This article introduces the paper "A Study on Cooling Characteristics of the LED Lamp Heat Sink for Automobile by Forced Convection".

1. Overview:

- Title: A Study on Cooling Characteristics of the LED Lamp Heat Sink for Automobile by Forced Convection

- Authors: Ho-Dong Yang, Jae-Young Yoo, Seul-Hyun Park

- Year of Publication: 2018

- Journal/Conference: Journal of the Korean Society of Manufacturing Process Engineers

- Keywords: Forced Convection, Cooling Characteristics, Heat Sink, LED Lamp, Computational Analysis

2. Research Background:

Automotive headlamps are crucial for driver visibility, and LED lamps are gaining popularity due to their energy efficiency and long lifespan. However, the high heat generation of LED lamps can reduce their lifespan and efficiency. Existing water-cooled cooling plates and heat pipes offer superior cooling performance but are limited by high costs and space constraints. Therefore, this study investigates improving the cooling performance of automotive LED lamp heat sinks using forced convection.

3. Research Objectives and Questions:

- Research Objective: To analyze the cooling characteristics of an automotive LED lamp heat sink under forced convection and verify the cooling effect improvement with increased airflow velocity.

- Key Research Questions: How do the temperature distribution and convective heat transfer coefficient of the heat sink change with varying airflow velocity? How well do the experimental and computational analysis results agree?

- Research Hypothesis: Increasing the airflow velocity around the heat sink fins will significantly increase the convective heat transfer coefficient and improve cooling efficiency.

4. Research Methodology:

- Research Design: Comparative analysis using experiments and computational fluid dynamics (CFD).

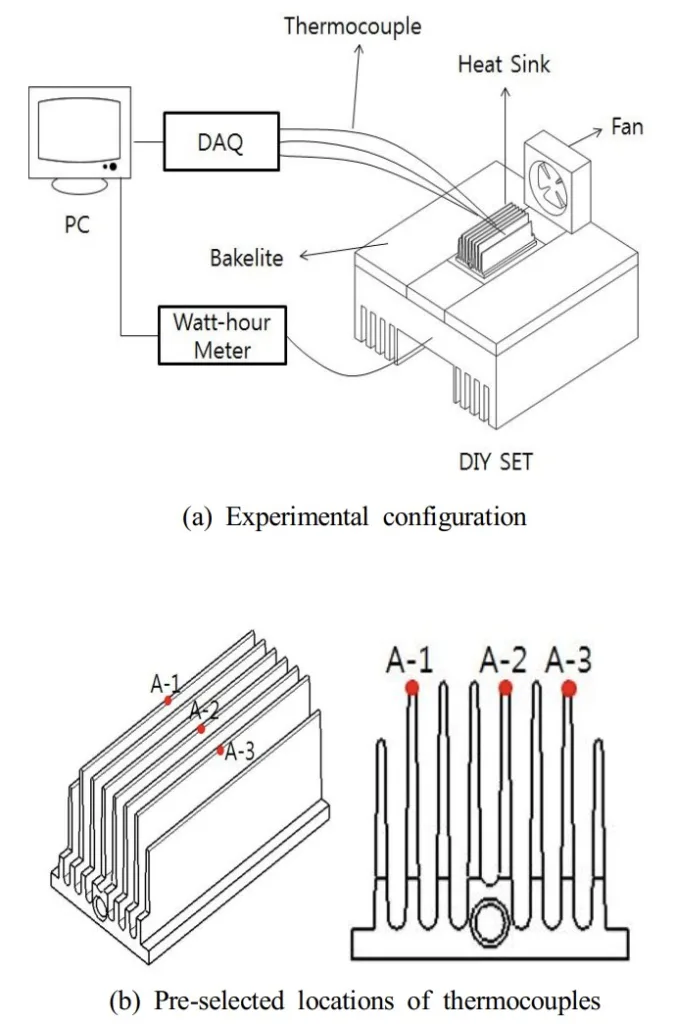

- Data Collection Methods: Experiments measured heat sink temperatures at various locations using thermocouples. Airflow velocity was controlled (2, 4, and 6 m/s) using a DC fan with pulse width modulation (PWM). A constant heat flux of 27 W/m² was applied to the heat sink. Computational analysis using Fluent 6.0 software calculated temperature distribution and convective heat transfer coefficient.

