This article introduces the paper "automated manufacturability analysis for injection-molded and die-cast parts".

1. Overview:

- Title: AUTOMATED MANUFACTURABILTY ANALYSIS FOR INJECTION-MOLDED AND DIE-CAST PARTS

- Authors: Daniel A. McAdams, Rahul A. Bidkar

- Publication Year: 2003

- Publishing Journal/Academic Society: Proceedings of the 2003 ASME International Design Engineering Technical Conferences and the Computers and Information in Engineering Conference

- Keywords: Design for Manufacturing, Feature Recognition, Automated Manufacturability Analysis, Injection-Molding, Die-Casting

2. Research Background:

- Social/Academic Context of the Research Topic: The paper highlights the crucial need for smooth integration between design and downstream applications for product success. Computer-based tools that assess part manufacturability during the design stage are essential for bridging design and manufacturing. Automated manufacturability research builds upon Design for Manufacturing (DFM), computational geometry, Computer-Aided Design (CAD), and feature recognition.

- Limitations of Existing Research: Existing automated manufacturability analysis research predominantly focuses on machining processes (milling, drilling, etc.). There is a noticeable lack of focus on non-machining processes like injection-molding, die-casting, forging, and stamping, despite their common and important roles in manufacturing. Current feature recognition techniques are also primarily geared towards machining applications, with limited applicability to non-material removal processes. Solid models in CAD systems, while advanced, store low-level data (points, edges, faces) and lack explicit feature information (bosses, holes, undercuts) needed for manufacturability analysis.

- Necessity of the Research: Developing automated manufacturability analysis methods for injection-molding and die-casting is a fundamental contribution to Design for Manufacturing. This research addresses the gap in existing tools by presenting a method to evaluate the manufacturability of injection-molded and die-cast parts, focusing on feature recognition techniques tailored for these processes.

3. Research Purpose and Research Questions:

- Research Purpose: To develop a mathematical framework and algorithm for automated manufacturability evaluation of injection-molded and die-cast parts. This includes creating a novel feature recognition method and addressing key challenges in feature recognition for manufacturability analysis in these specific processes.

- Key Research Questions:

- How to automatically evaluate the manufacturability of injection-molded and die-cast parts using a computer-based tool?

- How to develop a feature recognition method suitable for manufacturability analysis in injection-molding and die-casting?

- How to address the challenges of recognizing parting surfaces, undercuts, holes, and bosses in the context of injection-molded and die-cast parts?

- Can a binary representation of a 3D solid model be effectively used for feature recognition and manufacturability analysis in these processes?

- Research Hypotheses: The paper does not explicitly state research hypotheses but implies that:

- A mathematical framework based on decomposing a part into elemental cubes and evaluating their individual manufacturability can effectively assess the overall manufacturability of injection-molded and die-cast parts.

- A 3D binary representation of a solid model can be used to extract critical manufacturability information, overcoming limitations of traditional B-rep models for DFM analysis in injection-molding and die-casting.

4. Research Methodology

- Research Design: The research employs a development and implementation approach, creating a Manufacturability Evaluation Algorithm (MEA) and implementing it using C++ and Unigraphics solid modeling software. The algorithm is based on a novel feature recognition method.

- Data Collection Method: The method uses a procedure to obtain a 3D binary representation of the solid model. This involves:

- Decomposition into Elemental Cubes: The part is decomposed into a 3D binary array of 1s (solid cubes) and 0s (void cubes).

- Slicing: The solid model is sliced orthogonally to create a 3D mesh.

- Boolean Algebra: Solid/void cubes are determined using Boolean algebra, considering a cube as solid if more than 50% of its volume is within the solid model.

- Analysis Method: The core of the methodology is the Manufacturability Evaluation Algorithm (MEA). Key aspects of the MEA include:

- Type Classification of Solid Cubes: Solid cubes are classified as Type I (completely inside the part) and Type II (on the boundary). Type II cubes are critical for manufacturability.

- Accessibility Analysis: MEA investigates void cubes for accessibility to determine manufacturability. Inaccessible void cubes indicate manufacturing problems.

- Undercut Recognition: Undercuts are identified as surfaces formed by inaccessible Type II solid cubes, perpendicular to the mold closure direction.

- Parting Surface Determination: The parting surface is found by traversing columns in the binary representation and identifying the uppermost solid cube in each column.

- Boss and Hole Recognition: Bosses and holes are recognized by "clubbing," "connecting," and "checking" Type I solid cubes (for bosses) or void cubes (for holes) in adjacent layers, and analyzing the shape and spatial arrangement of Type II cubes on their boundaries.

