1. 概要:

- 論文題名: Design of gravity assisted heat exchanger and its application on enhanced waste heat recuperation utilizing organic Rankine and LNG system

- 著者: Rizvi Arefin Rinik, Naimul Islam, M. Monjurul Ehsan, Yasin Khan

- 発行年: 2024

- 発行雑誌/学会: International Journal of Thermofluids

- キーワード: 廃熱、重力熱交換器、有機ランキンサイクル、複合サイクル、パラメトリック最適化

2. 研究背景:

世界的なエネルギー需要の高まりと化石燃料枯渇の問題を背景に、廃熱回収技術の重要性が増しています。従来の廃熱回収技術は、初期投資コストや廃熱源の温度制限、汚れによる目詰まりなどの課題を抱えています。本研究は、これらの課題を克服するため、重力を利用した革新的な熱交換器システムを提案し、有機ランキンサイクル(ORC)と液化天然ガス(LNG)サイクルを組み合わせることで、低品位廃熱からの効率的なエネルギー回収を目指しています。

3. 研究目的と研究問い:

- 研究目的: 重力アシスト熱交換器とORC/LNG複合システムを用いた廃熱回収システムの設計、最適化、性能評価を行う。

- 核心研究問い: 重力アシスト熱交換器の最適な動作パラメータは何か?ORC/LNG複合システムのエネルギー効率を最大化するにはどうすればよいか?経済的観点から見て、重力アシスト熱交換器は既存の熱交換器に比べて優れているか?

- 研究仮説: 重力アシスト熱交換器は従来の熱交換器よりも効率的で経済的な廃熱回収を実現できる。ORC/LNG複合システムは、廃熱からのエネルギー回収をさらに向上させる。

4. 研究方法:

- 研究設計: 重力アシスト熱交換器、ORCサイクル、LNGサイクルを統合したシステムの設計と数値シミュレーション。

- データ収集方法: 既存の文献調査、数値解析、実験データを用いた検証。

- 分析方法: 熱伝達解析、エネルギー効率試験、エクセルギー分析、パラメトリック最適化、経済性分析。

- 研究対象と範囲: 繊維産業における熱設定機からの廃熱を対象とした数値シミュレーションと実験検証。

5. 主要な研究結果:

- 核心的な発見: 重力アシスト熱交換器は、最適温度275℃~280℃、空気流量35kg/sにおいて、約52.3%の高い有効性を示した。ORCサイクルは、ペンタン質量流量3.3kg/sで最大効率36.8%を達成。コンデンサ圧力の増加により、ORCタービン出力は220kWから240kWに、LNGタービン出力は25kWから40kWに増加。経済性分析の結果、設計された重力アシスト熱交換器は、汚れた排ガスからの廃熱回収において経済的に実現可能であることが示された。ピンチ温度が7℃上昇すると、システムのエクセルギー効率は4.94%低下する。

- 統計的/定性的分析結果: 様々な動作パラメータ(空気流量、排ガス温度、ORC作動流体、コンデンサ圧力など)に対するシステム性能の変化を数値シミュレーションと実験結果を用いて分析。

- データ解釈: シミュレーション結果と実験結果を比較することで、モデルの妥当性を検証し、最適な動作パラメータを特定。

- 図表リスト:

