1. 개요:

- 제목: A review of air-cooling battery thermal management systems for electric and hybrid electric vehicles

- 저자: Gang Zhao, Xiaolin Wang, Michael Negnevitsky, Hengyun Zhang

- 발행 연도: 2021

- 발행 학술지/학회: Journal of Power Sources

- Keywords: 전기 자동차, 리튬 이온 배터리, 공랭식, 배터리 열 관리 시스템, 검토

2. 연구 배경:

1900년대 이후 온실가스(GHGs) 농도가 증가해 왔으며, 특히 내연기관(ICEs)에서 화석 연료의 인위적 연소로 인해 대기 중 GHGs 농도가 크게 증가했습니다. 2018년 교통 부문의 CO2 배출량은 약 8258Mt로 전 세계 CO2 배출량의 24.3%를 차지했습니다.

온실가스 배출량 감소와 지구 온난화 문제 해결을 위한 방법으로 전기 자동차(EVs)와 하이브리드 전기 자동차(HEVs)가 주목받고 있습니다. EVs와 HEVs의 성능에 있어 배터리 성능이 중요하며, 배터리 성능은 에너지 저장 시스템(배터리)의 열 관리와 통합에 달려 있습니다.

리튬이온 배터리는 높은 비에너지 밀도, 높은 비출력, 경량, 고전압 출력, 낮은 자기 방전율, 낮은 유지 보수 비용, 낮은 질량-부피 생산 비용 등의 장점을 가지고 있지만, 높은 비용이라는 단점이 있습니다. 리튬이온 배터리는 EVs와 HEVs의 주요 에너지 저장 장치로 사용되고 있습니다.

그러나 리튬이온 배터리는 충전 및 방전 중에 열을 발생시키며, 과도한 열 축적은 배터리 온도 상승과 온도 불균일을 초래하여 배터리 성능 저하, 수명 단축, 열 폭주, 화재 등의 위험을 야기합니다. 따라서 EVs와 HEVs의 배터리에 효율적인 배터리 열 관리 시스템(BTMS)이 필수적입니다.

기존 연구에서는 공랭식, 액랭식, PCM 기반 냉각, 히트파이프 냉각 등 다양한 BTMS 냉각 기술을 검토했지만, EVs 및 HEVs를 위한 공랭식 BTMS에 대한 종합적인 검토는 부족했습니다.

본 연구는 이러한 기존 연구의 한계를 극복하고 공랭식 BTMS의 추가 개발을 위한 방향을 제시하기 위해 수행되었습니다.

![Fig. 5. Double silica cooling structure with copper meshes (Ref. [186]).](https://castman.co.kr/wp-content/uploads/Fig.-5.-Double-silica-cooling-structure-with-copper-meshes-Ref.-186-1024x453.webp)

3. 연구 목적 및 연구 질문:

- 연구 목적: EVs 및 HEVs에서 공랭식 배터리 열 관리 시스템(BTMS)을 종합적으로 검토하고, 성능 개선을 위한 잠재적인 솔루션을 제시하는 것입니다.

- 핵심 연구 질문: 공랭식 BTMS의 성능을 향상시키기 위한 최적화 기술은 무엇이며, 그 장단점은 무엇인가? 공랭식 BTMS의 미래 연구 방향은 무엇인가?

- 연구 가설: 첨단 계산 수치 시뮬레이션과 정교한 실험을 통해 새로운 배터리 팩 개념, 냉각 채널의 혁신적인 설계, 새로운 열 전도성 재료를 도입함으로써 공랭식 BTMS의 효율을 크게 향상시킬 수 있다.

4. 연구 방법론:

- 연구 설계: 리뷰 논문 연구 설계를 사용하여 기존 문헌을 분석하고, 공랭식 BTMS의 성능 향상을 위한 다양한 기술들을 평가했습니다.

- 데이터 수집 방법: 전기 및 하이브리드 전기 자동차의 공랭식 BTMS에 관한 기존의 관련 문헌들을 데이터베이스를 통해 수집했습니다.

- 분석 방법: 수집된 문헌들을 체계적으로 분석하여 공랭식 BTMS의 열 발생 메커니즘, 기존 설계, 다양한 설계 개선, 장단점, 미래 연구 방향 등을 평가했습니다. 계산 유체역학(CFD) 시뮬레이션 결과를 포함한 실험 데이터 및 시뮬레이션 결과들을 분석했습니다.

- 연구 대상 및 범위: 본 연구는 전기 자동차 및 하이브리드 전기 자동차에 사용되는 공랭식 배터리 열 관리 시스템(BTMS)에 초점을 맞추었습니다. 배터리 열 발생 메커니즘, 공랭식 BTMS 설계, 다양한 설계 개선(배터리 팩 배치, 냉각 채널, 입구 및 출구 위치, 새로운 열 전도성 재료, 보조 냉각 채널 등), 미래 연구 방향에 대한 논의를 포함했습니다.

5. 주요 연구 결과:

본 논문에서는 리튬이온 배터리의 열 발생 메커니즘과 그 영향(열 노화, 열 폭주 및 화재 사고 포함)에 대한 검토, 기본 공랭식 BTMS 설계 검토, 다양한 새로운 설계 개선(배터리 팩 배치, 냉각 채널, 입구 및 출구 위치, 새로운 열 전도성 재료, 보조 냉각 채널 등) 평가, 공랭식 BTMS의 장점과 과제 탐색을 수행했습니다.