- Research Subjects and Scope: The research focuses on developing a general algorithm applicable to injection-molded and die-cast parts. A crank case cover example and a simple part with boss and hole are used to demonstrate the algorithm's capabilities. The cube size used for binary representation was 1mm x 1mm x 1mm for parts approximately 70 mm x 40 mm x 20 mm.

5. Main Research Results:

- Key Research Results:

- Novel Feature Recognition Method: A new feature recognition method based on decomposing parts into elemental cubes and using a binary representation was developed.

- Automated Manufacturability Evaluation Algorithm (MEA): An algorithm was created and implemented to evaluate the manufacturability of injection-molded and die-cast parts.

- Parting Surface Determination: The MEA successfully determines the parting surface of a part.

- Undercut Recognition: The MEA can identify undercuts in a part.

- Boss and Hole Recognition: The MEA can recognize bosses and holes, distinguishing between cylindrical and other shapes.

- Accessibility Analysis for Manufacturability: The MEA uses accessibility analysis of void cubes to determine overall part manufacturability.

- Statistical/Qualitative Analysis Results: The paper primarily presents a methodological development and demonstrates its application through examples. No statistical analysis is presented. Qualitative results are demonstrated through the successful recognition of features in the example parts.

- Data Interpretation:

- The binary representation effectively captures the geometry of the part for manufacturability analysis.

- Type II solid cubes are crucial for identifying manufacturability issues and feature boundaries.

- Accessibility analysis of void cubes provides a direct method to assess moldability.

- The MEA algorithm successfully addresses the challenges of recognizing key features and manufacturability aspects for injection-molded and die-cast parts.

- Figure Name List:

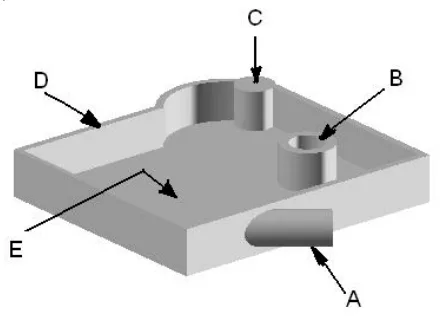

- Figure 1. A solid model representation of a part showing features critical to die-casting.

- Figure 2. A flow chart showing the primary steps of the Global manufacturability analysis algorithm.

- Figure 3. A detailed algorithm to determine whether a part is flat or box shaped. Step AA for the global manufacturability analysis algorithm.

- Figure 4. Summary of the applicability of existing feature recognition techniques as applied to the feature recognition needs of injection-molding and die-casting shown in part.

- Figure 5. A simple part to be molded.

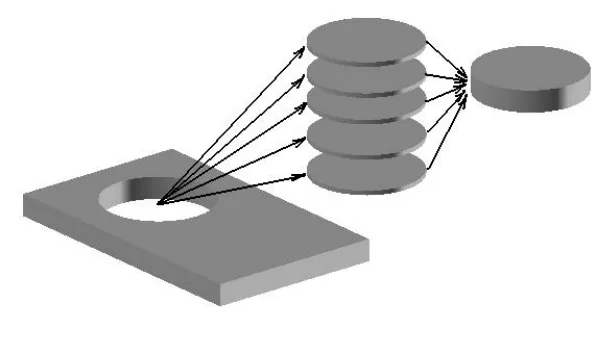

- Figure 6. A candidate part decomposed into small building blocks.

- Figure 7. A simple part with a hollow boss.

- Figure 8. A block with a cylindrical boss.

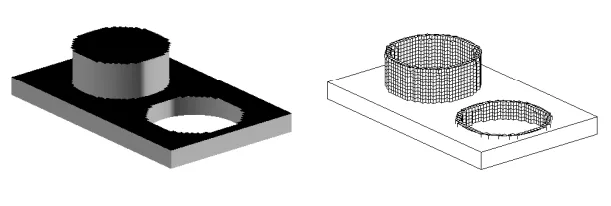

- Figure 9. The sliced version of the part.

- Figure 10. Classifying solid cubes as Type I or Type II.

- Figure 11. Illustrating the accessibility analysis to find undercuts.

- Figure 12. Illustration of the recognition of undercuts.

- Figure 13. Determining the parting surface for a simple part.

- Figure 14. A simple part with boss and hole.

- Figure 15. Type classifications of solid cubes for the part.

- Figure 16. A binary representation of a layer for the part shown in Figure 15.

- Figure 17. Illustration of the connection of adjacent layers.

- Figure 18. Illustration of "manufacturing requirements".

