Optimizing Aluminium Casting: How Moulding Sand Selection Impacts Solidification and Prevents Defects

This technical summary is based on the academic paper "Study of Thermo-Physical Changes in Casting of Aluminium Alloy at Different Moulding Sands" by Rahul Shukla, Amit Medhavi, Ambuj Kumar, and Shashank Kumar, published in the International Journal of Research in Engineering, IT and Social Sciences (2019).

Keywords

- Primary Keyword: Aluminium Casting Simulation

- Secondary Keywords: Heat Transfer in Casting, Solidification Analysis, ANSYS Casting, Moulding Sand Properties, Casting Defect Prediction, Thermo-physical Properties, Finite Element Technique

Executive Summary

- The Challenge: To accurately predict and prevent casting defects by understanding the complex thermo-physical phenomena that occur during the solidification of molten metal.

- The Method: Using ANSYS finite element analysis software to conduct a two-dimensional transient thermal simulation of an aluminium alloy solidifying in two different moulding sands: greensand and mullite.

- The Key Breakthrough: The simulation successfully predicted temperature distribution, thermal flux, and cooling curves, revealing significant differences in heat transfer rates and solidification behavior between the two mould materials.

- The Bottom Line: Finite element simulation is a powerful and accurate tool for predicting casting outcomes, enabling engineers to optimize mould materials and process parameters to improve quality and reduce defects before committing to physical production.

The Challenge: Why This Research Matters for HPDC Professionals

One of the most significant concerns for foundries worldwide is producing superior quality castings with minimal rejections. The quality of a final cast part is governed by a huge number of parameters, making it a complex process to control. During casting, phenomena like metal flow, thermal gradients, and heat transfer between the molten metal and the mould define the final grain size and mechanical properties. Inaccurate control over these factors can lead to defects like shrinkage and porosity.

This research addresses the critical need for predictive tools that can model the solidification process. By understanding how different mould materials affect heat transfer and cooling rates, engineers can make informed decisions to prevent defects, optimize die life, and improve overall casting quality before the first pour, saving significant time and resources.

The Approach: Unpacking the Methodology

The researchers conducted a transient thermal analysis to simulate the solidification of an aluminium alloy over a period of 2 hours (7200 seconds). The goal was to predict the temperature distribution in the cast-mould assembly.

Method 1: Finite Element Modelling in ANSYS

The study utilized ANSYS (version 14.5) software to perform a two-dimensional numerical simulation. The methodology involved three key stages:

* Pre-processing: Defining the geometry of the aluminium alloy casting and the mould, selecting element types, declaring the relevant material properties, and meshing the topology. The thermo-physical properties of the sand and mullite moulds were considered temperature-dependent, while the properties of the aluminium alloy were held constant.

* Solution: A transient (time-dependent) thermal analysis was performed. Thermal loads were applied to simulate the initial pouring of the hot metal at 600 K, and the simulation was run to model the solidification process. Convection from the mould's external surface to the environment was also included.

* Post-processing: The results were reviewed in the form of color-coded temperature contour plots and graphs showing the cooling curves at various points within the solidified specimen and the heating/cooling curves within the mould.

The Breakthrough: Key Findings & Data

The simulation provided a detailed look at the thermo-physical changes during solidification, highlighting the distinct performance of greensand versus mullite moulds.

Finding 1: Mould Material Directly Governs Temperature Distribution and Thermal Flow

