This article introduces the paper ['Advanced materials for application in the aerospace and automotive industries'] presented at the ['CSIR Materials Science and Manufacturing']

1. Overview:

- Title: Advanced materials for application in the aerospace and automotive industries

- Author: W B DU PREEZ, O F R A DAMM, N G TROLLIP, M J JOHN

- Publication Year: Not explicitly stated in the paper.

- Publishing Journal/Academic Society: CSIR Materials Science and Manufacturing

- Keywords: advanced materials, automotive industry, aerospace industry, light metals, composite materials, research and development (R&D), South Africa, industry trends, drivers, semi-solid metal (SSM) casting, natural fibre composites.

2. Research Background:

Background of the Research Topic:

The research addresses the growing demand for advanced materials in the automotive and aerospace industries, particularly in South Africa. This is set against the backdrop of the Advanced Manufacturing Technology Strategy (AMTS), commissioned in 2002 by the National Advisory Council on Innovation (NACI). The AMTS identified the necessity for national initiatives focusing on advanced materials to bolster priority industry sectors, with automotive and aerospace being key among them. This strategic direction led to the establishment of initiatives such as the Advanced Metals Initiative (AMI) and the Light Metals Development Network (LMDN).

Status of Existing Research:

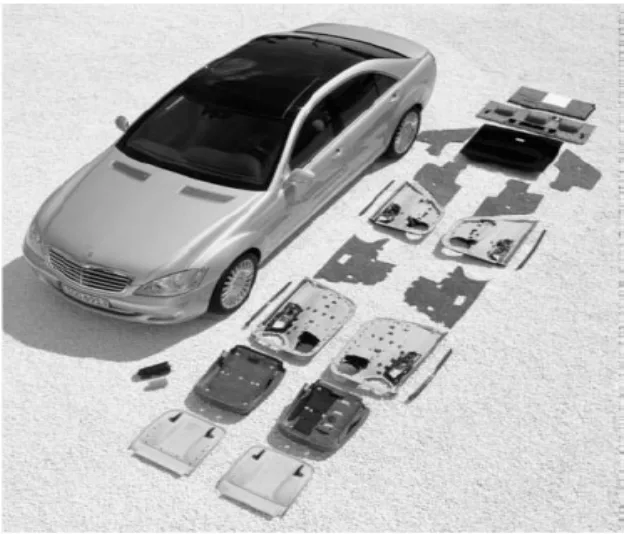

The paper highlights that technologically demanding sectors like aerospace and automotive are increasingly requiring "lighter, stronger and smarter materials and structures". In the automotive sector, key development drivers include "enhanced safety, reduced emissions and fuel consumption, and increasingly sophisticated consumer demand". Government legislation, excluding customer demand, is a significant driver, pushing for innovations like catalytic converters and efficient engines. The trend towards lightweighting is evident in the increased use of aluminium in European cars, rising from under 50 kg in 1980 to over 130 kg in 2005, as depicted in "Figure 1: Evolution of Al content in European cars (European Aluminium Association, 2007)". Concurrently, the aerospace industry prioritizes weight reduction to enhance fuel efficiency and payload capacity, traditionally relying on aluminium for airframe construction. The automotive industry also sees a rise in composite material usage, driven by the need for lighter, more economical, and environmentally sustainable vehicles.

Necessity of the Research:

