본 소개 자료는 "[IntechOpen]"에서 출판한 논문 "[Applications of High-Pressure Die-Casting (HPDC) Magnesium Alloys in Industry]"를 기반으로 작성되었습니다.

1. 개요:

- 제목: Applications of High-Pressure Die-Casting (HPDC) Magnesium Alloys in Industry (산업 분야에서의 고압 다이캐스팅(HPDC) 마그네슘 합금 응용)

- 저자: Sophia Fan, Xu Wang, Gerry Gang Wang and Jonathan P. Weiler

- 발행 연도: 2023 (논문 내 저작권 표기 기준)

- 발행 학술지/학회: IntechOpen (서적 "Magnesium Alloys – Processing, Potential and Applications" 내 챕터)

- 키워드: 고압 다이캐스팅(HPDC), 마그네슘 합금, 주조성, 자동차, 항공우주, 경량화 (high pressure die cast (HPDC), magnesium alloy, castability, automotive, aerospace, lightweighting)

2. 초록:

고압 다이캐스팅(HPDC) 마그네슘 합금은 주로 내연기관(ICE) 차량의 요구사항에 따라 자동차 산업에서 다양한 응용 분야를 보여왔습니다. 자동차 산업이 전기차(EV) 아키텍처로 전환됨에 따라, 주행 거리 효율성을 개선하기 위한 새로운 응용 가능성이 매우 큽니다. 또한, 더 큰 크기의 자동차 다이캐스팅 부품에 대한 추세와 무게 감소로 인한 항공우주 응용 분야에 대한 관심이 증가하고 있습니다. 본 챕터에서는 ICE 차량에서의 전통적인 자동차 구조 응용뿐만 아니라, HPDC 마그네슘 합금의 현재 및 잠재적인 미래 EV 및 항공우주 응용 분야를 검토했습니다. 기존 차량에서 AM50, AM60, AZ91 및 AE44 마그네슘 합금을 사용한 구조 응용은 현대 EV에도 적용될 수 있습니다. 추가적으로, 더 높은 열전도율, 개선된 주조성, 우수한 고온 특성 및 난연성을 다양한 수준으로 갖춘 마그네슘 합금이 개발되어야 하며, 이는 배터리 및 항공우주 객실 관련 구조 재료를 대체하여 모든 안전 요구사항을 충족시키기 위함입니다. 우수한 주조성을 가진 몇 가지 새로 개발된 마그네슘 합금 또한 잠재적인 자동차 및 항공우주 응용을 위해 검토되었습니다.

3. 서론:

배출가스 및 연비 규제로 인해 차량 무게를 줄여야 할 필요성이 증가하고 있습니다. 따라서 경량화는 안전과 성능을 유지하면서 동력 효율성을 개선하기 위한 매우 중요한 주제가 되었습니다. 제품 최적화, 재료 대체 및 부품 통합과 같은 여러 경량화 전략은 밀도가 높은 구조 재료를 밀도가 낮은 재료로 대체함으로써 추진됩니다.

마그네슘 및 그 합금은 다른 자동차 금속에 비해 여러 장점을 가집니다. 마그네슘의 밀도는 1.74 g/cm³로, 알루미늄과 강철보다 현저히 낮습니다 [1]. 마그네슘 합금은 우수한 비강도, 뛰어난 자동화 가능성 및 주조성 특성을 가지며 셀프 스레딩 패스너 사용에 적합한 것으로 잘 알려져 있습니다 [2]. 일반적으로 사용되는 마그네슘 합금은 150°C 이상의 사용 환경에는 부적합할 수 있지만 [3, 4], 적절한 합금 원소를 추가하여 내열성 [5–7] 및 내식성 [8, 9] 마그네슘 합금이 개발되었습니다. 자동차 산업은 내연기관(ICE)에서 전기차(EV)로 파워트레인 아키텍처가 전환되는 과정을 겪고 있습니다. 마그네슘 합금의 열전도율 증가 개발은 배터리 관련 응용을 지원했습니다 [7]. 한편, 난연성은 마그네슘 합금의 뜨거운 주제였으며, 관련 연구는 상당한 진전을 이루어 항공우주 응용에 매우 가치가 있습니다 [10–19]. 이러한 장점 덕분에 마그네슘 합금은 자동차 산업에서 광범위하게 활용되는 가장 가볍고 인기 있는 구조용 금속 중 하나가 되었습니다.

