This paper summary is based on the article ['Advances in Metal Casting Technology: A Review of State of the Art, Challenges and Trends—Part I: Changing Markets, Changing Products'] presented at the ['Metals']

1. 概要:

- タイトル: Advances in Metal Casting Technology: A Review of State of the Art, Challenges and Trends—Part I: Changing Markets, Changing Products

- 著者: Dirk Lehmhus

- 出版年: 2022年

- 出版ジャーナル/学会: Metals, MDPI

- キーワード: Metal casting, primary shaping processes, light alloys, automotive industry, digitalization, Industry 4.0, smart manufacturing, E-Mobility, structural castings, additive manufacturing, environment

![Figure 2. “The fundamental interconnectedness of all things” [14]: In the words of my namesake, a visual guide through this present text (PART I in the diagram), and the following, second part (PART II) to be published in a few months’ time—four colors, four main chapters, four subsections and some selected links between them.](https://castman.co.kr/wp-content/uploads/image-591-1024x501.webp)

2. 研究背景:

研究トピックの背景:

金属鋳造は、人類が知る最も古い一次成形プロセスの一つです。鋳造部品の最初の例は数千年前のもので、主に銅ベースの合金が使用され、加工は通常、二分割の石またはセラミックの鋳型に依存していました。現代のインベストメント鋳造の前身であるロストワックス鋳造は、早くも6000年前に登場し、おそらくインダス文明に起源を持つと考えられています [1,2]。ヨーロッパでは、ギリシャ古代の青銅鋳物が金属鋳造の最初の頂点を画し、再び主にロストワックス法が用いられました [3,4]。

既存研究の状況:

19世紀の変わり目から、自動車の導入が転換点となり、新製品と大量生産を供給できる高い生産性プロセスをもたらしました。鋳造業界にとって、技術的および経済的な発展の組み合わせは、高圧および低圧ダイカストなどの新しいプロセスを促進しました。最初の圧力補助ダイカストマシンは、例えば、19世紀半ばに開発されました [11]。

研究の必要性:

鋳造業界は、他の製造業と同様に、絶え間ない変化にさらされています。最近、スマートマニュファクチャリング、スマートファクトリー、インダストリー4.0などの見出しの下に包含される開発によって、変化の速度と影響は増大しています。技術的なトレンドも状況に加わっています。ICE(内燃機関)を搭載した自動車から電気自動車への移行の影響は依然として不明確であり(セクション3.2.1参照)、大規模な構造鋳造への移行などの相殺効果を活用しているため、さらに不明確です(セクション3.2.2参照)。

3. 研究目的と研究課題:

研究目的:

本稿は、「金属鋳造技術の進歩」に関する Metals の特集号の紹介を提供することを目的としています。そうすることで、金属鋳造における選択された技術開発に焦点を当てるとともに、市場と境界条件における現在のトレンドも考慮に入れています。

主要な研究課題:

このレビューは、金属鋳造業界が直面している主要な課題と、それらが業界の将来に与える影響を調査します。特に、以下の分野に焦点を当てています。

- E-モビリティへの移行の影響

- 自動車構造鋳造の進展

- アディティブマニュファクチャリングの競争力

- 環境問題への対応

研究仮説:

この論文はレビュー論文であり、特定の仮説を検証するものではありません。しかし、金属鋳造業界は、技術革新と市場の変化に適応することで、競争力を維持し、新たな機会を創出できるという前提に基づいています。

4. 研究方法:

研究デザイン:

文献レビュー、解説記事

データ収集方法:

既存の文献、World Foundry Organization (WFO) のデータ、業界レポートのレビュー

分析方法:

記述分析、レビューされたデータに基づくトレンド分析

研究対象と範囲:

グローバルな金属鋳造業界、特に市場トレンド、技術開発、および課題に焦点を当てる。

5. 主な研究成果:

主要な研究成果:

- 2000年代初頭から2018年まで、世界の鋳造業界は着実に成長していましたが、2007年から2010年、および2014年から2016年の2つの停滞期がありました。2019年にはトン数の減少が見られましたが、COVID-19パンデミックと関連付けるのは疑問です。

- 中国は世界の鋳造業界を大幅に支配しており、インドと米国がそれに続いています。中国は世界の鋳造生産におけるシェアを2004年の28.1%から2019年の44.7%に増加させました。

