1. 개요:

- 제목: Thin-walled and large-sized magnesium alloy die castings for passenger car cockpit: Application, materials, and manufacture

- 저자: Lei Zhan, Yu-meng Sun, Yang Song, Chun-hua Kong, **Kai Ma, Bai-xin Dong, Hong-yu Yang, Shi-li Shu, and *Feng Qiu

- 발행 연도: 2024

- 발행 학술지/학회: CHINA FOUNDRY Vol. 21 No. 5 September 2024

- Keywords: Mg alloys; thin wall; large size; automotive part; die casting

2. 연구 배경:

- 연구 주제의 사회적/학문적 맥락:

에너지 소비를 효과적으로 줄이고 주행 거리를 늘리기 위해 Tesla로 대표되는 신에너지 자동차는 자동차에 통합 마그네슘(Mg) 합금 다이캐스팅 기술의 적용을 크게 촉진했습니다.

과거 자동차, 특히 자동차 콕핏 부품에서 Mg 합금의 적용은 광범위했지만, 상대적으로 높은 비용으로 인해 한동안 거의 사라졌으며, 자동차 Mg 합금 부품의 응용 기술에 대한 정보 손실을 야기했습니다. 자동차 기술의 급속한 발전은 기존의 자동차 부품에 비해 더 높은 요구 사항을 가져왔습니다.

따라서 부품 자체든 Mg 합금 재료 및 다이캐스팅 공정이든 점점 더 큰 도전에 직면하여 업그레이드가 필요합니다.

또한 높은 통합 특성으로 인해 대형 및 박형 자동차 부품에 Mg 합금 다이캐스팅 기술을 적용하는 것은 고유한 장점이 있으며 긴급히 확장해야 합니다. 실제로 첨단 Mg 합금과 새로운 제품 구조를 탐색하고 다이캐스팅 공정을 최적화해야 합니다. - 기존 연구의 한계점:

논문에서 기존 연구의 명확한 한계점을 직접적으로 언급하고 있지는 않지만, 서론에서 "causing a certain degree of information loss in the application technology of Mg alloy parts in automobiles" 라고 언급하며, 마그네슘 합금 부품 적용 기술 정보의 부족을 간접적으로 시사합니다. - 연구의 필요성:

이 논문은 승용차 콕핏의 박형 및 대형 다이캐스팅 Mg 합금 부품의 개발 현황과 해당 재료 선택 방법, 다이캐스팅 공정 및 금형 설계 기술을 요약하고 분석합니다.

또한 이 연구는 연구자들이 자동차 콕핏의 박형 및 대형 다이캐스팅 Mg 합금 부품 제조에 대한 포괄적인 이해를 확립하는 데 도움이 될 것입니다.

또한 자동차 부품 다이캐스팅의 높은 요구 사항을 충족하기 위해 개선된 포괄적인 성능과 새로운 공정을 갖춘 새로운 Mg 합금을 개발하는 데 도움이 될 것입니다.

3. 연구 목적 및 연구 질문:

- 연구 목적: 승용차 콕핏에 사용되는 박형 및 대형 다이캐스팅 Mg 합금 부품의 개발 현황, 재료 선택 방법, 다이캐스팅 공정 및 금형 설계 기술을 분석하고 요약하는 것을 목표로 합니다. 궁극적으로 연구자들에게 해당 분야에 대한 종합적인 이해를 제공하고, 향후 자동차 부품의 고성능 다이캐스팅 요구사항을 충족하는 새로운 Mg 합금 및 공정 개발을 지원하는 것을 목표로 합니다.

- 핵심 연구 질문: 논문에 명시적인 연구 질문은 제시되지 않았지만, 연구 목적을 바탕으로 다음과 같은 핵심 질문을 도출할 수 있습니다.

- 승용차 콕핏 부품 중 박형 및 대형 Mg 합금 다이캐스팅에 적합한 부품은 무엇이며, 각 부품의 적용 현황은 어떠한가?

- 박형 및 대형 Mg 합금 다이캐스팅 부품에 요구되는 재료 특성은 무엇이며, 상용 Mg 합금 중 적합한 재료는 무엇인가?

- 박형 및 대형 Mg 합금 다이캐스팅 부품의 제조에 적합한 다이캐스팅 공정 및 조건은 무엇인가?

- 박형 및 대형 Mg 합금 다이캐스팅 부품의 품질을 확보하기 위한 금형 설계 고려 사항은 무엇인가?

- 연구 가설: 논문에 명시적인 연구 가설은 없습니다.

4. 연구 방법론

- 연구 설계: 본 연구는 특정 연구 설계보다는 리뷰 논문(Review article)의 형태를 취하고 있습니다. 기존 문헌 및 연구 자료를 종합적으로 분석하여 박형 및 대형 Mg 합금 다이캐스팅 부품의 기술 동향과 주요 이슈를 분석합니다.

- 데이터 수집 방법: 주로 학술 논문, 기술 보고서, 산업 자료 등 공개된 문헌 정보를 수집하여 분석합니다. 특정 실험 데이터 수집이나 설문 조사 등은 수행하지 않았습니다.

- 분석 방법: 수집된 문헌 정보를 바탕으로 기술 동향 분석, 재료 특성 비교 분석, 공정 기술 분석, 금형 설계 기술 분석 등을 수행합니다. 정량적 데이터 분석보다는 기술적 내용 분석 및 비교, 요약에 중점을 둡니다.

- 연구 대상 및 범위: 연구 대상은 승용차 콕핏 부품 중에서도 박형 및 대형 Mg 합금 다이캐스팅 부품에 초점을 맞춥니다. 구체적으로 seat frame, CCB (cross car beam), center console frame, door inner 등의 부품을 포함합니다. 연구 범위는 재료 선정, 다이캐스팅 공정, 금형 설계 및 표면 처리 기술을 포괄합니다.

5. 주요 연구 결과:

- 핵심 발견사항:

- 박형 및 대형 Mg 합금 다이캐스팅 부품은 자동차 콕핏 경량화에 효과적인 솔루션이며, 특히 신에너지 자동차 분야에서 중요성이 더욱 커지고 있습니다.

- 자동차 콕핏 부품 중 seat frame, CCB, center console frame은 Mg 합금 다이캐스팅 기술 적용이 비교적 성숙 단계에 있으며, door inner 및 rear tailgate 부품으로 적용 범위가 확대되고 있습니다.

- AM series alloys (AM50, AM60)는 현재 자동차 콕핏 다이캐스팅 부품에 가장 널리 사용되는 재료이지만, 더 높은 기계적 물성을 가진 Mg 합금에 대한 요구가 증가하고 있습니다. Mg-RE series alloys는 우수한 고온 특성을 가지지만, 높은 비용이 단점입니다.