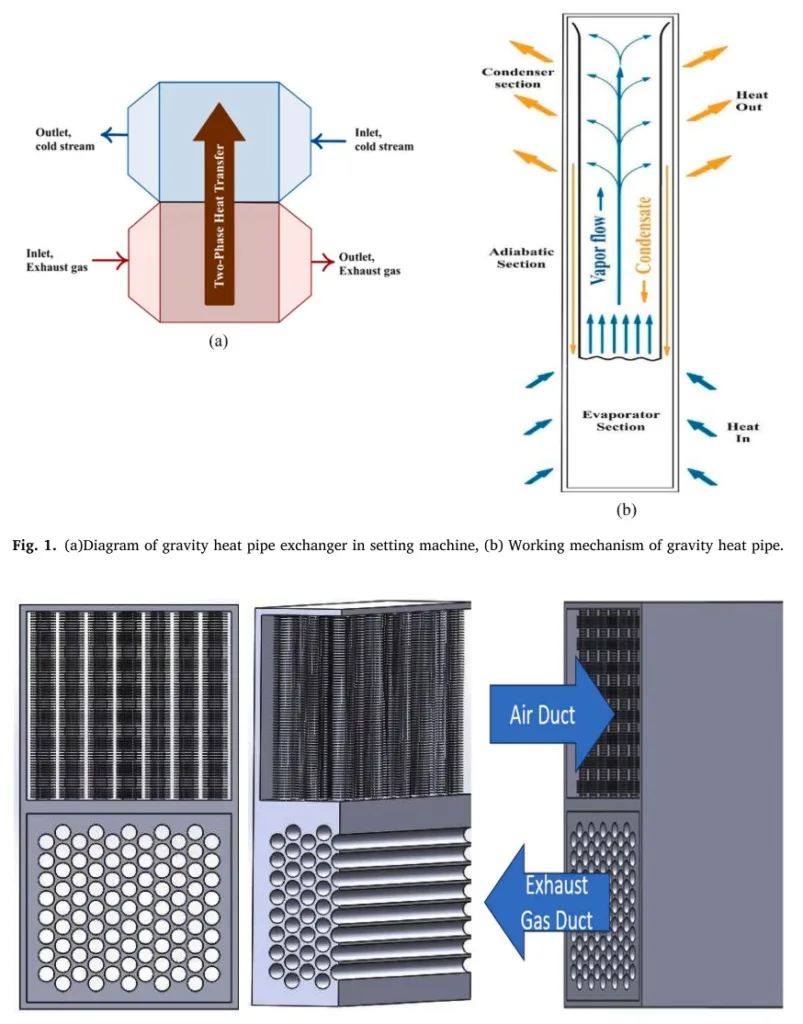

- 図1:重力熱交換器の模式図、

- 図2:設計された重力熱交換器の模式図、

- 図3:統合ハイブリッドシステム図、

- 図4:数値モデルの枠組み、

- 図5:モデル検証結果、

- 図6:伝熱係数と圧力降下、

- 図7:伝熱量と熱交換器有効性、

- 図8:ORCタービン入口圧力と発電出力、

- 図9:ORCタービン入口温度とサイクル効率、

- 図10:ORCコンデンサ圧力と発電出力、

- 図11:ORCコンデンサ圧力とエクセルギー効率、

- 図12:作動流体の影響、

- 図13:熱源温度とエクセルギー効率、

- 図14:ピンチ温度とシステム性能、

- 図15:各構成要素におけるエクセルギー損失、

- 図16:ORCタービン入口圧力とエクセルギー効率、

- 図17:コンデンサ圧力とエクセルギー損失、

- 図18:経済性分析、

- 図19:経済性比較

6. 結論と考察:

本研究は、重力アシスト熱交換器とORC/LNG複合システムを用いた廃熱回収システムを提案し、その有効性と経済性を示しました。数値シミュレーションと実験検証により、システムの最適な動作パラメータを明らかにし、高いエネルギー回収効率と経済性を達成できることを確認しました。本システムは、特に低品位廃熱を有する繊維産業などの分野において、環境負荷低減とエネルギー効率向上に大きく貢献する可能性があります。ただし、本研究では特定の産業における廃熱を対象としているため、他の産業への適用可能性についてはさらなる検討が必要です。

7. 今後の研究:

- 今後の研究方向: 様々な産業分野への適用可能性を検証、より複雑なシステムモデルの構築、より高精度な経済性分析、実験装置の改良による更なる検証。

- 追加調査が必要な分野: 異なる作動流体、熱交換器構造、制御戦略などを検討し、システム性能のさらなる向上を目指す。

8. 参考文献要約:

論文中には、廃熱回収、有機ランキンサイクル、LNGサイクル、重力熱交換器、熱力学的最適化、経済性評価に関する多数の参考文献が引用されています。これらの文献は、本研究の基礎となる知見を提供しており、研究の妥当性を高めています。

- [1] M.A. Islam, H.S. Che, M. Hasanuzzaman, N.A. Rahim, Energy demand forecasting. Energy for Sustainable Development, Elsevier, 2020, pp. 105–123, https://doi.org/ 10.1016/B978-0-12-814645-3.00005-5.

