이 소개 논문은 [Applied Thermal Engineering]에서 발행한 논문 "Medium temperature heat pipes – Applications, challenges and future direction"의 연구 내용입니다.

![Fig. 5. STRATFLY MR3 Hypersonic vehicle concept by Fusaro et al. [78].](https://castman.co.kr/wp-content/uploads/image-1638-png.webp)

1. 개요:

- 제목: Medium temperature heat pipes – Applications, challenges and future direction (중온 히트 파이프 – 응용 분야, 과제 및 미래 방향)

- 저자: Thomas C. Werner, Yuying Yan, Tassos Karayiannis, Volker Pickert, Rafal Wrobel, Richard Law

- 출판 연도: 2024

- 발표 저널/학회: Applied Thermal Engineering

- 키워드: 히트 파이프, 열 관리, 열 전달, 중온 유체, 2상 열 전달

2. 요약

히트 파이프는 특히 항공 우주, 전자, 자동차 및 발전 분야에서 열 관리에 사용되었습니다. 작동 온도 범위에 따라 특정 유체 및 케이싱 재료가 필요합니다. 300-600°C("중간" 또는 "중간" 온도) 범위에서 작동하는 히트 파이프에 대한 수요가 증가하고 있지만 적절한 유체가 부족하여 개발이 부족합니다. 이 논문은 유망한 유체와 벽 재료를 강조하면서 중온 히트 파이프 개발 노력을 요약합니다. (a) 현재 응용 분야, (b) 중온 유체 연구, (c) 히트 파이프 성능 예측 원리, (d) 표준화된 유체 평가 프레임워크를 포함한 향후 연구 방향을 탐구합니다.

3. 연구 배경:

연구 주제의 배경:

최신 엔지니어링에서는 전력 밀도가 증가함에 따라 열 관리가 중요합니다. 히트 파이프는 기존 고체 재료에 비해 우수한 열 전달 기능을 제공합니다.

이전 연구 현황:

히트 파이프는 극저온에서 고온까지 다양한 온도 범위에서 개발되었습니다. 그러나 중간 온도 범위(300-600°C)는 유체 옵션이 제한되어 있어 어려움에 직면해 있습니다. 기존 연구는 종종 장기적인 호환성 테스트와 제한된 분석적 접근 방식에 중점을 두어 연속성이 부족합니다.

연구의 필요성:

중온 범위의 히트 파이프에 대한 수요가 증가하고 있지만 적합한 작동 유체가 부족하여 개발이 지연되고 있습니다. 이전 작업은 단편적이며 포괄적인 솔루션이 없습니다.

4. 연구 목적 및 연구 질문:

연구 목적:

중온 히트 파이프 개발의 주요 노력을 요약하고 가장 유망한 유체 및 벽 재료를 강조합니다.

핵심 연구:

(a) 중온 히트 파이프의 이점을 얻을 수 있는 현재 응용 분야, (b) 중온 유체에 대한 기존 연구, (c) 히트 파이프 성능 예측, 유체 분석, 유체/금속 호환성 및 유체 선택의 원리, (d) 새로운 히트 파이프 유체에 특히 초점을 맞춘 잠재적인 미래 연구 방향.

5. 연구 방법론

이 논문은 문헌 검토입니다. 중온 히트 파이프에 대한 기존 연구를 요약하고 분석합니다. 이 논문은 현재 응용 분야, 중온 유체에 대한 이전 연구, 히트 파이프 성능 원리 및 향후 연구 방향을 탐구합니다. 유체 평가 프레임워크가 제안됩니다. 연구 설계는 실험 연구, 수치 모델링 및 이론적 분석을 포함한 출판된 문헌의 검토 및 분석입니다. 데이터 수집에는 관련 출판물에 대한 Scopus.com [29]과 같은 데이터베이스 검색이 포함되었습니다. 분석에는 연구 결과의 질적 평가와 유체 특성 및 성능의 정량적 비교가 포함됩니다.

6. 주요 연구 결과:

주요 연구 결과 및 제시된 데이터 분석:

- 재생 에너지 시장: 집광형 태양열 발전(CSP) 플랜트는 종종 중간 온도 범위에서 작동합니다(표 1, 그림 3).