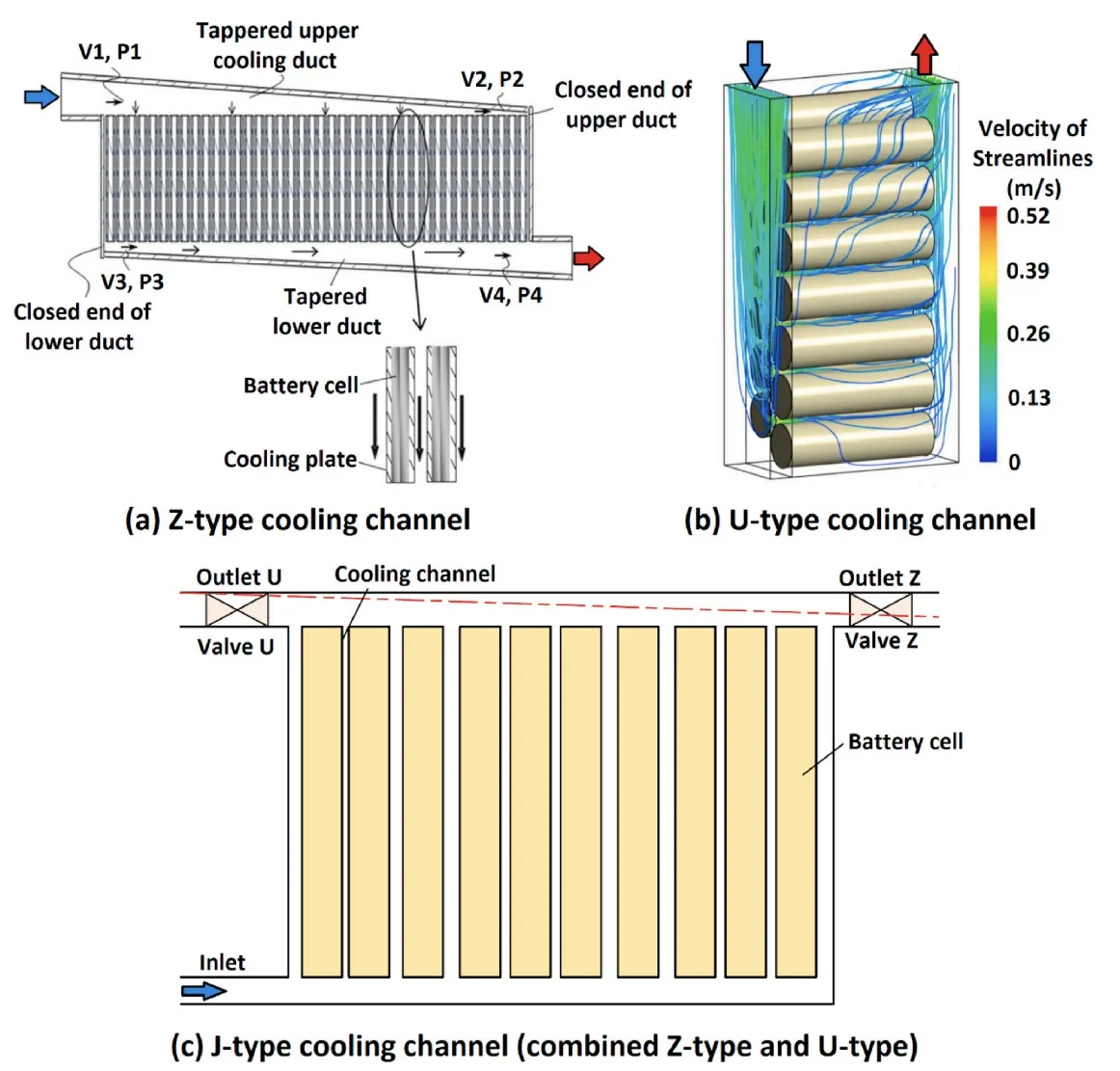

첨단 계산 수치 시뮬레이션 및 정교한 실험을 통해 공랭식 효율을 크게 향상시키는 새로운 개념의 배터리 팩, 혁신적인 냉각 채널 설계, 새로운 열 전도성 재료가 제시되었습니다. 다양한 배터리 셀 배열(정렬형, 스태거형, 교차형 등)과 냉각 채널 형태(Z형, U형, J형 등), 입출구 위치, 열전도성 재료 개선, 보조 냉각 채널 추가 등이 BTMS 성능 향상에 미치는 영향을 분석했습니다.

또한, 열 폭주 및 화재 사고의 위험성을 검토하고 이를 방지하기 위한 방안을 제시했습니다. 수치 시뮬레이션 및 실험 결과를 바탕으로 공랭식 BTMS의 미래 연구 방향 및 잠재적 해결책에 대한 논의가 이루어졌습니다.

Figure List and Description:

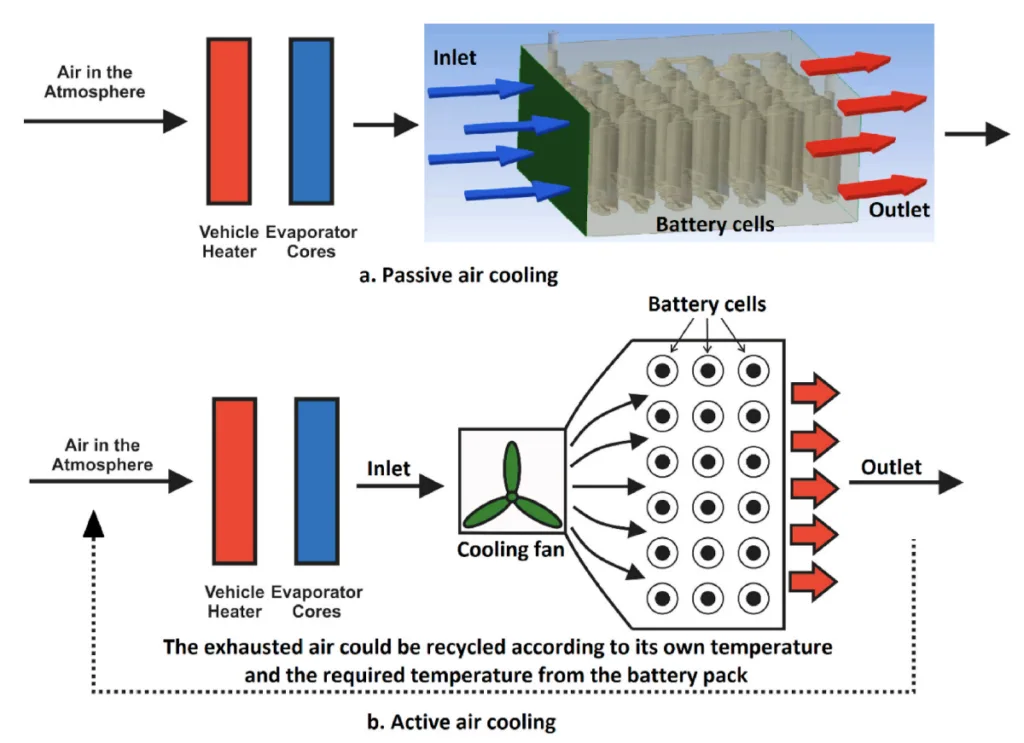

- 그림 1: 공랭식 BTMS의 개략도 (수동 및 능동 냉각 방식 포함)

- 그림 2: 스태거형 배열을 가진 3중 스택 배터리 팩

- 그림 3: 다양한 냉각 채널 설계 (Z형, U형, J형)

- 그림 4: 상이한 출구 디자인을 가진 BTMS

- 그림 5: 구리 메쉬를 사용한 이중 실리카 냉각 구조

- 그림 6: 델타 윙렛 디자인 (와류 발생기, 윙렛 어레이)

- 그림 7: 보조 친수성 섬유 채널이 있는 기본 공랭식 덕트

- 그림 8: 셀 구성요소 냉각 방식 (표면 냉각 방식, 탭 냉각 방식)

![Fig. 2. Three-stack battery pack with stagger-arranged Lithium-ion battery cells on each stack (Ref. [158]).](https://castman.co.kr/wp-content/uploads/Fig.-2.-Three-stack-battery-pack-with-stagger-arranged-Lithium-ion-battery-cells-on-each-stack-Ref.-158-1024x449.webp)

6. 결론 및 논의:

본 연구는 EVs와 HEVs에서 공랭식 BTMS의 성능을 향상시키기 위한 다양한 기술들을 검토했습니다. 배터리 팩 설계, 냉각 채널, 입출구, 열전도성 재료, 보조 냉각 채널 등의 개선을 통해 공랭식 BTMS의 효율을 높일 수 있음을 보여주었습니다.

그러나 고온 환경이나 고속 충방전 조건에서는 단일 공랭식 BTMS만으로는 충분한 냉각 성능을 확보하기 어려울 수 있습니다. 따라서 PCM, 히트파이프, 직접 증발 냉각(DEC) 등 다른 기술과의 결합을 통한 하이브리드 시스템 개발이 필요합니다.

또한, 향후 연구는 더욱 정교한 시뮬레이션 모델 개발, 다양한 작동 조건 하에서의 실험적 검증, 그리고 다양한 배터리 화학 물질과의 적합성 평가에 집중해야 합니다.

7. 향후 후속 연구:

향후 연구는 더욱 정교한 시뮬레이션 모델 개발, 다양한 작동 조건 하에서의 실험적 검증, 그리고 다양한 배터리 화학 물질과의 적합성 평가에 집중해야 합니다.

특히, 고온 및 고속 충방전 조건에서의 성능 향상, 열 폭주 방지 기술 개발, 다양한 배터리 형태 및 크기에 대한 적용성 확대 등에 대한 연구가 필요합니다. 또한, 실제 차량 환경에서의 성능 평가를 통해 실용성을 검증하는 연구도 중요합니다.

8. 참고문헌 요약:

- [1] L.H. Martinez, Post industrial revolution human activity and climate change: why the United States must implement mandatory limits on industrial greenhouse gas emmissions, J. Land Use Environ. Law (2005) 403–421.

- [2] O. Edenhofer, Climate Change 2014: Mitigation of Climate Change, Cambridge University Press, 2015.

- [3] IEA. CO2 emissions by sector. https://www.iea.org/data-and-statistics?countr y=WORLD&fuel=CO2%20emissions&indicator=CO2BySector (accessed 3 December, 2020).

- [4] W. Yuan, H.C. Frey, T. Wei, N. Rastogi, S. VanderGriend, D. Miller, L. Mattison, Comparison of real-world vehicle fuel use and tailpipe emissions for gasolineethanol fuel blends, Fuel 249 (2019) 352–364.

- [5] X. Sun, Z. Li, X. Wang, C. Li, Technology development of electric vehicles: a review, Energies 13 (1) (2020) 90.