- 다이캐스팅 공정 조건 및 금형 설계는 박형 및 대형 Mg 합금 다이캐스팅 부품의 품질에 큰 영향을 미치며, 최적화된 설계 및 공정 제어가 중요합니다. 특히, 박형 부품의 경우 불량 발생 가능성이 높으므로 세심한 공정 관리가 필요합니다.

- 진공 다이캐스팅(Vacuum-assisted HPDC)은 Mg 합금 다이캐스팅 부품의 기공(Porosity)을 줄이고 기계적 물성을 향상시키는 효과적인 방법입니다.

- 표면 처리는 Mg 합금 부품의 내식성 확보에 필수적이며, 다양한 표면 처리 기술(화학적 피막 처리, 아노다이징 등)이 적용될 수 있습니다.

- 통계적/정성적 분석 결과:

- 다양한 상용 Mg 합금(AZ91, AM50, AM60, WE43, WE54)의 재료 특성(YS, UTS, Elongation)을 비교 분석하여 각 합금의 장단점 및 적용 분야를 제시합니다 (Table 1, 2, 3).

- 다이캐스팅 공정 변수(주입 속도, 금형 온도, 압력 등)가 부품 품질에 미치는 영향을 분석하고, 최적 공정 조건 설정의 중요성을 강조합니다.

- 금형 설계 요소(die cavity, gating system, runner, gate, rib 등)가 부품 성형성 및 품질에 미치는 영향을 분석하고, 최적 금형 설계 방안을 제시합니다.

- 진공 다이캐스팅과 일반 HPDC의 LA42 합금 주조 시 기공 분포 및 기계적 물성을 비교 분석하여 진공 다이캐스팅의 효과를 입증합니다 (Fig. 11).

- 데이터 해석:

- Mg 합금은 경량성, 강성, 강도 등 우수한 특성을 가지고 있어 자동차 부품 경량화에 기여할 수 있지만, 낮은 연신율, 내식성, 높은 비용 등의 단점도 가지고 있습니다.

- 박형 및 대형 Mg 합금 다이캐스팅 부품의 성공적인 제조를 위해서는 재료 선택, 공정 최적화, 금형 설계, 표면 처리 등 모든 요소들을 종합적으로 고려해야 합니다.

- 기술 개발 및 비용 절감을 통해 Mg 합금 다이캐스팅 부품의 자동차 적용 범위를 더욱 확대할 수 있을 것으로 기대됩니다.

- Figure Name List:

- Fig. 1: First high-volume one-piece die cast Mg alloy CCB

- Fig. 2: Exploded view of the center console with conventional structure

- Fig. 3: Application of Mg alloys center console frame in automobile

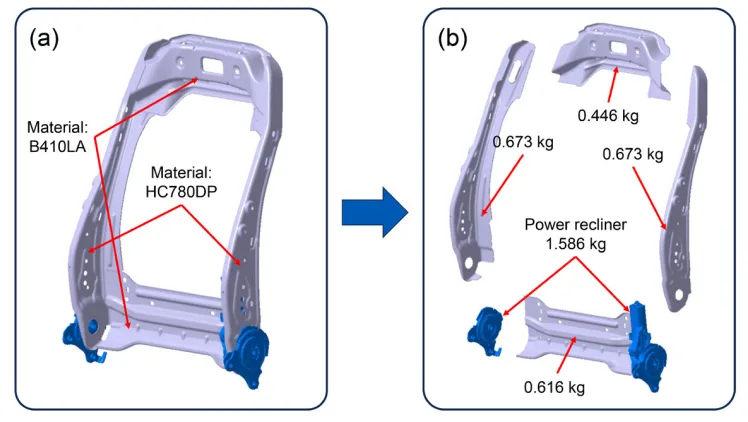

- Fig. 4: Traditional seat back frame structure

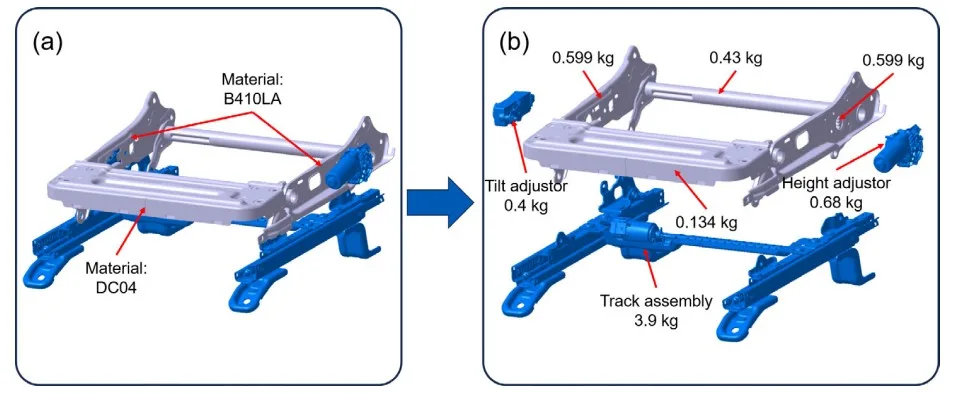

- Fig. 5: Traditional seat cushion frame structure

- Fig. 6: Seat frame consisting of 5 Mg die casting parts

- Fig. 7: Images showing Mg alloy seat frame applications in 2015 Mercedes-Benz SLK seat

- Fig. 8: Typical Mg alloy seat back frame

- Fig. 9: Prototype of Mg alloy door inner die casting

- Fig. 10: Schematic of a cold chamber die-casting machine

- Fig. 11: Comparison of the LA42 alloy casting of HPDC and vacuum-assisted HPDC

- Fig. 12: Typical redundant materials on the part of Mg alloy die casting

- Fig. 13: Surface treatment process flow for Mg alloy die casting parts

- Fig. 14: Surface morphologies of AZ31 Mg alloy after anodizing at 3 V (a), 10 V (b), 20 V (c), 70 V (d), 80 V (e), and 100 V (f)

- Fig. 15: Typical surface defects of thin wall Mg alloy parts

- Fig. 16: Suggestions for the design of the die casting parts with uniform wall thickness

- Fig. 17: Some suggestions about how to layout the ribs on the die casting parts

- Fig. 18: Gating system of Mg alloy die castings

- Fig. 19: Different runner designs of Mg alloy die casting dies and their impact on filling process