- 폐열 회수: 고온 폐열(300°C 이상)은 전 세계 폐열 회수 잠재력의 상당 부분을 차지합니다[68].

- 원자력 시장: 핵융합로의 전환기 타겟 플레이트는 300-600°C 범위 내에서 작동합니다(그림 4).

- 기타 시장: 극초음속 차량 열 관리(그림 5) 및 엔진 벽 냉각도 잠재적인 응용 분야를 제시합니다.

- 기존 유체의 문제점:

- 수은: 독성, 고밀도 및 심지 습윤 문제 [83, 97].

- 황 및 황/요오드: 고점도, 낮은 열전도율 및 화학적 공격성 [108].

- 유기 유체: 300°C ~ 400°C 사이의 열분해 [82, 93, 102, 104, 106].

- 칼륨 및 세슘: 중간 온도에서 낮은 증기 밀도, 취급 어려움 및 수분에 대한 극심한 민감성 [79].

- 나트륨/칼륨(Na/K): 800°C 미만의 온도에서 "간헐천 비등" 현상 [105, 109, 110].

- 유체의 범주별 분석:

- 유기 유체: 열분해로 인해 일반적으로 400°C 이하로 제한됩니다(그림 6, 7, 8, 표 4).

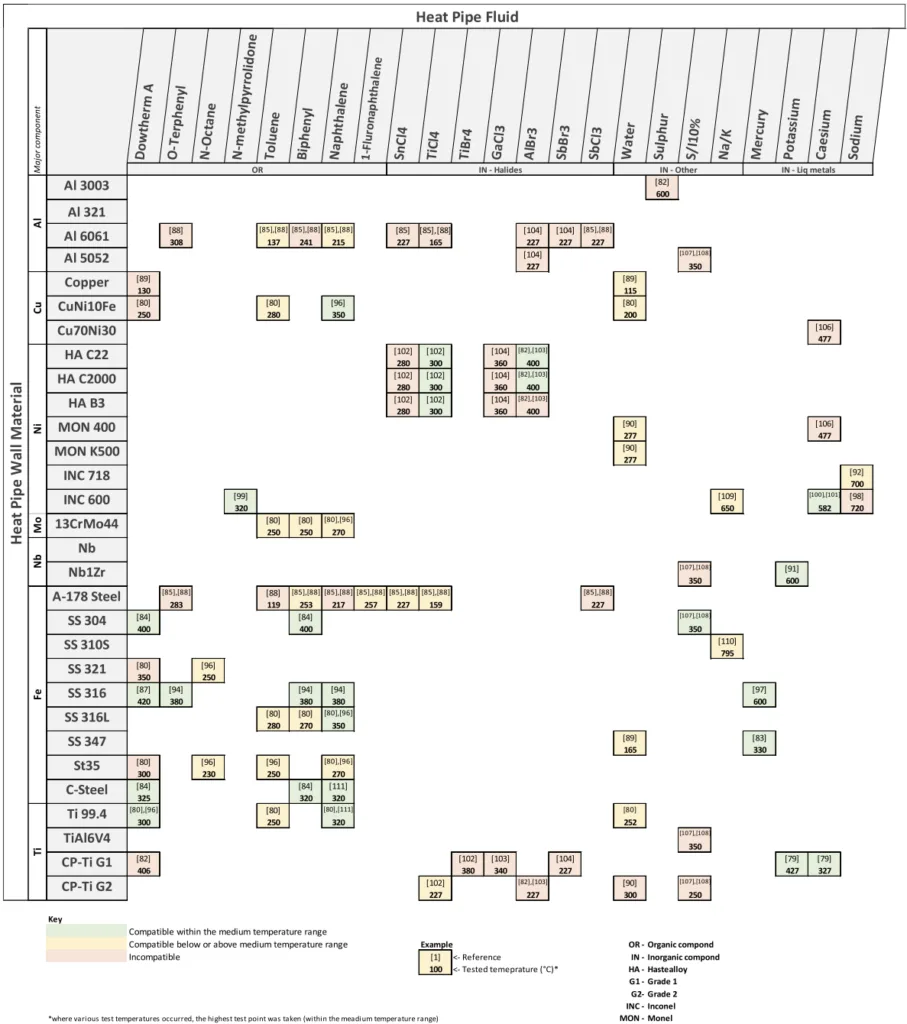

- 무기 유체(할로겐화물): 삼브롬화안티몬은 테스트된 할로겐화물 중에서 가장 좋은 잠재력을 보이지만 320°C 이상의 낮은 열유속 밀도 응용 분야로 제한됩니다(그림 9, 10, 11, 표 5).