- [6] O. Gippner, D. Torney, Shifting policy priorities in EU-China energy relations: implications for Chinese energy investments in Europe, Energy Pol. 101 (2017) 649–658.

- [7] M. Debert, G. Colin, G. Bloch, Y. Chamaillard, An observer looks at the cell temperature in automotive battery packs, Contr. Eng. Pract. 21 (8) (2013) 1035–1042.

- [8] P. Wolfram, N. Lutsey, Electric Vehicles: Literature Review of Technology Costs and Carbon Emissions, The International Council on Clean Transportation, Washington, DC, USA, 2016, pp. 1–23.

- [9] G. Berckmans, M. Messagie, J. Smekens, N. Omar, L. Vanhaverbeke, J. Van Mierlo, Cost projection of state of the art lithium-ion batteries for electric vehicles up to 2030, Energies 10 (9) (2017) 1314.

- [10] F.V. Conte, Battery and battery management for hybrid electric vehicles: a review, E I Elektrotechnik Inf. 123 (10) (2006) 424–431.

- [11] Z.M. Salameh, M.A. Casacca, W.A. Lynch, A mathematical model for lead-acid batteries, IEEE Trans. Energy Convers. 7 (1) (1992) 93–98.

- [12] S. Ovshinsky, M. Fetcenko, J. Ross, A nickel metal hydride battery for electric vehicles, Science 260 (5105) (1993) 176–181.

- [13] S. Yoon, J. Lee, T. Hyeon, S.M. Oh, Electric double-layer capacitor performance of a new mesoporous carbon, J. Electrochem. Soc. 147 (7) (2000) 2507–2512.

- [14] L.H. Saw, Y. Ye, A.A.O. Tay, Integration issues of lithium-ion battery into electric vehicles battery pack, J. Clean. Prod. 113 (2016) 1032–1045.

- [15] L.I.R. Batteries, Technical Handbook, disponible 25, 2013, pp. 27–29, http://car di.igeofcu.unam.mx/techdocs/PowerSonic_batteries.pdf.

- [16] M.S. Whittingham, Materials challenges facing electrical energy storage, MRS Bull. 33 (4) (2008) 411–419.

- [17] G. Pistoia, Lithium-ion Batteries: Advances and Applications, Newnes, 2013.

- [18] N. Nitta, F. Wu, J.T. Lee, G. Yushin, Li-ion battery materials: present and future, Mater. Today 18 (5) (2015) 252–264.

- [19] A. Mahmoudzadeh Andwari, A. Pesiridis, S. Rajoo, R. Martinez-Botas, V. Esfahanian, A review of Battery Electric Vehicle technology and readiness levels, Renew. Sustain. Energy Rev. 78 (2017) 414–430.

- [20] N. Sato, Thermal behavior analysis of lithium-ion batteries for electric and hybrid vehicles, J. Power Sources 99 (1–2) (2001) 70–77.

- [21] S. Al-Hallaj, J.R. Selman, Thermal modeling of secondary lithium batteries for electric vehicle/hybrid electric vehicle applications, J. Power Sources 110 (2) (2002) 341–348.

- [22] L. Fred. Tesla Model 3: exclusive first look at Tesla’s new battery pack architecture. Electrek. https://electrek.co/2017/08/24/tesla-model-3-exclusi ve-battery-pack-architecture/(accessed 31 December, 2019).

- [23] C. Luca. BMW plans different sized battery cells to preserve design of future models. Automotive News Europe. https://europe.autonews.com/article/ 20180418/ANE/180419811/bmw-plans-different-sized-battery-cells-to-preservedesign-of-future-models (accessed 31 December, 2019).

- [24] D. Phil. Honda e battery specs and platform revealed, 31,000 have ‘expressed interest’ in the electric car. Electrek. https://electrek.co/2019/06/13/honda-ebattery-platform/(accessed 31 December, 2019).

- [25] G. Auto. Emgrand EV, Fashionably eco-feiendly. http://global.geely.com/car /emgrand-ev-2/(accessed 31 December, 2019).

- [26] G. Renault. Zoe – the ultimate city car, designed for everyday practicality and convenience. https://group.renault.com/en/innovation-2/electric-vehicl e/(accessed 31 December, 2019).

- [27] B. Matt. Hyundai Kona electric 2019 review – Australia. Carsales. https://www.ca rsales.com.au/editorial/details/hyundai-kona-electric-2019-review-australia -117573/?&tracking=dsa&gclid=Cj0KCQiA0ZHwBRCRARIsAK0Tr-raGraRwr_h15 AjJfiyhWKNIOluj3Y6XhBUFQbaibgZvklKXUFF05jVYaAiEYEALw_wcB&gclsrc =aw.ds (accessed 31 December, 2019).

- [28] A. E. Paul. Exclusive: FCA has big news coming in electrification. The Detroit Bureau. https://www.thedetroitbureau.com/2019/06/exclusive-fca-has-big-ne ws-coming-in-electrification/(accessed 31 December, 2019).

- [29] Z. Rao, S. Wang, A review of power battery thermal energy management, Renew. Sustain. Energy Rev. 15 (9) (2011) 4554–4571.

- [30] Q. Wang, B. Jiang, B. Li, Y. Yan, A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles, Renew. Sustain. Energy Rev. 64 (2016) 106–128.

- [31] Z. An, L. Jia, Y. Ding, C. Dang, X. Li, A review on lithium-ion power battery thermal management technologies and thermal safety, J. Therm. Sci. 26 (5) (2017) 391–412.

- [32] G. Xia, L. Cao, G. Bi, A review on battery thermal management in electric vehicle application, J. Power Sources 367 (2017) 90–105.

- [33] J. Kim, J. Oh, H. Lee, Review on battery thermal management system for electric vehicles, Appl. Therm. Eng. 149 (2019) 192–212.

- [34] H. Liu, Z. Wei, W. He, J. Zhao, Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: a review, Energy Convers. Manag. 150 (2017) 304–330.

- [35] W. Wu, S. Wang, W. Wu, K. Chen, S. Hong, Y. Lai, A critical review of battery thermal performance and liquid based battery thermal management, Energy Convers. Manag. 182 (2019) 262–281.

- [36] A.H. Akinlabi, D. Solyali, Configuration, design, and optimization of air-cooled battery thermal management system for electric vehicles: a review, Renew. Sustain. Energy Rev. 125 (2020) 109815.

- [37] M.S. Islam, D.J. Driscoll, C.A. Fisher, P.R. Slater, Atomic-scale investigation of defects, dopants, and lithium transport in the LiFePO4 olivine-type battery material, Chem. Mater. 17 (20) (2005) 5085–5092.

- [38] C. Daniel, D. Mohanty, J. Li, D.L. Wood, Cathode Materials Review, 2014.

- [39] S.-L. Wu, W. Zhang, X. Song, A.K. Shukla, G. Liu, V. Battaglia, V. Srinivasan, High rate capability of Li (Ni1/3Mn1/3Co1/3) O2 electrode for Li-ion batteries, J. Electrochem. Soc. 159 (4) (2012) A438–A444.

- [40] H.-J. Noh, S. Youn, C.S. Yoon, Y.-K. Sun, Comparison of the structural and electrochemical properties of layered Li

- [NixCoyMnz] O2 (x= 1/3, 0.5, 0.6, 0.7, 0.8 and 0.85) cathode material for lithium-ion batteries, J. Power Sources 233 (2013) 121–130.

- [41] P. Kalyani, N. Kalaiselvi, Various aspects of LiNiO2chemistry: a review, Sci. Technol. Adv. Mater. 6 (6) (2016) 689–703.

- [42] T.-F. Yi, Y.-R. Zhu, X.-D. Zhu, J. Shu, C.-B. Yue, A.-N. Zhou, A review of recent developments in the surface modification of LiMn2O4 as cathode material of power lithium-ion battery, Ionics 15 (6) (2009) 779–784.

- [43] C. Forgez, D.V. Do, G. Friedrich, M. Morcrette, C. Delacourt, Thermal modeling of a cylindrical LiFePO4/graphite lithium-ion battery, J. Power Sources 195 (9) (2010) 2961–2968.