- 鋳鉄、鋼、アルミニウムが世界の鋳造生産を支配する主要な材料クラスです。アルミニウム鋳物の生産量の増加と、鋳鉄の生産量の減少が予測されています。

- E-モビリティは、自動車業界における鋳造部品の需要に大きな影響を与えています。電気パワートレインは、ICEパワートレインよりも鋳造部品の重量が大幅に少なくなります。

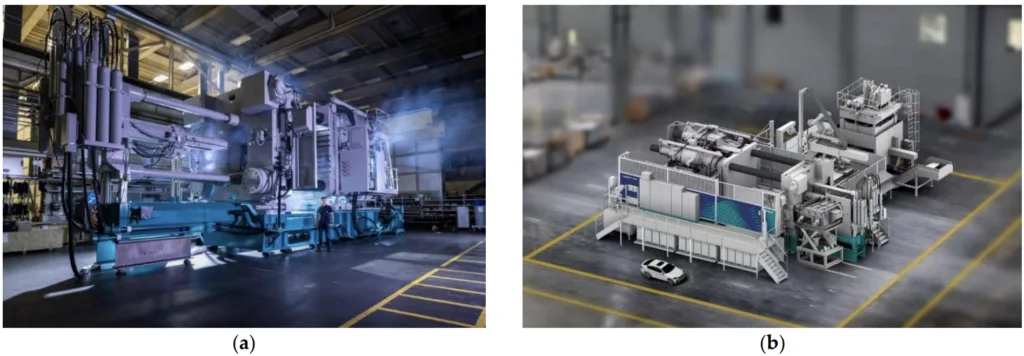

- 構造鋳造、特にギガキャスティングは、自動車業界でますます重要になっています。

- アディティブマニュファクチャリングは、鋳造業界にとって競争相手となる可能性がありますが、現時点では、主に特殊な機能を持つ鋳造部品の製造や、鋳造用の鋳型および中子の製造において補完的な技術と見なされています。

- 環境問題は、鋳造業界にますます影響を与えています。業界は、エネルギー消費、排出量、廃棄物を削減するための対策を講じる必要があります。

データ解釈:

表1と図3は、中国が世界の鋳造生産量で圧倒的なリーダーシップを握っていることを示しています。表2と図3は、鋳鉄が依然として最も生産量の多い材料ですが、アルミニウムの重要性が増していることを示しています。図4は、鋳鉄生産量が減少し、アルミニウム生産量が増加するという将来の予測を示しています。図6は、E-モビリティが自動車パワートレインの鋳造部品の重量に与える影響を示しており、電気自動車はICE車よりも大幅に軽量化されています。

図の名前リスト:

- Figure 1. Bronze art representing the history of casting across millennia and cultures, clockwise from top left: a Chinese Ding ritual cauldron of the late Shang Dynasty, 18–11th century BC [5]; the Dancing Girl of Mohenjo-Daro, Indus civilization, approx. 2300–1750 BC [6]; the Amitābha Buddha at Kamakura, Japan, allegedly cast in 1252 AD [7]; the bronze age Sun Chariot of Trundholm, Denmark, now at Nationalmuseet, Copenhagen, dating back to 1400 BC [8]; the Artemision Bronze, a classic Greek sculpture of either Poseidon or Zeus, cast in the 5th century BC [9]; the equestrian statue or Roman emperor Marcus Aurelius, 165–166 AD [10].

- Figure 2. "The fundamental interconnectedness of all things" [14]: In the words of my namesake, a visual guide through this present text (PART I in the diagram), and the following, second part (PART II) to be published in a few months' time—four colors, four main chapters, four subsections and some selected links between them.

- Figure 3. Graphical representation of the development of the relative importance of cast materials between 2004 and 2017 based on WFO data, as summarized in Table 2, (a) in absolute and (b) in relative numbers.

- Figure 4. Prognosis regarding future development of the casting industry until 2025 based on data presented by Büchner [28], covering (a,b) cast iron and (c,d) aluminum alloys in terms of absolute (a,c) and relative (b,d) figures. See Table 3 for production data per material class, including others.

- Figure 5. Projected development of the casting in industry according to the German Foundry Industry Association [29]: (a) Europe and (b) Asia, both with NAFTA data for comparison. Note the difference in the scale of the y-axis between (a,b).

- Figure 6. E-mobility's impact on the weight of castings in the automotive powertrain; (a) subcompact cars, (b) compact cars and (c) mid-size cars [35,36].

