Beyond FEA: How Simulating Manufacturing Processes Predicts Real-World Component Fatigue

This technical summary is based on the academic paper "ENHANCED FATIGUE ANALYSIS – INCORPORATING DOWNSTREAM MANUFACTURING PROCESSES" by Wilfried Eichlseder, published in Materials and Technology (2010).

Keywords

- Primary Keyword: Manufacturing Process Simulation

- Secondary Keywords: Fatigue Life, Finite Element Analysis (FEA), Complex Structures, Die Casting, Forging, Heat Treatment, Stress Gradient, Dendrite Arm Spacing (DAS)

Executive Summary

- The Challenge: Traditional fatigue analysis often fails to predict component failure accurately because it overlooks the profound impact of downstream manufacturing processes like casting, forging, and heat treatment on local material properties.

- The Method: The research integrates finite element analysis (FEA) with detailed simulations of manufacturing processes to model local microstructural changes, residual stresses, and their direct influence on fatigue strength.

- The Key Breakthrough: By quantifying manufacturing-induced variables—such as Dendrite Arm Spacing (DAS) in castings and grain size variation in forgings—the study develops localized S-N curves that provide a far more precise fatigue life prediction than generic material data.

- The Bottom Line: Incorporating manufacturing process simulation into the design phase enables engineers to create lighter, more reliable components by accurately predicting fatigue life based on how a part is actually made, not just how it is designed.

The Challenge: Why This Research Matters for HPDC Professionals

In engineering, most component failures are not due to a single overload event but to material fatigue from repeated cyclic loads. The goal has always been to design parts that meet a required lifetime without failure, while simultaneously pursuing lightweighting to reduce cost and improve performance. However, there's a critical gap in conventional design-by-simulation: the material properties used in a Finite Element Analysis (FEA) are often based on idealized lab specimens.

This approach ignores a crucial reality: manufacturing processes fundamentally alter the material. Forging changes grain structure, heat treatment creates different microstructures from the surface to the core, and in High-Pressure Die Casting (HPDC), the local solidification rate dictates Dendrite Arm Spacing (DAS) and porosity, all of which significantly impact a component's real-world fatigue strength. Relying on uniform material data for a non-uniform component leads to inaccurate life predictions, forcing engineers to either over-design with excessive safety factors (adding weight and cost) or risk unexpected field failures. This paper addresses the need to close the loop between the manufacturing process and the final performance prediction.

The Approach: Unpacking the Methodology

The author proposes a multi-stage simulation chain that extends traditional stress analysis to include the effects of manufacturing. This creates a virtual model that more closely mirrors the final physical component.

Method 1: Relative Stress Gradient (RSG) Concept

The study uses the RSG concept to account for how stress concentrations at notches affect fatigue life. Instead of using a single fatigue limit, this method calculates a localized fatigue limit based on the stress gradient (how quickly stress changes near the notch). This allows for a more accurate prediction in complex geometries where stress is not uniform.

Method 2: Forging and Heat Treatment Simulation

For forged components, the simulation models the degree of deformation, deformation rate, and temperature. This data is used to predict local grain size and structure. Similarly, for heat treatment, the cooling process is simulated. By combining local temperature-time curves with a continuous Time-Temperature-Transformation (TTT) diagram for the specific alloy (e.g., 42CrMo4), the model predicts the resulting microstructure (e.g., martensite content) at any point in the component, and thus its local strength.