- [44] W.-J. Zhang, Structure and performance of LiFePO4 cathode materials: a review, J. Power Sources 196 (6) (2011) 2962–2970.

- [45] C. Taubert, ¨ M. Fleischhammer, M. Wohlfahrt-Mehrens, U. Wietelmann, T. Buhrmester, LiBOB as electrolyte salt or additive for lithium-ion batteries based on LiNi0. 8Co0. 15Al0. 05O2/graphite, J. Electrochem. Soc. 157 (6) (2010) A721–A728.

- [46] D. Farhat, F. Ghamouss, J. Maibach, K. Edstrom, ¨ D. Lemordant, Adiponitrile–lithium bis (trimethylsulfonyl) imide solutions as Alkyl carbonatefree electrolytes for Li4Ti5O12 (LTO)/LiNi1/3Co1/3Mn1/3O2 (NMC) Li-ion batteries, ChemPhysChem 18 (10) (2017) 1333–1344.

- [47] Q. Fan, S. Yang, J. Liu, H. Liu, K. Lin, R. Liu, C. Hong, L. Liu, Y. Chen, K. An, Mixed-conducting interlayer boosting the electrochemical performance of Ni-rich layered oxide cathode materials for lithium ion batteries, J. Power Sources 421 (2019) 91–99.

- [48] Y. Jin, H. Yu, Y. Gao, X. He, T.A. White, X. Liang, Li4Ti5O12 coated with ultrathin aluminum-doped zinc oxide films as an anode material for lithium-ion batteries, J. Power Sources 436 (2019), 226859.

- [49] M. Han, J. Yu, Subnanoscopically and homogeneously dispersed SiOx/C composite spheres for high-performance lithium ion battery anodes, J. Power Sources 414 (2019) 435–443.

- [50] Y. Xiang, W. Zhang, B. Chen, Z. Jin, H. Zhang, P. Zhao, G. Cao, Q. Meng, NanoLi4Ti5O12 particles in-situ deposited on compact holey-graphene framework for high volumetric power capability of lithium ion battery anode, J. Power Sources 447 (2020) 227372.

- [51] M.E. Sotomayor, C. de La Torre-Gamarra, B. Levenfeld, J.-Y. Sanchez, A. Varez, G.-T. Kim, A. Varzi, S. Passerini, Ultra-thick battery electrodes for high gravimetric and volumetric energy density Li-ion batteries, J. Power Sources 437 (2019) 226923.

- [52] D. Li, L. Chen, L. Chen, Q. Sun, M. Zhu, Y. Zhang, Y. Liu, Z. Liang, P. Si, J. Lou, Potassium gluconate-derived N/S Co-doped carbon nanosheets as superior electrode materials for supercapacitors and sodium-ion batteries, J. Power Sources 414 (2019) 308–316.

- [53] X. Shi, Q. Sun, B. Boateng, Y. Niu, Y. Han, W. Lv, W. He, A quasi-solid composite separator with high ductility for safe and high-performance lithium-ion batteries, J. Power Sources 414 (2019) 225–232.

- [54] J. Oh, H. Jo, H. Lee, H.-T. Kim, Y.M. Lee, M.-H. Ryou, Polydopamine-treated three-dimensional carbon fiber-coated separator for achieving high-performance lithium metal batteries, J. Power Sources 430 (2019) 130–136.

- [55] J.R. Nair, F. Colo, ` A. Kazzazi, M. Moreno, D. Bresser, R. Lin, F. Bella, G. Meligrana, S. Fantini, E. Simonetti, Room temperature ionic liquid (RTIL)- based electrolyte cocktails for safe, high working potential Li-based polymer batteries, J. Power Sources 412 (2019) 398–407.

- [56] B. Peng, Y. Li, J. Gao, F. Zhang, J. Li, G. Zhang, High energy K-ion batteries based on P3-Type K0⋅ 5MnO2 hollow submicrosphere cathode, J. Power Sources 437 (2019), 226913.

- [57] Y. Wang, P. Cui, W. Zhu, Z. Feng, M.-J. Vigeant, H. Demers, A. Guerfi, K. Zaghib, Enhancing the electrochemical performance of an O3–NaCrO2 cathode in sodium-ion batteries by cation substitution, J. Power Sources 435 (2019), 226760.

- [58] J. Ming, J. Guo, C. Xia, W. Wang, H.N. Alshareef, Zinc-ion batteries: materials, mechanisms, and applications, Mater. Sci. Eng. R Rep. 135 (2019) 58–84.

- [59] S. Chen, Y. Zhang, H. Geng, Y. Yang, X. Rui, C.C. Li, Zinc ions pillared vanadate cathodes by chemical pre-intercalation towards long cycling life and lowtemperature zinc ion batteries, J. Power Sources 441 (2019), 227192.

- [60] H. Xiao. Battery thermal management in electric vehicles. ANSYS. https ://support.ansys.com/staticassets/ANSYS/staticassets/resourcelibrary/whitepa per/wp-battery-thermal-management.pdf (accessed 19 January, 2020).

- [61] D. Bernardi, E. Pawlikowski, J. Newman, A general energy balance for battery systems, J. Electrochem. Soc. 132 (1) (1985) 5.

- [62] Q. Norman. Industry developments in thermal management of electric vehicle batteries. Advanced Thermal Solutions. https://www.qats.com/cms/category/ battery-cooling/(accessed 19 January, 2020).

- [63] J. Gate, Rechargeable Batteries Applications Handbook, Newnes, Newton, 1998.

- [64] K. Jalkanen, T. Aho, K. Vuorilehto, Entropy change effects on the thermal behavior of a LiFePO4/graphite lithium-ion cell at different states of charge, J. Power Sources 243 (2013) 354–360.

- [65] X. Feng, H.B. Gooi, S.X. Chen, An improved lithium-ion battery model with temperature prediction considering entropy, in: 2012 3rd IEEE PES Innovative Smart Grid Technologies Europe (ISGT Europe), IEEE, 2012, pp. 1–8.

- [66] J. Newman, K.E. Thomas-Alyea, Electrochemical Systems, John Wiley & Sons, 2012.

- [67] Y. Xie, X.-j. He, X.-s. Hu, W. Li, Y.-j. Zhang, B. Liu, Y.-t. Sun, An improved resistance-based thermal model for a pouch lithium-ion battery considering heat generation of posts, Appl. Therm. Eng. 164 (2020), 114455.

- [68] Y. Kobayashi, H. Miyashiro, K. Kumai, K. Takei, T. Iwahori, I. Uchida, Precise electrochemical calorimetry of LiCoO2/graphite lithium-ion cell: understanding thermal behavior and estimation of degradation mechanism, J. Electrochem. Soc. 149 (8) (2002) A978.

- [69] K. Chen, G. Unsworth, X. Li, Measurements of heat generation in prismatic Li-ion batteries, J. Power Sources 261 (2014) 28–37.

- [70] S. Drake, M. Martin, D. Wetz, J. Ostanek, S. Miller, J. Heinzel, A. Jain, Heat generation rate measurement in a Li-ion cell at large C-rates through temperature and heat flux measurements, J. Power Sources 285 (2015) 266–273.

- [71] J. Zhang, J. Huang, Z. Li, B. Wu, Z. Nie, Y. Sun, F. An, N. Wu, Comparison and validation of methods for estimating heat generation rate of large-format lithiumion batteries, J. Therm. Anal. Calorim. 117 (1) (2014) 447–461.

- [72] B. Wu, Z. Li, J. Zhang, Thermal design for the pouch-type large-format lithiumion batteries: I. Thermo-electrical modeling and origins of temperature nonuniformity, J. Electrochem. Soc. 162 (1) (2014) A181.

- [73] E. Schuster, C. Ziebert, A. Melcher, M. Rohde, H.J. Seifert, Thermal behavior and electrochemical heat generation in a commercial 40 Ah lithium ion pouch cell, J. Power Sources 286 (2015) 580–589.

- [74] Y. Saito, M. Shikano, H. Kobayashi, Heat generation behavior during charging and discharging of lithium-ion batteries after long-time storage, J. Power Sources 244 (2013) 294–299.