- [2] D.M. Arias, O. García-Valladares, G. Besagni, C.N. Markides, A vision of renewable thermal technologies for drying, biofuels production and industrial waste, gas or water recovery, Appl. Therm. Eng. 223 (2023) 120022, https://doi.org/10.1016/j. applthermaleng.2023.120022.

- [3] S.S. Siwal, et al., Recovery processes of sustainable energy using different biomass and wastes, Renew. Sustain. Energy Rev. 150 (2021) 111483, https://doi.org/ 10.1016/j.rser.2021.111483.

- [4] S. Nallathambi, K. Ramasamy, Prediction of electricity consumption based on DT and RF: an application on USA country power consumption, in: 2017 IEEE International Conference on Electrical, Instrumentation and Communication Engineering (ICEICE), IEEE, 2017, pp. 1–7, https://doi.org/10.1109/ ICEICE.2017.8191939.

- [5] D. Pashchenko, Natural gas reforming in thermochemical waste-heat recuperation systems: a review, Energy 251 (Jul. 2022) 123854, https://doi.org/10.1016/j. energy.2022.123854.

- [6] Y. Zhao, et al., A comparative study of energy consumption and efficiency of Japanese and Chinese manufacturing industry, Energy Policy 70 (2014) 45–56, https://doi.org/10.1016/j.enpol.2014.02.034.

- [7] B. Liu, M. Lu, B. Shui, Y. Sun, W. Wei, Thermal-hydraulic performance analysis of printed circuit heat exchanger precooler in the Brayton cycle for supercritical CO2 waste heat recovery, Appl. Energy 305 (2022) 117923, https://doi.org/10.1016/j. apenergy.2021.117923.

- [8] S.M. Hosseinnia, M. Sorin, A systematic pinch approach to integrate stratified thermal energy storage in buildings, Energy Build. 232 (2021) 110663, https://doi. org/10.1016/j.enbuild.2020.110663.

- [9] Z. Zhang, L. Zhang, Y. Yuan, Numerical simulation of turbulent natural convection heat transfer in an MW-class offshore wind turbine nacelle based on a multi-feature acquisition meshing technique, Sustain. Energy Technol. Assess. 57 (2023) 103249, https://doi.org/10.1016/j.seta.2023.103249.

- [10] D. Brough, J. Ramos, B. Delpech, H. Jouhara, Development and validation of a TRNSYS type to simulate heat pipe heat exchangers in transient applications of waste heat recovery, Int. J. Thermofluids 9 (2021) 100056, https://doi.org/ 10.1016/j.ijft.2020.100056.

- [11] E. Tian, Y.-L. He, W.-Q. Tao, Research on a new type waste heat recovery gravity heat pipe exchanger, Appl. Energy 188 (2017) 586–594, https://doi.org/10.1016/ j.apenergy.2016.12.029.

- [12] L.Y. Zhang, et al., Experimental investigation and economic analysis of gravity heat pipe exchanger applied in communication base station, Appl. Energy 194 (2017) 499–507, https://doi.org/10.1016/j.apenergy.2016.06.023.

- [13] X. Liu, X. Han, Z. Wang, G. Hao, Z. Zhang, Y. Chen, Application of an anti-gravity oscillating heat pipe on enhancement of waste heat recovery, Energy Convers. Manage 205 (2020) 433–444, https://doi.org/10.1016/j.enconman.2019.112404.

