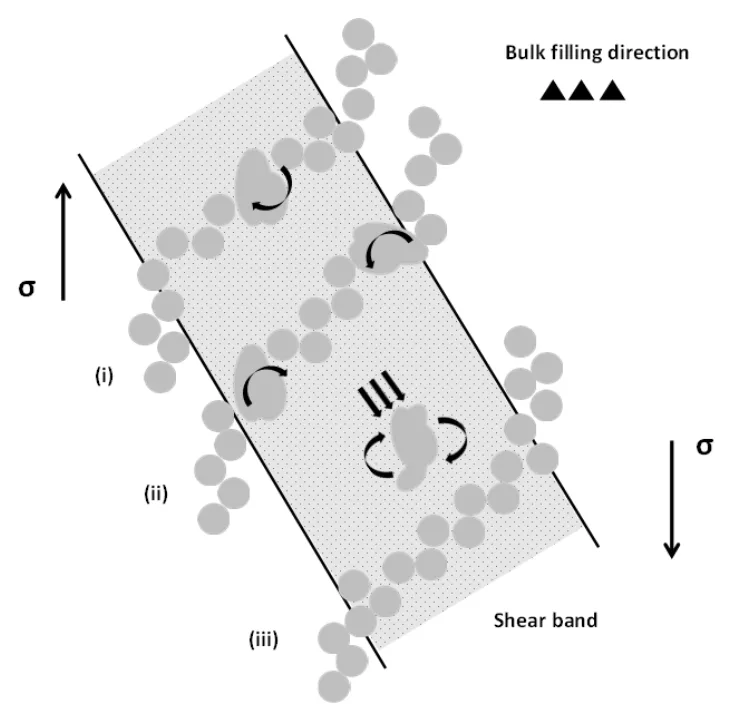

Figure 8. Graphical illustration highlighting the three mechanisms governing ESC enhanced dilation

within the shear band: (i) ‘Stacking faults’ introduced by the presence of ESCs along the force chain;

(ii) ESCs located on the outermost regions of the band effectively acting as pivots; (iii) ESCs propelled

by highly turbulent flow conditions, potentially dislodging crystals from the force chain. σ denotes

the major principle stress axis.