- 액체 금속: 수은과 세슘은 이론적으로 중간 온도 범위 내에서 작동할 수 있지만 실제적인 문제에 직면해 있습니다(그림 12, 13, 14, 표 6, 7).

- 무기 혼합물: 황/요오드 및 나트륨/칼륨은 유망하지만 충분한 특성 데이터가 부족합니다(표 8).

- 유체 분석 프로세스가 제안되었습니다(그림 15).

![Fig. 1. Papers published directly relating to heat pipes. Produced using data from Scopus.com [29].](https://castman.co.kr/wp-content/uploads/image-1639-1024x642.webp)

![Fig. 3. Share of subjects linked to the exploration of medium temperature heat pipes taken from 70 papers on the topic spanning 1972 to 2022. Produced using data

from Scopus.com [29].](https://castman.co.kr/wp-content/uploads/image-1640-1024x796.webp)

![Table 1

Specifications for main large-scale concentrated solar power plants Produced using data from He et al. [67]. Third generation plants are exploring the use of silica sand,

calcinated flint clay and ceramic particles as well as a range of chlorinated or carbonated molten salts as heat absorbing mediums within the medium temperature

range.](https://castman.co.kr/wp-content/uploads/image-1641-1024x219.webp)

Specifications for main large-scale concentrated solar power plants Produced using data from He et al. [67]. Third generation plants are exploring the use of silica sand, calcinated flint clay and ceramic particles as well as a range of chlorinated or carbonated molten salts as heat absorbing mediums within the medium temperature range.

![Fig. 4. Diverter target plate structure. A re-creation of images from You et al. [74].](https://castman.co.kr/wp-content/uploads/image-1642-png.webp)

![Fig. 14. Maximum thermal transport capacity for main liquid metals explored for use in the medium temperature range. Modelled with heat pipe dimensions

presented in the study by Werner et al. [114] (see Table 3).](https://castman.co.kr/wp-content/uploads/image-1644-png.webp)

그림 이름 목록:

- Fig. 1. Papers published directly relating to heat pipes. Produced using data from Scopus.com [29].

- Fig. 2. Share of top 13 countries contributing to heat pipe research data presented in Fig. 1 for years 1960-2022. Produced using data from Scopus.com [29].

- Fig. 3. Share of subjects linked to the exploration of medium temperature heat pipes taken from 70 papers on the topic spanning 1972 to 2022. Produced using data from Scopus.com [29].

- Fig. 4. Diverter target plate structure. A re-creation of images from You et al. [74].

- Fig. 5. STRATFLY MR3 Hypersonic vehicle concept by Fusaro et al. [78].

- Fig. 6. Liquid transport factor for main organic fluids explored for use in the medium temperature range.

- Fig. 7. Vapour pressure for main organic fluids explored for use in the medium temperature range.

- Fig. 8. Maximum thermal transport capacity for main organic fluids explored for use in the medium temperature range. Modelled with heat pipe dimensions presented in the study by Werner et al. [114] (see Table 3).

- Fig. 9. Liquid transport factor for main halide fluids explored for use in the medium temperature range.

- Fig. 10. Vapour pressure for main halides explored for use in the medium temperature range.

- Fig. 11. Maximum thermal transport capacity for main halide fluids explored for use in the medium temperature range. Modelled with heat pipe dimensions presented in the study by Werner et al. [114] (see Table 3).

- Fig. 12. Liquid transport factor for main liquid metal fluids explored for use in the medium temperature range.

- Fig. 13. Vapour pressure for main liquid metals explored for use in the medium temperature range.

