Transforming Aerospace Scrap into High-Performance Sacrificial Anodes

This technical brief is based on the academic paper “Recycling of magnesium alloys aeronautical parts for obtaining sacrificial anodes” by A. Buzaianu, G. Popescu, C.A. Popescu, A.F. Olteanu, I. Rusu, and P. Motoiu, published as an Article in 2008. It is summarized and analyzed for industry professionals by the experts at STI C&D.

Keywords

- Primary Keyword: Magnesium alloy recycling

- Secondary Keywords: Sacrificial anodes, Aeronautical scrap recycling, Magnesium electrochemical performance, Melting fluxes for magnesium, Cathodic protection, AZ91 alloy recycling

Executive Summary

- The Challenge: Effectively recycling complex, often painted, magnesium alloy components from the aeronautical industry presents significant challenges due to impurities and high reactivity during melting.

- The Method: Researchers developed a specialized recycling process using custom-formulated fluxes to melt, refine, and recast various types of aeronautical magnesium scrap (including AZ91, RZ5, and Mg-Al-Li) into sacrificial anodes.

- The Key Breakthrough: The study successfully demonstrated that recycled magnesium alloys can be used to manufacture high-quality sacrificial anodes with superior electrochemical performance compared to traditional materials like zinc.

- The Bottom Line: This recycling methodology can reduce the material cost for manufacturing magnesium anodes by as much as 75% compared to using virgin material, offering a significant economic and environmental advantage.

The Challenge: Why This Research Matters for HPDC Professionals

Magnesium alloys are highly valued in industries like aerospace for their low density and good machinability. However, a persistent misconception about high costs, coupled with a lack of robust supply chains for secondary materials, has limited their broader application. The primary challenge this research addresses is the effective recycling of discarded magnesium components, particularly complex aeronautical parts that are often painted and contain a mix of alloying elements.

For manufacturers and engineers, the inability to efficiently recycle this scrap translates to higher material costs and missed value-capture opportunities. The process is complicated by magnesium’s high reactivity with air, which can lead to oxidation and material loss during re-melting, and by surface contaminants like paint and chromate films that must be managed to ensure the quality of the final product. This study provides a technical roadmap to overcome these hurdles.

The Approach: Unpacking the Methodology

To establish a viable recycling pathway, the researchers conducted a series of experiments focused on melting, refining, and testing.

The methodology involved:

- Material Sourcing: Discarded aeronautical components made from various magnesium alloys, including Mg-Al-Zn (AZ91), Mg-Al-Li, and Mg-Zr-Nd (RZ5), were collected (Figures 1-3).

- Specialized Flux Development: Recognizing that standard melting practices would be insufficient, the researchers developed three distinct, specialized fluxes. These chloride and fluoride-based fluxes were designed to clean the melt, protect it from oxidation, and help separate impurities and slag.

- Melting and Casting: The scrap was melted in a gas electrical furnace at approximately 710°C. During casting into metallic dies, the use of fluxes was replaced by a sulphur protection atmosphere over the metal jet. The process yielded various types of cast anodes for different applications, such as for tanks, ship hulls, and underground structures (Figure 4).

- Electrochemical and Microstructural Analysis: The performance of the resulting anodes was rigorously tested. The team measured key electrochemical characteristics in synthetic seawater (3% NaCl solution) and used a Philips SEM–515 scanning electron microscope to analyze the microstructure and correlate it with performance.

The Breakthrough: Key Findings & Data

The study yielded several critical findings that validate the recycling process and highlight the quality of the end product.

- Finding 1: Massive Cost Reduction: The most significant economic outcome is the potential for dramatic cost savings. The paper concludes that “The use of recycled materials in anode manufacture can reduce the Mg alloy cost by about 75% of the total cost of this type of products” (Ref. Conclusion). This includes all associated costs from collection to final composition adjustment.

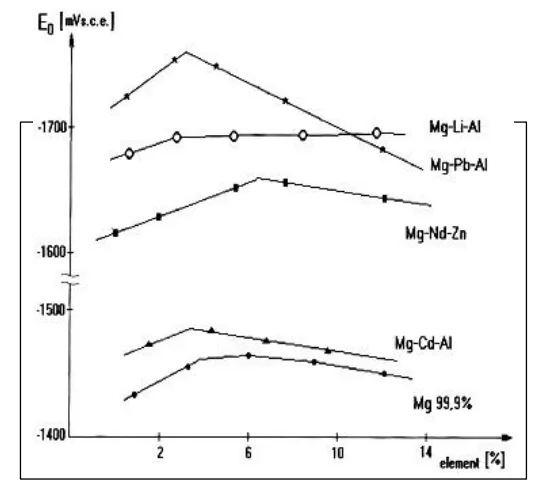

- Finding 2: Superior Electrochemical Performance: Anodes produced from recycled alloys demonstrated excellent performance for cathodic protection. As shown in Table II, recycled alloys like “MELMAG” achieved a nominal output voltage of 1.5-1.7 V, which is significantly higher than that of zinc anodes (0.20-0.25 V) listed in Table I. Figure 5 graphically illustrates that the electrochemical potential of the recycled alloys is substantially more negative (more active) than pure magnesium, making them highly effective for protecting steel structures.