- [14] Z. Guo, J. Yang, Z. Tan, X. Tian, Q. Wang, Numerical study on gravity-driven granular flow around tube out-wall: Effect of tube inclination on the heat transfer, Int. J. Heat. Mass Transf. 174 (2021) 121296, https://doi.org/10.1016/j. ijheatmasstransfer.2021.121296.

- [15] H. Jouhara, N. Nieto, B. Egilegor, J. Zuazua, E. Gonz´alez, I. Yebra, A. Igesias, B. Delpech, S. Almahmoud, D. Brough, J. Malinauskaite, A. Vlasopoulos, M. Hill, B. Axcell, Waste heat recovery solution based on a heat pipe heat exchanger for the aluminium die casting industry, Energy 266 (2023), https://doi.org/10.1016/j. energy.2022.126459.

- [16] M. Imran, R. Pili, M. Usman, F. Haglind, Dynamic modeling and control strategies of organic Rankine cycle systems: methods and challenges, Appl. Energy 276 (2020) 115537, https://doi.org/10.1016/j.apenergy.2020.115537.

- [17] P.R. Gupta, A.K. Tiwari, Z. Said, Solar organic Rankine cycle and its polygeneration applications – a review, Sustain. Energy Technol. Assess. 49 (2022) 101732, https://doi.org/10.1016/j.seta.2021.101732.

- [18] R. Loni, et al., A critical review of power generation using geothermal-driven organic Rankine cycle, Therm. Sci. Eng. Progr. 25 (2021) 101028, https://doi.org/ 10.1016/j.tsep.2021.101028.

- [19] C. Wieland, et al., Innovations for organic Rankine cycle power systems: current trends and future perspectives, Appl. Therm. Eng. 225 (2023) 120201, https://doi. org/10.1016/j.applthermaleng.2023.120201.

- [20] S. Hu, J. Li, F. Yang, Z. Yang, Y. Duan, Multi-objective optimization of organic Rankine cycle using hydrofluorolefins (HFOs) based on different target preferences, Energy 203 (2020) 117848, https://doi.org/10.1016/j. energy.2020.117848.

- [21] X. Li, et al., Organic Rankine cycle systems for engine waste-heat recovery: Heat exchanger design in space-constrained applications, Energy Convers. Manage 199 (2019) 111968, https://doi.org/10.1016/j.enconman.2019.111968.

- [22] M.A. Chatzopoulou, S. Lecompte, M. De Paepe, C.N. Markides, Off-design optimisation of organic Rankine cycle (ORC) engines with different heat exchangers and volumetric expanders in waste heat recovery applications, Appl. Energy 253 (2019) 113442, https://doi.org/10.1016/j.apenergy.2019.113442.

- [23] Z. Zheng, J. Cao, W. Wu, M.K.H. Leung, Parallel and in-series arrangements of zeotropic dual-pressure Organic Rankine Cycle (ORC) for low-grade waste heat recovery, Energy Rep. 8 (2022) 2630–2645, https://doi.org/10.1016/j. egyr.2022.01.057.

- [24] J. Song, X. Li, K. Wang, C.N. Markides, Parametric optimisation of a combined supercritical CO2 (S-CO2) cycle and organic Rankine cycle (ORC) system for internal combustion engine (ICE) waste-heat recovery, Energy Convers. Manage 218 (Aug. 2020) 112999, https://doi.org/10.1016/j.enconman.2020.112999.

- [25] Ł. Witanowski, P. Klonowicz, P. Lampart, T. Suchocki, Ł. Jędrzejewski, D. Zaniewski, P. Klimaszewski, Optimization of an axial turbine for a small scale ORC waste heat recovery system, Energy 205 (2020) 118059, https://doi.org/ 10.1016/j.energy.2020.118059. ISSN 0360-5442.

- [26] W. Qiang, L. Yanzhong, W. Jiang, Analysis of power cycle based on cold energy of liquefied natural gas and low-grade heat source, Appl. Therm. Eng. 24 (4) (2004) 539–548, https://doi.org/10.1016/j.applthermaleng.2003.09.010.