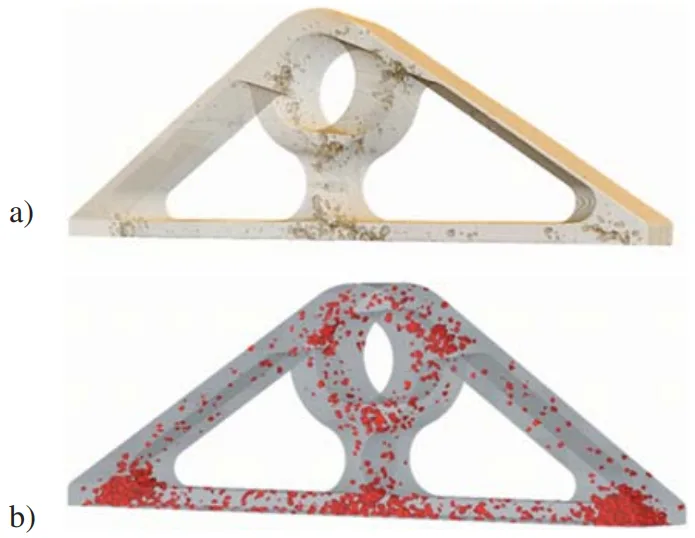

Method 3: Casting and Porosity Simulation

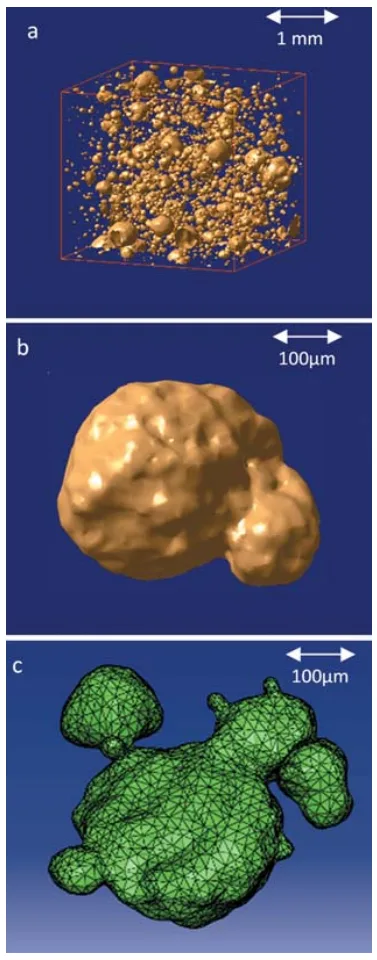

For cast aluminum components, the simulation focuses on the solidification process. The local freezing rate is calculated to determine the Dendrite Arm Spacing (DAS), a key microstructural feature directly linked to fatigue strength. For HPDC, where gas porosity is a major concern, the model uses computer tomography (CT) data and a statistical porosity model to predict the size, shape, and distribution of pores, which act as stress concentrators and fatigue initiation sites.

The Breakthrough: Key Findings & Data

By linking manufacturing simulation to fatigue analysis, the research demonstrates a clear, quantifiable relationship between process parameters and component life.

Finding 1: Forging Deformation Directly Impacts Fatigue Strength

The study shows that the degree of deformation during forging significantly alters fatigue performance. As shown in Figure 7, for 16MnCr4 steel, specimens with a high degree of deformation (φ=2.16 and φ=3) exhibited a lower fatigue limit compared to the undeformed material (φ=0). This is attributed to variations in grain size caused by the forging process, proving that assuming uniform strength in a forged part is a critical oversight.

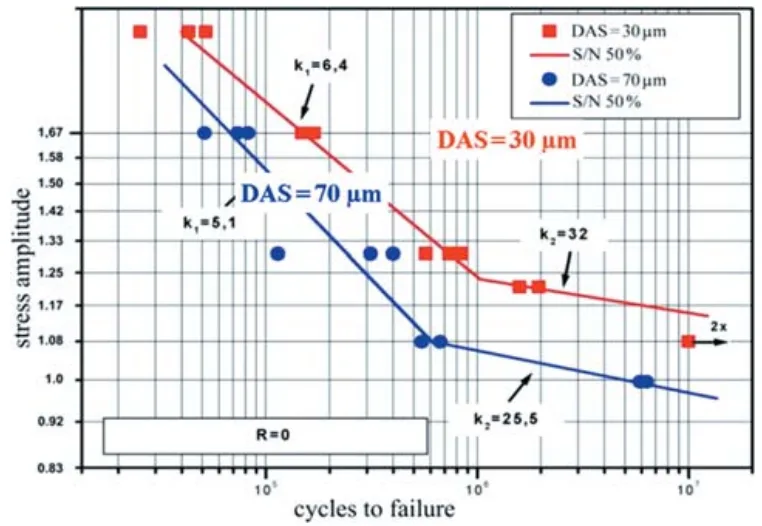

Finding 2: Dendrite Arm Spacing (DAS) Governs Fatigue Life in Castings

In die-cast aluminum, fatigue strength is heavily dependent on the microstructure, specifically the DAS. As shown in Figure 12, specimens with a fine microstructure (DAS = 30 µm), resulting from faster cooling, demonstrated a significantly higher fatigue strength than those with a coarser structure (DAS = 70 µm). The slope of the S-N curve also steepens with larger DAS, indicating a shorter life under higher stress amplitudes. This finding allows engineers to predict fatigue "hot spots" based on simulated solidification rates.