- Fig. 14. Maximum thermal transport capacity for main liquid metal fluids explored for use in the medium temperature range. Modelled with heat pipe dimensions presented in the study by Werner et al. [114] (see Table 3).

- Fig. 15. Fluid analysis and selection process.

7. 결론:

주요 결과 요약:

중온 히트 파이프에 대한 필요성이 증가하고 있습니다. 유기 유체는 일반적으로 400°C 이상에서는 적합하지 않습니다. 할로겐화물은 제한적인 성능을 보입니다. 액체 금속은 이론적으로 가장 우수한 성능을 갖지만 실제적인 문제에 직면합니다. 일부 혼합물은 유망하지만 데이터가 부족합니다.

{연구 결과 요약. 연구의 학문적 의의, 연구의 실제적 의미}

이 논문은 특히 새로운 유체를 개발하고 특성화하는 데 더 많은 연구가 필요하다고 결론지었습니다. 연구를 가속화하기 위해 표준화된 유체 평가 프레임워크가 제안되었습니다. 중앙 데이터베이스와 히트 파이프 모델링 도구의 개발이 중요합니다.

8. 참고 문헌:

- [1] D. Reay, P. Kew, Heat Pipes Theory, Design and Applications, 2006.

- [2] M. Mochizuki, R. Sigh, T. Nguyen, Completely passive heat pipe based emergency core cooling system, in: 16th International Heat Pipe Conference (16th IHPC), 2012.

- [3] C. Hoa, B. Demolder, A. Alexandre, Roadmap for developing heat pipes for ALCATEL SPACE's satellites, Appl. Therm. Eng. 23(9 SPEC) (2003) 1099-1108. 10.1016/S1359-4311(03)00039-5.

- [4] G. Wang, D. Mishkinis, D. Nikanpour, Capillary heat loop technology: Space applications and recent Canadian activities, Appl. Therm. Eng. 28 (4) (2008) 284-303, https://doi.org/10.1016/j.applthermaleng.2006.02.027.

- [5] P.V. Panetta, et al., NASA/GSFC nano-satellite technology development, Science (1998) 115-122.

- [6] G. Canti, G.P. Celata, M. Cumo, M. Furrer, Thermal hydraulic characterization of a heat pipe with extracapillary circulation, Int. J. Therm. Sci. 41 (2) (2002) 115-123, https://doi.org/10.1016/S1290-0729(01)01289-3.

- [7] R. Wrobel, D. Reay, A feasibility study of heat pipes for thermal management of electrical machines, in: ECCE 2020 - IEEE Energy Conversion Congress and Exposition, Institute of Electrical and Electronics Engineers Inc., Oct. 2020, pp. 4230-4237, https://doi.org/10.1109/ECCE44975.2020.9236391.

- [8] Y. Changbao, Z. Hui, Z. Jingyang, Performance simulation analysis of composite thermal management system for hypersonic vehicle, IOP Conf. Ser. Mater. Sci. Eng. 751 (1) (2020) pp, https://doi.org/10.1088/1757-899X/751/1/012078.

- [9] L. Hongpeng, L. Weiqiang, Thermal-structural analysis of the platelet heat-pipe-cooled leading edge of hypersonic vehicle, Acta Astronaut. 127 (2016) 13–19, https://doi.org/10.1016/j.actaastro.2016.05.014.

- [10] R. Hay, W.G. Anderson, Water-titanium heat pipes for spacecraft fission power, in: 13th International Energy Conversion Engineering Conference, 2015, pp. 1-12.

- [11] G. C. Birur, Thermal control of small spacecraft using single and two-phase fluid loops, in: International Two-Phase Thermal Control Technology Workshop, no. 1, p. 2003, 2003. http://hdl.handle.net/2014/7668.

- [12] S. M. Cummings, R. W. Baldauff, M. A. Brown, Advanced Loop Heat Pipes For Spacecraft Central Thermal Bus Concept Technical Background of A-LHP Technology, 2002.

- [13] J. Baumann, S. Rawal, Viability of loop heat pipes for space solar power applications, in: 35th AIAA Thermophysics Conference. 2001. 10.2514/6.2001-3078.