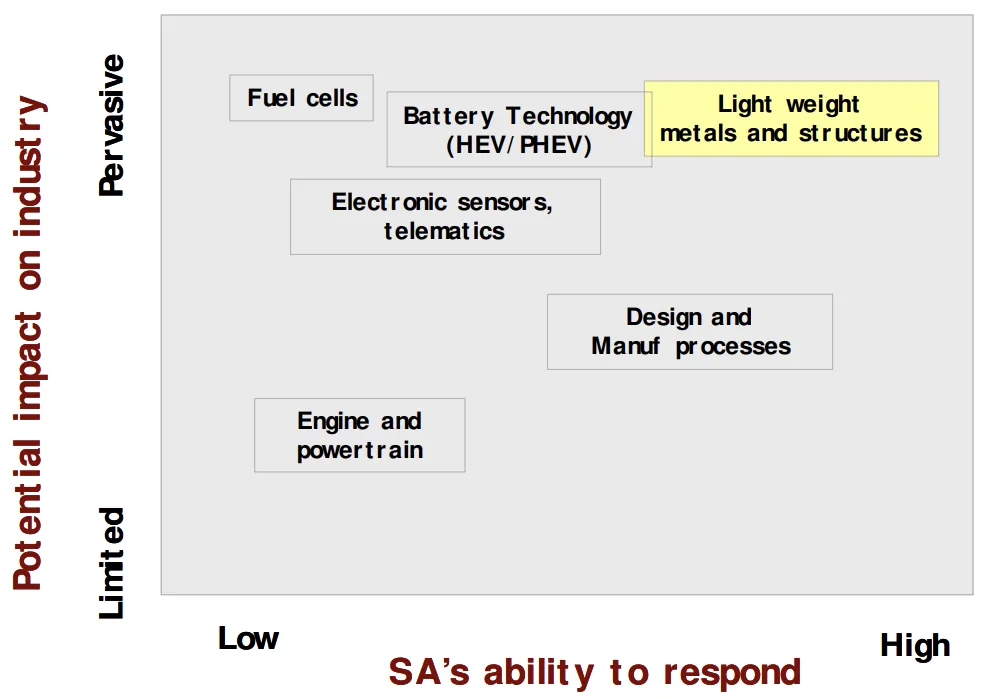

South Africa, despite being resource-rich, faces challenges in developing a robust downstream manufacturing sector. While the automotive industry is the largest advanced manufacturing sector in the country, its global market share remains small at 0.8%. Similarly, the aerospace industry is also limited in scale. This constrained capacity hinders South Africa's ability to effectively respond to global industry trends. Therefore, the research and development efforts are crucial for South Africa to develop niche competencies, particularly in "light weight structures and materials", to enhance its industrial competitiveness and contribute to socio-economic development.

3. Research Purpose and Research Questions:

Research Purpose:

The primary purpose of this paper is to illustrate the relevance of the Council for Scientific and Industrial Research (CSIR)'s research and development (R&D) programs in advanced materials for the South African automotive and aerospace industries. This is achieved by positioning these programs within the context of key industry trends and drivers. The paper aims to showcase examples of CSIR's R&D initiatives in light metals and advanced composite materials, emphasizing successes in collaborative expertise mobilization, progress achieved, and anticipated future impacts.

Key Research:

The key research areas explored in the paper are centered around:

- Light Metals: Specifically focusing on aluminium and titanium alloys and their application in lightweight structures.

- Advanced Composite Materials: With a significant emphasis on natural fibre composites as sustainable alternatives.

- Semi-Solid Metal (SSM) Casting Technology: Development and industrialization of rheocasting for high integrity lightweight components.

- Natural Fibre Composites Development: Enhancing the properties of natural fibre composites for automotive and aerospace applications through material modification and processing techniques.

Research Hypotheses:

While not explicitly stated as formal hypotheses, the research is guided by the implicit understanding that:

- Advanced materials are pivotal for future developments in the automotive and aerospace industries, driven by demands for lightweighting, performance, and sustainability.

- CSIR's R&D programs can play a crucial role in fostering South Africa's industrial capabilities and competitiveness in the advanced materials domain.

- Semi-solid metal casting and natural fibre composites represent promising technological pathways for achieving lightweighting and sustainability goals in these industries.

4. Research Methodology

Research Design:

This paper employs a descriptive research design, presenting an overview of CSIR's R&D programs and strategic initiatives in advanced materials. It utilizes case study examples of specific projects, such as semi-solid metal casting and natural fibre composites, to illustrate the practical application and outcomes of these programs. The design is further supported by referencing existing literature and data, presented in figures and tables, to contextualize the research within broader industry trends and technological advancements.