- Figure 7. Electric motor housing demonstrator cast at ae group using the MH Technologies ZLeak Tube® concept for realization of cooling channels: left, CAD image showing geometry and position of the tubes (tube length is approx. 1400 mm, outer diameter 14 mm, wall thickness 2 mm); center, CAD image of casting with runner, overflows, etc. with parts of the mold; right, photograph of an actual casting [44].

- Figure 8. The pitfalls of rotor casting made visible via advanced CT techniques by Yxlon in cooperation with Fraunhofer IFAM: photograph of the actual rotor (top left), 3D high-energy CT image highlighting porosity in short-circuit rings and conductor bars (top right), 2D conventional (bottom left) and high-energy CT image (bottom right), with the latter clearly showing the differences in discernability of features within the cast material (images courtesy of Yxlon and Fraunhofer IFAM [50]).

- Figure 9. State of the art and the shape and size of things to come: (a) Bühler's Carat 610 high-pressure die casting machine with a locking force of 61,000 kN—the person standing beside it may serve as an indication for the sheer size of this device, as does (b) the car in the rendering of the Carat 840 machine. The casting for the latter's movable die half's mounting plate alone weighs 99.5 tons (images provided by Bühler AG).

- Figure 10. Overview of global orders for HPDC machines with locking forces of 4000 t and above, as compiled by Gärtner and Zhou [73]. Note that there is some ambiguity in the data: nine smaller HPDC machines in the "unknown" category are linked to Tesla—here, it is not clear with which Giga Factory they are associated. Similarly, a batch of 8 machines of 5500 tons purportedly ordered by Tesla from IDRA for Grünheide and Fremont has been evenly shared between USA and Germany here.

- Figure 11. More promise than threat: binder jetting additive manufacturing used to produce molds and cores for sand casting. (a) Engine block core printed using an inorganic binder system, (b) water jacket core package printed with furan-based organic (black) and inorganic binders (Picture kindly provided by ExOne; copyright: ExOne).

![Figure 1. Bronze art representing the history of casting across millennia and cultures, clockwise from top left: a Chinese Ding ritual cauldron of the late Shang Dynasty, 18–11th century BC [5]; the Dancing Girl of Mohenjo-Daro, Indus civilization, approx. 2300–1750 BC [6]; the Amitabha Buddha at ¯ Kamakura, Japan, allegedly cast in 1252 AD [7]; the bronze age Sun Chariot of Trundholm, Denmark, now at Nationalmuseet, Copenhagen, dating back to 1400 BC [8]; the Artemision Bronze, a classic Greek sculpture of either Poseidon or Zeus, cast in the 5th century BC [9]; the equestrian statue or Roman emperor Marcus Aurelius, 165–166 AD [10]](https://castman.co.kr/wp-content/uploads/image-592-1024x791.webp)

![Figure 2. "The fundamental interconnectedness of all things" [14]: In the words of my namesake, a visual guide through this present text (PART I in the diagram), and the following, second part (PART II) to be published in a few months' time—four colors, four main chapters, four subsections and some selected links between them.](https://castman.co.kr/wp-content/uploads/image-593-678x1024.webp)

![Figure 4. Prognosis regarding future development of the casting industry until 2025 based on data presented by Büchner [28], covering (a,b) cast iron and (c,d) aluminum alloys in terms of absolute (a,c) and relative (b,d) figures. See Table 3 for production data per material class, including others.](https://castman.co.kr/wp-content/uploads/image-594-1024x708.webp)

![Figure 7. Electric motor housing demonstrator cast at ae group using the MH Technologies ZLeak Tube® concept for realization of cooling channels: left, CAD image showing geometry and position of the tubes (tube length is approx. 1400 mm, outer diameter 14 mm, wall thickness 2 mm); center, CAD image of casting with runner, overflows, etc. with parts of the mold; right, photograph of an actual casting [44].](https://castman.co.kr/wp-content/uploads/image-595-png.webp)

![Figure 8. The pitfalls of rotor casting made visible via advanced CT techniques by Yxlon in cooperation with Fraunhofer IFAM: photograph of the actual rotor (top left), 3D high-energy CT image highlighting porosity in short-circuit rings and conductor bars (top right), 2D conventional (bottom left) and highenergy CT image (bottom right), with the latter clearly showing the differences in discernability of features within the cast material (images courtesy of Yxlon and Fraunhofer IFAM [50]).](https://castman.co.kr/wp-content/uploads/image-596-png.webp)

