This introductory paper is the research content of the paper "Recent developments in Copper Rotor Motors in China" published by [Publisher is not mentioned in the paper].

1. Overview:

- Title: Recent developments in Copper Rotor Motors in China

- Author: Daniel Liang, Yu Jiabin, Yang Xu, Victor Zhou, Wang Qin

- Publication Year: Not specified in the provided text.

- Published Journal/Society: Not specified in the provided text.

- Keywords: Copper rotor motors, die casting, high efficiency, motor standards, optimization.

2. Abstract

This paper mainly focuses on the recent progress in the: optimization of the production process, development of high efficiency copper rotor motors as well as new copper rotor motor standards in China. Optimization during the casting process makes it more economical to produce high quality copper rotors via casting. The development of IE3 and IE4 copper rotor motors are introduced, and the detailed performance analysis is given. The new national standards for super efficiency copper rotor motors and flame proof copper rotor motors are also introduced.

3. Research Background:

Background of the research topic:

- Squirrel cage induction motors are the most commonly used motors, accounting for over 85% of middle and small motor output in China in 2007 [1].

- These motors are widely used across various industries.

- Current rotors are typically produced by aluminum die casting.

- Copper has 40% higher electrical conductivity than aluminum.

Status of previous research:

It is known that the copper's conductivity of electricity is around 40% higher than that of aluminum.

Need for research:

- Replacing aluminum with copper in rotors can significantly reduce motor losses and increase overall efficiency.

- Copper rotors can enable higher energy efficiency for the same motor size, and potentially super premium efficiency.

- Copper's lower electrical resistivity allows for material reduction, potentially leading to lower cost, lighter weight, and smaller volume.

- Copper's anti-corrosion properties enhance environmental tolerance and reliability.

4. Research purpose and research question:

Research purpose:

- To elaborate on the latest development of cast copper rotors in China.

- To introduce the improvement of die casting techniques.

- To introduce the R&D of super premium motors and special motors.

- To introduce the promulgation of standards for die casting copper rotors.

Core research:

- Optimization of the copper die casting process to make it economically viable.

- Development of IE3 and IE4 copper rotor motors and performance analysis.

- Introduction of new national standards for super efficiency and flame-proof copper rotor motors.

5. Research methodology

The research methodology includes improvements in die-casting techniques, R&D of super-premium and special motors, and the development of standards. The die-casting improvements focus on:

- Melting Technology of Pure Copper: Addressing oxidation issues in large-scale production through a melting system, feeding system, and innovative protection methods.

- Copper Casting Process: Optimization of the casting process to minimize flaws and improve rotor quality, using simulation software and parameter control.

- Mold: Development of innovative mold materials, mold temperature field simulation software, and new mold structure designs.

The research also involves the development and property analysis of super-premium cast copper motors (NEMA Premium and IE3 series), including performance testing and comparison with existing standards.

6. Key research results:

Key research results and presented data analysis:

- A mature solution for producing cast copper rotors based on horizontal casting machines has been developed and is in commercial production.

- NEMA Premium and IE3 series super premium cast copper motors have been successfully developed.

- Table 1, NEMA Premium CMR motor series

- Table 2, IE3 efficiency CMR motor series

- Table 3, Efficiency measured by IEEE122B

- Table 4, Power factor standards comparison of YX3 series and cast copper rotors

- Table 5, Comparison of the max torque multiple standard value of YX3 series and cast copper motors

- Table 6, Comparison of actual test value and guarantee value of power factors of super premium cast copper rotor motors

- Table 7, Comparison of actual test value and guarantee value of the max torque multiples of super premium cast copper rotor motors

- Table 8, Comparison of actual test value and guarantee value of the locked torque multiples of super premium cast copper rotor motors

- Table 9, Comparison of actual test value and guarantee value of the locked current multiples of super premium cast copper rotor motors

- Super premium cast copper rotor motors exhibit:

- Efficiency meeting IE3 standards (tested per IEEE112 B).

- Reduced temperature increase, vibration, and noise compared to YX3 series motors.

- Lower power factors, which can be offset by power compensators.

- Higher maximum torque multiple (10% higher than YX3 series).

- Stable locked torque and improved start-up performance.

- New standards for YZTE3 (super premium) and YBZT (explosion protection) series cast copper rotor motors have been developed.

List of figure names:

- Figure 1, internal quality of cast copper rotors

7. Conclusion:

Summary of key findings:

- Cast copper rotors offer a simple and effective way to improve motor efficiency.

- The horizon casting machine-based production process for cast copper rotors is mature and economically viable.

- National standards for cast copper motors will promote their large-scale adoption.

- Cast copper rotors can significantly improve motor efficiency and contribute to sustainable development.

- The main technical indicators of super premium cast copper rotor are relatively reasonable after being proved in theory and in practice.

{Summary of research results. Academic significance of the research, practical implications of the research}

8. References:

- [1] Motor market research, Sino-Trust, 2008.

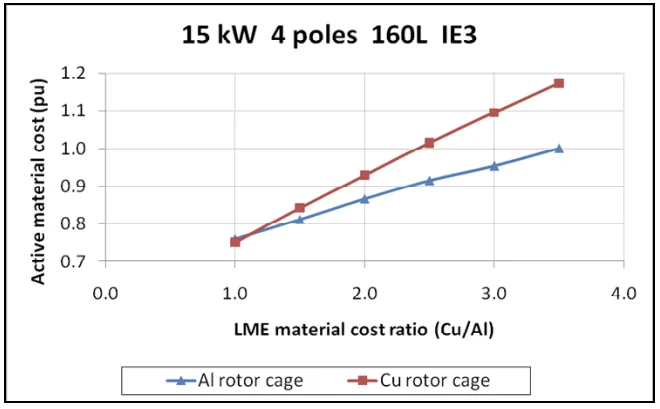

- [2] Daniel Liang, David Zhao, Victor Zhou, A Report on Analysis of the Performance and Cost of Energy Efficient and Super Efficient Copper Motor Rotor Based Motors, EEMODS'07 Conference Proceedings, Volume II, 2007, pp567-569.

9. Copyright:

- This material is a paper by "Daniel Liang, Yu Jiabin, Yang Xu, Victor Zhou, Wang Qin": Based on "Recent developments in Copper Rotor Motors in China".

- Source of paper: [DOI URL is not provided in the text]

This material was created to introduce the above paper, and unauthorized use for commercial purposes is prohibited. Copyright © 2025 CASTMAN. All rights reserved.