- Figure 19 Illustration of "manufacturing requirements" in terms of binary data.

- Figure 20 Recognized hole and boss.

- Figure 21. A simple part with a hole.

- Figure 22 Recognized hole.

- Figure 23. A Graphical comparison between MEA and ASV approach.

- Figure 24. The identified parting surface and recognized features for the example.

6. Conclusion and Discussion:

- Summary of Main Results: The research successfully developed and implemented a Manufacturability Evaluation Algorithm (MEA) for automated manufacturability analysis of injection-molded and die-cast parts. The MEA utilizes a novel binary representation of solid models and effectively addresses feature recognition challenges specific to these manufacturing processes, including parting surface determination, undercut, hole, and boss recognition.

- Academic Significance of the Research: This work contributes significantly to the field of automated manufacturability analysis by extending its application to non-material removal processes like injection-molding and die-casting. It introduces a new feature recognition framework inspired by the physics of molding and casting, offering a unique approach compared to existing techniques primarily focused on machining. The concept of using elemental cubes and binary representation for manufacturability evaluation is a novel contribution.

- Practical Implications: The MEA provides a valuable tool for design engineers to evaluate the manufacturability of injection-molded and die-cast parts early in the design stage. This can lead to:

- Reduced design iterations and faster product development cycles.

- Lower manufacturing costs by identifying and addressing manufacturability issues proactively.

- Improved part design for injection-molding and die-casting processes.

- Limitations of the Research:

- The feature recognition approach is currently limited to bosses and holes parallel to the direction of mold closure. Features at angles are classified as undercuts.

- The current implementation requires the direction of mold closure to be specified at the beginning.

- The paper acknowledges that further work is needed to formalize rules for recognizing walls, ribs, and other complex features.

- The generalizability and robustness of the MEA need to be tested on a wider range of complex injection-molded and die-cast parts.

7. Future Follow-up Research:

- Directions for Follow-up Research:

- Formalize and establish rules for recognizing walls, complex features like ribs, and other features in the 3D binary data.

- Develop algorithms to automatically determine the preferred direction of mold closure by scanning the 3D binary array and recognizing features.

- Extend the feature recognition capabilities to include features at angles to the mold closure direction, moving beyond just parallel features.

- Test and validate the MEA on a broader range of complex injection-molded and die-cast parts to establish its validity and robustness.

- Develop "automated synthesis" capabilities to provide part redesign suggestions based on manufacturability analysis results, moving towards a more complete "computer-aided design" system.

- Areas Requiring Further Exploration:

- Optimizing the mesh size for binary representation to balance accuracy and computational cost for different feature sizes and manufacturing capabilities.

- Investigating the integration of the MEA with commercial CAD systems for seamless manufacturability analysis within the design workflow.

- Exploring the application of the MEA to other non-machining processes like forging and stamping.

8. References:

- Dastidar, P. G., A knowledge-based manufacturing advisory system for the economical design of metal stampings, PhD dissertation, University of Massachusetts Amherst, 1991.

- Dixon, J. R. and Poli, C., Engineering Design and Design for Manufacturing, Field Stone Publishers, 1995. Gadh, R., Feature mapping and feature recognition in geometric design generation, In Jami Shah, Martti Mäntylä and Dana S. Nau, editors, Advances in Feature based Manufacturing, chapter 6, pp. 107-128, Elsevier publishers, 1994.

- Gadh, R. and Prinz, F. B., Recognition of geometric forms using the differential depth filter, Computer Aided Design, Butterworth-Heinemann publishers, 24 (11), pp. 583-598, 1992.

- Gupta, S. K., Regli, W. C., Nau, D. S., and Zhang, G., A methodology for systematic generation and evaluation of alternative operation plans, In Jami Shah, Martti Mäntylä and Dana S. Nau, editors, Advances in Feature based Manufacturing, chapter 8, pp. 161-184, Elsevier publishers, 1994.

- Gupta, S. K. and Nau, D. S., A systematic approach for analyzing the manufacturability of machined parts, Computer Aided Design, 1995.

- Gupta, S. K., Regli, W. C., Das, D., and Nau, D. S., Automated Manufacturability Analysis: A Survey, Research in Engineering Design, Vol. 9, No. 3, pp. 168- 190, 1997.

- Henderson, M. R., Extraction of feature information from three-dimensional CAD data, PhD dissertation, Purdue University, 1984.

