A Cost-Effective Simulation Method for Steel Ingot Solidification

This technical summary is based on the academic paper "Research of Casting and Solidification of Steel Ingots by Application of Low-Melting Materials" by E. Kantoríková and J. Moravec, published in ARCHIVES of FOUNDRY ENGINEERING (2024).

![Fig. 1. Scheme of the structure in the ingot Area 1 Thin outer

layer of fine, very clear polyhedral grains; Area 2 Columnar long

axis, still very clear crystals; Area 3 Thick polyhedral grains;

Area 4 Globular grains transformed into pyramid shape in bottom

part of ingot; Area 5 Small zone just under the head of ingot; Area

6 Minimal homogeneity; Area 7 Head of ingot with shrinkage

[23]](https://castman.co.kr/wp-content/uploads/image-3293.webp)

Keywords

- Primary Keyword: Steel Ingot Solidification

- Secondary Keywords: Casting Simulation, Shrinkage Defects, Low-Melting Materials, Foundry Engineering, Mold Design, Solidification Process

Executive Summary

- The Challenge: Predicting and controlling costly shrinkage defects in steel ingot casting is complex and expensive due to the high temperatures and materials involved.

- The Method: Researchers used a low-melting material, stearin, to physically simulate the casting and solidification process of steel in a metal mold at safe, low temperatures.

- The Key Breakthrough: The physical properties and shrinkage behavior of stearin were found to be directly comparable to molten steel, successfully capturing the real-world formation of shrinkage defects in a simple, fast, and inexpensive way.

- The Bottom Line: This low-cost, low-temperature simulation method is a practical and effective tool for validating mold designs and predicting solidification behavior in industrial steel casting applications before committing to expensive production trials.

The Challenge: Why This Research Matters for HPDC Professionals

In foundry production, success hinges on controlling the transformation of liquid metal into a solid, defect-free component. However, as the paper highlights, significant losses occur from defects caused by solidification, particularly shrinkage. Improper and undirected solidification leads to internal cavities and porosity, compromising the structural integrity of steel ingots.

For engineers, conducting trial-and-error tests with molten steel is not only expensive and time-consuming but also hazardous due to the extremely high temperatures. While computational simulations are powerful, they benefit from physical validation. The industry has long needed a method to test and refine casting processes that is convenient, simple, fast, and cheap. This research addresses that exact need by proposing a novel, low-temperature approach to understanding a high-temperature problem.

The Approach: Unpacking the Methodology

The researchers developed a practical, lab-scale experiment to mirror the industrial casting of steel ingots. The methodology was designed to be easily reproducible while providing high-fidelity data on the solidification process.

Method 1: Material and Mold Selection

- Material: The study used stearin, a mixture of fatty acids with a low melting point of 55-60°C. Its physical properties and volumetric shrinkage are comparable to molten steel, making it an ideal analog.

- Mold: A bottle-shaped mold, commonly used for forging ingots, was machined from H11 tool steel. This shape is designed to control solidification direction and concentrate shrinkage in the non-critical "head" of the ingot. The mold was treated with silicone oil to ensure easy removal of the casting.

Method 2: Process Monitoring and Simulation

- Casting: Liquid stearin was heated to a casting temperature of 60°C and poured into the mold via gravity.

- Data Acquisition: The temperature drop during cooling was monitored in real-time using thermocouples placed in the center of the ingot and near the mold wall. This allowed for precise tracking of the solidification front.

- Verification: The physical experiment was validated using ProCast, a finite element analysis software, to run numerical simulations of the solidification process for both stearin and high-carbon steel. This comparison confirmed the accuracy of the physical model.

The Breakthrough: Key Findings & Data

The study successfully demonstrated that a low-temperature, low-cost material can accurately predict the complex solidification behavior of high-temperature steel.