- [14] A. Faghri, Heat pipes: review, opportunities and challenges, Front. Heat Pipes 5 (1) (2014) pp, https://doi.org/10.5098/fhp.5.1.

- [15] S. Jafari, T. Nikolaidis, Thermal management systems for civil aircraft engines: Review, challenges and exploring the future, Appl. Sci. (Switzerland) 8 (11) (2018) 1-16, https://doi.org/10.3390/app8112044.

- [16] M. Omidi, M. Farhadi, M. Jafari, A comprehensive review on double pipe heat exchangers, Appl. Therm. Eng. 110 (2017) 1075-1090, https://doi.org/10.1016/ j.applthermaleng.2016.09.027.

- [17] J. Jose, R. Baby, "Recent advances in loop heat pipes: A review", IOP Conf Ser, Mater Sci Eng 396 (1) (2018) pp, https://doi.org/10.1088/1757-899X/396/1/ 012060.

- [18] A. Faghri, Review and advances in heat pipe science and technology, J. Heat Transfer 134 (12) (2012) 1-18, https://doi.org/10.1115/1.4007407.

- [19] H.E. Ahmed, B.H. Salman, A.S. Kherbeet, M.I. Ahmed, Optimization of thermal design of heat sinks: a review, Int. J. Heat Mass Transf. 118 (2018) 129-153, https://doi.org/10.1016/j.ijheatmasstransfer.2017.10.099.

- [20] R. Wrobel, R.J. McGlen, Heat pipes in thermal management of electrical machines - a review, Therm. Sci. Eng. Prog. 26(April) (2021), 101053, https://doi.org/ 10.1016/j.tsep.2021.101053.

- [21] J.M. Ochterbeck, Heat pipes, NASA Contractor Rep. (1975) 1181-1230.

- [22] J. Jose, T. Kumar Hotta, A comprehensive review of heat pipe: its types, incorporation techniques, methods of analysis and applications, Thermal Science and Engineering Progress, vol. 42. Elsevier Ltd, Jul. 01, 2023. doi:10.1016/j. tsep.2023.101860.

- [23] M. Rogowski, R. Andrzejczyk, Recent advances of selected passive heat transfer intensification methods for phase change material-based latent heat energy storage units: a review, Int. Commun. Heat Mass Transfer 144 (May 2023), https://doi.org/10.1016/j.icheatmasstransfer.2023.106795.

- [24] K. Cheung, Thermal Performance and Operational Characteristics Of Loop Heat Pipe (NRL LHP), 1998.

- [25] Y. Wang, G.P. Peterson, Investigation of a novel flat heat pipe, J. Heat Transfer 127 (2) (2005) 165-170, https://doi.org/10.1115/1.1842789.

- [26] A. A. M. Delil, F. Mugele, Unrealised & novel thermal control issues for applications in future spacecraft, 2005.

- [27] H. Jouhara, J. Milko, J. Danielewicz, M.A. Sayegh, The performance of a novel flat heat pipe based thermal and PV/T (photovoltaic and thermal systems) solar collector that can be used as an energy-active building envelope material, Energy 108 (2016) 148-154, https://doi.org/10.1016/j.energy.2015.07.063.

- [28] R. S. Gaugler, Heat transfer device, 1944.

- [29] Scopus.com. by Elsevier.

- [30] A. Devarakonda, W.G. Anderson, Thermo-physical properties of intermediate temperature heat pipe fluids, AIP Conf. Proc. 746 (February) (2005) 179-186.

- [31] J. H. Rosenfeld, An Overview of Long Duration Sodium Heat Pipe Tests, no. March 2004, pp. 140-147, 2004, 10.1063/1.1649568.

- [32] W. G. Anderson, J. J. Bland, High temperature loop heat pipe, 1995.

- [33] A. Devarakonda, J. K. Olminsky, An evaluation of halides and other substances as potential heat pipe fluids, Collection of Technical Papers - 2nd International Energy Conversion Engineering Conference, vol. 1. pp. 471-477, 2004.

- [34] M. Groll, O. Brost, D. Heine, T. Spendel, Heat transfer, vapour liquid flow interations and material compatibility in two-phase thermosyphons, Energy Conservation in Industry: Combustion, Heat Recovery and Rakine Cycle Machines, 1982.