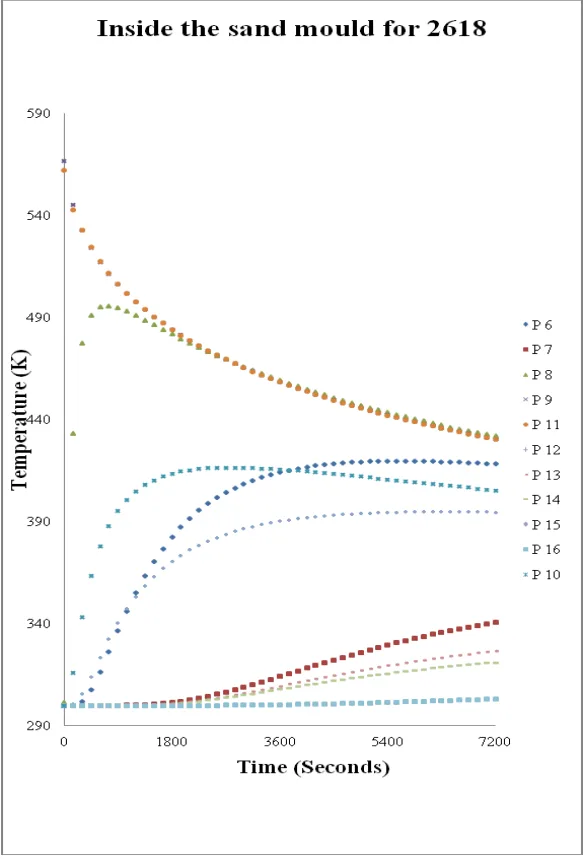

The analysis revealed a clear difference in the temperature distribution between the two systems. As shown in the temperature contour plots, a larger range of temperature variation occurred inside the sand mould compared to the mullite mould. This indicates different heat dissipation characteristics. The thermal flow analysis further confirmed this, showing that a larger thermal flow happened in the sand mould than in the mullite mould, affecting how quickly and uniformly the casting solidifies.

Finding 2: Mullite Moulds Enable Faster Heat Transfer and Solidification

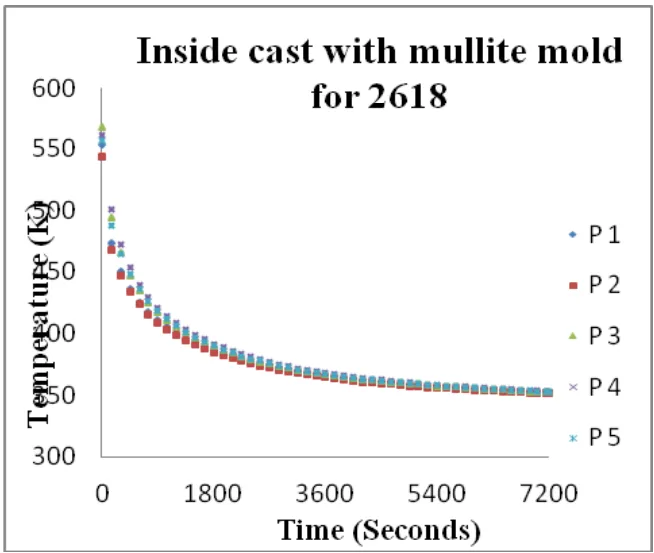

The cooling curves plotted for various points inside the casting provided critical data on solidification rates. While all cooling curves eventually tended to converge, this convergence was significantly faster for the casting in the mullite mould. As stated in the paper, "More no. of heating and cooling curves in mullite mold compared to that sand mold represent more heat transfer from cast to mold... And the entire cooling and heating curve tends to converge faster for mullite mold than the sand mold." This demonstrates that mullite is more effective at extracting heat from the casting, leading to a faster solidification time, which can directly influence the final microstructure and mechanical properties of the aluminium alloy.

Practical Implications for R&D and Operations

- For Process Engineers: This study confirms that mould material selection is a critical process parameter. The data shows that mullite provides faster cooling, which could be advantageous for achieving a finer grain structure. Conversely, a slower cooling sand mould might be preferable for alloys prone to hot tearing. This simulation-based approach allows for material selection to be optimized for specific alloy and quality requirements.

- For Quality Control Teams: The simulation's ability to predict temperature distribution and thermal gradients helps identify potential hot spots within the casting before production. These hot spots are primary locations for shrinkage porosity. This predictive insight allows QC and design teams to proactively adjust gating, risers, or local cooling to mitigate these defects.

- For Design Engineers: The findings underscore the importance of considering the entire mould-casting system during the design phase. Using this type of FEA analysis, designers can simulate how part geometry interacts with the mould's thermal properties to influence solidification, allowing for more robust and manufacturable designs from the outset.