Data Collection Method:

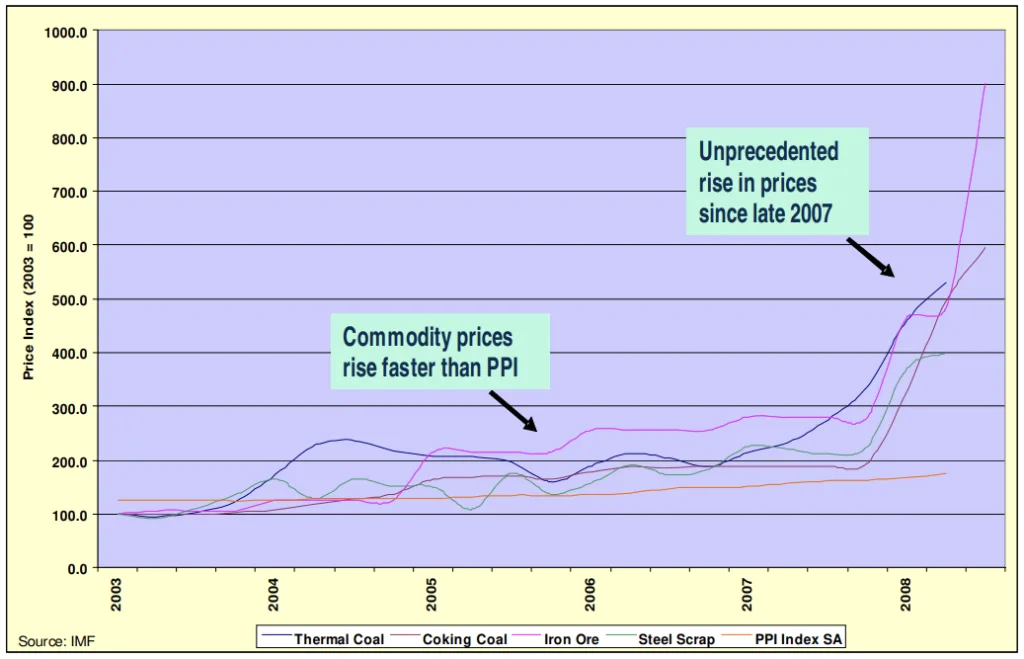

The paper synthesizes information derived from CSIR's ongoing R&D activities and project outcomes. Data is implicitly collected through the execution of research projects, experimental investigations, and technology development efforts within CSIR and its collaborative networks. The paper references figures and tables, such as "Figure 1: Evolution of Al content in European cars" and "Figure 4: Commodity price trends", which are sourced from external organizations like the European Aluminium Association and LHA, indicating the use of secondary data to support the analysis.

Analysis Method:

The analysis is primarily qualitative, focusing on describing industry trends, drivers, and CSIR's strategic response through its R&D programs. It involves a descriptive analysis of the technological advancements and potential impacts of the showcased projects, particularly in semi-solid metal casting and natural fibre composites. The paper interprets data presented in figures and tables to support its narrative, such as "Figure 5: SA's ability to respond to major global technology trends", which visually represents South Africa's positioning in various technology domains. The analysis also includes a discussion of the socio-economic implications and human capacity development aspects of the R&D initiatives.

Research Subjects and Scope:

The research subjects encompass CSIR's R&D programs in advanced materials, specifically targeting the South African automotive and aerospace industries. The scope is defined by the focus on light metals (aluminium and titanium) and advanced composite materials, with detailed examples provided for semi-solid metal casting and natural fibre composites. The research scope also includes the national initiatives and industry clusters within South Africa, such as the Advanced Metals Initiative (AMI) and the Light Metals Development Network (LMDN), and their role in fostering advanced materials development. The geographical scope is primarily South Africa, with consideration of global industry trends and international collaborations.

5. Main Research Results:

Key Research Results:

The key research results highlighted in the paper include:

- Development of CSIR Semi-Solid Metal (SSM) Technology: CSIR has developed and patented a new rheocasting technology and associated equipment for SSM casting. An industrial prototype machine based on this technology has been developed and built, as shown in "Figure 6: The current CSIR rheocasting industrial prototype machine".