- Fig. 20: Different gate system designs of Mg alloy die casting seat frame

![Fig. 1: First high-volume one-piece die cast Mg alloy CCB: (a) 3D data [18]; (b) CCB for GMC Savana

and Chevrolet Express; (c) CCB for Buick LaCrosse [19]](https://castman.co.kr/wp-content/uploads/Fig.-1-First-high-volume-one-piece-die-cast-Mg-alloy-CCB-a-3D-data-18-b-CCB-for-GMC-Savana-and-Chevrolet-Express-c-CCB-for-Buick-LaCrosse-19-1024x334.webp)

![Fig. 2: Exploded view of the center console with conventional structure: (a) the shell itself is outer skin;

(b) with a structural component inside [21]](https://castman.co.kr/wp-content/uploads/Fig.-2-Exploded-view-of-the-center-console-with-conventional-structure-a-the-shell-itself-is-outer-skin-b-with-a-structural-component-inside-21-1024x508.webp)

![Fig. 6: Seat frame consisting of 5 Mg die casting parts: (a) backrest; (b) cushion; (c) assembly [11]](https://castman.co.kr/wp-content/uploads/Fig.-6-Seat-frame-consisting-of-5-Mg-die-casting-parts-a-backrest-b-cushion-c-assembly-11.webp)

![Fig. 10: Schematic of a cold chamber die-casting machine (a), and stages of the shot profile for die casting

process showing changes of melt pressure and plunger displacement versus time (b) [91]](https://castman.co.kr/wp-content/uploads/Fig.-10-Schematic-of-a-cold-chamber-die-casting-machine-a-and-stages-of-the-shot-profile-for-die-casting-process-showing-changes-of-melt-pressure-and-plunger-displacement-versus-time-b-91-1024x425.webp)

![Fig. 17: Some suggestions about how to layout the ribs on the die casting parts [127]](https://castman.co.kr/wp-content/uploads/Fig.-17-Some-suggestions-about-how-to-layout-the-ribs-on-the-die-casting-parts-127-1024x607.webp)

![Fig. 19: Different runner designs of Mg alloy die casting dies and their impact on filling process: (a) Y shape

runner; (b) T shape runner; (c) radiation shape runner; (d) tracer particles during the filling simulation

of the Y shape runner; (e) tracer particles during the filling simulation of the T shape runner [125]](https://castman.co.kr/wp-content/uploads/Fig.-19-Different-runner-designs-of-Mg-alloy-die-casting-dies-and-their-impact-on-filling-process-1024x606.webp)

![Fig. 20: Different gate system designs of Mg alloy die casting seat frame: (a) [134] and (b) [29] for

backrest; (c) and (d) for cushion [25]](https://castman.co.kr/wp-content/uploads/Fig.-20-Different-gate-system-designs-of-Mg-alloy-die-casting-seat-frame.webp)

6. 결론 및 논의:

- 주요 결과 요약:

신에너지 자동차의 보급은 경량화 기술 발전을 촉진했으며, Mg 합금 다이캐스팅 기술은 많은 경량화 기술에서 바람직합니다. 비교적 높은 통합으로 인해 다이캐스팅 기술은 수많은 소형 부품을 통합하여 박형 및 대형 부품을 형성하는 데 더 적합하여 부품 경량화에 상당한 영향을 미칩니다.

기술적으로 적합한 부품, Mg 합금 재료 선택, 다이캐스팅 공정 및 다이캐스팅 금형 설계는 최종 부품의 품질에 큰 영향을 미칩니다. 관련된 연구를 통해 다음과 같은 결론을 얻을 수 있었습니다. - 연구의 학술적 의의:

본 연구는 박형 및 대형 Mg 합금 다이캐스팅 부품의 자동차 콕핏 적용에 대한 종합적인 기술 동향 분석을 제공하며, 향후 연구 개발 방향 설정에 기여할 수 있습니다. 특히, 재료, 공정, 금형 설계 등 다각적인 측면에서 기술적 과제와 해결 방안을 제시함으로써 학술적 가치를 높입니다. - 실무적 시사점:

본 연구는 자동차 부품 설계 및 제조 분야의 실무자들에게 Mg 합금 다이캐스팅 기술 적용에 대한 유용한 정보를 제공합니다. 특히, 박형 및 대형 부품 설계, 재료 선택, 공정 조건 설정, 금형 설계 등에 대한 구체적인 가이드라인을 제시하여 실무 적용 가능성을 높입니다. - 연구의 한계점:

본 연구는 문헌 연구에 기반한 리뷰 논문으로, 특정 합금 또는 공정에 대한 심층적인 실험적 검증이 부족합니다. 또한, 비용, 생산성, 재활용성 등 경제적 측면과 관련된 분석이 미흡합니다. 향후 연구에서는 이러한 한계점을 보완하는 심층적인 연구가 필요합니다.

7. 향후 후속 연구:

- 후속 연구 방향:

- 저비용 및 고강도 Mg-RE 합금 개발 연구

- 박형 및 대형 Mg 합금 다이캐스팅 부품의 성능 향상 연구 (강도, 연신율, 내식성, 피로 특성 등)

- 다이캐스팅 공정 최적화 및 결함 발생 메커니즘 규명 연구 (기공, ESC 등)

- Mg 합금 다이캐스팅 부품의 통합 설계 및 제조 기술 연구 (부품 수 절감, 조립 공정 단순화)

- Mg 합금 다이캐스팅 부품의 재활용 기술 개발 연구

- 추가 탐구가 필요한 영역:

- Mg 합금 다이캐스팅 부품의 피로 특성 및 내구성 평가

- Mg 합금 다이캐스팅 부품의 크리프 특성 및 고온 신뢰성 평가

- Mg 합금 다이캐스팅 부품의 충격 특성 및 안전성 평가

- Mg 합금 다이캐스팅 부품의 LCA (Life Cycle Assessment) 분석 및 친환경 제조 공정 개발

8. 참고문헌:

- [1] Polmear I J. Magnesium alloys and applications. Materials Science and Technology, 1994, 10(1): 1-16. https://doi. org/10.1179/mst.1994.10.1.1.

- [2] Eliezer D, Aghion E, Froes F H. Magnesium science, technology and applications. Advanced Performance Materials, 1998, 5: 201-212. https://doi.org/10.1023/A:1008682415141.

- [3] Wang G G, Weiler J P. Recent developments in highpressure die-cast magnesium alloys for automotive and future applications. Journal of Magnesium and Alloys, 2023, 11(1): 78-87. https://doi.org/10.1016/j.jma.2022.10.001.

- [4] Tan J, Ramakrishna S. Applications of magnesium and its alloys: A review. Applied Science, 2021, 11(5): 6861. https://doi. org/10.3390/app11156861.

