Hongyi Zhu, Cunjuan Xia, Huawei Zhang, Dechao Zhao, Mingliang Wang & Haowei Wang

Abstract

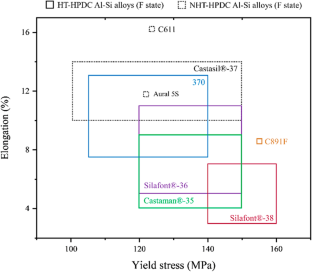

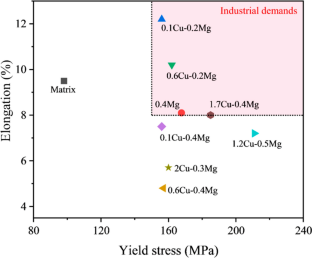

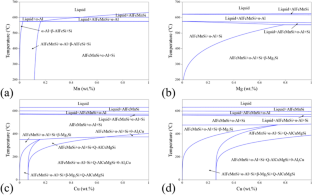

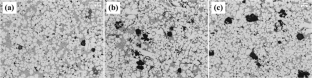

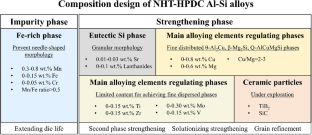

In recent years, Non-Heat Treatable High Pressure Die Casting Al alloys (NHT-HPDC Al alloys) have been proposed and developed for integrated die casting in the automotive industry. These alloys exhibit excellent castability and can achieve sufficient mechanical properties without the need for heat treatment. Despite their industrial significance, there is a lack of an updated and comprehensive description of such alloys. The insufficient availability of literature and the absence of a systematic design mentality have hindered their development. Therefore, this study reviews several aspects of NHT-HPDC Al alloys. Firstly, the NHT-HPDC Al alloys are divided into Al-Si, Al-Mg-Si and Al-Fe-Mg alloys, with the NHT-HPDC Al-Si alloys being the mainstream. The solidification behaviors of NHT-HPDC Al-Si-(Cu)-(Mg) alloys are discussed using phase diagram analyses. Secondly, the manipulation of critical phases is discussed, including: (i) impurity phase: Fe-rich phase (the neutralization treatment); (ii) strengthening phases: Eutectic Si phase (the modification treatment)/main alloying elements regulating phases/trace alloying elements regulating phases/ceramic particles. Thirdly, the typical three regions of NHT-HPDC Al-Si components and their formation mechanisms are identified and reviewed. Then, the influence of vacuum assistance and intensification pressure to the general quality of NHT-HPDC Al-Si components is comprehensively discussed. Finally, future challenges for NHT-HPDC Al-Si alloys are also proposed.

- Fig. 1

View in article

View in article - Fig. 2

View in article

View in article - Fig. 3

View in article

View in article - Fig. 4

View in article

View in article - Fig. 5

View in article

View in article - Fig. 6

View in article

View in article - Fig. 7

View in article

View in article - Fig. 8

View in article

View in article - Fig. 9

View in article

View in article - Fig. 10

View in article

View in article - Fig. 11

View in article

View in article - Fig. 12

View in article

View in article - Fig. 13

View in article

View in article - Fig. 14

View in article

View in article - Fig. 15

View in article

View in article - Fig. 16

View in article

View in article - Fig. 17

View in article

View in article

References

D. Castelvecchi, How the Hydrogen Revolution can Help Save the Planet — and How it can’t, Nature, 2022, 611, p 440–443. https://doi.org/10.1038/d41586-022-03699-0

Article

CAS

PubMed

Google Scholar

A.I. Taub and A.A. Luo, Advanced Lightweight Materials and Manufacturing Processes for Automotive Applications, MRS Bull., 2015, 40, p 1045–1054. https://doi.org/10.1557/mrs.2015.268

Article

Google Scholar

F. Czerwinski, Current Trends in Automotive Lightweighting Strategies and Materials, Materials, 2021, 14, p 6631. https://doi.org/10.3390/ma14216631

Article

CAS

PubMed

PubMed Central

Google Scholar

W. Zhang and J. Xu, Advanced Lightweight Materials for Automobiles: A Review, Mater. Des., 2022, 221, p 110994. https://doi.org/10.1016/j.matdes.2022.110994

