This article introduces the paper "Thermo-economic optimization for the advanced material selection of fins and heat sinks".

1. Overview:

- Title: Thermo-economic optimization for the advanced material selection of fins and heat sinks

- Authors: Hulusi Delibaş, İbrahim Halil Yılmaz

- Publication Year: February 2025

- Journal/Conference: Chemical Engineering and Processing - Process Intensification, Volume 208, 110109

2. Research Background:

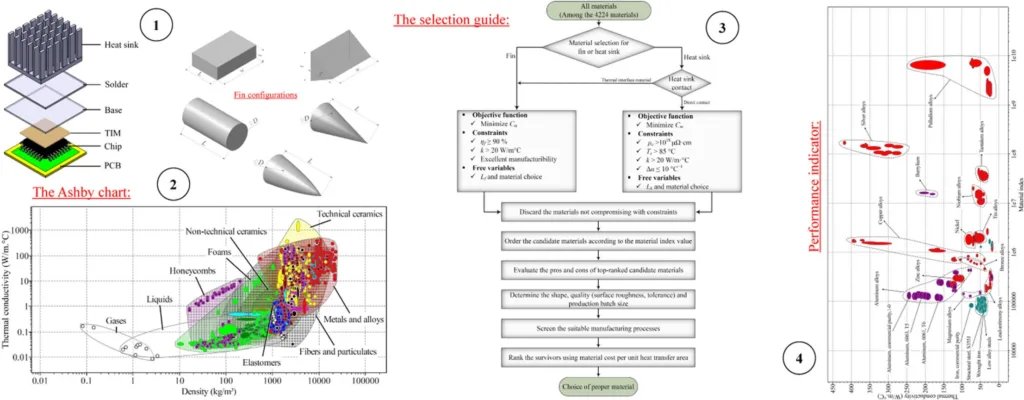

Fins and heat sinks are widely used thermal elements crucial for efficient heat removal. Efficient heat removal necessitates a low cost, and factors such as fin profile, material properties, surface properties, raw material cost, and manufacturing cost are decisive in selecting competitive materials. Existing research often focuses on specific materials or manufacturing processes, or considers only thermal conductivity. Therefore, a holistic approach considering both thermal conductivity and cost is needed. Furthermore, the miniaturization trend in microelectronics is leading to heat flux dissipation rates approaching 1 kW/cm², exceeding the capabilities of air-cooled systems and demanding liquid-cooled solutions. Limitations in previous studies include the lack of comprehensive comparisons of various fin configurations and materials, the neglect of manufacturing costs, and the absence of proposed material indices.

3. Research Objectives and Questions:

- Research Objective: To present a thermo-economic optimization approach for advanced material selection of fins and heat sinks, considering manufacturing processes.

- Key Research Questions: What are the optimal materials and manufacturing processes for fins and heat sinks, and what effective indices can guide their selection?

- Research Hypothesis: Selecting materials and processes with high thermal conductivity and low manufacturing costs will result in improved heat removal efficiency and reduced overall cost.

4. Research Methodology:

- Research Design: A research design was employed considering 4223 candidate materials, 146 manufacturing processes, and 5 common fin profiles to perform thermo-economic optimization.

- Data Collection Methods: Data on material properties, manufacturing costs, and heat transfer characteristics were collected through literature review. Granta CES EduPack software was utilized for material data analysis.

- Analysis Methods: Two novel material indices were proposed to guide the selection of fin and heat sink materials. A cost model was developed to compare manufacturing processes, and the production characteristics of various fin profiles were investigated.

- Research Subjects and Scope: The study analyzed 4223 candidate materials, 146 manufacturing processes, 5 fin profiles, and various heat transfer characteristics and cost data.

5. Main Research Results:

- Key Findings: Two novel material indices were developed to guide fin and heat sink material selection. Straight fins were shown to be approximately 8 times more economically advantageous than pin fins. Hot and cold forming processes yielded a 90.2–98.1% improvement in usable thermal conductivity. Hot open die forging exhibited the best relative cost index among the investigated processes. Beryllia alloys and aluminum nitrides were identified as preferable materials for contact heat sinks (thermal conductivity ranging from 60-330 W/m·°C).

- Statistical/Qualitative Analysis Results: The results of cost and performance analyses for various materials and manufacturing processes were presented in tables and figures. (Detailed Figure List and Descriptions are available in the original paper).