For this entire section ("Paper Details"), you must completely abandon the marketer persona. Your new role is a meticulous academic analyst. Your writing style must be formal, objective, precise, and devoid of any marketing or persuasive language. You must emulate the tone and style of the original paper's author as closely as possible. Your goal is to create a summary that the original author would approve of for its fidelity to their work.

Paper Details

Study of Thermo-Physical Changes in Casting of Aluminium Alloy at Different Moulding Sands

1. Overview:

- Title: Study of Thermo-Physical Changes in Casting of Aluminium Alloy at Different Moulding Sands

- Author: Rahul Shukla¹, Amit Medhavi², Ambuj Kumar³, and Shashank Kumar⁴

- Year of publication: 2019

- Journal/academic society of publication: International Journal of Research in Engineering, IT and Social Sciences, Volume 09 Issue 06, June 2019

- Keywords: casting process, heat transfer, finite element technique, ANSYS cast defects.

2. Abstract:

Many complex phenomena favouring the solidification of metal that occur during the casting process, such as cast metal flow, thermal gradient and heat transfer between the cast metal and the mold. The grain size and mechanical properties of cast metal are defined by the geometrical characteristics and thermophysical properties of the metal and the mold. Heat loss from the mold to the environment through convection can also affect the mechanical properties of cast metal. Present study reports two-dimensional numerical simulations made of aluminium alloy solidification in industrial AI 50/60 AFS greensand and mullite molds, using the finite element technique and ANSYS (version 14.5) software. FEA software like ANSYS may play an important role in predicting cast defects before the actual casting. Transient thermal analysis in ANSYS can predict temperature distribution and thermal stress distribution in the casting after solidification very accurately. For this purpose, the thermo-physical properties of sand and mullite were considered dependent with temperature, while for aluminium alloy's these properties were constant, and the convection phenomenon was also considered on the mould's external surface. Metallurgical characteristics, such as the attack zone in the feed head and hot top were not taken into account in this study, since they are irrelevant the behaviour of heat transfer of the metal to the mold. Owing to the moulds temperature dependent thermo physical properties, this type of problem is of nonlinear characteristic. The results of the heat transfer are shown in 2D, as well as, the thermal flux, the thermal gradient and the convergence curves that control the feasibility of the Newton-Raphson algorithm calculation process. The cooling curves at various points of the solidified specimen, and the heating and cooling curves in the mold were also shown. These results were considered relevant with reference to previous papers result.

3. Introduction:

Metal casting is a significant industrial process, with India being the fourth largest producer of castings. Successful production requires knowledge of mould preparation, melting and pouring, solidification, and quality control. A major concern for foundries is producing high-quality castings with minimal rejections. The process is influenced by numerous parameters. Mould design, including the size and arrangement of patterns, greatly impacts production costs. Multi-cavity moulds offer advantages such as better utilization of mould material (measured by metal to sand ratio) and higher yield. The design of cavity gaps is critical to prevent mould damage, avoid hot spots, and ensure rapid freezing for optimal mechanical properties. The solidification process involves heat loss in three phases: cooling from pouring to liquidus temperature, latent heat release, and cooling from solidus to ambient temperature. The basic mechanisms of heat transfer in casting are conduction, convection, and radiation. Heat flows from the interior of the casting through several resistances, including the liquid metal, solidified metal, the metal-mould interface, the mould itself, and the surroundings.

4. Summary of the study:

Background of the research topic:

The production of high-quality metal castings is a complex process dependent on controlling numerous variables that influence the solidification of molten metal. The thermo-physical interactions between the cast metal and the mould material are determinative of the final mechanical properties and the presence of defects.