Finding 3: Pore Size in HPDC Creates Quantifiable Stress Concentrations

For HPDC parts, porosity is a primary driver of fatigue failure. The research used FEM calculations on CT-scanned pore geometries to quantify their impact. Figure 14 shows a direct correlation between pore diameter and the local stress concentration factor. A 350 µm pore can elevate local stress by a factor of nearly 3.0. This data allows for the conversion of simulated porosity percentage into an equivalent pore diameter, enabling a fracture mechanics approach to predict fatigue life.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that controlling the local solidification rate in die casting by adjusting cooling channel design or process parameters can directly enhance the fatigue strength in critical areas of a component. For forgings, controlling temperature and deformation rates is key to achieving a consistent and favorable grain structure.

- For Quality Control Teams: The data in Figure 12 (DAS vs. fatigue) and Figure 14 (pore size vs. stress) provides a powerful, physics-based foundation for setting new quality inspection criteria. Instead of just looking for defects, QC can focus on quantifying the microstructural features that are proven to impact performance.

- For Design Engineers: The findings indicate that part geometry (e.g., wall thickness) directly influences local cooling rates and, therefore, microstructure and strength. This simulation-driven approach allows designers to optimize geometry not just for stress distribution but also for manufacturability and the resulting material properties, achieving true design-for-manufacturing excellence.

Paper Details

ENHANCED FATIGUE ANALYSIS – INCORPORATING DOWNSTREAM MANUFACTURING PROCESSES

1. Overview:

- Title: ENHANCED FATIGUE ANALYSIS – INCORPORATING DOWNSTREAM MANUFACTURING PROCESSES

- Author: Wilfried Eichlseder

- Year of publication: 2010

- Journal/academic society of publication: Materiali in tehnologije / Materials and technology 44 (4)

- Keywords: fatigue life, complex structures, simulation, manufacturing process, finite elements

2. Abstract:

Most failures of engineering components can be traced back to cyclic loads which cause fatigue of the material. These cyclic loads can be either constant or variable. This influence has to be taken into account in the fatigue analysis, the aim of which is to assure a minimum required lifetime of a component without breakdown. Simultaneously, a lightweight design is intended by reducing the size of the component. The strength of materials under cyclic loading is essentially lower than those under static loading. However, the cyclic strength is of more importance in practical applications, as more components fail by cyclic loading than by static loads. Regrettably, the strength of cyclic loaded components was discovered relatively late and the first systematic investigations were performed in the 19th century. Cyclic loadings result from mechanic or thermal service loads, which can be superimposed to static loads. When looking at a truck, the chassis is loaded by the dead load of the vehicle. Due to loading and unloading procedures the load is changed into a quasi-static way. Additional cyclic loads emerge during driving operation in addition to the static loads due to braking, acceleration, cornering, or physical conditions just like bumps on the roadway or air drag. Additional loading is also due to resonance vibrations of engine, gearbox, fuel tank, or the spare wheel. These cyclic loads lead to fatigue of material hence overstraining them to a crack. These cracks propagate and finally lead to failure of the component.

3. Introduction:

The science of fatigue analysis aims to dimension components to serve a minimum required lifetime under cyclic loads without failure, while also focusing on weight reduction. Dimensioning can be done by testing prototypes or by simulation. Simulation offers the advantage of being applicable early in the engineering phase and being less time and cost-intensive, though with lesser accuracy than physical testing. In real-life applications, dynamic loads have variable amplitudes, requiring damage accumulation models like the Palmgren-Miner rule to predict lifetime. A key challenge is that the local fatigue strength of a material within a component is not identical to that of idealized test specimens due to numerous influencing factors.

4. Summary of the study:

Background of the research topic:

The lifetime evaluation of complex geometric components requires concepts based on local stresses and strains, typically determined using the Finite Element Method (FEM). However, predicting fatigue life also requires knowledge of the local fatigue strength (S-N curve), which is significantly influenced by the manufacturing process.

Status of previous research:

While FEM is well-established for determining local stresses, traditional fatigue analysis often uses generic S-N curves that do not account for local variations in material properties caused by manufacturing. This creates a disconnect between the simulated stresses and the actual material strength at those locations.

Purpose of the study:

The study aims to extend the simulation chain to integrate the influence of downstream manufacturing processes—specifically casting, forging, heat treatment, and surface finishing—into the fatigue life prediction of complex components. The goal is to create a more accurate and holistic simulation model that bridges the gap from process parameters to component performance.