- [5] Luo A A. Applications: Aerospace, automotive and other structural applications of magnesium. In: Fundamentals of Magnesium Alloy Metallurgy, Elsevier: Amsterdam, The Netherlands, 2013: 266-316. https://doi.org/10.1533/9780857097293.266.

- [6] Liu B, Yang J, Zhang X Y, et al. Development and application of magnesium alloy parts for automotive OEMs: A review. Journal of Magnesium and Alloys, 2023,11(1): 15-47. https://doi. org/10.1016/j.jma.2022.12.015.

- [7] Westengen H, Rashed H M M A. Magnesium alloys: Properties and applications. Reference Module in Materials Science and Materials Engineering, 2016: 1-9. 10.1016/B978-0-12-803581- 8.02568-6.

- [8] Kim S K, Yoo H J, Kim Y J. Research strategy for AM60 magnesium steering wheel. Magnesium Technology 2002, 2002: 247-254.

- [9] Kawase Y, Shinto H. Development of magnesium steering wheel. SAE: International Congress and Exposition, Detroit, Michigan, USA, 1991: 910549. https://doi.org/10.4271/910549.

- [10] Abate M, Willman M. Use of cast magnesium back frames in automotive seating. 2005 SAE World Congress, Detroit, Michigan, USA, 2005: 2005-1-0723. https://doi. org/10.4271/2005-01-0723.

- [11] Hector B, Heiss W. Magnesium die castings as structural members in the integral seat of the new Mercedes-Benz roadster. 1990 SAE International Congress and Exposition, Detroit, Michigan, USA, 1990: 900798. https://doi. org/10.4271/900798.

- [12] Cui X P, Zhang Y X, Liu H F, et al. Development and application of magnesium alloy seat back for passenger cars. Foundry, 2022, 71(5): 637-644. (In Chinese)

- [13] Gao Y K, Gao D W, Gao Y H. A study on magnesium alloy substitution design and analysis for automotive seat back frame. Advanced Materials Research, 2011, 156-157: 245-251. https://doi.org/10.4028/www.scientific.net/AMR.156-157.245.

- [14] Li N Y, Chen X M, Hubbert T, et al. 2005 Ford GT magnesium instrument panel cross car beam. 2005 SAE World Congress, Detroit, Michigan, USA, 2005: 2005-01-0341. https://doi. org/10.4271/2005-01-0341.

- [15] Fan S, Wang X, Wang G G, et al. Applications of high-pressure die casting (HPDC) magnesium alloys in industry. Magnesium Alloys-processing, Potential and Applications, IntechOpen, 2023: 15. http://dx.doi.org/10.5772/intechopen.110494.

- [16] Kulekci M K. Magnesium and its alloys applications in automotive industry. International Journal of Advance Manufacture Technology, 2008, 39: 851-865. https://doi.org/10.1007/s00170- 007-1279-2.

- [17] Ma Q. Study of numerical simulation and design of die casting mould for magnesium vehicle parts. Master’s Dissertation, Harbin: Harbin University of Science and Technology, 2005. (In Chinese)

- [18] Luo A A. Magnesium casting technology for structural applications. Journal of Magnesium and Alloys, 2013, 1(1): 2-22. https:// doi.org/10.1016/j.jma.2013.02.002.

- [19] Nehan M, Maloney R. Magnesium AM60B instrument panel structure for crashworthiness FMVSS 204 and 208 compliance. 1996 SAE international Congress & Exposition, Detroit, Michigan, USA, 1996: 960419. https://doi.org/10.4271/960419.

- [20] Jiang J. Design and analysis of Mg-Al alloy beam. Commercial Vehicle, 2022, 12: 84-85+100. https://doi.org/10.20042/ j.cnki.1009-4903.2022.12.003. (In Chinese)

- [21] Schmiedel I, Winklbauer D M, Pfeufer L. Interior concept with light centre console. ATZ Worldwide, 2015, 117: 24-27. https:// doi.org/10.1007/s38311-015-0169-8.

- [22] Powell B R, Luo A A. Krajewski P E. 7-magnesium alloys for lightweight powertrains and automotive bodies. Advanced Materials in Automotive Engineering, 2012: 150-209. https://doi. org/10.1533/9780857095466.150.

- [23] Li W, Kang S L, Wang H M. Based on the lightweight design of an electric vehicle console. Auto Sci-Tech., 2020, 3: 76-83. https://doi.org/10.3969/j.issn.1005-2550.2020.03.015. (In Chinese)

- [24] D’Errico F, Tauber M, Just M. Magnesium alloys for sustainable weight-saving approach: A brief market overview, new trends, and perspectives. Current Trends in Magnesium (Mg) Research, 2022: 1-33. https://doi.org/10.5772/intechopen.102777.

- [25] Ko Y J, Kim J J, Park S C, et al. Module design concept for lightweight automotive seats. Magnesium: Proceedings of the 6th International Conference Magnesium Alloys and Their Applications, Shenyang, China, 2005: 924-929. https://doi. org/10.1002/3527603565.ch143.

- [26] Ren W, Li D P, Wang Z W, et al. Design of magnesium alloy seating riser. In: Proc. 2023 Chongqing Foundry Annual Conference, Chongqing, China, 2023: 367-370. https://doi. org/10.26914/c.cnkihy.2023.009736. (In Chinese)

- [27] Polavarapu S. Topology and free-size optimization with multiple loading conditions for light weight design of die cast automotive backrest frame. Master’s Dissertation, Clemson, South Carolina, USA: Clemson University, 2008: 414. https://open.clemson.edu/ all_theses/414.

- [28] Fantetti N, Szczesniak M. High ductility magnesium seat back structure. 1994 SAE International Congress & Exposition, Detroit, Michigan, USA, 1994: 940404. https://doi.org/10.4271/940404.

- [29] Long Z G, Zhang L, Xing X L. Magnesium alloy frame for car seat. SAECCE2020, 2020, 2: 51-54. https://doi.org/10.26914/ c.cnkihy.2020.023532. (In Chinese)

- [30] Brambilla S, Perotti P. Die casted magnesium front seat frame: An application for small and medium size cars. 1997 SAE International Congress and Exposition, Detroit Michigan, USA, 1997: 970323. https://doi.org/10.4271/970323.

- [31] Weiler J P, Sweet C, Adams A, et al. Next generation magnesium liftgate-utilizing advanced technologies to maximize mass reduction in a high volume vehicle application. In: Proceedings of the 2016 IMA World Magnesium Conference, Rome, Italy, 2016.