- [75] Y. Ye, L.H. Saw, Y. Shi, A.A. Tay, Numerical analyses on optimizing a heat pipe thermal management system for lithium-ion batteries during fast charging, Appl. Therm. Eng. 86 (2015) 281–291.

- [76] X. Xu, R. He, Review on the heat dissipation performance of battery pack with different structures and operation conditions, Renew. Sustain. Energy Rev. 29 (2014) 301–315.

- [77] C. Wang, G. Zhang, L. Meng, X. Li, W. Situ, Y. Lv, M. Rao, Liquid cooling based on thermal silica plate for battery thermal management system, Int. J. Energy Res. 41 (15) (2017) 2468–2479.

- [78] L. Sheng, L. Su, H. Zhang, Y. Fang, H. Xu, W. Ye, An improved calorimetric method for characterizations of the specific heat and the heat generation rate in a prismatic lithium ion battery cell, Energy Convers. Manag. 180 (2019) 724–732.

- [79] Z.H. Wu Qingyu, Junwei Li, Calibrated calorimetry for measuring the specific heat capacityand heat generation rate of lithium-ion battery, Automot. Eng. 42 (1) (2020) 59–65.

- [80] P. Ramadass, B. Haran, R. White, B.N. Popov, Capacity fade of Sony 18650 cells cycled at elevated temperatures: Part I. Cycling performance, J. Power Sources 112 (2) (2002) 606–613.

- [81] P. Ramadass, B. Haran, R. White, B.N. Popov, Capacity fade of Sony 18650 cells cycled at elevated temperatures: Part II. Capacity fade analysis, J. Power Sources 112 (2) (2002) 614–620.

- [82] A. Szumanowski, Y. Chang, Battery management system based on battery nonlinear dynamics modeling, IEEE Trans. Veh. Technol. 57 (3) (2008) 1425–1432.

- [83] J. Belt, V. Utgikar, I. Bloom, Calendar and PHEV cycle life aging of high-energy, lithium-ion cells containing blended spinel and layered-oxide cathodes, J. Power Sources 196 (23) (2011) 10213–10221.

- [84] D. Aurbach, Y. Talyosef, B. Markovsky, E. Markevich, E. Zinigrad, L. Asraf, J. S. Gnanaraj, H.-J. Kim, Design of electrolyte solutions for Li and Li-ion batteries: a review, Electrochim. Acta 50 (2–3) (2004) 247–254.

- [85] R. Zhao, J. Liu, J. Gu, The effects of electrode thickness on the electrochemical and thermal characteristics of lithium ion battery, Appl. Energy 139 (2015) 220–229.

- [86] J. Li, E. Murphy, J. Winnick, P. Kohl, Studies on the cycle life of commercial lithium ion batteries during rapid charge–discharge cycling, J. Power Sources 102 (1–2) (2001) 294–301.

- [87] Q. Zhang, R.E. White, Capacity fade analysis of a lithium ion cell, J. Power Sources 179 (2) (2008) 793–798.

- [88] Y. Kitagawa, K. Kato, M. Fukui, Analysis and experimentation for effective cooling of Li-ion batteries, Procedia Technology 18 (2014) 63–67.

- [89] W. Waag, S. K¨ abitz, D.U. Sauer, Experimental investigation of the lithium-ion battery impedance characteristic at various conditions and aging states and its influence on the application, Appl. Energy 102 (2013) 885–897.

- [90] S. Saxena, C. Hendricks, M. Pecht, Cycle life testing and modeling of graphite/ LiCoO2 cells under different state of charge ranges, J. Power Sources 327 (2016) 394–400.

- [91] L. Su, J. Zhang, C. Wang, Y. Zhang, Z. Li, Y. Song, T. Jin, Z. Ma, Identifying main factors of capacity fading in lithium ion cells using orthogonal design of experiments, Appl. Energy 163 (2016) 201–210.

- [92] M.M. Kabir, D.E. Demirocak, Degradation mechanisms in Li-ion batteries: a stateof-the-art review, Int. J. Energy Res. 41 (14) (2017) 1963–1986.

- [93] D. Li, D.L. Danilov, H.J. Bergveld, R.-A. Eichel, P.H. Notten, Understanding battery aging mechanisms, in: Future Lithium-Ion Batteries, 2019, pp. 220–250.

- [94] K. Smith, E. Wood, S. Santhanagopalan, G. Kim, A. Pesaran, Advanced models and controls for prediction and extension of battery lifetime, in: Advanced Automotive Battery Conference, Atlanta, GA, 2014, pp. 4–6.

- [95] F. Leng, C.M. Tan, M. Pecht, Effect of temperature on the aging rate of Li ion battery operating above room temperature, Sci. Rep. 5 (2015) 12967.

- [96] H. Gabrisch, Y. Ozawa, R. Yazami, Crystal structure studies of thermally aged LiCoO2 and LiMn2O4 cathodes, Electrochim. Acta 52 (4) (2006) 1499–1506.

- [97] X. Zhou, J. Huang, Z. Pan, M. Ouyang, Impedance characterization of lithium-ion batteries aging under high-temperature cycling: importance of electrolyte-phase diffusion, J. Power Sources 426 (2019) 216–222.

- [98] Z. Tang, S. Wang, Z. Liu, J. Cheng, Numerical analysis of temperature uniformity of a liquid cooling battery module composed of heat-conducting blocks with gradient contact surface angles, Appl. Therm. Eng. 178 (2020) 115509.

- [99] P. Ni, X. Wang, Temperature field and temperature difference of a battery package for a hybrid car, Case Stud. Therm. Eng. (2020) 100646.

- [100] A.A. Pesaran, Battery thermal models for hybrid vehicle simulations, J. Power Sources 110 (2) (2002) 377–382.

- [101] C. Park, A.K. Jaura, Dynamic Thermal Model of Li-Ion Battery for Predictive Behavior in Hybrid and Fuel Cell Vehicles, SAE Technical Paper, 0148-7191, 2003.

- [102] Z. Rao, S. Wang, G. Zhang, Simulation and experiment of thermal energy management with phase change material for ageing LiFePO4 power battery, Energy Convers. Manag. 52 (12) (2011) 3408–3414.

- [103] H. Park, A design of air flow configuration for cooling lithium ion battery in hybrid electric vehicles, J. Power Sources 239 (2013) 30–36.

- [104] L. Panasonic, Co. Lithium Ion NCR18650PF, 2016, June, p. 31

- [Online]. Available, https://www.omnitron.cz/download/datasheet/NCR-18650PF.pdf. (Accessed December 2019).

- [105] X.-H. Yang, S.-C. Tan, J. Liu, Thermal management of Li-ion battery with liquid metal 117, Energy Conversion and Management, 2016, pp. 577–585.

- [106] A. Schmidt, A. Smith, H. Ehrenberg, Power capability and cyclic aging of commercial, high power lithium ion battery cells with respect to different cell designs, J. Power Sources 425 (2019) 27–38.

- [107] Q. Wang, P. Ping, X. Zhao, G. Chu, J. Sun, C. Chen, Thermal runaway caused fire and explosion of lithium ion battery, J. Power Sources 208 (2012) 210–224.

- [108] S. Arora, W. Shen, A. Kapoor, Review of mechanical design and strategic placement technique of a robust battery pack for electric vehicles, Renew. Sustain. Energy Rev. 60 (2016) 1319–1331.

- [109] V. Ruiz, A. Pfrang, A. Kriston, N. Omar, P. Van den Bossche, L. Boon-Brett, A review of international abuse testing standards and regulations for lithium ion batteries in electric and hybrid electric vehicles, Renew. Sustain. Energy Rev. 81 (2018) 1427–1452.

- [110] A.W. Golubkov, D. Fuchs, J. Wagner, H. Wiltsche, C. Stangl, G. Fauler, G. Voitic, A. Thaler, V. Hacker, Thermal-runaway experiments on consumer Li-ion batteries with metal-oxide and olivin-type cathodes, RSC Adv. 4 (7) (2014) 3633–3642.

- [111] H.M. Barkholtz, Y. Preger, S. Ivanov, J. Langendorf, L. Torres-Castro, J. Lamb, B. Chalamala, S.R. Ferreira, Multi-scale thermal stability study of commercial lithium-ion batteries as a function of cathode chemistry and state-of-charge, J. Power Sources 435 (2019) 226777.