- Industrialization of SSM Casting: An HPDC cell has been established at CSIR to facilitate the industrialization of the SSM technology. The industrialization process was expected to be completed by April 2009.

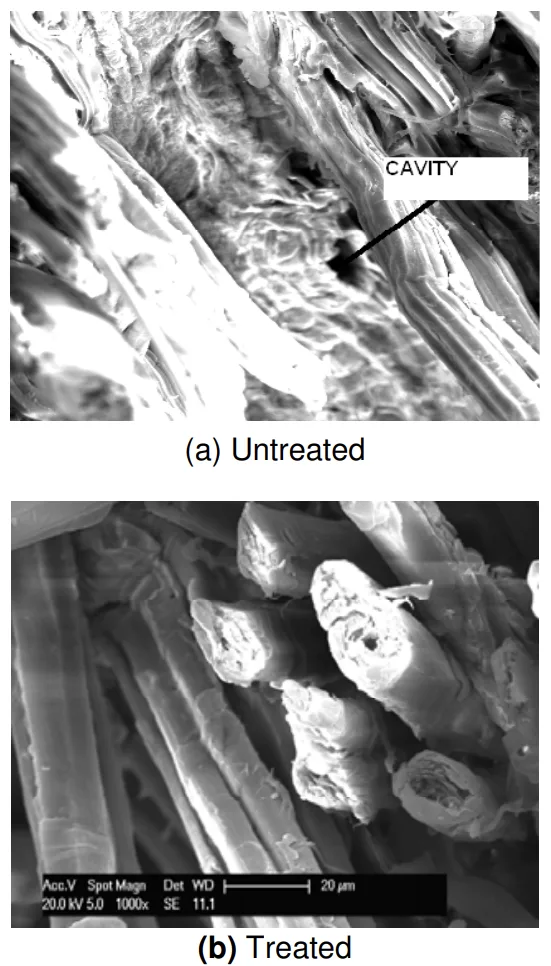

- Advancements in Natural Fibre Composites: CSIR has developed expertise in fibre-based composites, particularly natural fibre composites. Research has shown that chemical modification of natural fibres, such as flax and kenaf, improves their compatibility with polypropylene matrices, leading to enhanced mechanical properties, as illustrated in "Figure 8: Variation of modulus of flax-PP composites".

- Partnership with Airbus: CSIR has partnered with Airbus to jointly research the application of natural fibre-based materials in new-generation eco-friendly aircraft, specifically for interior components.

Data Interpretation:

- Figure 1 and 2 ("Figure 1: Evolution of Al content in European cars (European Aluminium Association, 2007)" and "Figure 2: Vehicle weight evolution in compact class (European Aluminium Association, 2007)") illustrate the industry trend towards lightweighting through increased aluminium usage, while also showing the paradoxical increase in average vehicle weight due to other factors.

- Figure 4 ("Figure 4: Commodity price trends (LHA, 2008)") highlights the macro-economic context of rising commodity prices, emphasizing the urgency for lightweight and resource-efficient materials.

- Figure 5 ("Figure 5: SA's ability to respond to major global technology trends") positions South Africa's potential strengths in light weight metals and structures relative to other automotive and aerospace technologies.

- Figure 7 ("Figure 7: (a) Dendrite microstructure typical of liquid castings (b) globular structure typical of a semi-solid metal casting") visually demonstrates the microstructural difference between conventional liquid castings and semi-solid metal castings, highlighting the globular structure achieved through SSM technology.

- Figure 9 ("Figure 9: Scanning electron micrograph of (a) untreated and (b) treated flax-PP composites") provides microscopic evidence of improved interfacial adhesion in chemically treated natural fibre composites.