- Analysis Methods: Experimental and computational analysis results were compared to analyze cooling characteristics. The convective heat transfer coefficient was calculated using a theoretical formula and compared with experimental and computational results.

- Subjects and Scope: The study focused on a specific model of automotive LED lamp heat sink. Experiments and CFD analysis were conducted at airflow velocities of 2, 4, and 6 m/s.

5. Main Research Findings:

- Key Findings: Increased airflow velocity significantly reduced heat sink temperature and increased the convective heat transfer coefficient. Experimental and computational results showed similar trends. The convective heat transfer coefficient calculated using the theoretical formula also showed a similar trend.

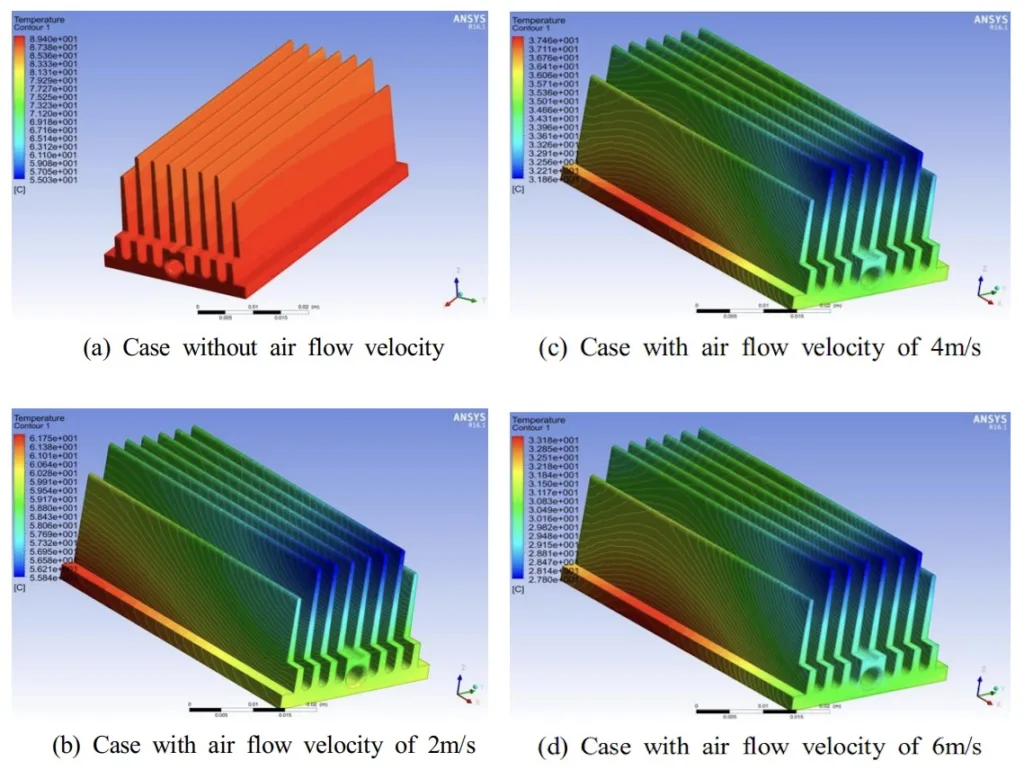

- Statistical/Qualitative Analysis Results: Figure 5 shows the change in heat sink temperature over time at different airflow velocities (2, 4, 6 m/s). Figure 6 presents CFD results showing temperature distribution at different airflow velocities. Figure 7 compares the convective heat transfer coefficients obtained from experiments, CFD, and theoretical calculations. The convective heat transfer coefficient increased from approximately 50 W/m²K to 280 W/m²K as the airflow velocity increased from 2 m/s to 6 m/s.

- Data Interpretation: The experimental and computational results confirm that increasing airflow velocity enhances cooling performance. The temperature difference between the hottest (bottom surface) and coldest (top surface) parts of the heat sink remained approximately 5℃ regardless of airflow velocity.

- Figure List and Description: (Figures would be listed and described here, mirroring the descriptions given in the Korean version. Due to the limitations of this text-based response, the actual figures cannot be included.)

6. Conclusions and Discussion:

This study analyzed the cooling characteristics of an automotive LED lamp heat sink under forced convection using experimental and computational methods. Increased airflow velocity significantly reduced heat sink temperature and increased the convective heat transfer coefficient, improving cooling efficiency. The consistency between experimental, computational, and theoretical results supports the study's findings. This research contributes to more efficient thermal management of LED lamps, potentially extending their lifespan. Practical implications include optimizing heat sink design and cooling fan performance.