Status of previous research:

Prior literature has identified various aspects of the casting process. Qiao et al. noted defects generated during filling and solidification. Pariona et al. demonstrated different solidification results for pure iron in sand and mullite moulds. Prabhu et al. investigated the relationship between heat flux, mould wall thickness, and casting thickness. Other studies have examined residual stresses in continuous casting (Seetharamul et al.), thermo-viscoelastic-viscoplastic models (Cervera et al.), and the use of simulation to identify defective locations (Vijayaram et al.). These studies highlight the utility of numerical simulation in understanding and predicting casting phenomena, while also noting the complexity of factors like air gap formation and the need for significant formulation effort in FEM.

Purpose of the study:

The goals of this study were:

1. To understand the physics of the casting solidification process.

2. To identify factors affecting solidification.

3. To study the inter-relationship of these parameters and their influence on the solidification process.

4. To develop a mathematical model to determine temperature distribution during solidification.

5. To implement and test this model in ANSYS.

Core study:

The study conducted a transient thermal analysis on an assembly of an Aluminium alloy casting within two different mould types: a sand mould and a mullite mould. The objective was to predict the temperature distribution of the cast-mould assembly after 2 hours (7200 seconds) of pouring the molten Aluminium alloy at 600 K. The analysis was performed using the finite element method in ANSYS APDL 14.5 software. The study focused on the nonlinear case where the thermo-physical properties of the mould materials were temperature-dependent. The analysis aimed to determine the temperature distribution, heat flux, thermal gradient, and the cooling/heating curves in both the cast metal and the moulds.

5. Research Methodology

Research Design:

The research employed a two-dimensional, nonlinear, transient thermal analysis using the finite element method. A comparative study was designed to analyze the solidification of an aluminium alloy in two different mould materials, greensand and mullite, under identical initial conditions.

Data Collection and Analysis Methods:

The simulation was performed using ANSYS (version 14.5) software. The methodology was divided into three stages:

1. Pre-processing: This involved modeling the simulation topology, selecting element types, declaring material properties (temperature-dependent for moulds, constant for alloy), discretizing and meshing the geometry, and setting boundary conditions, including convection on the mould's external surface.

2. Solution: The analysis type was defined as transient. Thermal loads were applied, and the solution was initiated to simulate the heat transfer over a 7200-second period.

3. Post-processing: Results were reviewed using the general post-processor to view outcomes at specific time steps (e.g., colour-coded temperature contour plots) and the time history post-processor to analyze results over the entire duration (e.g., generating cooling and heating curves).

Research Topics and Scope:

The scope of the study was a 2D analysis of heat transfer during the casting of an aluminium alloy. It compared the effects of greensand and mullite moulds. The analysis accounted for temperature-dependent thermo-physical properties of the moulds, making the problem nonlinear. Convection at the mould's outer surface was considered. However, the study did not take into account metallurgical characteristics such as the attack zone in the feed head, and the effect of radiation was ignored.

6. Key Results:

Key Results:

- The temperature distributions were observed to be different in the two mould systems, with a larger range of temperature variation occurring within the sand mould.

- The thermal flow was greater in the sand mould system compared to the mullite mould system.

- Cooling curves generated for various points within the cast metal showed distinct solidification profiles depending on the mould material.

- Heating and cooling curves within the mould material demonstrated the heat dissipation process. Points near the casting interface (e.g., P8, P10 in the sand mould) exhibited both heating and subsequent cooling, whereas points farther from the interface only exhibited heating during the simulated period.

- A key finding was that the cooling curves for the entire system tended to converge, and this convergence was faster for the mullite mould. This indicates a higher rate of heat transfer from the casting to the mould in the mullite system.

Figure Name List:

- Temperature contour plots for sand mold

- Temperature contour plot for mullite mold

- Thermal flow in assembly

- Inside the Cast with Sand Mold for 2618

- Inside cast with mullite mold for 2618

- Inside the sand mould for 2618

- Inside mullite mould for 2618

- Inside cast with sand mould for 2024

- Inside cast with mullite mold for 2024

- Inside sand mould for 2024

- Inside mullite mold for 2024

7. Conclusion:

The present work concludes that if it is possible to predict the output results from a casting process prior to actual production, it becomes highly useful for making decisions on different casting parameters to achieve a better cast product. As previously mentioned, the ability to predict temperature distribution and thermal stress after solidification allows for casting defects to be kept to a minimum.