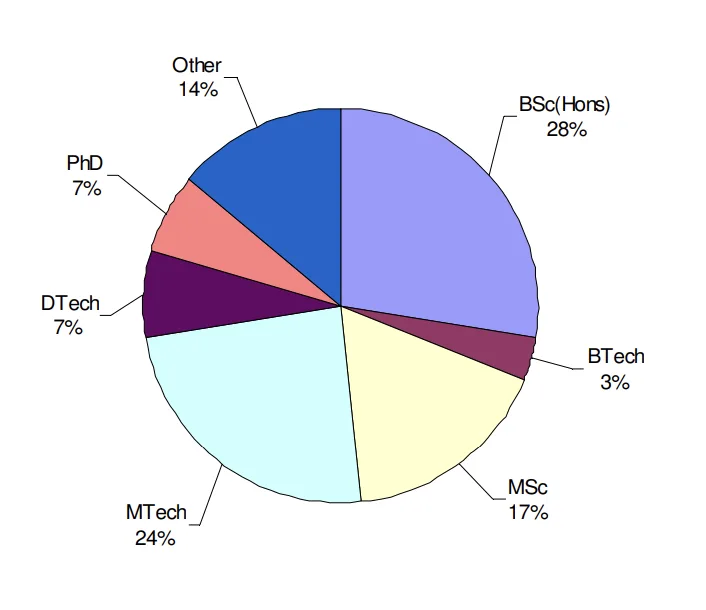

- Figure 10 ("Figure 10: Distribution of postgraduate qualifications supported by the LMDN and composites R&D") showcases the human capacity development aspect of the R&D programs, indicating the distribution of postgraduate qualifications supported by the initiatives.

Figure Name List:

- Figure 1: Evolution of Al content in European cars

- Figure 2: Vehicle weight evolution in compact class

- Figure 3: Mercedes S class automotive components

- Figure 4: Commodity price trends

- Figure 5: SA's ability to respond to major global technology trends

- Figure 6: The current CSIR rheocasting industrial prototype machine

- Figure 7: (a) Dendrite microstructure typical of liquid castings (b) globular structure typical of a semi-solid metal casting

- Figure 8: Variation of modulus of flax-PP composites

- Figure 9: Scanning electron micrograph of (a) untreated and (b) treated flax-PP composites

- Figure 10: Distribution of postgraduate qualifications supported by the LMDN and composites R&D

6. Conclusion:

Summary of Main Results:

The research paper concludes that CSIR's R&D programs on advanced materials, particularly light metals and advanced composites, are highly relevant and address critical industry needs. The development of CSIR's rheocasting technology for semi-solid metal casting and the advancements in natural fibre composites demonstrate tangible outcomes. These initiatives are strategically aligned with national priorities and global industry trends towards lightweighting, fuel efficiency, and environmental sustainability. The programs also contribute significantly to human capacity development within South Africa.

Academic Significance of the Research:

The paper highlights the academic significance of CSIR's R&D by showcasing its contribution to the field of advanced materials and manufacturing. It underscores the importance of national R&D initiatives in driving technological innovation and industrial development. The research exemplifies successful academia-industry collaboration and the effective mobilization of expertise to address complex technological challenges.

Practical Implications:

The practical implications of the research are substantial, with the potential for:

- Industrial Application of SSM Casting Technology: The CSIR rheocasting technology offers a pathway for local automotive industries to produce high integrity lightweight components, as listed in "Table 1: Automotive components suitable for SSM casting".

- Utilization of Natural Fibre Composites: The advancements in natural fibre composites provide sustainable and cost-effective material solutions for both automotive and aerospace applications, particularly for secondary structures and interior components.

- Human Resource Development: The R&D programs are actively contributing to the development of highly skilled personnel in advanced materials and manufacturing, as evidenced by the postgraduate qualifications supported ("Figure 10: Distribution of postgraduate qualifications supported by the LMDN and composites R&D").

Limitations of the Research

As a summary paper outlining ongoing R&D programs, explicit research limitations are not detailed. However, implicit limitations include the stage of technology development, particularly for SSM casting and natural fibre composites, which require further industrialization and validation. The paper acknowledges that the industrialization process for SSM casting was ongoing and expected to be completed by April 2009. For natural fibre composites, achieving stringent FST (flame, smoke and toxicity) standards for aerospace applications remains a key challenge.