6. 結論:

主な結果の要約:

金属鋳造業界は、市場の変化、技術革新、環境問題など、多くの課題に直面しています。E-モビリティへの移行、構造鋳造の普及、アディティブマニュファクチャリングの進展、環境規制の強化は、業界の将来を形作る主要な要因です。これらの課題にもかかわらず、金属鋳造業界は、技術革新と戦略的な適応を通じて、競争力を維持し、新たな成長機会を創出する可能性を秘めています。

研究の学術的意義:

このレビューは、金属鋳造技術の現状、課題、およびトレンドに関する包括的な概要を提供します。学術研究者や業界専門家にとって、業界の現状を理解し、将来の研究開発の方向性を検討するための貴重な情報源となります。

実践上の意義:

このレビューは、金属鋳造業界の企業が、市場の変化と技術革新に対応するための戦略を策定する上で役立ちます。特に、E-モビリティ、構造鋳造、アディティブマニュファクチャリング、環境問題への対応は、企業の競争力を維持し、成長を促進するために不可欠な要素です。

研究の限界:

このレビューは、著者の個人的な視点と活動に偏っている可能性があり、すべてのトピックを網羅しているわけではありません。特に、高圧ダイカストとアルミニウム合金に重点が置かれています。また、COVID-19パンデミックやウクライナ危機など、最近の出来事の影響を完全に反映しているわけではありません。

7. 今後のフォローアップ研究:

- フォローアップ研究の方向性

- セミソリッドプロセス、ハイブリッド鋳造、複合鋳造、スマート鋳造などの新しい技術に関するさらなる調査

- 高度なシミュレーション技術やデータ分析などのインダストリー4.0の側面に関する研究

- 鋳造の複雑さ、新素材、環境への影響低減など、さらなる探求が必要な分野の特定

- さらなる探求が必要な分野

- 鋳造の複雑さの増大に対応する技術

- 新しい合金および鋳造プロセスの開発

- 環境負荷を低減するための革新的なアプローチ

8. 参考文献:

- [1] Davey, C.J. The early history of lost-wax casting. In Metallurgy and Civilisation: Eurasia and Beyond; Mei, J., Rehren, T., Eds.; Archetype Books: London, UK, 2009; pp. 147-154.

- [2] Craddock, P.T. The Metal Casting Traditions of South Asia: Continuity and Innovation. Indian J. Hist. Sci. 2014, 50, 55–82. [CrossRef]

- [3] Mattusch, C.C. The Berlin Foundry Cup: The Casting of Greek Bronze Statuary in the Early Fifth Century B.C. Am. J. Archaeol. 1980, 84, 435-444. [CrossRef]

- [4] Mattusch, C.C. Greek Bronze Statuary: From the beginnings through the 5th Century B.C; Cornell University Press: Ithaca, NY, USA, 1988.

- [5] Mountain, Photograph of a Chinese Ding Ritual Cauldron, CC BY-SA 3.0. Available online: https://commons.wikimedia.org/w/index.php?curid=602198 (accessed on 26 October 2022).

- [6] Available online: http://www.columbia.edu/itc/mealac/pritchett/00routesdata/bce_500back/indusvalley/dancer/dancer.html (accessed on 26 October 2022).

- [7] Beyer, D. Photograph of Amitabha Buddha at Kamakura, Japan, CC BY-SA 3.0. Available online: https://commons.wikimedia.org/w/index.php?curid=230799 (accessed on 26 October 2022).

- [8] Nationalmuseet Copenhagen, Photograph of the Sun Chariot of Trundholm, CC BY-SA 3.0. Available online: https://commons.wikimedia.org/w/index.php?curid=90400464 (accessed on 26 October 2022).

- [9] Frantz, R.A. Photograph of the Sculpture of Zeus or Poseidon of Cape Artemision, CC BY-SA 3.0. Available online: https://commons.wikimedia.org/w/index.php?curid=2959518 (accessed on 26 October 2022).

- [10] Grandmont, J.-P. Photograph of Equestrian Sculpture of Marc Aurel, CC BY-SA 3.0. Available online: https://commons.wikimedia.org/w/index.php?curid=25800464 (accessed on 26 October 2022).

- [11] Murray, M.T. High pressure die casting of aluminium alloys. In Fundamentals of Aluminium Metallurgy: Production, Processing and Applications; Lumley, R., Ed.; Woodhead Publishing: Philadelphia, PA, USA, 2011.