- [27] T. He, Z.R. Chong, J. Zheng, Y. Ju, P. Linga, LNG cold energy utilization: prospects and challenges, Energy 170 (2019) 557–568, https://doi.org/10.1016/j. energy.2018.12.170.

- [28] K.A. Al-attab, Z.A. Zainal, Externally fired gas turbine technology: a review, Appl. Energy 138 (2015) 474–487, https://doi.org/10.1016/j.apenergy.2014.10.049.

- [29] M. Hou, Z. Wu, G. Yu, J. Hu, E. Luo, A thermoacoustic stirling electrical generator for cold exergy recovery of liquefied nature gas, Appl. Energy 226 (2018) 389–396, https://doi.org/10.1016/j.apenergy.2018.05.120.

- [30] X. Shi, D. Che, A combined power cycle utilizing low-temperature waste heat and LNG cold energy, Energy Convers. Manage. 50 (3) (2009) 567–575, https://doi. org/10.1016/j.enconman.2008.10.015.

- [31] M. Mehrpooya, B. Golestani, S.M. Ali Mousavian, Novel cryogenic argon recovery from the air separation unit integrated with LNG regasification and CO2 transcritical power cycle, Sustain. Energy Technol. Assess. 40 (2020) 100767, https://doi.org/10.1016/j.seta.2020.100767.

- [32] D.S. Ayou, V. Eveloy, Energy, exergy and exergoeconomic analysis of an ultra lowgrade heat-driven ammonia-water combined absorption power-cooling cycle for district space cooling, sub-zero refrigeration, power and LNG regasification, Energy Convers. Manage 213 (2020) 112790, https://doi.org/10.1016/j. enconman.2020.112790.

- [33] B. Ghorbani, A. Ebrahimi, M. Ziabasharhagh, Novel integrated CCHP system for generation of liquid methanol, power, cooling and liquid fuels using Kalina power cycle through liquefied natural gas regasification, Energy Convers. Manage 221 (2020) 113151, https://doi.org/10.1016/j.enconman.2020.113151.

- [34] H. Yu, T. Gundersen, E. Gençer, Optimal liquified natural gas (LNG) cold energy utilization in an Allam cycle power plant with carbon capture and storage, Energy Convers. Manage. 228 (2021) 113725, https://doi.org/10.1016/j. enconman.2020.113725.

- [35] J. Bao, T. Yuan, L. Zhang, N. Zhang, X. Zhang, G. He, Comparative study of liquefied natural gas (LNG) cold energy power generation systems in series and parallel, Energy Convers. Manage. 184 (2019) 107–126, https://doi.org/10.1016/ j.enconman.2019.01.040.

- [36] Z. Tian, Z. Qi, W. Gan, M. Tian, W. Gao, A novel negative carbon-emission, cooling, and power generation system based on combined LNG regasification and waste heat recovery: Energy, exergy, economic, environmental (4E) evaluations, Energy 257 (2022) 124528, https://doi.org/10.1016/j.energy.2022.124528.

- [37] A.H. Farajollahi, et al., Waste heat recovery of an UAV propulsion system based on PEM fuel cell by a novel transcritical CO 2 - LNG hybrid cycle; thermodynamic and multiple linear regression analyses, Energy Sources Part A Recov. Utiliz. Environ. Effects 44 (4) (2022) 8694–8717, https://doi.org/10.1080/ 15567036.2022.2123574.

- [38] Z. Tian, W. Zeng, B. Gu, Y. Zhang, X. Yuan, Energy, exergy, and economic (3E) analysis of an organic Rankine cycle using zeotropic mixtures based on marine engine waste heat and LNG cold energy, Energy Convers. Manage. 228 (2021) 113657, https://doi.org/10.1016/j.enconman.2020.113657.