7. Future Follow-up Research:

- Directions for Follow-up Research

Future research directions indicated in the paper include: - Further Industrialization of SSM Casting Technology: Continued efforts to implement and optimize the CSIR rheocasting technology in industrial settings.

- Development of High-Strength Aluminium Casting Alloys for Aerospace: Expanding the application of SSM casting to high-strength aluminium alloys like A201 for aerospace components.

- Application of Natural Fibre Composites in Aircraft Interiors: Further research and development to enable the use of natural fibre composites in aircraft interior components, focusing on meeting stringent safety and performance requirements.

- Achieving FST Standards for Natural Fibre Composites: Continued investigation into flame retardant treatments for plant fibres to meet the stringent FST standards required for aerospace applications.

- Areas Requiring Further Exploration

Areas requiring further exploration include: - Optimization of SSM Casting Processes: Refining the rheocasting process to enhance efficiency, reduce costs, and expand the range of applicable alloys and component geometries.

- Chemical Modification of Natural Fibres: Exploring novel and cost-effective chemical modification strategies to further improve the properties and performance of natural fibre composites.

- Long-Term Performance of Natural Fibre Composites in Aerospace Applications: Investigating the long-term durability, reliability, and environmental impact of natural fibre composites in demanding aerospace environments.

8. References:

- EUROPEAN ALUMINIUM ASSOCIATION, 2007. Aluminium in Cars.

- GOVENDER, G., MÖLLER, H., 2008. Evaluation of Surface Chemical Segregation of Semi-Solid Cast Aluminium Alloy A356, Solid State Phenomena 141-143, 433-438

- IVANCHEV, L., WILKINS, D., GOVENDER, G., DU PREEZ, W., BEAN, R., 2008. Rheo-casting of semi-solid metal alloys: a new technology for manufacturing automotive and aerospace components, South African Journal of Science, 104, 1

- JOHN, M.J, ANANDJIWALA, R.D., 2008a. Recent developments in chemical modification and characterization of natural fiber reinforced composites, Polymer Composites 29, 2, 187 207

- JOHN, M.J., ANANDJIWALA, R.D., 2008b. Chemical modification of flax and kenaf nonwovens reinforced polypropylene composites, International Conference on Advanced Materials, India, 18-21

- JOHN, M.J., ANANDJIWALA, R.D. 2008c. Static and dynamic mechanical properties of flax / polypropylene composites, Composites Part A (to be submitted)

- KARUS M.,ORTMANN S., 2004. Use of natural fibres in composites in the German automotive production 1996 till 2003 - Nova Institut

- KUNENE, G., GOVENDER, G., IVANCHEV, L., KNUTSEN, R., BURGER, H., 2008. The Influence of Heat Treatments for Laser Welded Semi Solid Metal Cast A356 Alloy on the Fracture Mode of Tensile Specimens, Solid State Phenomena 141-143, 169-174

- LHA, 2008. Proprietary Research into the Steel Industry.

- MASUKU, E.P., GOVENDER, G., IVANCHEV, L., MÖLLER, H., 2008. Rheocasting of Al-Cu Alloy A201 with Different Silver Contents, Solid State Phenomena 141-143, 151-156

- MÖLLER, H., GOVENDER, G., STUMPF, W.E., 2007. Natural and artificial aging response of semisolid metal processed Al-Si-Mg alloy A356, Int Journal of Cast Metals Research 20, No 6, 340

- MÖLLER, H., GOVENDER, G., STUMPF, W.E., 2008. The Natural and Artificial Aging Response of Semi-solid Metal Processed Alloy A356, Solid State Phenomena 141-143, 737-742

- SUDDELL B.C., EVANS W.J.,2005. Natural Fibre Composites in Automotive Applications, Natural Fibres, Biopolymers and Biocomposites, Ed. Mohanty A.K., Misra M., Drzal L.T., Taylor and Francis.

9. Copyright:

- This material is "W B DU PREEZ, O F R A DAMM, N G TROLLIP, M J JOHN"'s paper: Based on "Advanced materials for application in the aerospace and automotive industries".

- Paper Source: Email: wdupreez@csir.co.za

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.