- [12] Tripsas, M. Surviving Radical Technological Change through Dynamic Capability: Evidence from the Typesetter Industry. Ind. Corp. Chang. 1997, 6, 341-377. [CrossRef]

- [13] Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [CrossRef]

- [14] Adams, D. Dirk Gently's Holistic Detective Agency; William Heinemann Ltd.: London, UK, 1987.

- [15] Available online: http://www.thewfo.com/contentfiles/downloads/51.pdf (accessed on 26 October 2022).

- [16] Available online: http://www.thewfo.com/contentfiles/downloads/7.pdf (accessed on 26 October 2022).

- [17] Available online: http://www.thewfo.com/contentfiles/downloads/6.pdf (accessed on 26 October 2022).

- [18] Available online: http://www.thewfo.com/contentfiles/downloads/5.pdf (accessed on 26 October 2022).

- [19] Available online: http://www.thewfo.com/contentfiles/downloads/4.pdf (accessed on 26 October 2022).

- [20] Available online: http://www.thewfo.com/contentfiles/downloads/3.pdf (accessed on 26 October 2022).

- [21] Available online: http://www.thewfo.com/contentfiles/downloads/2.pdf (accessed on 26 October 2022).

- [22] Available online: http://www.thewfo.com/contentfiles/downloads/1.pdf (accessed on 26 October 2022).

- [23] Available online: http://www.thewfo.com/contentfiles/downloads/31.pdf (accessed on 26 October 2022).

- [24] Available online: http://www.thewfo.com/contentfiles/downloads/35.pdf (accessed on 26 October 2022).

- [25] Available online: http://www.thewfo.com/contentfiles/downloads/41.pdf (accessed on 26 October 2022).

- [26] Available online: http://www.thewfo.com/contentfiles/downloads/44.pdf (accessed on 26 October 2022).

- [27] Available online: http://www.thewfo.com/contentfiles/downloads/49.pdf (accessed on 26 October 2022).

- [28] Büchner, H.-J. Forecast 2025 for the global Foundry Industry. In Proceedings of the Presentation at GIFA 2019, 14th International Casting Trade Fair, Düsseldorf, Germany, 25-29 June 2020.

- [29] Mettler, S.; Schmitz-Cohnen, K. Guss 2035—Neue Perspektiven für Die Gießereiindustrie. Bundesverband der Deutschen Gießereiindustrie (BDG): Düsseldorf, DE, 2022. Available online: https://www.guss.de/fileadmin/user_upload/leitfaeden_und_broschueren/studie_guss_2035.pdf (accessed on 8 October 2022).

- [30] Spada, A. Revitalization of North American Metalcasting. Available online: https://www.diecasting.org/docs/statistics/NorthAmerica.pdf (accessed on 26 October 2022).

- [31] Available online: https://www.guss.de/organisation/bdg/branche (accessed on 8 October 2022).

- [32] Available online: https://www.guss.de/organisation/presseinformation/ukraine-umfrage (accessed on 26 October 2022).

- [33] Bonollo, F.; Gramegna, N.; Timelli, G. High-Pressure Die-Casting: Contradictions and Challenges. JOM 2015, 67, 901-908. [CrossRef]

- [34] Messer, J. The 4 Challenges in Aluminum HPDC—Aluminum Foundry Industry Is Changing. Johannes Messer Consulting GmbH, 14 January 2019. Available online: https://johannes-messer-consulting.de/pdf/the_4_challenges_in_aluminum_hpdc.pdf (accessed on 26 October 2022).

- [35] Wilhelm, C.; Kallien, L.H. Einfluss der Elektromobilität auf die Gussproduktion In der deutschen Gießereiindustrie—Influence of electromobility on the German casting industry. Prozesswärme 2018, 7, 35–40.

- [36] Wilhelm, C.; Kallien, L.H.; Görgün, V. Einfluss der Elektromobilität auf die Gussproduktion in der deutschen Gießereiindustrie (Teil 2)-Influence of electromobility on the German casting industry (Part 2). Prozesswärme 2019, 1, 39–46.