- [112] S. Hossain, Y.-K. Kim, Y. Saleh, R. Loutfy, Overcharge studies of carbon fiber composite-based lithium-ion cells, J. Power Sources 161 (1) (2006) 640–647.

- [113] E. Roth, D. Doughty, D. Pile, Effects of separator breakdown on abuse response of 18650 Li-ion cells, J. Power Sources 174 (2) (2007) 579–583.

- [114] C.L. Campion, W. Li, B.L. Lucht, Thermal decomposition of LiPF6-based electrolytes for lithium-ion batteries, J. Electrochem. Soc. 152 (12) (2005) A2327–A2334.

- [115] N.P. Lebedeva, F.D. Persio, T. Kosmidou, D. Dams, A. Pfrang, A. Kersys, L. BoonBrett, Amount of free liquid electrolyte in commercial large format prismatic Liion battery cells, J. Electrochem. Soc. 166 (4) (2019) A779–A786.

- [116] V. Peter, GM Recalls Volts to Fix Fire Risk, The Comeback of the American Car, CNN Money, 2012.

- [117] R. Charles, Tesla Dodges Full Investigation after Fiery Crash, CNN Money, Hongkong, 2013.

- [118] A. Pfrang, A. Kriston, V. Ruiz, N. Lebedeva, F. Di Persio, Safety of rechargeable energy storage systems with a focus on Li-ion technology, in: Emerging Nanotechnologies in Rechargeable Energy Storage Systems, Elsevier, 2017, pp. 253–290.

- [119] X. Feng, S. Zheng, D. Ren, X. He, L. Wang, H. Cui, X. Liu, C. Jin, F. Zhang, C. Xu, Investigating the thermal runaway mechanisms of lithium-ion batteries based on thermal analysis database, Appl. Energy 246 (2019) 53–64.

- [120] X. Feng, D. Ren, X. He, M. Ouyang, Mitigating Thermal Runaway of Lithium-Ion Batteries, Joule, 2020.

- [121] D.H. Doughty, E.P. Roth, A general discussion of Li ion battery safety, The Electrochemical Society Interface 21 (2) (2012) 37–44.

- [122] Y.S. Choi, D.M. Kang, Prediction of thermal behaviors of an air-cooled lithium-ion battery system for hybrid electric vehicles, J. Power Sources 270 (2014) 273–280.

- [123] Q. Wang, X. Zhao, J. Ye, Q. Sun, P. Ping, J. Sun, Thermal response of lithium-ion battery during charging and discharging under adiabatic conditions, J. Therm. Anal. Calorim. 124 (1) (2016) 417–428.

- [124] A.A. Pesaran, Battery thermal management in EV and HEVs: issues and solutions, Battery Man. 43 (5) (2001) 34–49.

- [125] K. Kelly, J. Rugh, A. Pesaran, Improving battery thermal management using design for six sigma process, in: For Presentation at the 20 th Electric Vehicle Symposium, Long Beach, CA November 15-18, 2003, 2003.

- [126] Y. Ye, Y. Shi, N. Cai, J. Lee, X. He, Electro-thermal modeling and experimental validation for lithium ion battery, J. Power Sources 199 (2012) 227–238.

- [127] L. Lu, X. Han, J. Li, J. Hua, M. Ouyang, A review on the key issues for lithium-ion battery management in electric vehicles, J. Power Sources 226 (2013) 272–288.

- [128] J. Jaguemont, L. Boulon, Y. Dub´e, A comprehensive review of lithium-ion batteries used in hybrid and electric vehicles at cold temperatures, Appl. Energy 164 (2016) 99–114.

- [129] R. Koyama, Y. Arai, Y. Yamauchi, S. Takeya, F. Endo, A. Hotta, R. Ohmura, Thermophysical properties of trimethylolethane (TME) hydrate as phase change material for cooling lithium-ion battery in electric vehicle, J. Power Sources 427 (2019) 70–76.

- [130] J. Chen, S. Kang, E. Jiaqiang, Z. Huang, K. Wei, B. Zhang, H. Zhu, Y. Deng, F. Zhang, G. Liao, Effects of different phase change material thermal management strategies on the cooling performance of the power lithium ion batteries: a review, J. Power Sources 442 (2019) 227228.

- [131] R. Zhao, S. Zhang, J. Liu, J. Gu, A review of thermal performance improving methods of lithium ion battery: electrode modification and thermal management system, J. Power Sources 299 (2015) 557–577.

- [132] D. Chen, J. Jiang, G.-H. Kim, C. Yang, A. Pesaran, Comparison of different cooling methods for lithium ion battery cells, Appl. Therm. Eng. 94 (2016) 846–854.

- [133] R. Kizilel, R. Sabbah, J.R. Selman, S. Al-Hallaj, An alternative cooling system to enhance the safety of Li-ion battery packs, J. Power Sources 194 (2) (2009) 1105–1112.

- [134] M.H. Westbrook, M. Westbrook, The Electric Car: Development and Future of Battery, Hybrid and Fuel-Cell Cars, Iet 38, 2001.

- [135] M. Arasu, Q. Ahmed, G. Rizzoni, Optimizing Battery Cooling System for a Range Extended Electric Truck, SAE Technical Paper, 0148-7191, 2019.

- [136] S. Park, D. Jung, Battery cell arrangement and heat transfer fluid effects on the parasitic power consumption and the cell temperature distribution in a hybrid electric vehicle, J. Power Sources 227 (2013) 191–198.

- [137] M.R. Giuliano, A.K. Prasad, S.G. Advani, Experimental study of an air-cooled thermal management system for high capacity lithium–titanate batteries, J. Power Sources 216 (2012) 345–352.

- [138] A. Pesaran, G. Kim, Battery Thermal Management System Design Modeling, National Renewable Energy Lab.(NREL), Golden, CO (United States), 2006.

- [139] K.J. Kelly, M. Mihalic, M. Zolot, Battery usage and thermal performance of the Toyota Prius and Honda Insight during chassis dynamometer testing, in: Seventeenth Annual Battery Conference on Applications and Advances. Proceedings of Conference (Cat. No. 02TH8576), IEEE, 2002, pp. 247–252.

- [140] A. Pesaran, M. Keyser, S. Burch, An Approach for Designing Thermal Management Systems for Electric and Hybrid Vehicle Battery Packs, National Renewable Energy Laboratory, Golden, CO (US), 1999.

- [141] Volkswagen E-up! Air cooled battery, featured in ViaVision magazine. My electric car forums. https://www.myelectriccarforums.com/volkswagen-e-up-air-cooledbattery-featured-in-viavision-magazine/(accessed 19 January, 2020).

- [142] L. Andrew. Volkswagen’s EV racecar just broke records during this year’s Pikes Peak Hill Climb. The Verge. https://www.theverge.com/2018/6/24/1 7078544/volkswagen-ev-race-car-pikes-peak-hill-climb-record (accessed 19 January, 2020).

- [143] D. G. Marcus. Lexus’ first-ever electric vehicle is the UX300e. Autoindustriya. htt ps://www.autoindustriya.com/auto-industry-news/lexus-first-ever-electric-veh icle-is-the-ux300e.html (accessed 20 January, 2020).

- [144] L. Eric. Here’s why nissan employs active air cooling in e-NV200 battery pack. InsideEVs. https://insideevs.com/news/322347/heres-why-nissan-employs-act ive-air cooling-in-e-nv200-battery-pack/(accessed 20 January, 2020).

- [145] P. Rodgers, V. Eveloy, M.G. Pecht, Limits of air cooling: status and challenges, in: Semiconductor Thermal Measurement and Management IEEE Twenty First Annual IEEE Symposium, IEEE, 2005, pp. 116–124.

- [146] R. Jilte, R. Kumar, Numerical investigation on cooling performance of Li-ion battery thermal management system at high galvanostatic discharge, Eng. Sci. Technology. Int. J. 21 (5) (2018) 957–969.