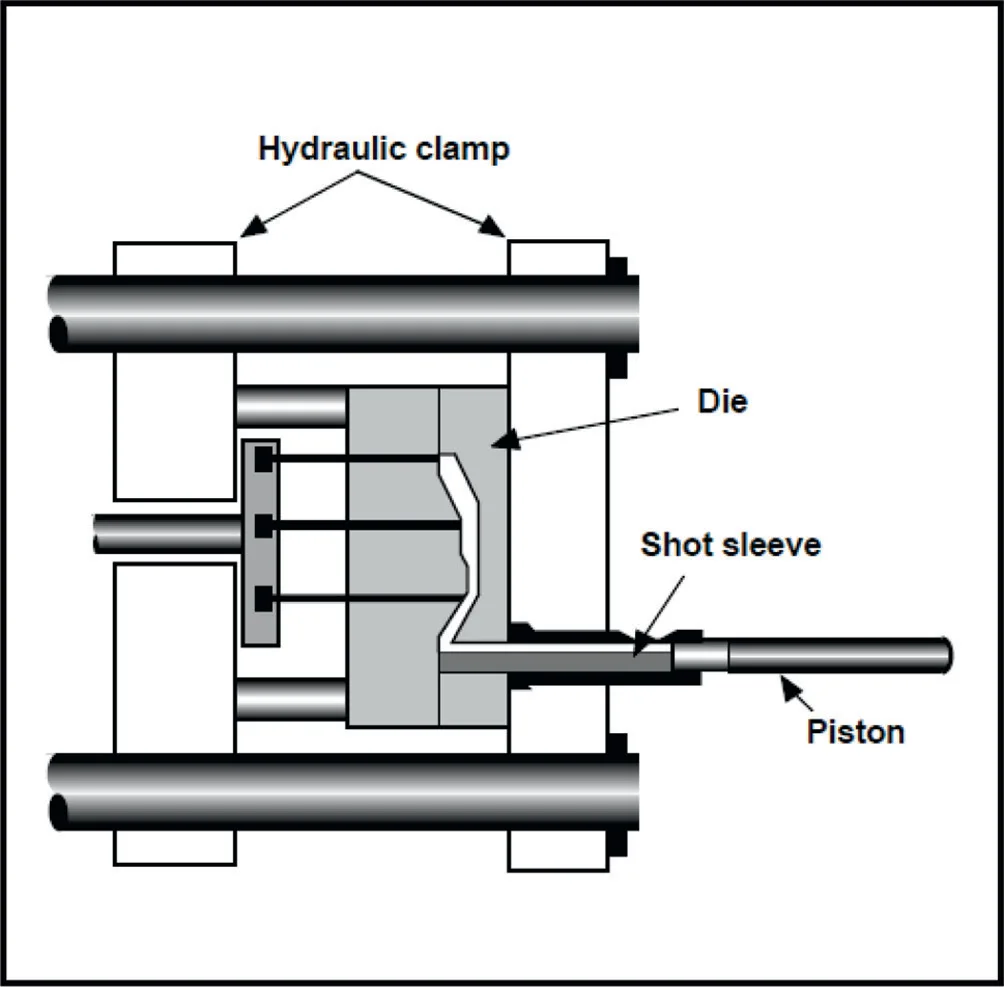

산업계의 대부분 마그네슘 합금 부품은 Figure 1에 설명된 고압 다이캐스팅(HPDC) 공정 [20–21]을 통해 제조됩니다. HPDC 공정은 설계 및 제조에서의 매력적인 유연성, 우수한 다이 충전 특성 및 강철 구조물에 필요한 2차 공정 감소의 높은 효율성을 제공합니다. Figure 2는 여러 다른 공정으로 제조된 AZ91의 항복 강도를 비교합니다 [22–25]. HPDC 공정으로 생산된 제품의 높은 강도는 빠른 냉각 속도로 인한 매우 미세한 미세구조의 결과입니다. 현대 HPDC 기술을 사용하면 마그네슘 합금은 크고 얇은 벽과 복잡한 형상을 가진 거의 최종 형상(near-net shape) 제품으로 생산될 수 있으며, 뛰어난 구조적 및 기능적 성능을 보여주므로 특히 대량 생산을 위한 효율적이고 비용 절감적인 방법으로 널리 적용되었습니다.

본 챕터에서는 역사적 및 잠재적 자동차 및 항공우주 산업에서의 HPDC 마그네슘 합금 응용을 검토하여 성공적인 사례와 진행 중인 개발 현황에 대한 전반적인 이해를 제공할 것입니다.

4. 연구 요약:

연구 주제 배경:

자동차 및 항공우주 산업은 연비/에너지 효율 및 성능 향상을 위해 차량 경량화에 대한 압박이 증가하고 있습니다(경량화). 마그네슘 합금은 낮은 밀도로 인해 매력적인 후보 재료입니다. 내연기관(ICE) 차량에서 전기차(EV)로의 전환은 경량 재료, 특히 특정 열 특성을 가진 재료에 대한 새로운 요구와 기회를 창출합니다. 항공우주 응용 분야 역시 경량화를 요구하지만 엄격한 난연성 요구사항이 있습니다.

이전 연구 현황:

HPDC 마그네슘 합금(예: AM50, AM60, AZ91, AE44)은 ICE 차량의 다양한 자동차 응용 분야에서 수십 년 동안 성공적으로 사용되어 왔습니다. 여기에는 내부 부품(계기판, 시트 프레임, 스티어링 휠), 차체 구조(라디에이터 서포트, 리프트게이트 이너, 도어 이너), 파워트레인 부품(오일 컨duit 모듈, 기어박스 하우징, 트랜스퍼 케이스), 섀시 부품(엔진 크래들, 서브프레임) 등이 포함됩니다. 연구는 합금화(예: RE 원소, Ca)를 통해 내식성, 내크리프성, 열전도율, 난연성과 같은 특성을 개선하는 데 중점을 두었습니다.

연구 목적:

본 챕터는 역사적 및 잠재적 자동차(ICE 및 EV) 및 항공우주 산업에서의 HPDC 마그네슘 합금 응용을 검토하는 것을 목표로 합니다. 성공적인 사례와 진행 중인 개발 현황에 대한 전반적인 이해를 제공하고, 이들 분야에서의 미래 성장 가능성을 강조하고자 합니다.

핵심 연구:

본 연구는 다양한 차량 시스템에 걸친 HPDC 마그네슘 합금의 특정 응용을 검토합니다:

- 내장: 계기판(IP)/크로스카빔(CCB), 시트 프레임, 스티어링 휠, 디스플레이 브래킷, 센터 콘솔, 리어 서포트 브래킷(RSB). 예시로는 JLR CCB의 진화(Figure 4), 다양한 시트백(Figure 5), 기타 내장 부품(Figure 6, Figure 7)이 포함됩니다.

- 차체: 루프 프레임, 마그네슘 라디에이터 서포트(MRS)(Figure 8), 프론트 오브 대시(FOD), 스페어 타이어 캐리어(STC)(Figure 9), 리프트게이트/해치백 이너, 사이드 도어 이너.

- 파워트레인: 엔진 프론트 커버, 오일 컨duit 모듈, 기어박스 하우징, 트랜스퍼/트랜스미션 케이스(Figure 10). AE44 및 AZ91D 사용이 언급됩니다.

- 섀시: 엔진 크래들, 서브프레임, 휠(주로 단조). 부식 및 기공이 주요 관심사입니다.

- 기타 자동차: 스트럿 타워 브레이스(Figure 11).

- 현재 EV 응용: ICE 응용의 이전 가능성(예: CCB, 프론트 엔드 캐리어, 도어 프레임). EV 특정 응용으로는 온보드 차저 하우징(Figure 12a) 및 잠재적 배터리 트레이(Figure 12b). 열전도율(Figure 13) 및 개선된 열 특성과 주조성을 가진 합금 개발(예: DSM-1, Mg-Al-Zn-RE-Ca, Mg-RE-Zn, Mg-La-Al-Mn)에 중점을 두며, RE 용해도(Figure 14)를 고려합니다.

- 항공우주 응용: 역사적 사용(예: F-80C, B-36, TU-95MS) 및 경량화 요구와 개선된 난연성으로 인한 최근 재도입 노력. 난연성 표준(FAA Chapter 25) 및 합금 원소(Ca, RE)의 저항성 개선 역할(Figure 15) 논의. 난연성, 주조성, 비용의 균형을 맞춘 합금(예: WE43 및 Ca 함유 합금 - ZACE05613, AMXS6020) 개발.

5. 연구 방법론

연구 설계:

본 연구는 포괄적인 문헌 검토 논문입니다. 출판된 문헌, 학회 발표 자료, 특허 및 산업 사례 연구 정보를 종합합니다.

데이터 수집 및 분석 방법:

데이터는 인용된 참고문헌 [1-152]에서 수집되었으며, 여기에는 학술 논문, 기술 보고서, 산업 간행물 및 특허가 포함됩니다. 분석은 역사적 및 현재 응용 요약, 다양한 마그네슘 합금의 특성 및 성능 비교(예: 기계적 특성, 부식, 열전도율, 난연성), 합금 개발 및 응용 요구사항(특히 EV 및 항공우주용)의 동향 파악, HPDC 마그네슘 합금 사용의 장점 및 과제 논의를 포함합니다.

연구 주제 및 범위:

본 연구는 고압 다이캐스팅(HPDC) 마그네슘 합금의 응용에 중점을 둡니다. 범위는 다음과 같습니다:

- 내연기관(ICE) 차량에서의 전통적인 응용 (내장, 차체, 파워트레인, 섀시).

- 배터리 관련 부품을 포함한 전기차(EV)에서의 현재 및 잠재적 응용.

- 항공우주 산업에서의 역사적 및 잠재적 응용.

- 사용된 주요 마그네슘 합금 (AM50, AM60, AZ91, AE44, WE43 및 최신 개발 합금).