- [39] Z. Yu, C. Feng, F. Bian, D. Wang, Investigation and optimization of a two-stage cascade ORC system for medium and low-grade waste heat recovery using liquefied natural gas cold energy, Int. J. Refriger. 135 (2022) 97–112, https://doi.org/ 10.1016/j.ijrefrig.2021.12.025.

- [40] J. Ma, X. Song, B. Zhang, N. Mao, T. He, Optimal design of dual-stage combined cycles to recover LNG cold energy and low-temperature waste thermal energy for sustainable power generation, Energy Convers. Manage. 269 (2022) 116141, https://doi.org/10.1016/j.enconman.2022.116141.

- [41] L.-H. Zhi, P. Hu, L.-X. Chen, G. Zhao, Thermodynamic analysis of an innovative transcritical CO2 parallel Rankine cycle driven by engine waste heat and liquefied natural gas cold, Energy Convers. Manage. 209 (2020) 112583, https://doi.org/ 10.1016/j.enconman.2020.112583.

- [42] S. Yao, C. Li, Y. Wei, Design and optimization of a zero carbon emission system integrated with the utilization of marine engine waste heat and LNG cold energy for LNG-powered ships, Appl. Therm. Eng. 231 (2023) 120976, https://doi.org/ 10.1016/j.applthermaleng.2023.120976.

- [43] T. Hai, et al., Optimization next to environmental analysis of harvesting waste heat from a biomass-driven externally-fired gas turbine cycle for sub-zero cooling and production of hydrogen, freshwater, and hot water, Appl. Therm. Eng. 223 (2023) 119884, https://doi.org/10.1016/j.applthermaleng.2022.119884.

- [44] O. Konur, C.O. Colpan, O.Y. Saatcioglu, A comprehensive review on organic Rankine cycle systems used as waste heat recovery technologies for marine applications, Energy Sources Part A Recov. Utiliz. Environ. Effects 44 (2) (2022) 4083–4122, https://doi.org/10.1080/15567036.2022.2072981.

- [45] C. Tian, C. Su, C. Yang, X. Wei, P. Pang, J. Xu, Exergetic and economic evaluation of a novel integrated system for cogeneration of power and freshwater using waste heat recovery of natural gas combined cycle, Energy 264 (2023) 126227, https:// doi.org/10.1016/j.energy.2022.126227.

- [46] S.-H. Cha, S.-I. Na, Y.H. Lee, M.S. Kim, Thermodynamic analysis of a gas turbine inlet air cooling and recovering system in gas turbine and CO2 combined cycle using cold energy from LNG terminal, Energy Convers. Manage 230 (2021) 113802, https://doi.org/10.1016/j.enconman.2020.113802.

- [47] B. Peris, J. Navarro-Esbrí, F. Mol´es, A. Mota-Babiloni, Experimental study of an ORC (organic Rankine cycle) for low grade waste heat recovery in a ceramic industry, Energy 85 (2015) 534–542. ISSN 0360-5442.

- [48] H. Jouhara, D. Bertrand, B. Axcell, L. Montorsi, M. Venturelli, S. Almahmoud, M. Milani, L. Ahmad, A. Chauhan, Investigation on a full-scale heat pipe heat exchanger in the ceramics industry for waste heat recovery, Energy 223 (2021) 120037. ISSN 0360-5442.

- [49] T.G.C. Veloso, C.A.R. Sotomonte, CJ.R. Coronado, MA.R. Nascimento, Multiobjective optimization and exergetic analysis of a low-grade waste heat recovery ORC application on a Brazilian FPSO, Energy Convers. Manage. 174 (2018) 537–551. ISSN 0196-8904.

- [50] Dwivedi, A. and Mishra, R.S., Analysis of organic Rankine cycle with waste heat recovery from gas power plant using loop heat pipes. J. Mech. Eng. Res. Dev., ISSN, pp.1024-1752.

- [51] Z. Tian, Y. Yue, B. Gu, W. Gao, Y. Zhang, Thermo-economic analysis and optimization of a combined Organic Rankine Cycle (ORC) system with LNG cold

- energy and waste heat recovery of dual-fuel marine engine, Int. J. Energy Res. 44 (2020) 9974–9994.