- [35] W. G. Anderson, W. Bienert, Loop heat pipe radiator trade study for the 300-550 K temperature range, 2005.

- [36] J.H. Rosenfeld, N.J. Gernert, Life test results for water heat pipes operating at 200 °C to 300 °C, AIP Conf. Proc. 969 (2008) 123-130, https://doi.org/10.1063/ 1.2844957.

- [37] E. W. Saaski, Two Phase working fluids for the temperature range 100°C to 350°C, 1977.

- [38] R.S. Reid, J.T. Sena, A.L. Martinez, Heat-pipe development for advanced energy transport concepts final report covering the period, Los Alamos National Lab no. September (2001).

- [39] J.H. Rosenfeld, N.J. Gernert, Advances in high temperature titanium-water heat pipe technology, AIP Conf. Proc. 880 (2007) 129-136, https://doi.org/10.1063/ 1.2437449.

- [40] R.S. Reid, M.A. Merrigan, J.T. Sena, Review of liquid metal heat pipe work at Los Alamos, AIP Conf. Proc. 999 (May) (1991) 999-1008, https://doi.org/10.1063/ 1.40058.

- [41] G.M. Grover, J.E. Kemme, E.S. Keddy, Advances in heat pipe technology, J. Chem. Inf. Model. 53 (9) (2013) 1689-1699, https://doi.org/10.1017/ CBO9781107415324.004.

- [42] E. W. Saaski, J. H. Hartl, High-performance heat pipes for heat recovery applications, 1980.

- [43] Y. Feng, Y. Ji, M. Wu, X. Yang, Y. Li, Z. Liu, Experimental investigation on diamond-sodium potassium alloy high- temperature oscillating heat pipe, J. Eng. Thermophys. (2022).

- [44] P. Wallin, Heat Pipe, Selection of Working Fluid, 2012, pp. 1-7.

- [45] J. H. Rosenfeld, Advances in High Temperature Ti-Water Heat Pipe Technology. pdf.

- [46] T. C. Werner, Challenges in operating heat pipes above 350°C, 2019. (Accessed Jul. 10, 2023).

- [47] T. C. Werner, Investigation of Novel Analytical Tools and Experimental Methods for the Development of Intermediate Temperature Heat Pipes.

- [48] P. Szymanski, D. Mikielewicz, Challenges in operating and testing loop heat pipes in 500-700 K temperature ranges, Arch. Thermodyn. 43(2) (2022) 61-73, 10.24425/ather.2022.141978.

- [49] H. Jouhara, N. Khordehgah, S. Almahmoud, B. Delpech, A. Chauhan, S.A. Tassou, Waste heat recovery technologies and applications, Therm. Sci. Eng. Prog. 6 (April) (2018) 268-289, https://doi.org/10.1016/j.tsep.2018.04.017.

- [50] J. Hammoud, S. Dudley, N. Apte, Use of heat pipe technology for multi media thermal management, SAE Techn. Papers 724 (2006), https://doi.org/10.4271/ 2006-01-0482.

- [51] J. Wen, Thermal resistance modeling of oscillating heat pipes filled with acetone by using artificial neural network, J. Therm. Anal. Calorim. 144 (5) (2021) 1873-1881, https://doi.org/10.1007/s10973-020-10536-x.

- [52] S.N. Li, Z.T. Liang, B.H. Yan, A medium temperature heat pipe cooled reactor, Ann. Nucl. Energy 172 (2022), https://doi.org/10.1016/j.anucene. 2022.109068.

- [53] P. A. Anil, Compound Parabolic Concentrator, 2018.

- [54] U.R. Singh, A. Kumar, Review on solar stirling engine: development and performance, Therm. Sci. Eng. Prog. 8 (July) (2018) 244-256, https://doi.org/ 10.1016/j.tsep. 2018.08.

- [55] G. Jing-hu, L. Yong, W. Jun, P. Lund, Performance optimization of larger-aperture parabolic trough concentrator solar power station using multi-stage heating technology, Energy 268 (2023), https://doi.org/10.1016/j.energy.2023.126640.