The future scope for this research includes:

1. Studying the effect of the Interfacial Heat Transfer Coefficient (IHTC) and radiation in more detail.

2. Extending the scope to other casting processes and materials beyond ferrous sand castings.

3. Considering more complex casting geometries.

4. Performing coupled field analysis.

5. Incorporating radiation boundary conditions into the analysis.

8. References:

- [1] Campbell, J., 1991, “Casting”, Butterworth-Heinemann, Oxford.

- [2] Campbell J., "Casting practice the 10 rules of casting," Elsevier Butterworth-Heinemann, Oxford, 1 st edition, 2004.

- [3] Pariona, M.M., Bolfarini, C. dos Santos, R.J. and Kiminami, C.S., 2000, "Application of Mathematical Simulation and Factorial Design Method to the Optimization the Atomization Stage in the Forming of a Cu–6% Zn Alloy", Journal of Materials Processing Technology, v.102, n.1, pp. 221-229.

- [4] Prabhu K.N., Chowdary B. and Venkatraman N., "Casting/Mould thermal contact transfer during solidification of Al-Cu-Si Alloy(LM 21) plates in thick and thin moulds," Journal of Material Engineering and Performance, Vol 14, No. 5, pp. 604-609, 2005

- [5] K N Seetharamu, R Paragasam, Ghulam a Quadir, Z A zainal, B Sathya Prasad and T Sundararajan "Finite element modelling of solidification phenomena” Journal of Material Engineering and Performance, Vol. 26,pp. 103–120.2001

- [6] Miguel Cervera, Carlos Agelet De Saracibar And Michele Chiumenti "thermo-mechanical analysis of industrial solidification processes", Int. J. Numer. Meth. Engng, 46, 1575{1591 (1999)

- [7] Sunanda Das, Dr. Rakesh L. Himte "Design & Analysis of Pure Iron Casting with Different Moulds" International Journal of Modern Engineering Research (IJMER), Vol. 3, Issue. 5, Sep - Oct. 2013 pp-2875-2887

- [8] Qiao Yin-hu, Zhang Chun-yan, Chen Jie-ping "Casting Forming Process simulation of Aluminium Flywheel" TELKOMNIKA, Vol. 11, No. 4, April 2013, pp. 1930~1933

- [9] T.R. Vijayaram, S. Sulaiman, A.M.S. Hamouda, M.H. Ahmad "Numerical simulation of casting solidification in permanent metallic molds", Journal of Materials Processing Technology 178 (2006) 29–33

- [10] A.A. Canales, J Talamantes-Silva, D Gloria, S. Valtierra, R. Colas "Thermal Analysis During Solidification of cast Al-Si alloys", Thermochimia Acta 510 (2010) 82-87

- [11] C.G. Kang, Y.I. Son,S.W. Youn, "Experimental investigation of semi-solid casting and die design by thermal fluid-solidification analysis",journal of Material Processing Technology 113(2001) 251-256

- [12] Prashant R. Anerao, Yashwant S. Munde "Thermal analysis of feeder neck using FEM for metal casting" International Journal of Emerging Technology and Advanced Engineering ISSN 2250-2459, Volume 2, 2012

- [13] Sergey V.Shepel, Samuel Paolucci "Numerical simulation of filling and solidification of permanent mold casting Applied Thermal Engineering 22 (2002) 229–248

- [14] Campbell J., “The new metallurgy of cast metals: Casting," Elsevier Butterworth Heinemann, Oxford, 3 rd edition, 2003.