- Finding 3: Effective Impurity Management with Custom Fluxes: The presence of paint and other contaminants was successfully managed through the use of specially designed fluxes. The paper details three flux compositions (Flux 1, Flux 2, Flux 3) tailored for different alloy types (non-zirconium, zirconium-containing, and lithium-containing), which were essential for achieving a clean melt and high metal recovery of over 85-90%.

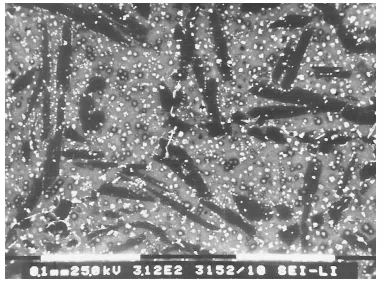

- Finding 4: Controlled Anodic Dissolution: Microstructural analysis (Figures 6-9) revealed that alloying elements like Cd, Pb, Li, and Nd influenced the anode’s structure. The research noted a “selective anodic dissolution… at the grain boundaries,” which ultimately leads to a more homogeneous anode surface and stable potential over time, a desirable characteristic for a sacrificial anode.

Practical Implications for Your HPDC Operations

The findings from this paper offer actionable insights for engineers and managers in metallurgy, manufacturing, and corrosion protection.

- For Process Engineers: The study provides concrete formulations for melting fluxes (Flux 1, 2, and 3) that can be adapted to recycle specific types of magnesium alloy scrap. The specified melting temperature of ~710°C and the use of sulphur protection during casting offer a practical process window for minimizing oxidation and ensuring high yield.

- For Quality Control: The strong correlation established between chemical composition (Table III) and electrochemical potential (Figure 5) provides a powerful predictive tool. By analyzing the composition of a recycled melt, quality teams can reliably forecast the performance of the final anode, ensuring it meets specifications for cathodic protection.

- For Procurement and Product Development: This research validates a business case for creating value from scrap material. Companies can source lower-cost aeronautical scrap and, by applying the described refining techniques, produce high-margin, high-performance products like sacrificial anodes. This opens a new, cost-effective material stream that reduces reliance on expensive virgin magnesium.

Paper Details

Recycling of magnesium alloys aeronautical parts for obtaining sacrificial anodes

1. Overview:

- Title: Recycling of magnesium alloys aeronautical parts for obtaining sacrificial anodes

- Author: A. Buzaianu, G. Popescu, C.A. Popescu, A.F. Olteanu, I. Rusu, P. Motoiu

- Year of publication: 2008

- Journal/academic society of publication: Article

- Keywords: Magnesium recycling, disassembling aeronautical parts, sacrificial anodes, magnesium electrochemical performances.

2. Abstract:

In recent years, the recycling magnesium metallurgy has developed new types of alloys, some of which exhibiting special electrochemical characteristics. Their application has found a fertile field in the energy conversion technologies. The paper introduces some technologic data on the recycling of aeronautical parts and scrap materials generated from the disassembling of magnesium alloy components, attempting to also solve the recycling of magnesium painted parts. The approach is meant to establish a superior quality method for recycling discarded parts or the excess of re-melting material in order to reduce environmental impact and costs. Magnesium-base alloys used as anodic materials are characterized by a high uniformity of the structural properties as well as by superior electrochemical performances, as compared to the “classically” used materials: Zn, Pb, etc. In nonconventional applications of magnesium alloys used as sacrificial anodes working in seawater, special alloying elements contribute to improving anodic processes. The influence of these alloying elements on magnesium sacrificial anodes was studied. It was found that the use of recycled materials in anode manufacture could reduce the Mg alloy cost by as much as up to 75% of the cost for virgin material, including the costs for the entire sequence of collection and transportation from a molding factory to a refinery, re-melting and composition adjustment.

3. Introduction:

Magnesium alloys are valuable materials due to their low density, good formability, and high recycling potential. This research was motivated by the need to dispel the “false idea” of high costs associated with magnesium, which is partly due to a lack of secondary material suppliers. The study was spurred by the need to develop new alloys, coatings, and processing techniques to expand magnesium’s use. The goal was to develop an efficient recycling method for magnesium, particularly for complex and painted aeronautical parts, to create value-added products, reduce energy consumption, and minimize environmental impact.