Finding 1: Stearin Accurately Mimics Steel Shrinkage Behavior

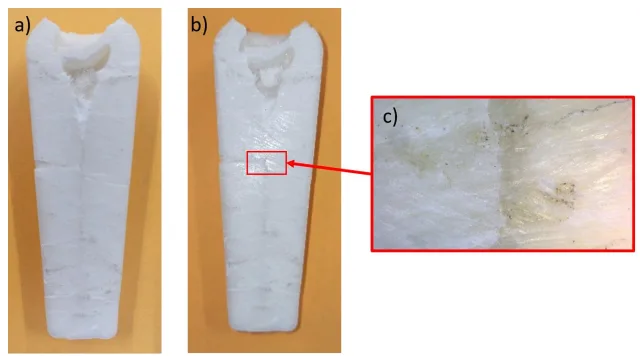

The experiment visually confirmed that stearin behaves like steel during solidification. As the stearin cooled, its volume decreased, resulting in the formation of a shrinkage cavity at the top of the ingot and a visible gap between the casting and the mold wall. As shown in Figure 4, the resulting stearin casting clearly displays the characteristic shrinkage patterns that engineers work to control in steel production. This provides a tangible, physical model for training and process validation.

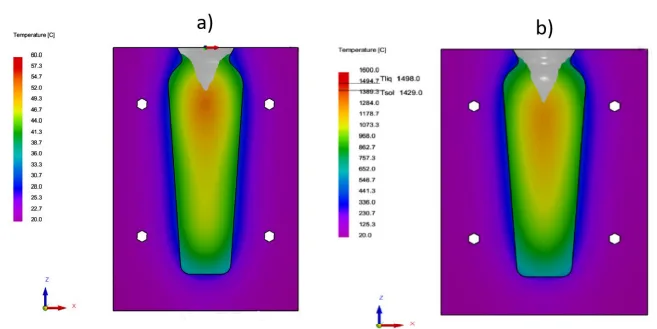

Finding 2: Simulation Confirms Strong Correlation Between Stearin and Steel

The most compelling finding comes from the numerical simulation. As shown in Figure 5, the simulated solidification process for stearin (Fig. 5a) shows a remarkable similarity to the simulation for high-carbon steel (Fig. 5b). Although the temperature scales are vastly different (20-60°C for stearin vs. 400-1300°C for steel), the thermal gradients, solidification patterns, and final location of shrinkage are analogous. This confirms that the stearin model is not just a qualitative tool but a scientifically valid method for predicting the behavior of cast steel.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that adjusting mold design, pouring temperature, and cooling conditions can be tested quickly and inexpensively using stearin. This allows for rapid optimization of the Steel Ingot Solidification process before committing to costly and time-consuming production trials.

- For Quality Control Teams: The data in Figure 3 (temperature curves) and Figure 4 (visual shrinkage) of the paper provides a clear model for how solidification fronts move and where shrinkage defects are most likely to form. This can inform the development of more targeted and effective quality inspection criteria for final steel products.

- For Design Engineers: The findings prove that mold geometry, such as the bottle shape, has a direct and predictable influence on defect formation. This method enables designers to physically prototype and validate different mold designs to minimize internal defects and maximize material yield in the early design phase.

Paper Details

Research of Casting and Solidification of Steel Ingots by Application of Low-Melting Materials

1. Overview:

- Title: Research of Casting and Solidification of Steel Ingots by Application of Low-Melting Materials

- Author: E. Kantoríková, J. Moravec

- Year of publication: 2024

- Journal/academic society of publication: ARCHIVES of FOUNDRY ENGINEERING

- Keywords: Casting process, Mold, Shrinkage, Temperature course

2. Abstract:

The article describes the simulation of the casting of the low-melting material stearin into a mold, which serves as a real simulation basis for monitoring the displacement during the solidification of steel ingots. The physical properties and occurrence of shrinkage are comparable for both liquid stearin and molten steel. In this way, it is possible to easily monitor the solidification of ingots after casting, while the entire simulation takes place at low temperatures, which is experimentally simpler and more practical than trial casting steel at high temperatures. The process is convenient, simple, fast and cheap. The essence is therefore the application of a new perspective on the mentioned process and its transfer into foundry practice. The temperature drop in the entire volume of the sample was monitored from filling the mold to cooling to ambient temperature and the formation of shrinkage, which was monitored and evaluated in the internal body of the ingot. The tests confirmed the suitability of selected material for this method of experimental work because they were able to capture the real behavior of the cast steel in the mold. The method proves to be suitable for industrial applications where similar multidimensional castings are produced.