- 관련 재료 특성: 기계적 강도, 연성, 주조성, 내식성, 열전도율, 난연성.

- HPDC 공정의 역할.

6. 주요 결과:

주요 결과:

- HPDC 마그네슘 합금(AM50, AM60, AZ91, AE44)은 경량화 잠재력, 우수한 비강도, HPDC를 통한 뛰어난 주조성 덕분에 복잡한 부품 통합을 가능하게 하여 수십 년 동안 자동차 산업에서 널리 채택되었습니다.

- 주요 전통적 응용 분야에는 계기판, 크로스카빔, 시트 프레임, 스티어링 휠, 라디에이터 서포트, 스페어 타이어 캐리어, 리프트게이트 이너, 도어 이너, 파워트레인 케이싱 및 엔진 크래들과 같은 섀시 부품이 포함됩니다.

- ICE 차량용으로 개발된 많은 구조 응용은 EV 아키텍처로 직접 이전 가능합니다.

- EV는 특히 배터리 관리 시스템을 위한 높은 열전도율과 같은 새로운 요구사항을 도입합니다. 우수한 주조성과 기계적 특성을 유지하면서 개선된 열전도율을 가진 HPDC 합금(예: 낮은 용해도를 가진 RE 원소 La, Ce 함유) 개발 연구가 진행 중입니다.

- 역사적으로 부식 및 난연성 문제로 제한되었던 항공우주 응용은 FAA 표준을 충족하는 개선된 난연성을 가진 합금(예: WE43, Ca 함유 합금)의 발전으로 인해 새로운 잠재력을 보여줍니다. 비용 효율적이고 주조 가능한 솔루션(특히 Ca 합금화)이 주요 초점입니다.

- HPDC 공정은 복잡하고 얇은 벽의 마그네슘 부품을 대량 생산에 효율적으로 제조하는 데 중요합니다.

- 부식 관리(특히 갈바닉 부식), 일부 신규 합금의 주조성 개선, 중요 응용 분야에서의 기공 제어, 비용 경쟁력 등의 과제가 남아 있습니다.

- 우수한 기계적 특성과 높은 열전도율 또는 난연성과 같은 응용 특정 요구를 결합한 새로운 합금 시스템이 개발되고 있습니다.

그림 이름 목록:

- Figure 1. Schematic diagram showing high pressure die casting (HPDC) process.

- Figure 2. Comparison of the yield strength of AZ91 fabricated by four different processes [22, 25].

- Figure 3. Mechanical and corrosion properties of conventional HPDC magnesium alloys: (a) mechanical properties [25–27] and (b) salt spray test for 1000 hours conducted by Meridian lightweight technologies.

- Figure 4. Evolution of jaguar land rover (JLR) cross car beams (CCB): (a) jaguar S-type 1963 initial design (1998); (b) first-generation magnesium CCB (2002 ~ 2007 jaguar S-type X202); (c) second-generation magnesium CCB (2008-2015 jaguar XF X250) and (d) third-generation magnesium CCB (2015-present XF X260) [28].

- Figure 5. Images showing backseat applications: (a) 2014 Chevrolet corvette seatback (courtesy of GM); (b) 2015 Mercedes-Benz SLK seatback [37] (courtesy of GF casting solutions) and (c) 2014 BMW i3 seatback [38] (courtesy of BASF).

- Figure 6. Images showing interior applications of HPDC magnesium alloys: (a) AZ91D automotive audio amplifier cast by Twin City die casting company [44]; (b) AM60 display bracket on 2021 ford explorer; (c) AM60 steering column cast by Meridian lightweight technologies; (d) AM50 center console on Audi A8 and (e) AM60 center stack on JLR defender [45] (courtesy of GF casting solutions).

- Figure 7. AM50 left hand (LH) and right hand (RH) rear support brackets on 2022 Mercedes-AMG SL roadster cast by Meridian lightweight technologies [46].

- Figure 8. Evolution of ford F-150 AM50A magnesium radiator support (MRS): (a) 2004 model; (b) 2009 model, (c) and (d) 2017 model before and after coating.

- Figure 9. Evolution of jeep wrangler spare tire carrier (STC): (a) first generation on 1996 ~ 2006 model; (b) second generation on 2007 ~ 2018 model and (c) third generation on 2018 ~ present model.

- Figure 10. Powertrain applications of HPDC magnesium alloys: (a) AE44 oil conduit module on Porsche Panamera [48] (courtesy of GF casting solutions) and (b) AZ91 gearbox on Volkswagen golf and Passat [45] (courtesy of GF casting solutions); (c) AZ91 transfer case on ford F-150 and (d) AZ91 transmission case prototype made by Meridian lightweight technologies.

- Figure 11. Evolution of ford mustang GT strut tower mount: (top) steel stamping and aluminum extrusion strut tower mount and (bottom) HPDC magnesium strut tower brace manufactured by Meridian lightweight technologies.

- Figure 12. Battery-related application of magnesium alloys: (a) HPDC AZ91D battery charger housing manufactured by Meridian lightweight technologies [89] and (b) prototyped battery tray [92] (courtesy of Fusium).

- Figure 13. Influence of aluminum content on thermal conductivity of magnesium alloys: Comparison results from PANDAT simulation and tests on Mg-Al and Mg-Al-RE alloys.

- Figure 14. Solubility of selected RE elements in magnesium [107, 108, 113, 114].

- Figure 15. Influence of alloying on mass loss of magnesium alloys tested as per FAA chapter 25 by Meridian lightweight technologies.

7. 결론:

본 검토는 경량화 요구와 HPDC 공정의 장점에 힘입어 자동차 산업에서 내장, 차체, 파워트레인 응용 분야에 HPDC 마그네슘 합금(연성용 AM50/AM60, 강도/내식성용 AZ91D, 고온용 AE44 등)이 광범위하고 성공적으로 사용되었음을 강조합니다. 이러한 구조 응용 중 다수는 EV 아키텍처로 이전 가능합니다. 또한, HPDC 마그네슘 합금은 온보드 차저 하우징 및 배터리 트레이와 같은 EV 특정 부품에 상당한 잠재력을 보여주지만, 주조성과 열전도율을 최적화하기 위한 개발이 진행 중입니다. 항공우주 산업 역시 FAA 표준을 충족하는 개선된 난연성을 가진 합금(예: WE43, Ca 함유 합금) 덕분에 기회를 제공하며, 비용 효율적인 난연성 개선(특히 Ca 합금화)이 주요 초점입니다. 우수한 기계적 성능과 함께 맞춤형 특성(예: 우수한 열전도율, 난연성)을 결합한 새로운 마그네슘 합금의 지속적인 개발은 자동차 및 항공우주 산업 모두에서 HPDC 마그네슘 합금의 강력하고 밝은 미래를 시사합니다.