- [56] M. Tawalbeh, H.A. Khan, A. Al-Othman, F. Almomani, S. Ajith, A comprehensive review on the recent advances in materials for thermal energy storage applications, Int. J. Thermofluids 18 (2023), 100326, https://doi.org/10.1016/j. ijft.2023.100326.

- [57] R.P. Merchán, M.J. Santos, A. Medina, A. Calvo Hernández, High temperature central tower plants for concentrated solar power: 2021 overview, Renew. Sustain. Energy Rev. 155 (2022), 111828, https://doi.org/10.1016/j. rser.2021.111828.

- [58] R. Senthil, et al., A holistic review on the integration of heat pipes in solar thermal and photovoltaic systems, Sol. Energy 227 (June) (2021) 577-605, https://doi. org/10.1016/j.solener.2021.09.036.

- [59] M. Aramesh, B. Shabani, Experimental evaluation of a self storage integrated evacuated tube solar thermal collector, J. Energy Storage 62 (Jun. 2023), https:// doi.org/10.1016/j.est.: 106920.

- [60] P.V. Chilbule, L.P. Dhole, Heat pipe integrated solar thermal systems and applications: a review, Mater. Today Proc. 60 (2022) 1491-1496, https://doi. org/10.1016/j.matpr.2021.11.563.

- [61] R. Xu, J. Chen, X. Zhang, R. Wang, S. Xu, Heat leakage numerical investigation of a compound parabolic concentrator-pulsating heat pipe solar collector, J. Therm. Sci. 31 (5) (2022) 1318-1326, https://doi.org/10.1007/s11630-020-1293-3.

- [62] A. Kumar, Z. Said, E. Bellos, An up-to-date review on evacuated tube solar collectors, J. Therm. Anal. Calorim. vol. 145, no. 6. Springer Science and Business Media B.V., pp. 2873-2889, Sep. 01, 2021. 10.1007/s10973-020-09953-9.

- [63] Z. Wang, Y. Diao, Y. Zhao, C. Chen, T. Wang, L. Liang, Visualization experiment and numerical study of latent heat storage unit using micro-heat pipe arrays: melting process, Energy 246 (2022), https://doi.org/10.1016/j. energy.2022.123443.

- [64] S. Kraemer, TEXEL Explores US Market for 2-Cent Thermal Energy Storage in Metal Hydrides, 2020. .

- [65] P. White, Texel offers another candidate for a hydrogen based battery, 2021. (Accessed Jun. 24, 2023).

- [66] S. Simmonds, R. Corbishley, J. Hughes, G. Taylor, The Development of the MAHLE 25kWe Solar Heated Stirling Engine Topics: Thermodynamic & Mechanical Simulation, Engine Testing, p. 738100.

- [67] Y.L. He, Y. Qiu, K. Wang, F. Yuan, W.Q. Wang, Perspective of concentrating solar power, Energy 198 (2020), https://doi.org/10.1016/j.energy.2020.117373.

- [68] C. Forman, I.K. Muritala, R. Pardemann, B. Meyer, Estimating the global waste heat potential, Renew. Sustain. Energy Rev. 57 (2016) 1568-1579, https://doi. org/10.1016/j.rser.2015.12.192.

- [69] R.S. Vizitiu, A. Burlacu, C. Abid, M. Verdes, M.C. Balan, M. Branoaea, Experimental and numerical study of thermal performance of an innovative waste heat recovery system, Appl. Sci. (Switzerland) 11 (23) (2021), https://doi.org/ 10.3390/app112311542.

- [70] M. Sakthi Priya, D. Sakthivadivel, Experimental investigation on the thermal performance of a novel thermosyphon heat pipe with truncated cone for heat recovery systems, Energy Convers. Manag. 276 (2023), https://doi.org/10.1016/ j.enconman.2022.116522.

- [71] H. Jouhara, et al., Waste heat recovery solution based on a heat pipe heat exchanger for the aluminium die casting industry, Energy 266 (2023), https:// doi.org/10.1016/j.energy.2022.126459.

- [72] H. Jouhara, et al., Investigation on a full-scale heat pipe heat exchanger in the ceramics industry for waste heat recovery, Energy 223 (2021), 120037, https:// doi.org/10.1016/j.energy.2021.120037.

