy Compd, 463(1-2) (2009) 308-314.

- [10]Y.K. Kim, S.W. Sohn, Do H. Kim, W.T. Kim, D.H. Kim: J Alloy Compd 549 (2013) 46-50.

- [11] S.F. Liu, L.Y. Liu, L.G. Kang: J Alloy Compd 450(1-2) (2008) 546-550.

- [12]J. Kaneko, M. Sugamata, M. Numa, Y. Nishikawa, H. Takada: Mat Trans 47(10) (2006) 2555-2560.

- [13] D.V. Wilson: J I Met 98 (1970) 133-143.

- [14]S.H. Hsiang, J.L. Kuo: J Mater Process Tech. 140 (2003) 6-12.

- [15] G. Kurz, J. Bohlen, L. Stutz, D. Letzig, K.U. Kainer: Magnesium Technology 2013 (eds. N. Hort, S. N. Mathaudhu, N. R. Neelameggham and M. Alderman), John Wiley & Sons, Inc. 2013.

- [16]H. Zhao, S. Guan, F. Zheng, Q. Li, L. Wang: Trans Nonferrous Met Soc China 15(1) (2005).

- [17]M.T. Pérez-Prado, O.A. Ruano: Scripta Mater 46(2) (2002) 149-155.

- [18]J. Zhang, Z. Leng, M. Zhang, J. Meng, R. Wu: J Alloy Compd 509(3) (2011) 1069-1078.

- [19]D.K. Xu, W.N. Tang, L. Liu, Y.B. Xu, E.H. Xan: J Alloy Compd 461(1-2) (2008) 248–252.

- [20] H.E. Friedrich, B.L. Mordike: Magnesium Technology metallurgy, design data and application, Springer verlag, Berlin, Heidelberg, Germany 2006.

- [21] J.S. Waltrip: Fresh Look at Some Old Magnesium Diecasting Alloys for elevated Temperature Applications. 47th Annual World Magnesium Conf. IMA, Cannes 1990, pp. 124-129.

- [22] W.E. Mercer: Magnesium Die cast Alloys for Elevated Temperature Applications, SAE 900788 1990.

- [23] Q. Han, H. Xu: Scripta Mater 53(1) (2005) 7–10.

- [24]L. Hay, P. Agee: In: Magnesium Technology 2013 (eds N. Hort, S. N. Mathaudhu, N. R. Neelameggham and M. Alderman), John Wiley & Sons, Inc., Hoboken, NJ, USA 2013.

- [25] A. Jager, P. Lukac, V. Gartnerova, J. Bohlen, K.U. Kainer: J Alloy Compd 378(1-2) (2004) 184-187.

9. Copyright:

- This material is a paper by "Mariia Zimina, Přemysl Málek, Jan Bohlen, Dietmar Letzig, Gerrit Kurz, Miroslav Cieslar". Based on "Mechanical properties of homogenized twin-roll cast and conventionally cast AZ31 magnesium alloys".

- Source of the paper: http://fstroj.uniza.sk/journal-mi/PDF/2015/02-2015.pdf

This material is summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.