8. 참고문헌:

- [1] Calado LM, Carmezim MJ, Montemor MF. Rare earth based magnesium alloys—A review on WE series. Frontiers in Materials. 2022;8:1-18. DOI: 10.3389/fmats.2021.804906

- [2] Wang GG, Bos J. A study on joining magnesium alloy high pressure die casting components with thread forming fasteners. Journal of Magnesium Alloy. 2018;6:114-120

- [3] Dargusch MS, Easton MA, Zhu SM, Wang G. Elevated temperature mechanical properties and microstructures of high pressure die cast magnesium AZ91 alloy cast with different section thicknesses. Materials Science and Engineering A. 2009;523:282-288

- [4] Sheng SD, Chen D, Chen ZH. Effects of Si addition on microstructure and mechanical properties of RS/PM (rapid solidification and powder metallurgy) AZ91 alloy. Journal of Alloys and Compounds. 2009;470:L17

- [5] Dong X, Feng L, Wang S, Nyberg EA, Ji S. A new die-cast magnesium alloy for applications at higher elevated temperatures of 200-300°C. Journal of Magnesium and Alloys. 2021;9:90-101. DOI: 10.1016/j.jma.2020.09.012

- [6] Zhu SM, Gibson MA, Nie JF, Easton MA, Abbott TB. Microstructural analysis of the creep resistance of die-cast Mg-4Al–2RE alloy. Scripta Materialia. 2008;58:477-480

- [7] Su CY, Li DJ, Luo AA, Shi RH, Zeng XQ. Quantitative study of microstructure-dependent thermal conductivity in Mg-4Ce-xAl–0.5Mn alloys. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science. 2015;50A:1970-1984

- [8] Zhang JH, Liu K, Fang DQ, Qiu X, Yu P, Tang DX, et al. Microstructures, mechanical properties and corrosion behavior of high-pressure die-cast Mg-4Al-0.4Mn–xPr (x = 1, 2, 4, 6) alloys. Materials Science and Engineering A. 2009;480:810-819

- [9] Zhang JH, Zhang DP, Tian Z, Wang J, Liu K, Lu HY, et al. Microstructures, tensile properties and corrosion behavior of die-cast Mg-4Albased alloys containing La and/or Ce. Materials Science and Engineering A. 2008;489:113-119

- [10] Liu M, Shih DS, Parish C, Atrens A. The ignition temperature of Mg alloys WE43, AZ31 and AZ91. Corrosion Science. 2012;54:139-142. DOI: 10.1016/j.corsci.2011.09.004

- [11] Kumar NVR, Blandin JJ, Suéry M, Grosjean E. Effect of alloying elements on the ignition resistance of magnesium alloys. Scripta Materialia. 2003;49:225-230. DOI: 10.1016/S1359-6462(03)00263-X

- [12] Li F, Peh WY, Nagarajan V, Ho MK, Danno A, Chua BW, et al. Development of non-flammable high strength AZ91 + Ca alloys via liquid forging and extrusion. Materials and Design. 2016;99:37-43. DOI: 10.1016/j.matdes.2016.03.014

- [13] Gneiger S, Gradinger R, Simson C, Kim M, You BS. Investigations on microstructure and mechanical properties of non-flammable Mg-Al-Zn-Ca-Y extruded alloys. In: 7th European Conference for Aeronautics and Space Sciences (EUCASS), Milano, Italia. Bruxelles, Belgium: The EUCASS Association; 2017. pp. 1-7. DOI: 10.13009/EUCASS2017-252

- [14] Frank S, Gneiger S. Development of cost-effective non-flammable magnesium alloys. Light Metal Age. 2017;75:54-56

- [15] Yi S, Victoria-Hernández J, Kim YM, Letzig D, You BS. Modification of microstructure and texture in highly non-flammable Mg-Al-Zn-Y-Ca alloy sheets by controlled thermomechanical processes. Metals (Basel). 2019;9:181. DOI: 10.3390/met9020181

- [16] Cheng C, Lan Q, Wang A, Le Q, Yang F, Li X. Effect of Ca additions on ignition temperature and multi-stage oxidation behavior of AZ80. Metals (Basel). 2018;8:766. DOI: 10.3390/met8100766

- [17] Dvorsky D, Dalibor Vojtech JK, Vojtech D, Minárik P, Straska J. The effect of Y, Gd and Ca on the ignition temperature OF extruded magnesium alloys. Materials and Tehnology. 2020;54:669-675. DOI: 10.17222/mit.2019.284

- [18] Prasad A, Shi Z, Atrens A. Flammability of Mg-X binary alloys. Advanced Engineering Materials. 2012;14:772-784. DOI: 10.1002/adem.201200124

- [19] Cheng C, Lan Q, Liao Q, Le Q, Li X, Chen X, et al. Effect of Ca and Gd combined addition on ignition temperature and oxidation resistance of AZ80. Corrosion Science. 2019;160:108176. DOI: 10.1016/j.corsci.2019.108176

- [20] Joost WJ, Krajewski PE. Towards magnesium alloys for high-volume automotive applications. Scripta Materialia. 2017;128:107-112

- [21] Luo AA. Magnesium casting technology for structural applications. Journal of Magnesium Alloy. 2013;1:2-22. DOI: 10.1016/j.jma.2013.02.002

- [22] ASTM B80-15, Standard Specification for Magnesium-Alloy Sand Castings, 2015

- [23] ASTM B199-12, Standard Specification for Magnesium-Alloy Permanent Mold Castings, 2012

- [24] ASTM B403-12, Standard Specification for Magnesium-Alloy Investment Castings, 2012

- [25] ASTM B94-13, Standard Specification for Magnesium Alloy Die Castings, 2013

- [26] Bakke P, Westengen H, Wang G, Jekl J, Berkmortel R. Die castability and property evaluation of AE alloys for drive train components. In: 13th Magnesium Automotive and End User Seminar. FH Aalen, Aalen, Germany: European Research Association for Magnesium; 2005

- [27] ASTM B85-14, Standard Specification for Aluminum-Alloy Die Castings, 2014. doi:10.1520/B0085

- [28] Fackler H. Magnesium cross car beam – 3 generations. In: 5th Annual Global Automotive Lightweight Material Supply, Design & Engineering. Eur., Birmingham: Global Automotive Lightweight Materials (GALM); 2015

- [29] SAE-China, Energy-saving and New Energy Vehicle Technology Roadmap 2.0, 2020;1-64. Available from: http://www.sae-china.org/news/society/202010/3957.html

- [30] Hector B, Heiss W. Magnesium die-castings as structural members in the integral seat of the new Mercedes-Benz roadster. In: SAE Tech. Pap. Warrendale, PA: SAE International; 1990-02-01. 1990. DOI: 10.4271/900798

- [31] Brambilla S, Perotti P. Die casted magnesium front seat frame: An application for small and medium size cars. In: SAE Tech. Pap. Warrendale, PA: SAE International; 1997-02-24. 1997. DOI: 10.4271/970323

- [32] Gerard DA. Materials and process in the Z06 CORV. Advanced Materials and Processes. 2008;166:30-33

- [33] Kim JJ, Han DS. Recent development and applications of magnesium alloys in the Hyundai and Kia motors corporation. Materials Transactions. 2008;49(5):894-897

- [34] Wang S, Hu W, Gao Z, Tian P. The application of magnesium alloy in automotive seat design. Applied Mechanics and Materials. 2013;395-396:266-270