- [37] Chong, Y.C.; Staton, D.; Gai, Y.; Adam, H.; Popescu, M. Review of Advanced Cooling Systems of Modern Electric Machines for EMobility Application. In Proceedings of the 2021 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD 2021), Modena, Italy, 8-9 April 2021. [CrossRef]

- [38] Scherer, H.; Bek, M.; Kilian, S. ZF New 8-speed Automatic Transmission 8HP70—Basic Design and Hybridization. SAE Int. J. Engines 2009, 2, 314-326. [CrossRef]

- [39] Lahaye-Geusen, M. Leichtes und Kompaktes Gehäuse für Achtgang-Automatikgetriebe-Viel Funktion auf Wenig Raum. Available online: https://automobilkonstruktion.industrie.de/allgemein/viel-funktion-auf-wenigraum/ (accessed on 19 July 2021).

- [40] Lehmhus, D.; Pille, C.; Rahn, T.; Struss, A.; Gromzig, P.; Seibel, A.; Wischeropp, T.; Becker, H.; Diefenthal, F. Druckgießen und Additive Fertigung: Durch strategische Kombination das Beste aus zwei Welten nutzen. Giesserei 2021, 108, 36-43.

- [41] Rupp, S.; Heppes, F. Combicore—Giesskerne für den Druckguss. Giess. Erfahr. 2013, 3, 6–9.

- [42] Jelinek, P.; Adamkova, E.; Miksovsky, F.; Beno, J. Advances in Technology of Soluble Cores for Die Castings. Arch. Foundry Eng. 2015, 15, 29-34. [CrossRef]

- [43] Kim, J.S.; Yoo, J. High Pressure Die Casting Core and Preparation Method of High Pressure Die Casting Core. Korean Patent KR101965669B1, 4 April 2019.

- [44] Lehmhus, D.; Pille, C.; Borheck, D.; Bumbu, F.; Schwegler, T.; Lee, J.; Yoo, J.; Lutze, P.; Vomhof, R.; Weiss, K. Leckagefreie Kühlkanäle für Druckguss-Gehäusekomponenten. Giesserei 2021, 108, 40–49.

- [45] Feikus, F.J.; Bernsteiner, P.; Gutiérrez, R.F.; Luszczak, M. Further Development of Electric Motor Housings. MTZ Worldw. 2020, 81, 38-43. [CrossRef]

- [46] Jin, Y.; Song, Y.; Liu, Y.; Cui, W.; Sun, C. Design of low-pressure sand casting process for water-cooled motor shell in electric vehicles. J. Phys. Conf. Ser. 2021, 2102, 012052. [CrossRef]

- [47] Chen, H.; Yang, L.; Long, J. First-principles investigation of the elastic, Vickers hardness and thermodynamic properties of Al-Cu intermetallic compounds. Superlattices Microstruct. 2015, 79, 156-165. [CrossRef]

- [48] Kim, K.; Kim, D.; Park, K.; Cho, M.; Cho, S.; Kwon, H. Effect of Intermetallic Compounds on the Thermal and Mechanical Properties of Al-Cu Composite Materials Fabricated by Spark Plasma Sintering. Materials 2019, 12, 1546. [CrossRef]

- [49] Kim, D.; Kim, K.; Kwon, H. Interdiffusion and Intermetallic Compounds at Al/Cu Interfaces in Al-50vol.%Cu Composite Prepared by Solid-State Sintering. Materials 2021, 14, 4307. [CrossRef]

- [50] Pille, C.; Mäurer, G. A Look into the hidden—The First Complete CT of Cast Rotors in Electric Asynchronous Motors. Insp. Int. 2020, 2, 12-13.

- [51] Yun, J.; Lee, S.B. Influence of Aluminum Die-Cast Rotor Porosity on the Efficiency of Induction Machines. IEEE Trans. Magn. 2018, 54, 8104905. [CrossRef]

- [52] Jeong, M.; Yun, J.; Park, Y.; Lee, S.B.; Gyftakis, K. Quality Assurance Testing for Screening Defective Aluminum Die-Cast Rotors of Squirrel Cage Induction Machines. IEEE Trans. Ind. Appl. 2018, 54, 2246–2254. [CrossRef]

- [53] Lee, C.-Y.; Huang, K.-Y.; Jen, L.-Y.; Zhuo, G.-L. Diagnosis of Defective Rotor Bars in Induction Motors. Symmetry 2020, 12, 1753. [CrossRef]

- [54] Khaliq, A.; Rhamdhani, M.A.; Brooks, G.A.; Grandfield, J. Proceedings in Light Metals 2011; Lindsay, S.J., Ed.; Springer: Cham, Switzerland, 2011; pp. 751–756.