4. Summary of the study:

Background of the research topic:

The recycling of magnesium, especially from specialized applications like aerospace, is a key area for cost and environmental impact reduction. Painted and compositionally complex parts pose a significant challenge. Simultaneously, there is a demand for high-performance sacrificial anodes for the cathodic protection of steel structures in environments like seawater. This study connects these two areas by proposing a method to turn problematic scrap into a valuable product.

Status of previous research:

The paper notes that previous research had already established that magnesium anodes are attractive for pipeline protection due to the high potential difference they create with steel. It also references prior discoveries that limiting trace impurities like iron, nickel, and copper can dramatically reduce the corrosion of magnesium alloys. This work builds on that foundation by applying these principles to a complex recycling stream.

Purpose of the study:

The primary purpose was to establish a superior quality method for recycling discarded and painted magnesium aeronautical parts. The goal was to transform this scrap into high-performance sacrificial anodes, thereby reducing costs, minimizing environmental impact, and creating a valuable secondary material stream.

Core study:

The core of the study involved the experimental recycling of three types of magnesium alloy scrap: Mg-Al-Zn (AZ91), Mg-Al-Li, and Mg-Zr-Nd (RZ5). The researchers developed and utilized specific melting and refining fluxes to handle impurities and paint coatings. The recycled material was then cast into anodes of various sizes. The key part of the study was the subsequent electrochemical testing and microstructural analysis to validate the performance of these recycled anodes and understand the influence of different alloying elements.

5. Research Methodology

Research Design:

The study was an experimental investigation. It involved collecting real-world scrap, developing specific flux compositions for melting and refining, executing the melting and casting process under controlled conditions, and then conducting a series of characterization tests on the final products.

Data Collection and Analysis Methods:

- Chemical Analysis: Samples were taken from the melt to test and adjust composition.

- Process Control: Temperature was measured with a Pt/Pt-Rh10 thermocouple.

- Electrochemical Testing: Anodes were tested in synthetic seawater (3% NaCl solution). A high-sensitivity voltmeter was used to determine the characteristic potential. The rate of anodic dissolution was evaluated by measuring the short-circuit current of a galvanic couple and the volume of hydrogen released.

- Microstructural Analysis: A Philips SEM–515 scanning electron microscope equipped with EDS and WDS systems was used to examine the structure of the alloys and the distribution of alloying elements.

Research Topics and Scope:

The research focused on the complete recycling chain for magnesium aeronautical parts. The scope included:

- Recycling of Mg-Al-Zn (type AZ 91), Mg-Al-Li, and Mg-Zr-Nd (type RZ5) alloys.

- The influence of paint coatings on the melting process.

- The development and application of specialized fluxes for melting and refining.

- The casting of sacrificial anodes from the recycled material.

- The evaluation of the electrochemical performance and microstructure of the resulting anodes.

6. Key Results:

Key Results:

The study successfully demonstrated that painted aeronautical magnesium parts can be recycled into high-performance sacrificial anodes. The key results were:

- A potential cost reduction of up to 75% compared to using virgin magnesium.

- The development of three effective flux compositions for melting different types of magnesium alloys, achieving metal recovery rates of 85-90%.

- The recycled anodes exhibited high nominal output voltages (1.4-1.7 V, as per Table II), making them highly suitable for cathodic protection.

- Specific alloying elements (Pb, Cd, Nd, Li) were shown to significantly influence the electrochemical potential and dissolution behavior of the anodes, allowing for performance tuning.

- The process was robust enough to produce anodes in various shapes and sizes for diverse applications (Figure 4).

Figure Name List:

- Figure 1. Example of recycling Mg-Al-Zn aeronautical components (alloys type: AZ 91 )

- Figure 2. Example of recycling of Mg-Al-Li aeronautical components

- Figure 3. Example of recycling of Mg-Zr-Nd aeronautical components (alloys type: RZ5).

- Figure 4a. The anode weight 0.5 – 3 kg. Particular type anodes for the protection of tanks

- Figure 4b. The anode weight 3-10 kg . Type anodes for attached outside of a ship hull

- Figure 4c. The anode weight 15-25 kg. Particular type anodes for the protection the undeground steel structures

- Figure 4. Cast anodes for cathodic protection obtained from recycled magnesium base alloys for specific requirements and flexible uses. ( Conformity to METAV specification)

- Figure 5. The electrochemical potential variation in seawater for the recycled alloy, in comparison with the pure Mg sacrificial anodes.

- Figure 6. SEI image of Mg-Cd-Al sacrificial anode with 1.5%Cd (-1250 mV e.s.c). Inter-granular selective solution in anode matrix.

- Figure 7. Image of Mg-Pb-Al sacrificial anode with 1.5%Pb (-1250 mVe.s.c). Inter-granular selective solution in anode matrix.