- [35] Abate M, Willman M. Use of cast magnesium Back frames in automotive seating. In: SAE Tech. Pap. Warrendale, PA: SAE International; 2005-01-0723. 2005. pp. 91-98

- [36] Cornett K. The Seating Options in the 2014 Corvette Stingray, CORVETTEBlogger.Com. (2013) 1-5

- [37] D'Errico F, Tauber M, Just M. Magnesium alloys for sustainable weight-saving approach: A brief market overview, new trends, and perspectives. Current Trends in Magnesium (Mg) Research; 2022:1-33. DOI: 10.5772/intechopen.102777

- [38] Caffrey C, Bolon K, Kolwich G, Johnston R, Shaw T. Cost-effectiveness of a lightweight design for 2020-2025: An assessment of a light-duty pickup truck. In: SAE Tech. Pap. Warrendale, PA: SAE International; 2015-01-0559. 2015. DOI: 10.4271/2015-01-0559

- [39] R. Conroy, G. Exner, M. Shermetaro, Magnesium Steering Wheel, WO 94/16114, 1994

- [40] Kawase Y, Shinto H, Yoshida T. Development of Magnesium Steering Wheel. Warrendale, PA: SAE International; 1991. DOI: 10.4271/910549

- [41] Katsunobu S, Mikio K. Steering Wheel, US5070742. Alexandria, VA: United States Patent and Trademark Office (USPTO); 1991

- [42] Marşavina L, Krausz T, Tamas Krausz L, Pîrvulescu LR. A methodology for durability of AM50 magnesium alloy steering wheels. Semantic Scholar. 2019;64:137-151

- [43] Kim SK, Yoo HJ, Kim YJ. Research strategy for AM60 magnesium steering wheel. In: TMS Annu. Meet. Pittsburgh, PA: The Minerals, Metals and Materials Society (TMS); 2002. pp. 247-252

- [44] North American Die Casting Association. International die casting design competition winner. Die Casting Congress & Tabletop. 2014;2014:63-81

- [45] GF Casting Solutions. Innovative Products for you. Schaffhausen, Switzerland: GF Casting Solutions; 2019. pp. 1-83

- [46] International Magnesium Association. 2022 IMA Awards of Excellence Showcase. St. Paul, MN: International Magnesium Association; 2022

- [47] Balzer JS, Dellock PK, Maj MH, Cole GS, Reed D, Davis T, et al. Structural magnesium front end support assembly. In: SAE Tech. Pap. 2003-01-0186. Warrendale, PA: SAE International; 2003

- [48] Riopelle L. Magnesium application. In: International Magnesium Association. Annu. Semin. Livonia; 2004

- [49] International Magnesium Association. 2006 IMA Awards of Excellence. St. Paul, MN: International Magnesium Association; 2006

- [50] Duke CJ. FCA US LLC-magnesium closures development. SAE Technical Papers. 2021:1-11. DOI: 10.4271/2021-01-0278

- [51] Duke CJ, Logan SD. Lightweight magnesium spare Tire carrier. In: 64th Annu. World Magnes. Conf. St. Paul, MN: International Magnesium Association; 2007. pp. 75-80. DOI: 10.1107/s0021889891006921

- [52] Schreckenberger H, Papke M, Eisenberg S. The Magnesium Hatchback of the 3-Liter Car: Processing and Corrosion Protection. Warrendale, PA: SAE Technical Papers; 2000. pp. 01-1123

- [53] Blawert C, Heitmann V, Höche D, Kainer KU, Schreckenberger H, Izquierdo P, et al. Design of hybrid Mg/Al components for the automotive body - preventing general and galvanic corrosion. In: IMA 67th Annu. World Magnes. Conf. Hong Kong; International Magnesium Association; 2010. p. 9

- [54] Automotive News PACE Awards, 2010-PACE Award Winner. 2010. Available from: https://www.autonews.com/awards/2010-winner-meridian-lightweight-technologies-inc-single-piece-cast-magnesium-liftgate-inner

- [55] Inside L. International die casting design competition winners. Die Casting Engineering. 2010;2010:10-19

- [56] American Foundry Society. GM Wins Funding to Develop Magnesium Diecasting Process, Mod. Cast. Schaumburg, IL: American Foundry Society; 2012. pp. 1-23

- [57] Weiler JP, Sweet C, Adams A, Berkmortel R, Rejc S, Duke C. Next generation magnesium liftgate - utilizing advanced technologies to maximize mass reduction in a high volume vehicle application. In: International Magnesium Association 73rd Annual World Magnesium Conference. Rome: International Magnesium Association; 2016

- [58] Weiler JP. A review of magnesium die-castings for closure applications. Journal of Magnesium Alloy. 2019;7:297-304. DOI: 10.1016/j.jma.2019.02.005

- [59] New Car Test Drive, 2000 Mercedes-Benz CL-Class Review, New Car Test Drive. 1999. Available from: https://www.newcartestdrive.com/reviews/2000-mercedes-benz-cl-class/

- [60] Kacher G. Mercedes-Benz SL500, Motortrend. 2001. Available from: https://www.motortrend.com/reviews/mercedes-benz-sl500-2/

- [61] R.E. Bonnett, G. T. Bretz, P. Blanchard, S. Subramanian, Magnesium Door Assembly for Automobiles, US 2003/0188492 A1, Alexandria, VA: United States Patent and Trademark Office (USPTO); 2003

- [62] Blanchard PJ, Bretz GT, Subramanian S, Devries JE, Syvret A, Macdonald A, et al. The application of magnesium die casting to vehicle closures. In: SAE Tech. Pap. Warrendale, PA: SAE International; 2005-01-0338. 2005. DOI: 10.4271/2005-01-0338

- [63] Wang GG, MacKenzie K, Sweet C, Carter JT, O'Kane JC, Resch SA, et al. Development of a Thin-Wall magnesium automotive door inner panel. SAE International Journal of Materials and Manufacturing. 2020;13:199-208

- [64] International Magnesium Association. 2013 IMA Awards of Excellence. St. Paul, MN: International Magnesium Association; 2013

- [65] International Magnesium Association. IMA Awards of Excellence Winners, Mg Showc. St. Paul, MN: International Magnesium Association; 2012. pp. 1-4

- [66] Friedrich H, Schumann S. The use of magnesium in cars - today and in the future. In: Int. Conf. Exhib. Magnes. Alloy. Their Appl. Wolfsburg: The Minerals, Metals and Materials Society; 1998. pp. 3-13

- [67] Bronfin B, Moscovitch N. New magnesium alloys for transmission parts. Metal Science and Heat Treatment. 2006;48:479-486. DOI: 10.1007/s11041-006-0121-z

- [68] International Magnesium Association. IMA AWARDS OF EXCELLENCE Design. St. Paul, MN: International Magnesium Association; 2014

- [69] Beals RS, Tissington C, Zhang X, Kainer K, Petrillo J, Verbrugge M, et al. Magnesium global development: Outcomes from the TMS 2007 annual meeting. JOM. 2007;59:39-42. DOI: 10.1007/s11837-007-0102-8

- [70] Koike S, Washizu K, Tanak S, Baba T, Kikawa K. Development of lightweight oil pans made of a heat resistant magnesium alloy for hybrid engines. In: SAE Tech. Pap. Warrendale, PA: SAE International; 2000-01-1117. 2000. pp. 1-9