- [147] C.-W. Park, A.K. Jaura, Thermal Analysis of Cooling System in Hybrid Electric Vehicles, SAE Technical Paper, 0148-7191, 2002.

- [148] T. Wang, K.J. Tseng, J. Zhao, Development of efficient air cooling strategies for lithium-ion battery module based on empirical heat source model, Appl. Therm. Eng. 90 (2015) 521–529.

- [149] D.C. Erb, S. Kumar, S.E. Sarma, E. Carlson, Size matters: why cell size is vital for minimizing cost of air cooling in battery packs, in: 2015 IEEE Transportation Electrification Conference and Expo (ITEC), IEEE, 2015, pp. 1–6.

- [150] T. Wang, K.J. Tseng, J. Zhao, Z. Wei, Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air cooling strategies, Appl. Energy 134 (2014) 229–238.

- [151] D. Kang, P.-Y. Lee, K. Yoo, J. Kim, Internal thermal network model-based inner temperature distribution of high-power lithium-ion battery packs with different shapes for thermal management, J. Energy Stor. vol. 27, 2020.

- [152] Y. Zhang, X. Song, C. Ma, D. Hao, Y. Chen, Effects of the structure arrangement and spacing on the thermal characteristics of Li-ion battery pack at various discharge rates, Appl. Therm. Eng. 165 (2020).

- [153] N. Yang, X. Zhang, G. Li, D. Hua, Assessment of the forced air cooling performance for cylindrical lithium-ion battery packs: a comparative analysis between aligned and staggered cell arrangements, Appl. Therm. Eng. 80 (2015) 55–65.

- [154] Y. Fan, Y. Bao, C. Ling, Y. Chu, X. Tan, S. Yang, Experimental study on the thermal management performance of air cooling for high energy density cylindrical lithium-ion batteries, Appl. Therm. Eng. 155 (2019) 96–109.

- [155] M. Ye, Y. Xu, Y. Huangfu, The structure optimization of lithium-ion battery pack based on fluid-solid conjugate thermodynamic analysis, Energy Procedia 152 (2018) 643–648.

- [156] K. Chen, S. Wang, M. Song, L. Chen, Configuration optimization of battery pack in parallel air-cooled battery thermal management system using an optimization strategy, Appl. Therm. Eng. 123 (2017) 177–186.

- [157] T. Yang, N. Yang, X. Zhang, G. Li, Investigation of the thermal performance of axial-flow air cooling for the lithium-ion battery pack, Int. J. Therm. Sci. 108 (2016) 132–144.

- [158] X. Yu, Z. Lu, L. Zhang, L. Wei, X. Cui, L. Jin, Experimental study on transient thermal characteristics of stagger-arranged lithium-ion battery pack with air cooling strategy, Int. J. Heat Mass Tran. 143 (2019) 118576.

- [159] B. Severino, F. Gana, R. Palma-Behnke, P.A. Est´evez, W.R. Calderon-Mu ´ noz, ˜ M. E. Orchard, J. Reyes, M. Cort´es, Multi-objective optimal design of lithium-ion battery packs based on evolutionary algorithms, J. Power Sources 267 (2014) 288–299.

- [160] W. Li, M. Xiao, X. Peng, A. Garg, L. Gao, A surrogate thermal modeling and parametric optimization of battery pack with air cooling for EVs, Appl. Therm. Eng. 147 (2019) 90–100.

- [161] L. Fan, J.M. Khodadadi, A.A. Pesaran, A parametric study on thermal management of an air-cooled lithium-ion battery module for plug-in hybrid electric vehicles, J. Power Sources 238 (2013) 301–312.

- [162] J. Xun, R. Liu, K. Jiao, Numerical and analytical modeling of lithium ion battery thermal behaviors with different cooling designs, J. Power Sources 233 (2013) 47–61.

- [163] X.M. Xu, R. He, Research on the heat dissipation performance of battery pack based on forced air cooling, J. Power Sources 240 (2013) 33–41.

- [164] H. Sun, R. Dixon, Development of cooling strategy for an air cooled lithium-ion battery pack, J. Power Sources 272 (2014) 404–414.

- [165] K. Chen, M. Song, W. Wei, S. Wang, Structure optimization of parallel air-cooled battery thermal management system with U-type flow for cooling efficiency improvement, Energy 145 (2018) 603–613.

- [166] Z. Lu, X. Yu, L. Wei, Y. Qiu, L. Zhang, X. Meng, L. Jin, Parametric study of forced air cooling strategy for lithium-ion battery pack with staggered arrangement, Appl. Therm. Eng. 136 (2018) 28–40.

- [167] Y. Liu, J. Zhang, Design a J-type air-based battery thermal management system through surrogate-based optimization, Appl. Energy 252 (2019).

- [168] K. Yu, X. Yang, Y. Cheng, C. Li, Thermal analysis and two-directional air flow thermal management for lithium-ion battery pack, J. Power Sources 270 (2014) 193–200.

- [169] H. Fathabadi, A novel design including cooling media for Lithium-ion batteries pack used in hybrid and electric vehicles, J. Power Sources 245 (2014) 495–500.

- [170] H. Zhou, F. Zhou, L. Xu, J. Kong, QingxinYang, Thermal performance of cylindrical Lithium-ion battery thermal management system based on air distribution pipe, Int. J. Heat Mass Tran. 131 (2019) 984–998.

- [171] Z. Lu, X.Z. Meng, L.C. Wei, W.Y. Hu, L.Y. Zhang, L.W. Jin, Thermal management of densely-packed EV battery with forced air cooling strategies, Energy Procedia 88 (2016) 682–688.

- [172] H. Wang, L. Ma, Thermal management of a large prismatic battery pack based on reciprocating flow and active control, Int. J. Heat Mass Tran. 115 (2017) 296–303.

- [173] X. Na, H. Kang, T. Wang, Y. Wang, Reverse layered air flow for Li-ion battery thermal management, Appl. Therm. Eng. 143 (2018) 257–262.

- [174] M. Soltani, G. Berckmans, J. Jaguemont, J. Ronsmans, S. Kakihara, O. Hegazy, J. Van Mierlo, N. Omar, Three dimensional thermal model development and validation for lithium-ion capacitor module including air cooling system, Appl. Therm. Eng. 153 (2019) 264–274.

- [175] J. Zhao, Z. Rao, Y. Li, Thermal performance of mini-channel liquid cooled cylinder based battery thermal management for cylindrical lithium-ion power battery, Energy Convers. Manag. 103 (2015) 157–165.

- [176] K. Chen, W. Wu, F. Yuan, L. Chen, S. Wang, Cooling efficiency improvement of air-cooled battery thermal management system through designing the flow pattern, Energy 167 (2019) 781–790.

- [177] K. Chen, Y. Chen, Y. She, M. Song, S. Wang, L. Chen, Construction of effective symmetrical air-cooled system for battery thermal management, Appl. Therm. Eng. 166 (2020) 114679.

- [178] Y.-W. Wang, J.-M. Jiang, Y.-H. Chung, W.-C. Chen, C.-M. Shu, Forced-air cooling system for large-scale lithium-ion battery modules during charge and discharge processes, J. Therm. Anal. Calorim. 135 (5) (2018) 2891–2901.

- [179] J. E, M. Yue, J. Chen, H. Zhu, Y. Deng, Y. Zhu, F. Zhang, M. Wen, B. Zhang, S. Kang, Effects of the different air cooling strategies on cooling performance of a lithium-ion battery module with baffle, Appl. Therm. Eng. 144 (2018) 231–241.

- [180] S. Shahid, M. Agelin-Chaab, Experimental and numerical studies on air cooling and temperature uniformity in a battery pack, Int. J. Energy Res. 42 (6) (2018) 2246–2262.

- [181] S. Shahid, M. Agelin-Chaab, Analysis of cooling effectiveness and temperature uniformity in a battery pack for cylindrical batteries, Energies 10 (8) (2017) 1157.

- [182] K. Chen, Z. Li, Y. Chen, S. Long, J. Hou, M. Song, S. Wang, Design of parallel aircooled battery thermal management system through numerical study, Energies 10 (10) (2017).