3. Introduction:

Foundry production is a supporting industry significantly involved in engineering. It is a broad scientific field where large losses can occur, not only from liquid metal during production but also from defects caused by solidification. Improper and undirected solidification is a primary cause of various defects in castings. This article deals with the research of casting and solidification of steel ingots, specifically bottle-shaped ones, using metal casting molds. It explores the application of similar materials with low melting temperatures as a preferential alternative to expensive operational tests, particularly from an ecological and practical standpoint. The knowledge presented is based on experiments conducted in laboratory conditions.

4. Summary of the study:

Background of the research topic:

The formation of stress and defects, such as shrinkage, during the solidification of steel castings is a persistent challenge in foundry engineering. These defects compromise the mechanical properties and quality of the final product. Understanding and controlling the solidification process is critical, but direct experimentation with molten steel is technologically complex, costly, and hazardous.

Status of previous research:

The paper acknowledges the use of classical methods for researching casting and solidification. It builds upon established principles regarding stress formation in castings, volumetric shrinkage of liquid metal, and the influence of mold design on solidification patterns. However, it notes that non-standard methods, such as using low-melting point analog materials, are used to a small extent, representing an area for practical innovation.

Purpose of the study:

The study's purpose was to demonstrate and validate a practical, low-cost simulation method for monitoring the solidification and shrinkage formation in steel ingots. By using the low-melting material stearin, the research aimed to create a real simulation basis that is experimentally simpler, safer, and more accessible than traditional high-temperature steel casting trials.

Core study:

The core of the study involved the physical casting of liquid stearin into a specially designed, bottle-shaped metal mold. The temperature evolution within the casting was monitored using thermocouples at the center and near the wall. The formation of shrinkage was visually observed and documented. These experimental results were then compared with numerical simulations performed using ProCast software for both stearin and high-carbon steel to validate the analogy between the two materials.

5. Research Methodology

Research Design:

The study employed a combined experimental and numerical simulation approach. A physical experiment was conducted to cast a low-melting material (stearin) and observe its solidification behavior. The data and observations from this experiment were then used to verify a numerical simulation model.

Data Collection and Analysis Methods:

- Temperature Measurement: Thermocouples were placed in the center and near the wall of the casting to record the temperature course during cooling. Data was collected using an ALMENO 2890-9 Ahlbonn measuring station.

- Visual Observation: The cast stearin ingot was visually inspected to identify and document the formation and location of shrinkage.

- Numerical Simulation: ProCast software, which uses the finite element method, was used to simulate the solidification process for both the stearin casting and a comparable high-carbon steel casting.

Research Topics and Scope:

The research was focused on the casting and solidification of a bottle-shaped ingot. The scope included monitoring the temperature drop, observing the formation of shrinkage, and comparing the physical behavior of stearin with the simulated behavior of steel to confirm the suitability of stearin as an analog material for studying solidification phenomena.

6. Key Results:

Key Results:

- The experimental setup successfully monitored the temperature drop over time during the cooling of the stearin ingot, with a clear distinction between the cooling rates at the center and the wall (Figure 3).

- Visual evidence confirmed the formation of a shrinkage cavity in the upper part of the stearin ingot, demonstrating the material's ability to replicate this critical casting defect (Figure 4).

- Numerical simulations showed a strong visual and procedural similarity between the solidification process of stearin at low temperatures and high-carbon steel at high temperatures, validating the experimental method (Figure 5).

- A comparison of material properties (Table 1) showed that stearin and steel have comparable specific weights and volumetric shrinkage percentages, further supporting the use of stearin as a physical analog.

Figure Name List:

- Fig. 1. Scheme of the structure in the ingot Area 1 Thin outer layer of fine, very clear polyhedral grains; Area 2 Columnar long axis, still very clear crystals; Area 3 Thick polyhedral grains; Area 4 Globular grains transformed into pyramid shape in bottom part of ingot; Area 5 Small zone just under the head of ingot; Area 6 Minimal homogeneity; Area 7 Head of ingot with shrinkage [23]

- Fig. 2. a) metal mold; b) stearin casting

- Fig. 3. Dependence of temperature on time during the cooling of the ingot

- Fig. 4. Shrinkage in casted stearin a) left side; b) right side; c) detail

- Fig. 5. Solidification process a) Stearin; b) high carbon steel.