- Figure 8. SEI image of Mg-Li sacrificial anode with 8Li% (-1650mVe.s.c). Inter-metallic compound on the boundary grains and structural homogeneity of matrix

- Figure 9. SEI image of the structure of quaternary compounds Mg-Al-Zn and 1%Zn wt. (-1357 mV e.s.c ).

7. Conclusion:

The study concludes that recycling painted magnesium alloy aeronautical parts to produce sacrificial anodes is a highly effective and economically advantageous process. The researchers successfully developed compositions and techniques to manage impurities and achieve desired electrochemical properties. A key finding was that selective anodic dissolution at the grain boundaries leads to a homogenization of the anode surface and a stable potential. The most impactful conclusion is that this recycling method can reduce the Mg alloy cost by approximately 75%, covering the entire process from collection and transportation to re-melting and composition adjustment.

8. References:

- A.Buzaianu, M. Corban, I. Ciupitu, Roxana Trusca and P. Nita, Some Design Considerations for Magnesium Sacrificial Anodes, in URB-CORR Sibiu Romania, Vol. Study and Control of Corrosion in the Perspective of Sustainable Development of Urban Distribution Grids, ISBN: 973-718-259-6, Ed. PRINTECH Printhouse (2005), p. 40-45 .

- H.T. Gao, G.H. Wu, W. J. Ding, Y.P. Zhu, Recycling of Magnesium Alloy AZ91 Scrap by a B2O3- Containing Flux, Journal of Materials Science, Vol.39, Nr.21 (2004) p. 6449-6456.

- E.D.Morales, E.Ghali, N.Hort,W.Dietzel,K.U.Kainer,Corrosion Behavior of Magnesium Alloys with RE Additions in Sodium Chloride Solution, Materials Science Forum 419-422 (2003), p.867-872.

- K.Kimura, K.Nishii and M.Kawarada, Recycling Magnesium Alloy Housings for Notebook Computers, Fujisu Sci. Tech, J. 38,1.Tokyo (2002), p.102-110.

- 5.K. Koichi, N. Kouta and K. Motonobu, Mater.Trans. 43 (2002), p.2516.

Conclusion & Next Steps

This research provides a valuable roadmap for enhancing the circular economy for magnesium alloys. The findings offer a clear, data-driven path toward turning low-value, complex scrap into high-performance products, improving sustainability and profitability.

STI C&D is committed to applying cutting-edge industry research to solve our customers’ most challenging technical problems. If the problem discussed in this white paper aligns with your research goals, please contact our engineering team to discuss how we can help you apply these advanced principles to your research.

Expert Q&A:

- Q1: What is the main economic benefit of the recycling process described in the paper?

- A: The primary economic benefit is a significant cost reduction. The study concludes that using recycled aeronautical materials can lower the cost of manufacturing magnesium sacrificial anodes by up to 75% compared to using virgin material, as stated in the paper’s abstract and conclusion.

- Q2: Can painted magnesium parts be recycled using this method?

- A: Yes. The paper specifically addresses the challenge of recycling painted parts. The method’s success relies on using specially formulated fluxes (detailed as Flux 1, 2, and 3) during the melting process to manage the impurities and contaminants from the paint and surface treatments, as described in the section “The influence of the presence of paint coatings.”

- Q3: How does the performance of these recycled magnesium anodes compare to traditional anodes?

- A: The recycled magnesium anodes show superior electrochemical performance. According to Table I and Table II, the recycled alloys achieve a much higher potential difference against steel (e.g., 1.5-1.7 V for MELMAG) than traditional zinc anodes (0.20-0.25 V), making them more effective for cathodic protection.

- Q4: What was the key to achieving a high-quality melt from the scrap material?

- A: The key was the use of protective, specialized fluxes. The paper highlights that magnesium has a high tendency to oxidize, and the scrap contained impurities. The custom-developed chloride and fluoride-based fluxes were crucial for protecting the melt, cleaning it, and ensuring good separation of the metal from the slag, leading to a high recovery of 85-90%.

- Q5: Which recycled alloy composition showed the highest nominal output voltage?

- A: The “MELMAG” alloy, with a composition of 5-7% Al and 2.5-3.5% Zn, demonstrated the highest nominal output voltage, ranging from 1.5-1.7 V. This is supported by the data in Table II, “Comparative features of selected recycled magnesium alloys.”

Copyright

- This material is an analysis of the paper “Recycling of magnesium alloys aeronautical parts for obtaining sacrificial anodes” by A. Buzaianu et al.

- Source of the paper: https://www.researchgate.net/publication/288099243

- This material is for informational purposes only. Unauthorized commercial use is prohibited.

- Copyright © 2025 STI C&D. All rights reserved.