- [183] S. Hong, X. Zhang, K. Chen, S. Wang, Design of flow configuration for parallel aircooled battery thermal management system with secondary vent, Int. J. Heat Mass Tran. 116 (2018) 1204–1212.

- [184] C. Zhu, X. Li, L. Song, L. Xiang, Development of a theoretically based thermal model for lithium ion battery pack, J. Power Sources 223 (2013) 155–164.

- [185] L.H. Saw, Y. Ye, M.C. Yew, W.T. Chong, M.K. Yew, T.C. Ng, Computational fluid dynamics simulation on open cell aluminium foams for Li-ion battery cooling system, Appl. Energy 204 (2017) 1489–1499.

- [186] X. Li, F. He, G. Zhang, Q. Huang, D. Zhou, Experiment and simulation for pouch battery with silica cooling plates and copper mesh based air cooling thermal management system, Appl. Therm. Eng. 146 (2019) 866–880.

- [187] S.K. Mohammadian, S.M. Rassoulinejad-Mousavi, Y. Zhang, Thermal management improvement of an air-cooled high-power lithium-ion battery by embedding metal foam, J. Power Sources 296 (2015) 305–313.

- [188] S.K. Mohammadian, Y. Zhang, Cumulative effects of using pin fin heat sink and porous metal foam on thermal management of lithium-ion batteries, Appl. Therm. Eng. 118 (2017) 375–384.

- [189] R.D. Jilte, R. Kumar, M.H. Ahmadi, L. Chen, Battery thermal management system employing phase change material with cell-to-cell air cooling, Appl. Therm. Eng. 161 (2019).

- [190] P. Qin, M. Liao, D. Zhang, Y. Liu, J. Sun, Q. Wang, Experimental and numerical study on a novel hybrid battery thermal management system integrated forced-air convection and phase change material, Energy Convers. Manag. 195 (2019) 1371–1381.

- [191] M. Mehrabi-Kermani, E. Houshfar, M. Ashjaee, A novel hybrid thermal management for Li-ion batteries using phase change materials embedded in copper foams combined with forced-air convection, Int. J. Therm. Sci. 141 (2019) 47–61.

- [192] W. Luo, F. He, Q. Huang, X. Li, G. Zhang, Z. Zhong, Experimental investigation on thermal performance of silica cooling plate-aluminate thermal plate-coupled forced convection-based pouch battery thermal management system, Int. J. Energy Res. 43 (13) (2019) 7604–7613.

- [193] L.H. Saw, H.M. Poon, H.S. Thiam, Z. Cai, W.T. Chong, N.A. Pambudi, Y.J. King, Novel thermal management system using mist cooling for lithium-ion battery packs, Appl. Energy 223 (2018) 146–158.

- [194] A.M. Sefidan, A. Sojoudi, S.C. Saha, Nanofluid-based cooling of cylindrical lithium-ion battery packs employing forced air flow, Int. J. Therm. Sci. 117 (2017) 44–58.

- [195] R. Zhao, J. Liu, J. Gu, L. Zhai, F. Ma, Experimental study of a direct evaporative cooling approach for Li-ion battery thermal management, Int. J. Energy Res. (2020).

- [196] S.K. Mohammadian, Y. Zhang, Thermal management optimization of an aircooled Li-ion battery module using pin-fin heat sinks for hybrid electric vehicles, J. Power Sources 273 (2015) 431–439.

- [197] D. Dan, C. Yao, Y. Zhang, H. Zhang, Z. Zeng, X. Xu, Dynamic thermal behavior of micro heat pipe array-air cooling battery thermal management system based on thermal network model, Appl. Therm. Eng. 162 (2019).

- [198] T. Han, B. Khalighi, E.C. Yen, S. Kaushik, Li-ion battery pack thermal management: liquid versus air cooling, J. Therm. Sci. Eng. Appl. 11 (2) (2019).

- [199] W. Li, A. Jishnu, A. Garg, M. Xiao, X. Peng, L. Gao, Heat transfer efficiency enhancement of lithium-ion battery packs by using novel design of herringbone fins, J. Electrochem. Energy Convers. Stor. 17 (2) (2020).

- [200] Y. Wei, M. Agelin-Chaab, Development and experimental analysis of a hybrid cooling concept for electric vehicle battery packs, J. Energy Stor. 25 (2019) 100906.

- [201] Y. Zhao, Y. Patel, T. Zhang, G.J. Offer, Modeling the effects of thermal gradients induced by tab and surface cooling on lithium ion cell performance, J. Electrochem. Soc. 165 (13) (2018) A3169.

- [202] I.A. Hunt, Y. Zhao, Y. Patel, G. Offer, Surface cooling causes accelerated degradation compared to tab cooling for lithium-ion pouch cells, J. Electrochem. Soc. 163 (9) (2016) A1846.

- [203] O. Dondelewski, T.S. O’Connor, Y. Zhao, I.A. Hunt, A. Holland, A. Hales, G. J. Offer, Y. Patel, The role of cell geometry when selecting tab or surface cooling to minimise cell degradation, eTransportation 5 (2020) 100073.

- [204] S. Li, N. Kirkaldy, C. Zhang, K. Gopalakrishnan, T. Amietszajew, L.B. Diaz, J. V. Barreras, M. Shams, X. Hua, Y. Patel, Optimal cell tab design and cooling strategy for cylindrical lithium-ion batteries, J. Power Sources 492 (2021), 229594

- [205] H. Heimes, A. Kampker, A. Mohsseni, F. Maltoni, J. Biederbeck, Cell tab cooling system for battery life extension, in: 2019 18th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), IEEE, 2019, pp. 1125–1133.

- [206] M.S. Patil, J.-H. Seo, M.-Y. Lee, A novel dielectric fluid immersion cooling technology for Li-ion battery thermal management, Energy Convers. Manag. 229 (2021) 113715.

- [207] J.-C. Jang, S.-H. Rhi, Battery thermal management system of future electric vehicles with loop thermosyphon, in: US-Korea Conference on Science, Technology, and Entrepreneurship, UKC), 2010.

- [208] P. Gupta, S. Vardhan, Optimizing OEE, productivity and production cost for improving sales volume in an automobile industry through TPM: a case study, Int. J. Prod. Res. 54 (10) (2016) 2976–2988.

- [209] A. Brooker, M. Thornton, J. Rugh, Technology Improvement Pathways to CostEffective Vehicle Electrification, 2010.

- [210] R.J. Orsato, P. Wells, U-turn: the rise and demise of the automobile industry, J. Clean. Prod. 15 (11–12) (2007) 994–1006.

- [211] K. Kisu, S. Kim, H. Oguchi, N. Toyama, S.-i. Orimo, Interfacial stability between LiBH4-based complex hydride solid electrolytes and Li metal anode for all-solidstate Li batteries, J. Power Sources 436 (2019) 226821.

- [212] Y. Zhang, W. Lu, L. Cong, J. Liu, L. Sun, A. Mauger, C.M. Julien, H. Xie, J. Liu, Cross-linking network based on Poly (ethylene oxide): solid polymer electrolyte for room temperature lithium battery, J. Power Sources 420 (2019) 63–72.

- [213] B. Zhang, L. Chen, J. Hu, Y. Liu, Y. Liu, Q. Feng, G. Zhu, L.-Z. Fan, Solid-state lithium metal batteries enabled with high loading composite cathode materials and ceramic-based composite electrolytes, J. Power Sources 442 (2019) 227230.

- [214] H. Nguyen, A. Banerjee, X. Wang, D. Tan, E.A. Wu, J.-M. Doux, R. Stephens, G. Verbist, Y.S. Meng, Single-step synthesis of highly conductive Na3PS4 solid electrolyte for sodium all solid-state batteries, J. Power Sources 435 (2019), 126623

저작권 및 참고 자료:

본 자료는 Gang Zhao 외의 논문 "전기 및 하이브리드 전기 자동차를 위한 공랭식 배터리 열 관리 시스템에 대한 검토"를 기반으로 작성되었습니다.

https://doi.org/10.1016/j.jpowsour.2021.230001

본 자료는 위 논문을 바탕으로 요약 작성되었으며, 상업적 목적으로 무단 사용이 금지됩니다.

Copyright © 2025 CASTMAN. All rights reserved.