7. Limitations of the Study:

The study focused on a specific heat sink model and operating conditions. Generalizing the results to other heat sink designs and operating environments requires further research.

8. Future Research:

Future research should investigate various heat sink designs and sizes, different operating conditions (temperature, humidity), real-world automotive testing, and the development of more sophisticated CFD models.

Summary of References:

- Kang, B. D., Lee. H. S., Kim, J. G., “A Study on the Possibility of Applications of LED Head Lamp,” KSAE Symposium, pp. 177-183, 2006.

- Cho, M. R., Jeon, S. K., Lee, H. Y., Kim, D. H., Na, J. H., Yang, S. Y., “The Analysis on National and International Standards of LED Headlamp for Automobile,” Proc. of KIIEE Annual Conference, pp. 142-143, 2010.

- Kim, D. H., “Study of Optimized Tuning in Full AFLS Head Lamps,” Proc. of the FISITA 2012 World Automotive Congress, pp. 1719-1731, 2012.

- Yoo, J. Y., Park, S. H., “Natural Cooling Characteristics of a Heat Sink for LED Headlight used in Passenger Cars,” Journal of the Korean Society of Manufacturing Process Engineers, Vol. 16, No. 2, pp. 142-148, 2017.

- Balvis, E., Bendana, R., Michinel, H., Cordoba, P. F., Paredes, A., “Analysis of a passive heat sink for temperature stabilization of high-power LED bulbs,” Journal of Physics: Conference Series, Vol. 605, Conference 1, pp. 1-8, 2015.

- Kang, B. D., Park, K. S., Yong, B. J., “The Dissipation Effect of Automotive LED headlamps Using Heat Sink and Cooling Fan,” KSAE Symposium, pp. 1314-1319, 2010.

- Ko, M. S., Lee, J. H., Oh, S. J., Cho, H. S., Seo, T. B., “Cooling Performance of LED Head Lamp with Heat Sink and Cooling Fan,” Transactions of the Korean Society of Mechanical Engineers B, Vol. 33, No. 12, pp. 947-951, 2009.

- Lai, Y., Cordero, N., Barthel, F., Tebbe, F., Kuhn, J., Apfelbeck, R., Würtenberger, D., “Liquid cooling of bright LEDs for automotive applications,” Applied Thermal Engineering, Vol. 29, No. 5-6, pp. 1239-1244, 2009.

- Jung, H. H., “A Study on the Numerical Analysis of Heat Sink for Automotive LED Head Lamp,” Master Thesis, Chosun University, Republic of Korea, 2011.

- Kang, H. W., Kang, B. D., Park, K. S., “A Study on Contact Thermal Resistance of LED and Heat Sink from LED HEAD LAMP,” KSAE Symposium, pp. 481, 2008.

- Yoon, S. U., Kim, J. Y., Gao, J. C., “An Experimental Study on Cooling Characteristic according to Fin Array of Aluminum Heat Sink,” Journal of the Korean Society of Manufacturing Process Engineers, Vol. 17, No. 1, pp. 138-143, 2018.

- Lee, J. S., Jang, H. S., Park, D. K., Hong, H. L., “Heat Analysis for Heat Sink of LED Lamp Using Cooling System,” KSPE Conference, pp. 669-670, 2012.

- Arzande, A., “Heat Sink Analytical Modeling,” Joaquim Guitart Corominas, 2010.

- Teertstra, P., Yovanovich, M. M., Culham, J. R., “Analytical forced convection modeling of plate fin heat sink,” Journal of Electronics Manufacturing, Vol. 10, No. 4, pp. 253-261, 2000.

Copyright:

This summary is based on the research paper "A Study on Cooling Characteristics of the LED Lamp Heat Sink for Automobile by Forced Convection" by Yang, Ho-Dong et al.

The original publication details are available in the Journal of the Korean Society of Manufacturing Process Engineers, Vol. 17, No. 6, pp.117-123 (2018).

DOI : https://doi.org/10.14775/ksmpe.2018.17.6.117

This summary is for informational purposes only and cannot be used for commercial purposes without permission. Copyright © 2023 CASTMAN. All rights reserved.