- [32] Blanchard P J, Bretz G T, Subramanian S, et al. The application of magnesium die casting to vehicle closures. 2005 SAE World Congress, Detroit Michigan, USA, 2005: 2005-01-0338. https:// doi.org/10.4271/2005-01-0338.

- [33] Weiler J J. A review of magnesium die-castings for closure application. Journal of Magnesium and Alloys, 2019, 7: 297-304. https://doi.org/10.1016/j.jma.2019.02.005.

- [34] Jekl J, Auld J, Sweet C, et al. Development of a thin-wall magnesium side door inner panel for automobiles. In: Proceedings of the 2015 IMA World Magnesium Conference, Detroit Michigan, USA, 2015.

- [35] Jonason P, Nilsson P, Isacsson M. MAGDOOR-magnesium in structural application. SAE International Body Engineering Conference and Exposition, Detroit Michigan, USA, 1999: 1999- 01-3198. https://doi.org/10.4271/1999-01-3198.

- [36] Pan F S, Yang M B, Chen X H. A review on casting magnesium alloys: Modification of commercial alloys and development of new alloys. Journal of Materials Science & Technology, 2016, 32(12): 1211-1221. http://dx.doi.org/10.1016/j.jmst.2016.07.001.

- [37] Kubásek J, Dvorský D, Čavojský M, et al. WE43 magnesium alloy-material for challenging applications. Kovove Material, 2019, 57(3): 159-165. https://doi.org/10.4149/km_2019_3_159.

- [38] Maltais A, Dube D, Fiset M, et al. Improvements in the metallography of as-cast AZ91 alloy. Materials Characterization, 2004, 52(2): 103-119. https://doi.org/10.1016/j.matchar.2004.04.002.

- [39] Kiełbus A, Rzychoń T, Cibis R. Microstructure of AM50 die casting magnesium alloy. Journal of Achievements in Materials and Manufacturing Engineering, 2006, 18(1-2): 135-138.

- [40] Chadha G, Allison J E, Jones J W. The role of microstructure on ductility of die-cast AM50 and AM60 magnesium alloys. Metallurgical and Materials Transactions: A, 2007, 38A: 286- 297. https://doi.org/10.1007/s11661-006-9027-z.

- [41] Wang G G, Weiler J P. Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications. Journal of Magnesium and Alloys, 2023, 11(1): 78-87. https:// doi.org/10.1016/j.jma.2022.10.001.

- [42] Park S S, Park Y S, Kim N J. Microstructure and properties of strip cast AZ91 Mg alloy. Metals and Materials International, 2002, 8(6): 551-554. https://doi.org/10.1007/BF03178256.

- [43] Zhao H L, Guan S K, Zheng F Y. Effects of Sr and B addition on microstructure and mechanical properties of AZ91 magnesium alloy. Journal of Material Research, 2007, 22(9): 2423-2429. https://doi.org/10.1557/JMR.2007.0331.

- [44] Candan S, Unal M, Koc E, et al. Effects of titanium addition on mechanical and corrosion behaviours of AZ91 magnesium alloy. Journal of Alloys and Compounds, 2011, 509(5): 1958-1963. https://doi.org/10.1016/j.jallcom.2010.10.100.

- [45] Afsharnaderi A, Malekan M, Emamy M, et al. Microstructure evolution and mechanical properties of the AZ91 magnesium alloy with Sr and Ti additions in the as-cast and as-aged conditions. Journal of Materials Engineering and Performance, 2019, 28: 6853–6863. https://doi.org/10.1007/s11665-019- 04396-2.

- [46] Khomamizadeh F, Naml B, Khoshkhooel S. Effect of rare-earth element additions on high-temperature mechanical properties of AZ91 magnesium alloy. Metallurgical and Materials Transactions: A, 2005, 36A: 3489-3494. https://doi.org/10.1007/s11661-005- 0022-6.

- [47] Cížek L, Greger M, Pawlica L, et al. Study of selected properties of magnesium alloy AZ91 after heat treatment and forming. Journal of Materials Processing Technology, 2004, 157-158: 466-471. https://doi.org/10.1016/j.jmatprotec.2004.07.149.

- [48] Zhu Y L, Liu F Y, Xin R L, et al. Improving mechanical properties of an AZ91 alloy by properly combining aging treatment and torsion deformation. Materials Science & Engineering: A, 2020, 779: 139156. https://doi.org/10.1016/j.msea.2020.139156.

- [49] Ma Y L, Chen Q J, Wang Y, et al. Research progress in casting magnesium alloys of AM family. Materials Reports, 2007, 8: 84-87. (In Chinese)

- [50] Tian Z, Song B, Liu Y B. Application and development of AM magnesium alloy in automobile industry. Automobile Technology & Material, 2004, 7: 21-23. (In Chinese)

- [51] Luo A A, Sachdev A K. 12-Applications of magnesium alloys in automotive engineering. Advances in Wrought Magnesium Alloys, 2012, 4: 393-426. https://doi.org/10.1533/9780857093844.3.39.

- [52] Luo A A, Renaud J, Nakatsugawa I, et al. Magnesium castings for automotive applications. JOM, 1995, 47: 28-31. https://doi. org/10.1007/BF03221226.

- [53] He F, Li J P, Yang Z. The microstructure and mechanical properties of as cast AM60-Ti magnesium alloy. Special Casting & Nonferrous Alloys, 2008, 3: 227-229. (In Chinese)

- [54] Zhang S, Song J F, Liao H X, et al. Effect of boron on the grain refinement and mechanical properties of as-cast Mg alloy AM50. Materials, 2019, 12: 1100. https://doi.org/10.3390/ma12071100.

- [55] Mert F, Özdemir A, Kainer K U, et al. Influence of Ce addition on microstructure and mechanical properties of high pressure die cast AM50 magnesium alloy. Transactions of Nonferrous Metals Society of China, 2013, 23(1): 66-72. https://doi.org/10.1016/ S1003-6326(13)62430-9.

- [56] Zhou G B. Effect of Y, Sb and Cd on microstructure and properties of AM50 magnesium alloy. Master’s Dissertation, Nanjing: Nanjing University of Aeronautics and Astronautics, 2012. (In Chinese)

- [57] Sevik H, Acikgoz S, Kurnaz S C. The effect of tin addition on the microstructure and mechanical properties of squeeze cast AM60 alloy. Journal of Alloys and Compounds, 2010, 508(1): 110-114. https://doi.org/10.1016/j.jallcom.2010.07.185.