Article

CAS

Google Scholar

F. Casarotto, A.J. Franke and R. Franke, High-pressure die-cast (HPDC) Aluminium Alloys for Automotive Applications, Advanced Materials in Automotive Engineering. J. Rowe Ed., Woodhead Publishing, 2012, p 109–149

Chapter

Google Scholar

M. Hartlieb, Aluminum Alloys for Structural Die Casting, Die Casting Engineer, 2013, 57, p 40–43.

Google Scholar

T. Liu, Z. Pei, D. Barton, G.B. Thompson and L.N. Brewer, Characterization of Nanostructures in a high Pressure Die Cast Al-Si-Cu Alloy, Acta Mater., 2022, 224, p 117500. https://doi.org/10.1016/j.actamat.2021.117500

Article

CAS

Google Scholar

L. Wang, M. Makhlouf and D. Apelian, Aluminium Die Casting Alloys: Alloy Composition, Microstructure, and Properties-Performance Relationships, Int. Mater. Rev., 1995, 40, p 221–238. https://doi.org/10.1179/imr.1995.40.6.221

Article

CAS

Google Scholar

C.M. Dinnis, J.A. Taylor and A.K. Dahle, As-Cast Morphology of Iron-Intermetallics in Al-Si Foundry Alloys, Scr. Mater., 2005, 53, p 955–958. https://doi.org/10.1016/j.scriptamat.2005.06.028

Article

CAS

Google Scholar

G. Ubertalli, F. D’Aiuto, S. Plano and D. De Caro, High Strain Rate Behavior of Aluminum Die Cast Components, Procedia Struct. Integrity, 2016, 2, p 3617–3624. https://doi.org/10.1016/j.prostr.2016.06.451

Article

Google Scholar

J. Hirsch, Recent Development in Aluminium for Automotive Applications, Trans. Nonferrous Met. Soc. China, 2014, 24, p 1995–2002. https://doi.org/10.1016/S1003-6326(14)63305-7

Article

CAS

Google Scholar

Z. Hu, L. Wan, S. Wu, H. Wu and X. Liu, Microstructure and Mechanical Properties of High Strength Die-Casting Al-Mg-Si-Mn Alloy, Mater. Des., 2013, 46, p 451–456. https://doi.org/10.1016/j.matdes.2012.10.020

Article

CAS

Google Scholar

Y.M. Kim, S.W. Choi, Y.C. Kim, C.S. Kang and S.K. Hong, The Influence of the Additional Fe and Mn in Al Alloy on the Die Soldering Phenomenon, J. Nanosci. Nanotechnol., 2016, 16, p 11252–11255. https://doi.org/10.1166/jnn.2016.13488

Article

CAS

Google Scholar

G.K. Sigworth and R.J. Donahue, The Metallurgy of Aluminum Alloys for Structural High-Pressure Die Castings, Int. J. Metalcast., 2021, 15, p 1031–1046. https://doi.org/10.1007/s40962-020-00535-x

Article

CAS

Google Scholar

X.G. Hu, Q. Zhu, S.P. Midson, H.V. Atkinson, H.B. Dong, F. Zhang and Y.L. Kang, Blistering in Semi-Solid Die Casting of Aluminium Alloys and its Avoidance, Acta Mater., 2017, 124, p 446–455. https://doi.org/10.1016/j.actamat.2016.11.032

Article

CAS

Google Scholar

J. Zhang, E. Cinkilic, X. Huang, G.G. Wang, Y. Liu, J.P. Weiler and A.A. Luo, Optimization of T5 Heat Treatment in high Pressure Die Casting of Al-Si-Mg-Mn Alloys by Using an Improved Kampmann-Wagner Numerical (KWN) Model, Mater. Sci. Eng. A, 2023, 865, p 144604. https://doi.org/10.1016/j.msea.2023.144604

Article

CAS

Google Scholar

U.E.T. Baser and V. Akinci, New Trends in Aluminum Die Casting Alloys for Automotive Applications, EPSTEM, 2022, 21, p 79–87. https://doi.org/10.55549/epstem.1227541

Article

Google Scholar

S.K. Das, H.W. Hayden and G.B. Barthold, Development of Non-Heat-Treatable Automotive Aluminum Sheet Alloys, Mater. Sci. Forum, 2000, 331–337, p 913–920. https://doi.org/10.4028/www.scientific.net/MSF.331-337.913

Article

Google Scholar

BEALS, Randolf, Scott, Process for Low-Cost tempering of Aluminum Casting, US patent 2022/0228242 A1, 2022 Jul 21.