- [55] Rhamdhani, M.A.; Grandfield, J.F.; Khaliq, A.; Brooks, G. Light Metals 2013; Sadler, B.A., Ed.; Springer: Cham, Switzerland, 2013; pp. 33-38.

- [56] Kotiadis, S.; Zimmer, A.; Elsayed, A.; Vandersluis, E.; Ravindran, C. High Electrical and Thermal Conductivity Cast Al-Fe-Mg-Si alloys with Ni Additions. Metall. Mater. Trans. A 2020, 51A, 4195-4214. [CrossRef]

- [57] Kim, C.-W.; Cho, J.-I.; Choi, S.-W.; Kim, Y.-C. The effect of alloying elements on thermal conductivity of aluminum alloys in high pressure die casting. Adv. Mater. Res. 2013, 813, 175-178. [CrossRef]

- [58] Abdo, H.S.; Seikh, A.H.; Mohammed, J.A.; Soliman, M.S. Alloying Elements Effects on Electrical Conductivity and Mechanical Properties of Newly Fabricated Al Based Alloys Produced by Conventional Casting Processes. Materials 2021, 14, 3971. [CrossRef] [PubMed]

- [59] Kim, J.-M.; Yun, H.-S.; Shin, J.-S.; Kim, K.-T.; Ko, S.-H. Mold filling ability and hot cracking susceptibility of Al-Fe-Ni alloys for high conductivity applications. J. Teknol. 2015, 75, 71-77. [CrossRef]

- [60] Li, K.; Zhang, J.; Chen, X.; Yin, Y.; He, Y.; Zhou, Z.; Guan, R. Microstructure evolution of eutectic Si in Al-7Si binary alloy by heat treatment and its effect on enhancing thermal conductivity. J. Mater. Res. Technol. 2020, 9, 8780-8786. [CrossRef]

- [61] Vandersluis, E.; Lombardi, A.; Ravindran, C.; Bois-Brochu, A.; Chiesa, F.; MacKay, R. Factors influencing thermal conductivity and mechanical properties in 319 Al alloy cylinder heads. Mater. Sci. Eng. A 2015, 648, 401-411. [CrossRef]

- [62] Vandersluis, E.; Ravindran, C. The Role of Porosity in Reducing the Thermal Conductivity of B319 Al Alloy with Decreasing Solidification Rate. JOM 2019, 71, 2072–2077. [CrossRef]

- [63] Vandersluis, E.; Ravindran, C. Influence of solidification rate on the microstructure, mechanical properties, and thermal conductivity of cast A319 Al alloy. J. Mater. Sci. 2019, 54, 4325-4339. [CrossRef]

- [64] Visnic, B. Tesla Casts a New Strategy for Lightweight Structures. Automot. Eng. 2020, 6, 12–14. Available online: https://www.nxtbook.com/nxtbooks/sae/20AUTP06/index.php#/p/12 (accessed on 4 January 2021).

- [65] Tesla's Switch to Giga Press Die Castings for Model 3 Eliminates 370 Parts. Available online: https://www.designnews.com/automotive-engineering/teslas-switch-giga-press-die-castings-model-3-eliminates-370-parts (accessed on 4 January 2022).

- [66] Kallas, M.K. Multi-Directional Unibody Casting Machine for a Vehicle Frame and Associated Methods. US Patent Application US 2019/0217380 A1, 18 July 2019.

- [67] Available online: https://www.buhlergroup.com/content/buhlergroup/global/en/products/carat_die-castingmachine.html (accessed on 4 January 2022).

- [68] Available online: https://www.teslarati.com/idra-9000-ton-giga-press/ (accessed on 8 October 2022).

- [69] Stegmaier, G. Alu-Guss Statt nur Schwedenstahl: Volvo Investiert 1 Milliarde in Tesla-Trick. Available online: https://www.auto-motor-und-sport.de/tech-zukunft/volvo-mega-casting-alu-elektroauto-produktion-nachhaltigkeit-neue-e-auto-plattformen/ (accessed on 10 February 2022).

- [70] Kacher, G.; Johannsen, F. Aus einem Guss. In der Neuen Trinity-Fabrik von Volkswagen Sollen Karosserien Nicht Mehr Geschweißt Werden-Tesla dient als Vorbild; Automobilwoche: Weßling, Germany, 2022.

- [71] Available online: http://www.lk.world/us/news_detail.php?type=&nid=455 (accessed on 10 February 2022).