- [15] M. M. Pariona and A. C. Mossi, "Numerical Simulation of Heat Transfer During the Solidification of Pure Iron in Sand and Mullite Molds", J. of the Braz. Soc. of Mech. Sci. & Eng., October-December 2005, Vol. XXVII, No. 4 / 399

- [16] K. Narayan Prabhu, Bheemappa Chowdary, and N. Venkataraman "Casting/Mold Thermal Contact Heat Transfer during Solidification of Al-Cu-Si Alloy (LM 21) Plates in Thick and Thin Molds", Journal of Materials Engineering and Performance, Volume 14(5) October 2005—605

- [17] K N Seetharamu, R Paragasam, Ghulam a Quadir, Z A zainal, B Sathya Prasad and T Sundararajan "Finite element modelling of solidification phenomena” Journal of Material Engineering and Performance, Vol. 26,pp. 103–120.2001

- [18] Miguel Cervera, Carlos Agelet De Saracibar And Michele Chiumenti "Thermo mechanical analysis of industrial solidification processes", Int. J. Numer. Meth. Engng, 46, 15751591 (1999)

Expert Q&A: Your Top Questions Answered

Q1: Why was a transient thermal analysis chosen for this study instead of a steady-state analysis?

A1: A transient analysis was essential because the study's objective was to track time-dependent phenomena. The paper states the goal is to "track the temperature distribution... during the solidification process and to calculate the solidification time of casting." Solidification is inherently a process that changes over time, so a transient analysis is required to capture the cooling curves and temperature changes from the initial pour to the final solidified state.

Q2: The study assumed constant thermo-physical properties for the aluminium alloy but temperature-dependent properties for the moulds. What was the reason for this distinction?

A2: The abstract specifies this choice, noting that the moulds' temperature-dependent properties make the problem "of nonlinear characteristic." This suggests the primary focus of the study's complexity was on accurately modeling the mould's behavior as it heats up from contact with the molten metal. While alloy properties also change with temperature, simplifying this aspect allowed the researchers to isolate and analyze the significant impact of the mould's changing thermal conductivity and specific heat on the overall heat transfer process.

Q3: What is the significance of observing different heating and cooling curves at various points within the mould itself?

A3: This observation demonstrates the thermal gradient and heat dissipation through the mould over time. As explained on page 6, points near the cast metal (e.g., P8, P6) experience a rapid temperature increase followed by a slow cooling period as the entire assembly moves towards thermal equilibrium. Points farther away (e.g., P7, P12) only experience a gradual heating during the 7200-second simulation, as the heat wave has not yet fully penetrated and begun to dissipate from those locations. This provides a detailed picture of how effectively the mould is drawing heat away from the casting.

Q4: The paper mentions that the effect of radiation was ignored. How might including radiation affect the simulation's accuracy?

A4: The paper explicitly states on page 4, "The effect of radiation was ignored here." While it does not speculate on the impact, radiation is a key mode of heat transfer, especially at the high temperatures involved in casting. It would primarily affect the heat loss from the external surface of the mould to the environment. The "Future Scope" section lists "Radiation boundary condition can also consider for analysis," acknowledging that its inclusion would represent a refinement to the model and likely improve its predictive accuracy.

Q5: What is the practical industrial implication of the finding that cooling curve convergence is faster in the mullite mould?

A5: On page 8, the paper states that faster convergence in the mullite mould "represent[s] more heat transfer from cast to mold." This has direct industrial consequences. A higher rate of heat extraction leads to faster solidification, which typically results in a finer grain structure in the final casting. This can improve mechanical properties like strength and hardness. Therefore, for an application requiring enhanced mechanical performance, a mullite mould may be superior to a standard sand mould.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenges of producing defect-free castings demand advanced predictive tools. This research effectively demonstrates that Aluminium Casting Simulation using finite element analysis is not just an academic exercise but a powerful industrial tool. By accurately modeling the complex heat transfer between the casting and different mould materials, engineers can foresee and mitigate issues like hot spots and undesirable cooling rates, which are root causes of common defects.

The key takeaway is that a simulation-driven approach allows for the optimization of process parameters, like mould material selection, before any metal is poured. This leads to reduced scrap, faster process development, and higher-quality final products.

"At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components."

Copyright Information

This content is a summary and analysis based on the paper "Study of Thermo-Physical Changes in Casting of Aluminium Alloy at Different Moulding Sands" by "Rahul Shukla, Amit Medhavi, Ambuj Kumar, and Shashank Kumar".

Source: http://indusedu.org

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.