- [58] Su G H, Zhang L, Cheng L R, et al. Microstructure and mechanical properties of Mg-6Al-0.3Mn-xY alloys prepared by casting and hot rolling. Transactions of Nonferrous Metals Society of China, 2010, 20(3): 383-389. https://doi.org/10.1016/ S1003-6326(09)60150-3.

- [59] Mao Z L, Huang X F, Chuang H J. Effect of neodymium on structure and mechanical properties of AM60 magnesium alloys. China Foundry Machinery & Technology, 2008, 1: 15-17. (In Chinese)

- [60] Wang L G, Zhang B F, Guan S K, et al. Effects of RE, B on microstructure and properties of AM60 alloy. Rare Metal Materials and Engineering, 2007, 36: 59-62. (In Chinese)

- [61] Zander D, Schnatterer C, Kuhnt C. Influence of heat treatments and Ca additions on the passivation behaviour of high-pressure die cast AM50. Materials and Corrosion, 2016, 66(12): 1519- 1528. https://doi.org/10.1002/maco.201508273.

- [62] Hoseini S M B, Malekan M, Emamy M, et al. Microstructure, tensile and bending behaviour of the as-cast AM50 alloy modified with different antimony and copper additions. Materials Science and Technology, 2021, 37(1): 86-102. https://doi.org/10. 1080/02670836.2020.1866847.

- [63] Mert F, Blawert C, Kainer K U, et al. Influence of cerium additions on the corrosion behaviour of high pressure die cast AM50 alloy. Corrosion Science, 2012, 65: 145-151. https://doi. org/10.1016/j.corsci.2012.08.011.

- [64] Itoh D, Terada Y, Sato T. Effect of calcium additions on creep properties of a die-cast AM50 magnesium alloy. Materials Transactions, 2008, 49(9): 1957-1962. https://doi.org/10.2320/ matertrans.MAW200830.

- [65] Teimoory F S, Emamy M, Malekan M. Effect of Pr on the grain refinement and mechanical properties of AM50 alloy in as-cast condition. AIP Conference Proceedings, Kish Island, Iran, 2018, 1920(1): 020016. https://doi.org/10.1063/1.5018948.

- [66] Yang M, Liu Y H, Song Y L. Corrosion and mechanical properties of AM50 magnesium alloy after being modified by 1 wt.% rare earth element gadolinium. Journal of Rare Earths, 2014, 32(6): 558-563. https://doi.org/10.1016/S1002-0721(14)60108-3.

- [67] Zhao P, Wang Q, Zhai C, et al. Effects of strontium and titanium on the microstructure, tensile properties and creep behavior of AM50 alloys. Materials Science and Engineering: A, 2007, 444(1-2): 318-326. https://doi.org/10.1016/j.msea.2006.08.111.

- [68] Fechner D, Maier P, Hort N, et al. Development of a magnesium recycling alloy based on AM50. Materials Science Forum, 2007, 539-543: 108-113. https://doi.org/10.4028/www.scientific.net/ MSF.539-543.108.

- [69] Matsubara H, Ichige Y, Fujita K, et al. Effect of impurity Fe on corrosion behavior of AM50 and AM60 magnesium alloys. Corrosion Science, 2013, 66: 203-210. https:// doi.org/10.1016/ j.corsci.2012.09.021.

- [70] Yang M, Liu Y H, Liu J A, et al. Effect of T6 heat treatment on corrosion resistance and mechanical properties of AM50 magnesium alloy. Materials Research Innovations, 2015, 19: S10-259-S10-264. https:// doi.org/10.1179/143289171 5Z.0000000002160.

- [71] Qiu X, Yang Q, Guan K, et al. Microstructures and tensile properties of Mg-Zn-(Gd)-Zr alloys extruded at various temperatures. Rare Metals, 2017, 36(12): 962-970. https://doi. org/10.1007/s12598-017-0966-x.

- [72] Wang G, Guo C X, Pang S J. Thermal stability, mechanical properties and corrosion behavior of a Mg-Cu-Ag-Gd metallic glass with Nd addition. Rare Metals, 2017, 3: 183-187. https:// doi.org/10.1007/s12598-017-0885-x.

- [73] Jiang H S, Qiao X G, Zheng M Y, et al. The partial substitution of Y with Gd on microstructures and mechanical properties of as-cast and as-extruded Mg-10Zn-6Y-0.5Zr alloy. Materials Characterization, 2018, 135: 96-103. https://doi.org/10.1016/ j.matchar.2017.11.025.

- [74] Yu H H, Li C Z, Xin Y C, et al. The mechanism for the high dependence of the Hall-Petch slope for twinning/slip on texture in Mg alloys. Acta Materialia, 2017, 128: 313-326. https://doi. org/10.1016/j.actamat.2017.02.044.

- [75] Li Y F, Zhang A, Li C M, et al. Recent advances of high strength Mg-RE alloys: Alloy development, forming and application. Journal of Materials Research and Technology, 2023, 26: 2919- 2940. https://doi.org/10.1016/j.jmrt.2023.08.055.

- [76] King J F. Development of practical high temperature magnesium casting alloys. Magnesium Alloys and their Applications, WileyVCH Verlag GmbH & Co. KGaA, 2006: 14-22. https://doi. org/10.1002/3527607552.ch3.

- [77] Nie J F. Precipitation and hardening in magnesium alloys. Metallurgical and Materials Transactions: A, 2012, 43: 3891- 3939. https://doi.org/10.1007/s11661-012-1217-2.

- [78] Kang Y H, Huang Z H, Wang S C, et al. Effect of pre-deformation on microstructure and mechanical properties of WE43 magnesium alloy II: Aging at 250 and 300 °C. Journal of Magnesium and Alloys, 2020, 8(1): 103-110. https://doi.org/10.1016/ j.jma.2019.11.012.

- [79] Li J L, Chen R S, Ma Y Q, et al. Effect of Zr modification on solidification behavior and mechanical properties of Mg-Y-RE (WE54) alloy. Journal of Magnesium and Alloys, 2013, 1(4): 346-351. https:// doi.org/10.1016/j.jma.2013.12.001.

- [80] Gui Y W, Li Q A, Chen J. Effects of Sm content on microstructures and mechanical properties of casting Mg-Y-Nd-Sm-Zr alloys. Materials Research Express, 2018, 5(7): 076515. https:// iopscience.iop.org/article/10.1088/2053-1591/aad07e.

- [81] Li J L, Ma Y Q, Chen R S, et al. Effects of shrinkage porosity on mechanical properties of a sand cast Mg-Y-RE (WE54) alloy. Materials Science Forum, 2013, 747-748: 390-397. https://doi. org/10.4028/www.scientific.net/MSF.747-748.390.