- [72] Available online: https://www.laitimes.com/en/article/3kycy_41ndm.html (accessed on 8 October 2022).

- [73] Gärtner, J.; Zhou, Y. Realized & Planned Installment Of GIGA-/MEGA-Presses “By Whom-When-Where-Why” Insights & Prospects. In Proceedings of the 3rd VDI-Fachkonferenz Gießtechnik und E-Mobilität, Bremen, Germany, 18–19 October 2022.

- [74] Rai, A.; Sawant, S.S.; Winberg, P.; Burgess, M.; Spencer, T.; Kornmayer, P.; Pattinson, G.; Edwards, P.D.; Rinaldi, C.; Reikher, A.; et al. Integrated Energy Absorbing Castings. Patent Publication Number WO/2022/031991, 5 August 2021.

- [75] Tayal, R.K.; Singh, V.; Kumar, S.; Garg, R. Compound Casting-A Literature Review. In Proceedings of the National Conference on Trends and Advances in Mechanical Engineering, Faridabad, India, 19–20 October 2012; pp. 501–510.

- [76] Lehmhus, D.; von Hehl, A.; Hausmann, J.; Kayvantash, K.; Alderliesten, R.; Hohe, J. New Materials and Processes for Transport Applications: Going Hybrid and Beyond. Adv. Eng. Mater. 2019, 21, 1900056. [CrossRef]

- [77] Yurko, J.A.; Martinez, R.A.; Flemings, M.C. The Use of Semi-Solid Rheocasting (SSR) for Aluminum Automotive Castings. SAE Trans. J. Mater. Manuf. 2003, 112, 119–123.

- [78] Roos, H.J.; Lagler, M.; Quintana, L. Whitepaper: Die Zukunft von Strukturbauteilen für Druckgusslösungen. Bühler AG, 2019. Available online: https://assetcdn.buhlergroup.com/asset/874601345621/86bd505f19e643b2b3ce79957169681c (accessed on 24 February 2022).

- [79] Sigworth, G.K.; Donahue, R.J. The Metallurgy of Aluminum Alloys for Structural High Pressure Die Castings. Int. J. Met. 2021, 15, 1031-1046. [CrossRef]

- [80] Kang, J.W.; Ma, Q.-X. The role and impact of 3D printing technologies in casting. China Foundry 2017, 14, 157-168. [CrossRef]

- [81] Roth, C.C.; Tancogne-Dejean, T.; Mohr, D. Plasticity and fracture of cast and SLM AlSi10Mg: High throughput testing and modelling. Addit. Manuf. 2021, 43, 101998. [CrossRef]

- [82] Lehmhus, D.; Busse, M. Structural Health Monitoring. In Material-Integrated Intelligent Systems—Technology and Applications; Bosse, S., Lehmhus, D., Lang, W., Busse, M., Eds.; Wiley-VCH Verlag: Weinheim, Germany, 2018; pp. 531-594.

- [83] Lores, A.; Azurmendi, N.; Agote, I.; Zuza, E. A review on recent developments in binder jetting metal additive manufacturing: Materials and process characteristics. Powder Metall. 2019, 62, 267-296. [CrossRef]

- [84] Li, M.; Du, W.; Elwany, A.; Pei, Z.; Ma, C. Metal binder jetting additive manufacturing: A literature review. J. Manuf. Sci. Eng. 2020, 142, 090810. [CrossRef]

- [85] Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing-Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [CrossRef]

- [86] Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + Arc Additive Manufacturing. Mater. Sci. Technol. 2016, 32, 641-647. [CrossRef]

- [87] Lehmhus, D.; Busse, M. Sensor Integration in Additive Manufacturing. In Material-Integrated Intelligent Systems—Technology and Applications; Bosse, S., Lehmhus, D., Lang, W., Busse, M., Eds.; Wiley-VCH Verlag: Weinheim, Germany, 2018; pp. 217–256.

9. 著作権:

- この資料は、"[Dirk Lehmhus]"氏の論文: "[Advances in Metal Casting Technology: A Review of State of the Art, Challenges and Trends—Part I: Changing Markets, Changing Products]"に基づいています。

- 論文ソース: https://doi.org/10.3390/met12111959

この資料は上記の論文に基づいて要約されたものであり、商業目的での無断使用は禁止されています。

Copyright © 2025 CASTMAN. All rights reserved.