L.Y. Yuan, P.W. Han, G. Asghar, B.L. Liu, J.P. Li, B. Hu, P.H. Fu and L.M. Peng, Development of High Strength and Toughness Non-Heated Al-Mg-Si Alloys for High-Pressure Die-Casting, Acta Metall. Sin. (Engl. Lett.), 2021, 34, p 845–860. https://doi.org/10.1007/s40195-020-01174-1

Article

CAS

Google Scholar

G. Soares, R. Neto, R. Madureira, R. Soares, J. Silva, R.P. Silva and L. Araújo, Characterization of Al Alloys Injected Through Vacuum-Assisted HPDC and Influence of T6 Heat Treatment, Metals, 2023, 13, p 389. https://doi.org/10.3390/met13020389

Article

CAS

Google Scholar

C. Hu, H. Zhu, Y. Wang, C. Xia, J. Geng, D. Chen, H. Zhang, M. Wang and H. Wang, Microstructure Features and Mechanical Properties of Non-Heat Treated HPDC Al9Si0.6Mn-TiB2 Alloys, J. Mater. Res. Technol., 2023, 27, p 2117–2131. https://doi.org/10.1016/j.jmrt.2023.10.060

Article

CAS

Google Scholar

N. Rokon, M.S. Haque and M. Kaiser, On the Mechanical Behaviour of Thermally Affected Non-Heat-Treatable Aluminium Alloys, J. Chem. Technol. Metall., 2023, 58, p 1153–1162. https://doi.org/10.59957/jctm.v58i6.156

Article

CAS

Google Scholar

R.E. Sanders, S.F. Baumann and H.C. Stumpf, Wrought Non-Heat-Treatable Aluminum Alloy, Treatise on Materials Science & Technology. A.K. Vasudevan, R.D. Doherty Ed., Elsevier, NJ, 1989, p 65–105

Google Scholar

M. Rix, B. Kujat, T. Meisen and S. Jeschke, An Agile Information Processing Framework for High Pressure Die Casting Applications in Modern Manufacturing Systems, Procedia CIRP, 2016, 41, p 1084–1089. https://doi.org/10.1016/j.procir.2015.12.134

Article

Google Scholar

Z. Niu, G. Liu, T. Li and S. Ji, Effect of High Pressure Die Casting on the Castability, Defects and Mechanical Properties of Aluminium Alloys in Extra-Large Thin-Wall Castings, J. Mater. Process. Technol., 2022, 303, p 117525. https://doi.org/10.1016/j.jmatprotec.2022.117525

Article

CAS

Google Scholar

D. Blondheim and A. Monroe, Macro Porosity Formation: A Study in High pressure Die Casting, Int. J. Metalcast., 2022, 16, p 330–341. https://doi.org/10.1007/s40962-021-00602-x

Article

Google Scholar

R. Hu, C. Guo and M. Ma, A Study on High Strength High Plasticity, Non-Heat Treated Die-Cast Aluminum Alloy, Materials, 2022, 15, p 295.

Article

CAS

Google Scholar

X. Dong, H. Yang, X. Zhu and S. Ji, High Strength and Ductility Aluminium Alloy Processed by High Pressure Die Casting, J. Alloys Compd., 2019, 773, p 86–96. https://doi.org/10.1016/j.jallcom.2018.09.260

Article

CAS

Google Scholar

X. Zhu, X. Dong, P. Blake and S. Ji, Improvement in as-cast Strength of High Pressure Die-Cast Al-Si-Cu-Mg Alloys by Synergistic Effect of Q-Al5Cu2Mg8Si6 and θ-Al2Cu Phases, Mater. Sci. Eng. A, 2021, 802, p 140612. https://doi.org/10.1016/j.msea.2020.140612

Article

CAS

Google Scholar

A. Graf, Aluminum Alloys for Lightweight Automotive Structures, Materials, Design and Manufacturing for Lightweight Vehicles, 2nd ed., P.K. Mallick Ed., Woodhead Publishing, NJ, 2021, p 97–123

Chapter

Google Scholar

H.L. Chen, Q. Chen, Y. Du, J. Bratberg and A. EngstrÖM, Update of Al-Fe-Si, Al-Mn-Si and Al-Fe-Mn-Si Thermodynamic Descriptions, Trans. Nonferrous Met. Soc. China, 2014, 24, p 2041–2053. https://doi.org/10.1016/S1003-6326(14)63310-0

Article

CAS

Google Scholar

RHEINFELDEN, Families of Alloys. https://rheinfelden-alloys.eu/en/alloys/, 2023 (accessed 6 September 2023).