- Henderson, M. R., Srinath, G., Stage, R., Walker, K. and Regli, W., Boundary Representation-based Feature Identification, In Jami Shah, Martti Mäntylä and Dana S. Nau, editors, Advances in Feature based Manufacturing, chapter 2, pp. 15-38, Elsevier publishers, 1994.

- Joshi, S. and Chang, T. C., Graph based heuristics for recognition of machined features from a 3D solid model, Computer Aided Design, 20 (2), pp. 58-66, 1988.

- J. W. Van Vliet C. A. Van Luttervelt and H. J. J. Kals, State Of the Art report on Design for Manufacturing. In Design Engineering Technical Conference, ASME, 1999. INCLUDE PAPER NUMBER

- Kramer, T. R., Nau, D. S., Gupta, S. K., Regli, W. and Zhang, G., Development of Machining Alternatives, Based on MRSEVs, Proc. of the ASME Computers in Engineering Conference, 1993.

- Kyprianou, L., Shape classification in Computer Aided Design, PhD dissertation, Cambridge, UK, 1980.

- Lei, S. and Qamhiyah, A., Wavelet-based surface analysis for form feature extraction, Proc. of Design for Manufacturing Conf. ASME, 2000. INCLUDE PAPER NUMBER

- Mill, F.G., Naish, J.C. and Salmon, J.C., Design for machining with a simultaneous-engineering workstation, Computer Aided Design, pp. 521-527, 1994.

- Mortenson, M., Geometric modeling, Wiley, 1985.

- Poli, C., Escudero, J. and Fernandez, R., How Part Design Affects Injection Molding Tool Costs, Machine Design, 1988.

- Poli, C., Fredette, L. and Sunderland, J. E., Trimming the cost of die-castings, Machine Design, 1990.

- Poli, C., Design for Manufacturing: A Structured Approach, Butterworth Heinemann, Boston, 2001.

- Prabhakar, S., An experiment on the use of neural nets in form feature recognition, Master’s thesis, Arizona State University, 1990.

- Priest, J. W. and Sanchez, J. M., An empirical methodology for measuring producibility early in product development., International Journal of Computer Integrated Manufacturing, 4(2),pp. 114-- 120, 1991.

- Regli, W. and Nau, D. S., Building a general approach to feature recognition of material removal shape element volumes (MRSEVs), Second Symposium on Solid Modeling Foundations and CAD/CAM Applications, 1993.

- Regli, W., Gupta, S. K. and Nau, D. S., Feature recognition for manufacturability analysis, ASME Computers in Engineering Conference, pp. 93-104,1994.

- Regli, W., Geometric Algorithms for the Recognition of Features from Solid Models, Ph.D. dissertation, University of Maryland, 1995.

- Requicha, A. A. G. and Han, J., Feature recognition from CAD models, IEEE Computer Graphics, 1998.

- Sakurai, H. and Gossard, D. C., Shape Feature Recognition from 3D solid models, ASME Computers in Engineering, 1988.

- Shah, J., Mäntylä, M. and Nau, D. S., editors, Advances in Feature based Manufacturing, chapter 1, pp. 1-11, Elsevier publishers, 1994.

- Shah, J. and Mäntylä, M., Parametric and Feature-Based CAD/CAM: Concepts, techniques and applications, Wiley–Interscience Publication, 1995.

- Trucks, H. E., Designing for Economical Production, Society of Manufacturing Engineers, MI, 1987. UniGraphics Solutions Inc., V18.0 UniGraphics Help, 2001.

- Vandenbrande, J., Automatic recognition of machinable features in solid models, PhD dissertation, University of Southern California, 1990.

- Vandenbrande, J. H. and Requicha, A. A. G., Spatial reasoning for the automatic recognition of machinable features in solid models, IEEE Pattern Analysis and Machine Intelligence, vol. 15, no. 12, pp. 1269-1285, 1993.

- Woo, T., Feature recognition by volume decomposition, Proc. of Conference CAD/CAM technology in Mechanical Engineering, Cambridge, MA, 1982.

- Yong Se Kim, Volumetric feature recognition using convex decomposition, In Jami Shah, Martti Mäntylä and Dana S. Nau, editors, Advances in Feature based Manufacturing, chapter 3, pp. 39-63, Elsevier publishers, 1994. Zeid, I., CAD/CAM Theory and Practice, McGraw-Hill, 1991.

9. Copyright:

*This material is Daniel A. McAdams and Rahul A. Bidkar's paper: Based on AUTOMATED MANUFACTURABILTY ANALYSIS FOR INJECTION-MOLDED AND DIE-CAST PARTS.

*Paper Source:

This material was summarized based on the above paper, and unauthorized use for commercial purposes is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.