- [82] Zhan L, Sun J, He J G, et al. Research status on the lightweight of the automotive seat. Automobile Parts, 2015, 11: 68-73. 10.19466/j.cnki.1674-1986.2015.11.019. (In Chinese)

- [83] Lee H S, Kim J H, Kang G S, et al. Development of seat side frame by sheet forming of DP980 with die compensation. International Journal of Precision Engineering and Manufacturing, 2017, 18: 115-120. https://doi.org/10.1007/s12541-017-0014-7.

- [84] Oh W J, Lee C M. A study on the sheet forming of the lower seat rail using 1180 TRIP steel. International Journal of Precision Engineering and Manufacturing, 2018, 19: 299-302. https://doi. org/10.1007/s12541-018-0036-9.

- [85] Forsmark J H, Boileau J, Houston D, et al. A microstructural and mechanical property study of an AM50 HPDC magnesium alloy. International Journal of Metalcasting, 2012, 6: 15-26. https://doi. org/10.1007/BF03355474.

- [86] Wang X J, Zhu S M, Easton M A, et al. Heat treatment of vacuum high pressure die cast magnesium alloy AZ91. International Journal of Cast Metals Research, 2014, 27(3): 161-166. https://doi.org/10.1179/1743133613Y.0000000091.

- [87] Suman C. Heat treatment of magnesium die casting alloys AZ91D and AM60B. 1989 SAE International Congress and Exposition, Detroit, Michigan, USA, 1989: 890207. https://doi. org/10.4271/890207.

- [88] Tański1 T, Dobrzański L A, Čížek L. Influence of heat treatment on structure and properties of the cast magnesium alloys. Advanced Materials Research, 2007, 15-17: 491-496. https:// doi.org/10.4028/www.scientific.net/AMR.15-17.491.

- [89] Fu P H, Luo A A, Jiang H Y, et al. Low-pressure die casting of magnesium alloy AM50: Response to process parameters. Journal of Materials Processing Technology, 2008, 205(1-3): 224-234. https://doi.org/10.1016/j.jmatprotec.2007.11.111.

- [90] Luo A A, Sachdev A K, Powell B R. Advanced casting technologies for lightweight automotive applications. China Foundry, 2010, 7(4): 248-254.

- [91] Czerwinski F. Magnesium injection molding. Springer New York, NY, 2008. https://doi.org/10.1007/978-0-387-72528-4.

- [92] Vinarcik E J. High integrity die casting processes. John Wiley & Sons, Inc., New York, 2003.

- [93] Vanli A S, Akdogan A, Sonmez H. Investigation the effects of process parameters on product quality in cold chamber high pressure die casting of magnesium alloys. International Journal of Arts and Sciences, 2010, 3(9): 320-325.

- [94] ASM Handbook Committee. Properties and selection: Nonferrous alloys and special purpose materials. ASM Handbook, 1990, Volume 2. https://doi.org/10.31399/asm. hb.v02.9781627081627

- [95] Aghion E, Moscovitch N, Arnon A. The correlation between wall thickness and properties of HPDC magnesium alloys. Materials Science and Engineering: A, 2007, 447(1-2): 341-346. https:// doi.org/10.1016/j.msea.2006.10.065.

- [96] Woo S H, Han B S, Yoo H J, et al. Development of magnesium seat frames using the vacuum die casting process. Journal of Korean Society for Precision Engineering, 2009, 26: 88-97.

- [97] Uchida M. Development of vacuum die casting process. China Foundry, 2009, 6(2): 137-144.

- [98] Li Z X, Zhang W C, Li D J, et al. Effect of vacuum-assisted die casting on the thermal conductivity and mechanical properties of LA42 magnesium alloy. Special Casting & Nonferrous Alloys, 2023, 43: 590-595. https://doi.org/10.15980/j.tzzz.2023.05.003. (In Chinese)

- [99] Brown Z, Luo A A, Musser M, et al. Development of supervacuum die casting process for magnesium alloys. North American Die Casting Association Transactions, 2009, T09-043: 723-729.

- [100] Yuan J, Zhao B H. Effects of post treatment on deformation of die casting generator bracket. Special Casting & Nonferrous Alloys, 2010, 30: 645-648. (In Chinese)

- [101] Liang C S, Yu L L, Xie Y J. Discussion on the application of trimming die in die casting products. In: Proc. 2023 Chongqing Foundry Annual Conference, Chongqing, 2011: 291-292. https://doi.org/10.26914/c.cnkihy.2023.009736. (In Chinese)

- [102] Sayak R B E E. Investigation of flash-free die casting by overflow design optimization. Master’s Dissertation, Columbus, Ohio, USA: The Ohio State University, 2014.

- [103] Wu W, Huang Z L. The ways to reduce the flashes and improve the accuracy of die casting. Special Casting & Nonferrous Alloys, 1998(Supplement): 43-45. (In Chinese)

- [104] Wu L P, Zhao J J, Xie Y P, et al. Progress of electroplating and electroless plating on magnesium alloy. Transactions of Nonferrous Metals Society of China 2010, 20(supplement 2): s630-s637. https://doi.org/10.1016/S1003-6326(10)60552-3.

- [105] Seifzadeh D, Rajabalizadeh Z. Environmentally-friendly method for electroless Ni-P plating on magnesium alloy. Surface and Coatings Technology, 2013, 218: 119-126. https://doi. org/10.1016/j.surfcoat.2012.12.039.

- [106] Wang Z C, Jia F, Yu L, et al. Direct electroless nickel-boron plating on AZ91D magnesium alloy. Surface & Coatings Technology, 2012, 206(17): 3676-3685. https://doi.org/10.1016/ j.surfcoat.2012.03.020.

- [107] Saji V S. Review of rare-earth-based conversion coatings for magnesium and its alloys. Journal of Materials Research and Technology, 2019, 8(5): 5012-5035. https://doi.org/10.1016/ j.jmrt.2019.08.013.

- [108] Pommiers B S, Frayret J, Uhart A, et al. Determination of the chemical mechanism of chromate conversion coating on magnesium alloys EV31A. Applied Surface Science, 2014, 298: 199–207. https://doi.org/10.1016/j.apsusc.2014.01.162.

- [109] Guo Y, Frankel G S. Characterization of trivalent chromium process coating on AA2024-T3. Surface and Coatings Technology, 2012, 206(19-20): 3895-3902. https://doi. org/10.1016/j.surfcoat.2012.03.046.

- [110] Ogle K, Tomandl A, Meddahi N, et al. The alkaline stability of phosphate coatings I: ICP atomic emission spectroelectrochemistry. Corrosion Science, 2004, 46(4): 979- 995. https://doi.org/10.1016/S0010-938X(03)00182-3.