- [52] B. Jiang, D. Xia, H. Zhang, H. Pei, X. Liu, Effective waste heat recovery from industrial high-temperature granules: a moving bed indirect heat exchanger with embedded agitation, Energy 208 (2020) 118346. ISSN 0360-5442.

- [53] A.M. Alsayah, JJ. Faraj, AA. Eidan, The augmentation of the heat recovery by using evaporative cooling in HVAC applications: experimental study, Int. J. Thermofluids 22 (2024) 100671. ISSN 2666-2027.

- [54] D. Brough, J. Ramos, B. Delpech, H. Jouhara, Development and validation of a TRNSYS type to simulate heat pipe heat exchangers in transient applications of waste heat recovery, Int. J. Thermofluids 9 (2021) 100056. ISSN 2666-2027.

- [55] A.I. Turja, K.N. Sadat, Y. Khan, M. Monjurul Ehsan, Cascading the transcritical CO2 and organic Rankine cycles with supercritical CO2 cycles for waste heat recovery, Int. J. Thermofluids 20 (2023) 100508. ISSN 2666-2027.

- [56] A.S. Chowdhury, M.M. Ehsan, A critical overview of working fluids in organic Rankine, supercritical rankine, and supercritical brayton cycles under various heat grade sources, Int. J. Thermofluids 20 (2023) 100426. ISSN 2666-2027.

- [57] A.E. Elahi, T. Mahmud, M. Alam, J. Hossain, B.N. Biswas, Exergy analysis of organic Rankine cycle for waste heat recovery using low GWP refrigerants, Int. J. Thermofluids 16 (2022) 100243. ISSN 2666-2027.

- [58] M. Mahmoud, S. Naher, M. Ramadan, M.A. Abdelkareem, H. Jaber, A.-G. Olabi, Investigation of a ground-cooled organic Rankine cycle for waste heat recovery, Int. J. Thermofluids 18 (2023) 100348. ISSN 2666-2027.

- [59] AR. Imre, AM. Ahmed, Effect of the working fluids critical temperature on thermal performance for trilateral flash cycle and organic Rankine cycle, Int. J. Thermofluids 20 (2023) 100417. ISSN 2666-2027.

- [60] Xu Zheng, Y. Li, Ji Zhang, Z. Zhang, C. Guo, N. Mei, Design and multi-objective optimization of combined air separation and ORC system for harnessing LNG cold energy considering variable regasification rates, Int. J. Hydrogen. Energy 57 (2024) 210–223. ISSN 0360-3199.

- [61] Y.A.A. Laouid, C. Kezrane, Y. Lasbet, Apostolos Pesyridis, Towards improvement of waste heat recovery systems: A multi-objective optimization of different organic Rankine cycle configurations, Int. J. Thermofluids 11 (2021) 100100. ISSN 26662027.

- [62] M. Taal, I. Bulatov, J. Klemes, P. Stehlik, Cost estimation and energy price forecasts for economic evaluation of retrofit projects, Appl. Therm. Eng. 23 (2003) 1819–1835.

- [63] A.C. Caputo, P.M. Pelagagge, P. Salini, Heat exchanger design based on economic optimization, Appl. Therm. Eng. 28 (2008) 1151–1159.

- [64] M.A.A Sadreddini, M. Fani, A. Mohammadi, Thermodynamic analysis of a new cascade ORC and transcritical CO2 cycle to recover energy from medium temperature heat source and liquefied natural gas, Energy Convers. Manage 167 (2018) 9–20, https://doi.org/10.1016/j.enconman.2018.04.093.

著作権および参考文献

本資料は、[論文作成者]の論文[論文題名]を基に作成されました。

論文出典:https://doi.org/10.1016/j.ijft.2024.100822

本資料は上記の論文に基づき要約を作成したものであり、商業目的での無断使用を禁じます。

Copyright © 2025 CASTMAN. All rights reserved.