- [73] L. Yodrak, S. Rittidech, N. Poomsa-ad, Waste heat recovery by heat pipe air- preheater to energy thrift from the furnace in a hot forging process, Am. J. Appl. Sci. 7 (5) (2010) 675-681, https://doi.org/10.3844/ajassp.2010.675.681.

- [74] J.H. You, et al., European divertor target concepts for DEMO: design rationales and high heat flux performance, Nucl. Mater. Energy 16 (April) (2018) 1-11, https://doi.org/10.1016/j.nme. 2018.05.012.

- [75] B.H. Yan, C. Wang, L.G. Li, The technology of micro heat pipe cooled reactor: a review, Ann. Nucl. Energy 135 (2020), https://doi.org/10.1016/j. anucene.2019.106948.

- [76] B. Zohuri, S. Lam, C. Forsberg, Heat-pipe heat exchangers for salt-cooled fission and fusion reactors to avoid salt freezing and control tritium: a review, Nucl. Technol. 206(11). Bellwether Publishing, Ltd., pp. 1642-1658, Nov. 01, 2020. 10.1080/00295450.2019.1681222.

- [77] M. Coutinho et al., A review on the recent developments in thermal management systems for hybrid-electric aircraft, Appl. Therm. Eng. vol. 227. Elsevier Ltd, Jun. 05, 2023. 10.1016/j.applthermaleng.2023.120427.

- [78] R. Fusaro, D. Ferretto, N. Viola, R. Scigliano, V. De Simone, M. Marini, Liquid Metals Heat-Pipe solution for hypersonic air-intake leading edge: Conceptual design, numerical analysis and verification, Acta Astronaut. 197 (2022) 336-352, https://doi.org/10.1016/j.actaastro.2022.05.034.

- [79] P. M. Dussinger, W. G. Anderson, E. T. Sunada, Design and testing of titanium/ cesium and titanium/potassium heat pipes, in: Collection of Technical Papers - 3rd International Energy Conversion Engineering Conference, vol. 2, pp. 1088-1096, 2005.

- [80] M. Groll, Heat pipe research and development in western Europe, Heat Recovery Syst. CHP 9 (1) (1989) 19-66, https://doi.org/10.1016/0890-4332(89)90139-7.

- [81] W.G. Anderson, Evaluation of heat pipes in the temperature range of 450 to 700 K, AIP Conf. Proc. 746 (2005) 171-178, https://doi.org/10.1063/1.1867132.

- [82] W. G. Anderson, Intermediate temperature fluids for heat pipes and loop heat pipes, in: Collection of Technical Papers - 5th International Energy Conversion Engineering Conference, vol. 2, no. June, pp. 1147-1164, 2007.

- [83] J. E. Deverall, Mercury as a heat pipe fluid, 1970.

- [84] D. D. Kenney, K. T. Feldman, K. T. Jr. Feldman, Heat pipe life tests at temperatures up to 400 C, 1978.

- [85] E.W. Saaski, P.C. Owzarski, Two-phase working fluids for the temperature range 50° to 350°C, Heat Transfer Therm. Control Syst. (1978) 63-79, https://doi.org/ 10.2514/5.9781600865343.0063.0079.

- [86] I. E. Locci, A. Devarakonda, E. H. Copland, J. K. Olminsky, Analytical and experimental thermo-chemical compatibility study of potential heat pipe materials, in: Collection of Technical Papers - 3rd International Energy Conversion Engineering Conference, vol. 2, no. August, pp. 1285-1292, 2005, 10.2514/

9. 저작권:

- This material is a paper by "Thomas C. Werner, Yuying Yan, Tassos Karayiannis, Volker Pickert, Rafal Wrobel, Richard Law": Based on "Medium temperature heat pipes – Applications, challenges and future direction".

- Source of paper: https://doi.org/10.1016/j.applthermaleng.2023.121371

이 자료는 위 논문을 소개하기 위해 제작되었으며, 상업적 목적으로 무단 사용하는 것을 금합니다. Copyright © 2025 CASTMAN. All rights reserved.