- [71] Merens N, NADCA. Competition rewards versatility and innovation. International Die Casting Design and Competition. 2006;2006:26-35

- [72] Chen X, Wagner D, Heath G, Mehta S, Uicker J. Cast magnesium subframe development-bolt load retention. SAE Technical Papers. 2021:1-8. DOI: 10.4271/2021-01-0274

- [73] Chen X, Wagner D, Wedepohl A, Redlin K, Mehta S, Uicker J. Cast magnesium subframe development-corrosion mitigation strategy and testing. SAE Technical Papers. 2021:1-7. DOI: 10.4271/2021-01-0279

- [74] North American Die Casting Association. 2018 Die Casting Award Winner. In: 2018 NADCA Die Cast. Congr. Arlington Heights, IL: North American Die Casting Association; 2018. pp. 57-66

- [75] Porsche Tequipmenrt. Exclusive Magnesium Wheels. 2021. Available from: https://dealer.porsche.com/za/johannesburg/en-GB/Accessories/Magnesium-Wheels

- [76] Ceppos R. 2022 Cadillac V-Series Blackwings to Get Magnesium Wheels, Car Driv. 2020. Available from: https://www.caranddriver.com/news/a34536259/2022-cadillac-v-series-blackwing-magnesium-wheels/

- [77] Yamaha Motor Co., Magnesium Die-Cast Wheels. (n.d.). Available from: https://global.yamaha-motor.com/business/cf/example/casting/ex011/

- [78] Choudhary VS, Akram W, Yaseen JM, Saifudheen SM. Design and analysis of wheel rim with magnesium alloys (ZK60A) by using Solidworks and finite element method. International Journal of Automotive Technology. 2016;1:16-29

- [79] Jiang X, Liu H, Lyu R, Fukushima Y, Kawada N, Zhang Z, et al. Optimization of magnesium alloy wheel dynamic impact performance. Advances in Materials Science and Engineering. 2019;2019:1-12. DOI: 10.1155/2019/2632031

- [80] Frishfelds V, Timuhins A, Bethers U. Benefits of magnesium wheels for consumer cars. In: IOP Conference Series: Materials Science and Engineering. Philadelphia, PA: IOP Publishing; Vol. 355. 2018. pp. 1-9. DOI: 10.1088/1757-899X/355/1/012023

- [81] North American Die Casting Association. 2021 Die Casting Award Winners. In: 2021 Int. Die Cast. Compet. Arlington Heights, IL: North American Die Casting Association, Lexington; 2021. p. 55. DOI: 10.31399/asm.hb.v02a.a0006525

- [82] American Foundry Society. Outstanding achievement-magnesium strut tower brace. In: Mod. Cast. Vol. 27. Schaumburg, IL: American Foundry Society; 2020

- [83] Lazarz K, Cahill J, Ciccone TJ, Redlin K, Simko S. Corrosion performance of a magnesium tower brace. SAE Technical Papers. 2021:1-7. DOI: 10.4271/2021-01-0276

- [84] Ciccone TJ, Kurane A, Delaney R, Ng S, Thai P, Hameedi J. Strut-Tower Brace, US10144456 B1. Alexandria, VA: United States Patent and Trademark Office (USPTO); 2018

- [85] Wang GG, Weiler JP. Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications. Journal of Magnesium Alloy. 2022;11:78-87

- [86] Cadillac CT4-V Blackwing. NetCarShow.Com. (2022). Available from: https://www.netcarshow.com/cadillac/2022-ct4-v_blackwing/

- [87] Foote B. 2021 Ford Mustang Mach-E Instrument Panel Analysis Reveals Mystery Space: Video, Ford Auth. 2021. Available from: https://doi.org/https://fordauthority.com/2021/07/2021-ford-mustang-mach-e-instrument-panel-analysis-reveals-mystery-space-video/

- [88] 2016 AWARDS OF EXCELLENCE. Automotive Cast Product: Georg Fischer Automotive AG for Upper Door Frame. St. Paul, MN: International Magnesium Association; 2016

- [89] American Foundry Society. Outstanding achievement - magnesium charger housing. In: Mod. Cast. Schaumburg, IL: American Foundry Society; 2022. p. 24

- [90] North American Die Casting Association. 2022 industry awards casting winners - magnesium battery charger housing. In: 2022 Int. Die Cast. Compet. Arlington Heights, IL: North American Die Casting Association; 2022

- [91] International Magnesium Association. 2021 IMA AWARDS OF EXCELLENCE for automotive - AZ91D magnesium charger housing for the Subaru Crosstrek plug-In hybrid. In: 2021 Int. Magnes. Assoc. Conf. St. Paul, MN: International Magnesium Association; 2021

- [92] FUSIUM. Magnesium Alloy Battery Tray. n.d. Available from: https://fusium.ca/en/portfolio/battery-tray/

- [93] Lee S, Ham HJ, Kwon SY, Kim SW, Suh CM. Thermal conductivity of magnesium alloys in the temperature range from -125 C to 400 C. International Journal of Thermophysics. 2010;34:2343-2350. DOI: 10.1007/s10765-011-1145-1

- [94] Ying T, Chi H, Zheng M, Li Z, Uher C. Low-temperature electrical resistivity and thermal conductivity of binary magnesium alloys. Acta Materialia. 2014;80:288-295. DOI: 10.1016/j.actamat.2014.07.063

- [95] Rudajevova OLA, Stanek M. Determination of thermal diffusivity and thermal conductivity of Mg-Al alloys. Materials Science and Engineering A. 2003;341:152-157

- [96] Ying T, Zheng MY, Li ZT, Qiao XG. Thermal conductivity of as-cast and as-extruded binary Mg-Al alloys. Journal of Alloys and Compounds. 2014;608:19-24. DOI: 10.1016/j.jallcom.2014.04.107

- [97] Pan H, Pan F, Yang R, Peng J, Zhao C, She J, et al. Thermal and electrical conductivity of binary magnesium alloys. Journal of Materials Science. 2014;49:3107-3124. DOI: 10.1007/s10853-013-8012-3

- [98] Yuan J, Zhang K, Zhang X, Li X, Li T, Li Y, et al. Thermal characteristics of Mg-Zn-Mn alloys with high specific strength and high thermal conductivity. Journal of Alloys and Compounds. 2013;578:32-36. DOI: 10.1016/j.jallcom.2013.03.184

- [99] Pan H, Pan F, Peng J, Gou J, Tang A, Wua L, et al. High-conductivity binary Mg-Zn sheet processed by cold rolling and subsequent aging. Journal of Alloys and Compounds. 2013;578:493-500. DOI: 10.1016/j.jallcom.2013.06.082

- [100] Liu X, Wu Y, Liu Z, Lu C, Xie H, Li J. Thermal and Electrical Conductivity of as-Cast Mg-4Y-xZn Alloys. Philadelphia, PA: IOP Publishing; 2018

- [101] Zhou X, Mo L, Du J, Luo G. Microstructure evolution and improvement of thermal conductivity in Mg-2Sn alloy induced by La addition. Journal of Materials Research and Technology. 2022;17:1380-1389. DOI: 10.1016/j.jmrt.2022.01.083