Core study:

The paper investigates several models to describe the influence of manufacturing processes on fatigue strength. It examines the effect of stress gradients in notches (Relative Stress Gradient Concept), the statistical size effect, and technological influences from forging (degree of deformation), heat treatment (cooling rates and microstructure), and casting (Dendrite Arm Spacing and porosity). By simulating these processes, the study derives local material properties which are then used to generate location-specific S-N curves for a more accurate fatigue life calculation.

5. Research Methodology

Research Design:

The research follows a combined simulation and experimental validation approach. Manufacturing processes like forging, casting, and heat treatment are simulated to predict local material properties (e.g., grain size, microstructure, DAS, porosity). Specimens are then prepared with defined process parameters, and their fatigue life is determined experimentally to validate the simulation models. These validated models are then applied to predict the fatigue life of complex geometric components.

Data Collection and Analysis Methods:

Data is collected through finite element simulations of both mechanical loads and manufacturing processes (e.g., thermal analysis for casting and heat treatment, deformation analysis for forging). Experimental data is collected from rotating bending fatigue tests on specimens manufactured under controlled conditions. For cast components, computer tomography (CT) is used to analyze the geometry and distribution of pores.

Research Topics and Scope:

The scope covers the influence of several key factors on fatigue life:

1. Notches and load type, analyzed via the Relative Stress Gradient Concept.

2. Statistical size effect in large components.

3. Technological influences on forged components (degree of deformation).

4. Influence of heat treatment on microstructure and strength.

5. Technological influences on cast aluminum components, including Dendrite Arm Spacing (DAS) in die casting and porosity in high-pressure die casting.

6. Key Results:

Key Results:

- The relationship between fatigue limit and stress gradient is non-linear; the fatigue limit's growth diminishes with increasing stress gradients.

- Forging deformation influences fatigue strength; in the case of 16MnCr4, higher degrees of deformation led to a decrease in fatigue strength due to variations in grain size.

- Heat treatment simulation, combined with TTT diagrams, allows for the prediction of local microstructure and, consequently, local strength. For 42CrMo4, a tempering temperature of 540 °C resulted in a 7% higher fatigue strength compared to 620 °C.

- In cast aluminum, fatigue strength is strongly dependent on Dendrite Arm Spacing (DAS); specimens with a 30 µm DAS showed significantly higher fatigue strength than those with a 70 µm DAS.

- In HPDC, gas pore shape and size are critical. Local stress elevations at pores range from 1.8 to 2.9, with larger pores causing higher stress concentrations.

- A statistical porosity model, combined with a fracture mechanics approach, allows for the calculation of safety against cyclic failure in HPDC components based on simulated pore distribution.

Figure Name List:

- Figure 1: Lifetime prediction based on local stresses and strains

- Figure 2: Stress gradient in notch root

- Figure 3: Stress gradient in notch for tension-compression and bending

- Figure 4: Fatigue limit at 10⁷ load cycles depending on stress gradient

- Figure 5: Principle chain of production process

- Figure 6: Simulation of degree of deformation

- Figure 7: Influence of degree of deformation on performance of fatigue limit

- Figure 8: FE Simulation of annealing

- Figure 9: Continuous TTT curve of 42CrMo4

- Figure 10: Influence of tempering temperature on fatigue strength

- Figure 11: Definition of DAS

- Figure 12: S-N curves for specimens with different DAS

- Figure 13: Results of computer tomography: a – Overview of tomographed cube; b – pore pressed by dendrites; c – meshed pore.

- Figure 14: FEM calculation for tomographed spherical gas pores with varying diameters

- Figure 15: Pore distribution in real component (computertomography) (a), calculated pore distribution (b)

- Figure 16: Distribution of safety against cyclic failure in the component

7. Conclusion:

For further optimization of components, knowledge of local strengths is needed in addition to local stresses. Local strength is influenced by numerous factors, including loading type, geometry, temperature, surface layer, and, critically, the production process (casting, deforming, welding, etc.). These influences can either strengthen or attenuate each other. A comprehensive experimental investigation of all effects is nearly impossible due to time and cost. Therefore, additional simulation is required. By combining stress calculations from FEM with simulations of casting and deforming processes, the paper demonstrates how an interdisciplinary approach enhances the significance and accuracy of strength calculations for component dimensioning.