7. Conclusion:

The study concludes that the described process of casting low-melting stearin into a metal mold serves as a viable real simulation base for monitoring the solidification of steel ingots. The research demonstrates that the physical properties and shrinkage incidence are comparable for both liquid stearin and molten steel, allowing for easy observation of solidification at low temperatures, which is experimentally simpler and more practical. The essence of the method is the application of a new perspective on testing materials. The tests confirmed the suitability of stearin for this experimental work, as it was able to capture the real behavior of cast steel in the mold. A comparison of stearin and steel casting simulations is relevant and suitable as a complementary test method.

8. References:

- [1] Moravec, J., Langa, J. & Solfronk, P. (2017). Verification of shrinkage formation in steel ingots in laboratory conditions. Communications. 19(2A), 15-22. ISSN 1335 – 4205

- [2] Šmrha, L. (1983). Solidification and crystallization of steel ingots. Praha: STNL.

- [3] Moravec, J., Kopas, P., Jakubovičová, L., Leitner, B. (2018). Experimental casting of forging ingots from model material. MATEC Web of Conferences. 36-46.

- [4] Szekely, J. (1988). The mathematical modelling revolution in extractive metallurgy. Metallurgical Transactions B. 19B, 525-540.

- [5] Giamej, A.F., Abbaschian, G.J. (1988). Modeling of Casting and Welding Processes IV. TMS, Warrendale, PA

- [6] Piwonka, T.S. (1980). Process modeling in the foundry. Process Modeling Fundamentals and Applications to Metals. ASM, Metals Park, Ohio, 57-75.

Expert Q&A: Your Top Questions Answered

Q1: Why was stearin chosen as the simulation material over other low-melting compounds like paraffin?

A1: The paper states that the physical properties and occurrence of shrinkage are comparable for both liquid stearin and molten steel. While other materials like paraffin are mentioned as possibilities, the text explicitly notes that "Stearin is very suitable e.g. for the study of the formation of shrinkage defects in ingots and castings." The selection was based on its proven ability to effectively mimic the relevant solidification phenomena necessary for the study.

Q2: What was the rationale for using a "bottle shaped" ingot mold in this experiment?

A2: The paper identifies the bottle shape, with a wide end up, as a "frequently used ingot for forges." This design is intentional; it promotes directional solidification from the bottom upwards. This ensures a reservoir of liquid metal remains at the top to feed the lower, solidifying sections, thereby confining the inevitable shrinkage to the upper "lost head" and improving the quality of the main ingot body.

Q3: The paper mentions both direct and indirect methods for researching solidification. Which category does this experiment fall into?

A3: The methodology used in this study falls under the "Indirect" methods listed in Section 2 of the paper. Specifically, it combines two indirect techniques: "Temperature measurement with thermocouples" to track the thermal profile and "Modeling using low-melting compounds" to physically simulate the process.

Q4: How was the numerical simulation validated against the physical experiment?

A4: The paper states, "The course of the experimental work was verified by the ProCast software simulation." The validation is demonstrated in Figure 5, which shows a strong visual correspondence between the simulated solidification pattern of stearin (Fig. 5a) and the simulated solidification of high-carbon steel (Fig. 5b). This confirms that the physical model behaves as predicted and is a suitable analog for the steel process.

Q5: What is the primary limitation of using stearin as an analog for steel, according to the paper?

A5: The paper explicitly states in the discussion section that "A big disadvantage of stearin is its very low thermal conductivity." This difference in heat transfer properties is significant and must be considered when interpreting the timeline of solidification, even though the overall pattern of shrinkage formation remains comparable.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of controlling defects during Steel Ingot Solidification is a major hurdle in achieving high-quality, cost-effective production. This research presents a breakthrough by validating a simple, inexpensive, and safe method using stearin to physically model the complex process. By providing a tangible way to test mold designs and casting parameters, this approach empowers engineers to mitigate shrinkage defects before they impact the production line.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Research of Casting and Solidification of Steel Ingots by Application of Low-Melting Materials" by "E. Kantoríková and J. Moravec".

Source: https://doi.org/10.24425/afe.2024.149282

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.