- [102] Rzychoń T, Kiełbus A. The influence of rare earth, strontium and calcium on the thermal diffusivity of Mg-Al alloys. Defect and Diffusion Forum. 2011;312-315:824-829. DOI: 10.4028/www.scientific.net/DDF.312-315.824

- [103] Zhou X, Guo T, Wu S, Lü S, Yang X, Guo W. Effects of Si content and Ca addition on thermal conductivity of As-cast Mg-Si alloys. Materials (Basel). 2018;11:2376-2387. DOI: 10.3390/ma11122376

- [104] Rudajevová A, Lukáč P. Comparison of the thermal properties of AM20 and AS21 magnesium alloys. Materials Science and Engineering A. 2005;397:16-21. DOI: 10.1016/j.msea.2004.12.036

- [105] Rudajevová A, Von Buch F, Mordike BL. Thermal diffusivity and thermal conductivity of MgSc alloys. Journal of Alloys and Compounds. 1999;292:27-30. DOI: 10.1016/S0925-8388(99)00444-2

- [106] Yamasaki M, Kawamura Y. Thermal diffusivity and thermal conductivity of Mg-Zn-rare earth element alloys with long-period stacking ordered phase. Scripta Materialia. 2009;60:264-267. DOI: 10.1016/j.scriptamat.2008.10.022

- [107] Zhong L, Peng J, Sun S, Wang Y, Lu Y, Pan F. Microstructure and thermal conductivity of As-cast and As-Solutionized Mg-rare earth binary alloys. Journal of Materials Science and Technology. 2017;33:1240-1248. DOI: 10.1016/j.jmst.2016.08.026

- [108] Su C, Li D, Luo AA, Ying T, Zeng X. Effect of solute atoms and second phases on the thermal conductivity of Mg-RE alloys: A quantitative study. Journal of Alloys and Compounds. 2018;747:431-437. DOI: 10.1016/j.jallcom.2018.03.070

- [109] Zhong L, Wang Y, Gong M, Zheng X, Peng J. Effects of precipitates and its interface on thermal conductivity of Mg-12Gd alloy during aging treatment. Materials Characterization. 2018;138:284-288. DOI: 10.1016/j.matchar.2018.02.019

- [110] Peng J, Zhong L, Wang Y, Yang J, Lu Y, Pan F. Effect of Ce addition on thermal conductivity of Mg-2Zn-1Mn alloy. Journal of Alloys and Compounds. 2015;639:556-562. DOI: 10.1016/j.jallcom.2015.03.197

- [111] Peng J, Zhong L, Wang Y, Lu Y, Pan F. Effect of extrusion temperature on the microstructure and thermal conductivity of Mg-2.0Zn-1.0Mn-0.2Ce alloys. Materials and Design. 2015;87:914-919. DOI: 10.1016/j.matdes.2015.08.043

- [112] Zhong L, Peng J, Li M, Wang Y, Lu Y, Pan F. Effect of Ce addition on the microstructure, thermal conductivity and mechanical properties of Mg-0.5Mn alloys. Journal of Alloys and Compounds. 2016;661:402-410. DOI: 10.1016/j.jallcom. 2015.11.107

- [113] Guo H, Liu S, Huang L, Wang D, Du Y, Chu M. Thermal conductivity of As-cast and annealed Mg-RE binary alloys. Metals (Basel). 2021;11:1-12. DOI: 10.3390/met11040554

- [114] Xie T, Shi H, Wang H, Luo Q, Li Q, Chou KC. Thermodynamic prediction of thermal diffusivity and thermal conductivity in Mg-Zn-La/Ce system. Journal of Materials Science and Technology. 2022;97:147-155. DOI: 10.1016/j.jmst.2021.04.044

- [115] Zhu WF, Luo Q, Zhang JY, Li Q. Phase equilibria of Mg-La-Zr system and thermal conductivity of selected alloys. Journal of Alloys and Compounds. 2018;731:784-795. DOI: 10.1016/j.jallcom.2017.10.013

- [116] Liu H, Zuo J, Nakata T, Xu C, Wang G, Shi H, et al. Effects of La addition on the microstructure, thermal conductivity and mechanical properties of Mg-3A1-0.3Mn alloys. Materials (Basel). 2022;15:1078. DOI: 10.3390/ma15031078

- [117] Su C, Li D, Ying T, Zhou L, Li L, Zeng X. Effect of Nd content and heat treatment on the thermal conductivity of Mg-Nd alloys. Journal of Alloys and Compounds. 2016;685:114-121. DOI: 10.1016/j.jallcom.2016.05.261

- [118] Li S, Yang X, Hou J, Du W. A review on thermal conductivity of magnesium and its alloys. Journal of Magnesium Alloy. 2020;8:78-90. DOI: 10.1016/j.jma.2019.08.002

- [119] Bazhenov VE, Koltygin AV, Sung MC, Park SH, Titov AY, Bautin VA, et al. Design of Mg-Zn-Si–Ca casting magnesium alloy with high thermal conductivity. Journal of Magnesium and Alloys. 2020;8:184-191. DOI: 10.1016/j.jma.2019.11.008

- [120] Rong J, Zhu JN, Xiao W, Zhao X, Ma C. A high pressure die cast magnesium alloy with superior thermal conductivity and high strength. Intermetallics. 2021;139:107350. DOI: 10.1016/j.intermet.2021.107350

- [121] Rong J, Xiao W, Zhao X, Ma C, Liao H, He D, et al. High thermal conductivity and high strength magnesium alloy for high pressure die casting ultrathin-walled components. International Journal of Minerals, Metallurgy, and Materials. 2022;29:88-96. DOI: 10.1007/s12613-021-2318-y

- [122] Rong J, Xiao W, Zhao X, Fu Y, Liao H, Ma C, et al. Effects of Al addition on the microstructure, mechanical properties and thermal conductivity of high pressure die cast Mg-3RE–0.5Zn alloy ultrathin-walled component. Journal of Alloys and Compounds. 2022;896:162943. DOI: 10.1016/j.jallcom.2021.162943

- [123] Zhao X, Li Z, Zhou W, Li D, Qin M, Zeng X. Effect of Al content on microstructure, thermal conductivity, and mechanical properties of Mg-La-Al-Mn alloys. Journal of Materials Research. 2021;36:3145-3154. DOI: 10.1557/s43578-021-00319-x

- [124] Czerwinski F. Controlling the ignition and flammability of magnesium for aerospace applications. Corrosion Science. 2014;86:1-16. DOI: 10.1016/j.corsci.2014.04.047

- [125] Conference I, Ostrovsky I, Henn Y. Present state and future of magnesium application in aerospace industry. In: Int. Conf. New Challenges Aeronaut. ASTEC 07. Moscow: Advanced Surface Technology Exhibition & Conference (ASTEC); 2007. pp. 1-5

- [126] Gupta M, Guota N. The promise of magnesium based materials in aerospace sector. International Journal of Aeronautical and Aerospace Research. 2017;4:141-149. DOI: 10.19070/2470-4415-1700017