8. References:

- 1 Bargel H. J., Schulze G.: Werkstoffkunde, Springer-Verlag Berlin Heidelberg, 2005

- 2 Böhm J.: Zur Vorhersage von Dauerschwingfestigkeiten ungekerbter und gekerbter Bauteile unter Berücksichtigung des statistischen Größeneinflusses. Dissertation, TU München, 1980

- 3 Sonsino, C. M.: Zur Bewertung des Schwingfestigkeitsverhaltens von Bauteilen mit Hilfe örtlicher Beanspruchungen. Konstruktion 45 (1993)

- 4 Fröschl J.: Fatigue effects of forged components: Technological effects and multiaxial fatigue, Dissertation, Montanuniversität Leoben, 2006

- 5 Altenpohl, D.: Aluminium von innen. Aluminium-Verlag, Düsseldorf, 1994

- 6 Minichmayr, R., Eichlseder, W.: Lebensdauerberechnung von Gussbauteilen unter Berücksichtigung des lokalen Dendritenarmabstandes und der Porosität, Gießerei, (2003) 5

- 7 Powazka D.: Einfluss der Porosität auf die Betriebsfestigkeit von Al-Druckgussbauteilen, Dissertation, Montanuniversität Leoben, 2009

- 8 Oberwinkler Christian: Virtuelle betriebsfeste Auslegung von Aluminium-Druckgussbauteilen, Dissertation, Montanuniversität Leoben, 2009

Expert Q&A: Your Top Questions Answered

Q1: Why is the Relative Stress Gradient (RSG) concept more effective than a standard notch factor for predicting fatigue in complex geometries?

A1: A standard notch factor (Kt) only describes the peak stress but doesn't account for the "support effect," where the less-stressed material beneath the surface supports the highly stressed material at the notch root. The RSG concept quantifies this by considering how rapidly the stress decreases away from the peak. This provides a more physically accurate basis for calculating the local fatigue limit, especially in components with sharp notches or bending loads, leading to more realistic lifetime predictions.

Q2: How does the simulation practically determine the local Dendrite Arm Spacing (DAS) in a die-cast part?

A2: The simulation determines DAS by first performing a thermal analysis of the casting process during solidification. It calculates the local freezing rate (or solidification time) for every element in the component model. DAS is directly correlated with this cooling rate—faster cooling leads to finer dendrites (smaller DAS). This relationship, established through empirical data, allows the simulation to generate a detailed map of the DAS distribution throughout the part, which is then used to assign local fatigue properties.

Q3: For High-Pressure Die Casting (HPDC), the paper discusses a statistical model for porosity. How does this improve upon simply assuming a worst-case defect?

A3: Assuming a worst-case defect everywhere is overly conservative and leads to heavy, over-engineered parts. The statistical porosity model, based on a Weibull distribution, predicts the distribution of porosity based on process parameters like temperature and pressure. This provides a more realistic assessment, acknowledging that porosity is not uniform. It allows engineers to calculate a distribution of safety factors across the component (as seen in Figure 16), identifying areas with a higher probability of critical pores rather than penalizing the entire design.

Q4: How does the simulation account for the effects of heat treatment on a component's fatigue strength?

A4: The simulation models the cooling phase of the heat treatment process, calculating the temperature-versus-time curve for different locations within the component (e.g., surface vs. core). As shown in Figure 9, this cooling curve is then overlaid on the material's continuous Time-Temperature-Transformation (TTT) diagram. This allows the model to predict the resulting microstructure (e.g., percentage of martensite, bainite, or pearlite) at each location, which directly corresponds to local hardness and fatigue strength.

Q5: What is the primary business advantage of this enhanced analysis over simply using a larger safety factor in traditional FEA?

A5: The primary advantage is optimization, which translates to cost and weight savings without compromising reliability. A large, uniform safety factor results in over-engineered, heavy components where material is wasted in low-stress or high-strength areas. This enhanced Manufacturing Process Simulation allows for a more intelligent use of material by accurately predicting both local stresses and local strengths. This enables confident lightweighting, reduces material costs, and prevents unexpected failures that traditional analysis might miss.

Conclusion: Paving the Way for Higher Quality and Productivity

The core challenge in modern component design is bridging the gap between the ideal digital model and the imperfect physical reality. This research demonstrates that by integrating Manufacturing Process Simulation into fatigue analysis, we can finally account for the critical effects of casting, forging, and heat treatment. The key breakthrough is the ability to move beyond generic material data and predict localized strength based on how a part is actually produced. This leads to more accurate lifetime predictions, enabling the design of lighter, more cost-effective, and more reliable components.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "ENHANCED FATIGUE ANALYSIS – INCORPORATING DOWNSTREAM MANUFACTURING PROCESSES" by "Wilfried Eichlseder".

Source: UDK 620.178.3:539.42, ISSN 1580-2949, MTAEC9, 44(4)185(2010)

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.