- Data Interpretation: The proposed material indices and cost model provide a methodology for selecting optimal materials and manufacturing processes. The relationship between thermal conductivity, cost, and various fin profiles and manufacturing methods was analyzed.

- Figure List and Description: Refer to the original paper for detailed descriptions of the figures and tables.

6. Conclusions and Discussion:

This study introduced two novel material indices for fin and heat sink material selection, optimizing the trade-off between thermal conductivity and cost. Straight fins showed significant economic advantages over pin fins, while hot and cold forming processes enhanced thermal conductivity. Beryllia alloys and aluminum nitrides emerged as suitable materials for contact heat sinks. The study offers a cost-effective advanced material selection approach by integrating heat transfer and economic analyses to optimize fin properties and applicable manufacturing processes. The findings have practical implications for heat system design and manufacturing. However, the study's scope is limited to a specific range of materials and processes, necessitating further research.

7. Suggestions for Future Research:

- Future research should expand the scope to encompass a wider range of materials and manufacturing processes. Studies considering various coolants are also warranted.

- Experimental validation of the simulation results is needed to verify the accuracy of the findings in real-world applications.

- Further investigation is required to assess the accuracy and generalizability of the proposed material indices.

8. Summary of References:

A list of 33 references is provided in the original paper and is not included in this summary. Please refer to the original paper for the complete list.

References (33)

- Z. Khattak et al.Air cooled heat sink geometries subjected to forced flow: a critical reviewInt. J. Heat. Mass Transf.(2019)

- Z. Mehmood et al.Material selection for micro-electro-mechanical-systems (MEMS) using Ashby's approachMater. Des.(2018)

- M. Rezaee et al.Heat transfer intensification in pin-fin heat sink by changing pin-length/longitudinal-pitchChem. Eng. Process. Process Intensif.(2019)

- Y. Yan et al.Numerical investigation on the characteristics of flow and heat transfer enhancement by micro pin-fin array heat sink with fin-shaped stripsChem. Eng. Process. Process Intensif.(2021)

- Y. Yan et al.Thermal-hydraulic performance enhancement of miniature heat sinks using connected Y-shaped fractal micro-channelsChem. Eng. Process. Process Intensif.(2021)

- M. Khoshvaght-Aliabadi et al.Effects of central cut on performance intensification of counter-flow integral heat sinksChem. Eng. Process. Process Intensif.(2022)

- A. Mwesigye et al.Thermal and thermodynamic benchmarking of liquid heat transfer fluids in a high concentration ratio parabolic trough solar collector systemJ. Mol. Liq.(2020)

- İ.H. Yılmaz et al.Design and computer simulation on multi-effect evaporation seawater desalination system using hybrid renewable energy sources in TurkeyDesalination.(2012)

- İ.H. Yılmaz et al.Prioritization of heat transfer fluids in parabolic trough solar systems using CFD-assisted AHP-VIKOR approachRenew. Energy(2023)

- F. Kılıç et al.Adaptive co-optimization of artificial neural networks using evolutionary algorithm for global radiation forecastingRenew. Energy(2021)

- K. Üstün et al.Design of spectrally selective multilayer stacks with optimized properties for mid-temperature concentrating solar applicationsSolar Energy Materials and Solar Cells(2024)

- İ.H. YılmazResidential use of solar water heating in Turkey: a novel thermo-economic optimization for energy savings, cost benefit and ecologyJ. Clean. Prod.(2018)

- İ.H. Yılmaz et al.Modeling, simulation and performance analysis of parabolic trough solar collectors: a comprehensive reviewAppl. Energy(2018)

- T.T. Göksu et al.Numerical investigation of the thermo-hydraulic performance of DNA inspired double and triple helix wire coilsChem. Eng. Process. Process Intensif.(2022)

- M. SöylemezOn the thermoeconomical optimization of fin sizing for waste heat recoveryEnergy Convers. Manage(2003)

Copyright and Reference Materials:

This summary is based on the research paper "Thermo-economic optimization for the advanced material selection of fins and heat sinks" by Hulusi Delibaş and İbrahim Halil Yılmaz.

Paper Source: https://doi.org/10.1016/j.cep.2024.110109

This summary is based on the above-mentioned paper and its unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.