- [111] Jiang L, Wolpers M, Volovitch P, et al. The degradation of phosphate conversion coatings by electrochemically generated hydroxide. Corrosion Science, 2012, 55: 76-89. https://doi. org/10.1016/j.corsci.2011.10.004.

- [112] Jian S Y, Chu Y R, Lin C S. Permanganate conversion coating on AZ31 magnesium alloys with enhanced corrosion resistance. Corrosion Science, 2015, 93: 301-309. https://doi. org/10.1016/j.corsci.2015.01.040.

- [113] Liang C S, Lv Z F, Zhu Y L, et al. Protection of aluminium foil AA8021 by molybdate-based conversion coatings. Applied Surface Science, 2014, 288: 497-502. https://doi.org/10.1016/ j.apsusc.2013.10.060.

- [114] Dabalà M, Armelao L, Buchberger A, et al. Cerium-based conversion layers on aluminum alloys. Applied Surface Science, 2001, 172: 312-322. https://doi.org/10.1016/S0169- 4332(00)00873-4.

- [115] Rudd A L, Breslin C B, Mansfeld F. The corrosion protection afforded by rare earth conversion coatings applied to magnesium. Corrosion Science, 2000, 42(2): 275-288. https:// doi.org/10.1016/S0010-938X(99)00076-1.

- [116] Rocca E, Juers C, Steinmetz J. Corrosion behavior of chemical conversion treatments on as-cast Mg-Al alloys: Electrochemical and non-electrochemical methods. Corrosion Science, 2010, 52(6): 2172-2178. https://doi.org/10.1016/j.corsci.2010.02.036.

- [117] Zhou W Q, Shan D Y, Han E H, et al. Structure and formation mechanism of phosphate conversion coating on die cast AZ91D magnesium alloy. Corrosion Science, 2008, 50(2): 329-337. https://doi.org/10.1016/j.corsci.2007.08.007.

- [118] Hawke D, Albright A. A phosphate-permanganate conversion coating for magnesium. Metal Finishing, 1995, 93(10): 34-38. https://doi.org/10.1016/0026-0576(96)80428-4.

- [119] Salman S A, Okido M. 8-anodization of magnesium (Mg) alloys to improve corrosion resistance. Corrosion Prevention of Magnesium Alloys, 2013: 197-231. https://doi.org/10.1533/978 0857098962.2.197.

- [120] Blawert C, Dietzel W, Ghali E, et al. Anodizing treatments for magnesium alloys and their effect on corrosion resistance in various environments. Advanced Engineering Materials, 2006, 8(6): 511-533. https://doi.org/10.1002/adem.200500257.

- [121] Salman S A, Mori R, Ichino R, et al. Effect of anodizing potential on the surface morphology and corrosion property of AZ31 magnesium alloy. Materials Transactions, 2010, 51(6): 1109-1113. https://doi.org/10.2320/matertrans.M2009380.

- [122] Wu C S, Zhang Z, Cao F H, et al. Study on the anodizing of AZ31 magnesium alloys in alkaline borate solutions. Applied Surface Science, 2007, 253: 3893-3898. https://doi. org/10.1016/j.apsusc.2006.08.020.

- [123] Chen R S, Lu G D. Design key points and material selection of the magnesium alloy die casting mold. MW Metal Forming, 2011, 3: 26-27. (In Chinese)

- [124] Friedrich H E, Mordike B L. 6 technology of magnesium and magnesium alloys. In: Magnesium Technology, Springer, Berlin, Heidelberg, 2006: 219-430. https://doi.org/10.1007/3-540- 30812-1_6.

- [125] Timelli G, Capuzzi S, Bonollo F. Optimization of a permanent step mold design for Mg alloy castings. Metallurgical and Materials Transactions: B, 2015, 46: 473-484. https://doi. org/10.1007/s11663-014-0197-6.

- [126] Wang J D, Lu C, Ding W J. Key technologies for the design of Mg alloy die casting and die. Special Casting & Nonferrous Alloys, 2002, 2: 24-26+2. https://doi.org/10.15980/ j.tzzz.2002.02.011. (In Chinese)

- [127] Tan G Y. Structure design principles of die-casts for automobile use. Special Purpose Vehicle, 2000, 3: 40-41+47. (In Chinese)

- [128] Renner F, Zenner H. Fatigue strength of die-cast magnesium components. Fatigue & Fracture of Engineering Materials & Structures, 2002, 25: 1157-1168. https://doi.org/10.1046/ j.1460-2695.2002.00607.x.

- [129] Shawki G S A, Kandeil A Y. A review of design parameters and machine performance for improved die casting quality. Journal of Mechanical Working Technology, 1988, 16(3): 315-333. https://doi.org/10.1016/0378-3804(88)90059-9.

- [130] Chavan R, Kulkarni P S. Die design and optimization of cooling channel position for cold chamber high pressure die casting machine. IOP Conference Series: Materials Science and Engineering, 2020, 810: 012017. https://doi.org/10.1088/1757- 899X/810/1/012017.

- [131] Zhao K P. Simulation and optimization of gating system of die casting die for magnesium alloy AM60B part. Die & Mould Industry, 2008, 1: 53-56. https://doi.org/10.16787/ j.cnki.1001-2168.dmi.2008.01.015. (In Chinese)

- [132] Zhang Y W, Cheng T S. Automobile weight lightening and Mg-alloy mold. Automobile Technology & Material, 2003, 11: 1-4. (In Chinese)

- [133] Jadhav A R, Hujare D P, Hujare P P. Design and optimization of gating system, modification of cooling system position and flow simulation for cold chamber high pressure die casting machine. Materials Today: Proceedings, 2021, 46(17): 7175-7181. https://doi.org/10.1016/j.matpr.2020.11.346.

- [134] Han J L. Numerical design of Mg seat frame and its die-casting process optimization. Master’s Dissertation, Chongqing: Chongqing University, 2008. (In Chinese)

9. Copyright:

본 자료는 Feng Qiu의 논문: Thin-walled and large-sized magnesium alloy die castings for passenger car cockpit: Application, materials, and manufacture을 기반으로 작성되었습니다.

논문 출처: https://doi.org/10.1007/s41230-024-4100-z

본 자료는 위 논문을 바탕으로 요약 작성되었으며, 상업적 목적으로 무단 사용이 금지됩니다.

Copyright © 2025 CASTMAN. All rights reserved.

Thin-walled and large-sized magnesium alloy die castings for passenger car cockpit-Application, materials, and manufactureDownload