- [127] Davis B. The application of magnesium alloys in aircraft interiors - changing the rules. TMS: The Minerals, Metals and Materials Society. 2015;2015:5

- [128] Bin Huang Y, Chung IS, You BS, Park WW, Choi BH. Effect of Be addition on the oxidation behavior of Mg-Ca alloys at elevated temperature. Metals and Materials International. 2004;10:7-11. DOI: 10.1007/BF03027357

- [129] Zeng XQ, Wang QD, Lü YZ, Ding WJ, Lu C, Zhu YP, et al. Study on ignition proof magnesium alloy with beryllium and rare earth additions. Scripta Materialia. 2000;43:403-409. DOI: 10.1016/S1359-6462(00)00440-1

- [130] Lin P, Zhou H, Li W, Li WP, Sun N, Yang R. Interactive effect of cerium and aluminum on the ignition point and the oxidation resistance of magnesium alloy. Corrosion Science. 2008;50:2669-2675. DOI: 10.1016/j.corsci.2008.06.025

- [131] Lin P, Zhou H, Sun N, Li WP, Wang CT, Wang M, et al. Influence of cerium addition on the resistance to oxidation of AM50 alloy prepared by rapid solidification. Corrosion Science. 2010;52:416-421. DOI: 10.1016/j.corsci.2009.09.029

- [132] Li W, Zhou H, Zhou W, Li WP, Wang MX. Effect of cooling rate on ignition point of AZ91D-0.98 wt.% Ce magnesium alloy. Materials Letters. 2007;61:2772-2774. DOI: 10.1016/j.matlet.2006.10.028

- [133] Hongjin Z, Yinghui Z, Yonglin K. Effect of cerium on ignition point of AZ91D magnesium alloy. China Foundry. 2008;5:32-35

- [134] Fan JF, Yang GC, Chen SL, Xie H, Wang M, Zhou YH. Effect of rare earths (Y, Ce) additions on the ignition points of magnesium alloys. Journal of Materials Science. 2004;39:6375-6377. DOI: 10.1023/b:jmsc.0000043613.94027.04

- [135] Marker TR. Evaluating the flammability of various magnesium alloys during laboratory- and full-scale aircraft fite tests. Public report published by the Federal Aviation Administration. 2013;15

- [136] Wang G, Zhao Z, Zhang S, Zheng L. Effects of Al, Zn, and rare earth elements on flammability of magnesium alloys subjected to sonic burner-generated flame by Federal Aviation Administration standards. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering. 2021;235:1-12. DOI: 10.1177/0954410020987758

- [137] Baar N. Uber die Legierungen des Molybdans mit Nickel, Mangans mit Thallium und des Calcium mit Magnesium, Thallium, Blei, Kupfer und Silber, Zeitschrift Für Anorg. Zeitschrift für anorganische und allgemeine Chemie. 1911;70:352-394

- [138] Jiang Z, Jiang B, Zhang J, Dai J, Yang Q, Yang Q, et al. Effect of Al2Ca intermetallic compound addition on grain refinement of AZ31 magnesium alloy. Transactions of the Nonferrous Metals Society of China. 2016;26:1284-1293. DOI: 10.1016/S1003-6326(16)64229-2

- [139] Lee DB. High temperature oxidation of AZ31+0.3wt.%Ca and AZ31+0.3wt.%CaO magnesium alloys. Corrosion Science. 2013;70:243-251. DOI: 10.1016/j.corsci.2013.01.036

- [140] Wiese B. The Effect of CaO on Magnesium and Magnesium Calcium Alloys. Clausthal-Zellerfeld, Germany: Clausthal University of Technology; 2016. p. 134

- [141] Kim SK, Lee J, Yoon Y, Jo H. Development of AZ31 Mg alloy wrought process route without protective gas. Journal of Materials Processing Technology. 2007;188:757-760. DOI: 10.1016/j.jmatprotec.2006.11.172

- [142] Jang DI, Kim SK. Effect of Ca(OH)2 on oxidation and ignition resistances of pure Mg, Essent. Readings. Readings Magnesium Technology. 2014:145-149. DOI: 10.1002/9781118859803.ch24

- [143] Sakamoto M, Akiyama S, Ogi K. Suppression of ignition and burning of molten Mg alloys by Ca bearing stable oxide film. Journal of Materials Science Letters. 1997;16:1048-1050. DOI: 10.1023/A:1018526708423

- [144] Wu G, Fan Y, Gao H, Zhai C, Zhu YP. The effect of Ca and rare earth elements on the microstructure, mechanical properties and corrosion behavior of AZ91D. Materials Science and Engineering A. 2005;408:255-263. DOI: 10.1016/j.msea.2005.08.011

- [145] You BS, Park WW, Chung IS. Effect of calcium additions on the oxidation behavior in magnesium alloys. Scripta Materialia. 2000;42:1089-1094. DOI: 10.1016/S1359-6462(00)00344-4

- [146] Lee DB, Hong LS, Kim YJ. Effect of Ca and CaO on the high temperature oxidation of AZ91D Mg alloys. Materials Transactions. 2008;49:1084-1088. DOI: 10.2320/matertrans.MC200799

- [147] Weiler JP. Exploring the concept of castability in magnesium die-casting alloys. Journal of Magnesium Alloy. 2021;9:102-111. DOI: 10.1016/j.jma.2020.05.008

- [148] Tang B, Li SS, Wang XS, Ben Zeng D, Wu R. An investigation on hot crack mechanism of Ca addition into AZ91D alloy. Scripta Materialia. 2005;53:1077-1082. DOI: 10.1016/j.scriptamat.2005.06.039

- [149] Anyanwu IA, Gokan Y, Nozawa S, Suzuki A, Kamado S, Kojima Y, et al. Development of new die-castable Mg-Zn-Al-Ca-RE alloys for high temperature applications. Materials Transactions. 2003;44:562-570. DOI: 10.2320/matertrans.44.562

- [150] Terada Y, Ishimatsu N, Mori Y, Sato T. Eutectic phase investigation in a Ca-added AM50 magnesium alloy produced by die casting. Materials Transactions. 2005;46:145-147. DOI: 10.2320/matertrans.46.145

- [151] Easton MA, Gibson MA, Gershenzon M, Savage G, Tyagi V, Abbott TB, et al. Castability of some magnesium alloys in a novel castability die. Materials Science Forum. 2011;690:61-64. DOI: 10.4028/www.scientific.net/MSF.690.61

- [152] Mori Y, Sugimura S, Koshi A, Liao J. Corrosion behavior of die cast Mg-Al-Mn-Ca-Si magnesium alloy. Materials Transactions. 2019;61:1-9

9. 저작권:

- 본 자료는 "Sophia Fan, Xu Wang, Gerry Gang Wang and Jonathan P. Weiler"의 논문입니다. "[Applications of High-Pressure Die-Casting (HPDC) Magnesium Alloys in Industry]"를 기반으로 합니다.

- 논문 출처: http://dx.doi.org/10.5772/intechopen.110494

본 자료는 상기 논문을 바탕으로 요약되었으며, 상업적 목적의 무단 사용을 금지합니다.

Copyright © 2025 CASTMAN. All rights reserved.