Alcoa, Advanced Aluminum Alloys. https://www.alcoa.com/global/en/what-we-do/aluminum/cast-products/foundry-aluminum-alloys, 2023 (accessed 6 September 2023).

J. Stucki, G. Pattinson, Q. Hamill, A. Prabhu, S. Palanivel, O. Lopez-Garri-Ty, Die Cast Aluminum Alloys for Structural Components, WO Patent 2021/150604 A1 2021

S. Ji, D. Watson, Z. Fan and M. White, Development of a Super Ductile Diecast Al-Mg-Si Alloy, Mater. Sci. Eng. A, 2012, 556, p 824–833. https://doi.org/10.1016/j.msea.2012.07.074

Article

CAS

Google Scholar

X. Dong, X. Zhu and S. Ji, Effect of Super Vacuum Assisted High Pressure Die Casting on the Repeatability of Mechanical Properties of Al-Si-Mg-Mn Die-Cast Alloys, J. Mater. Process. Technol., 2019, 266, p 105–113. https://doi.org/10.1016/j.jmatprotec.2018.10.030

Article

CAS

Google Scholar

F. Liu, H. Zheng, Y. Zhong, Y. Jiang, X. Li, B. Chen and H. Zhao, Effect of Cu/Mg-Containing Intermetallics on the Mechanical Properties of the As-Cast HVDC AlSiMgMnCu Alloys by SBFSEM at Nano-Scale, J. Alloys Compd., 2022, 926, p 166837. https://doi.org/10.1016/j.jallcom.2022.166837

Article

CAS

Google Scholar

P. Zhang, Z. Li, B. Liu and W. Ding, Tensile Properties and Deformation Behaviors of a New Aluminum Alloy for High Pressure Die Casting, J. Mater. Sci. Technol., 2017, 33, p 367–378. https://doi.org/10.1016/j.jmst.2016.02.013

Article

CAS

Google Scholar

X. Zhu, P. Blake, K. Dou and S. Ji, Strengthening Die-Cast Al-Mg and Al-Mg-Mn Alloys with Fe as a Beneficial element, Mater. Sci. Eng. A, 2018, 732, p 240–250. https://doi.org/10.1016/j.msea.2018.07.005

Article

CAS

Google Scholar

X. Fang, G. Shao, Y.Q. Liu and Z. Fan, Effects of Intensive Forced Melt Convection on the Mechanical Properties of Fe Containing Al-Si Based Alloys, Mater. Sci. Eng. A, 2007, 445–446, p 65–72. https://doi.org/10.1016/j.msea.2006.09.038

Article

CAS

Google Scholar

E. Samuel, A.M. Samuel, H.W. Doty, S. Valtierra and F.H. Samuel, Intermetallic Phases in Al-Si Based Cast Alloys: New Perspective, Int. J. Cast Met. Res., 2014, 27, p 107–114. https://doi.org/10.1179/1743133613Y.0000000083

Article

CAS

Google Scholar

X. Dong, H. Youssef, Y. Zhang, S. Wang and S. Ji, High Performance Al/TiB2 Composites Fabricated by Nanoparticle Reinforcement and Cutting-Edge Super Vacuum Assisted Die Casting Process, Compos. B, 2019, 177, p 107453. https://doi.org/10.1016/j.compositesb.2019.107453

Article

CAS

Google Scholar

J. Rakhmonov, G. Timelli and F. Bonollo, The Effect of Transition Elements on High-Temperature Mechanical Properties of Al-Si Foundry Alloys-a Review, Adv. Eng. Mater., 2016, 18, p 1096–1105. https://doi.org/10.1002/adem.201500468

Article

CAS

Google Scholar

H.Y. Kim, T.Y. Park, S.W. Han and H.M. Lee, Effects of Mn on the Crystal Structure of α-Al(Mn, Fe)Si Particles in A356 Alloys, J. Cryst. Growth, 2006, 291, p 207–211. https://doi.org/10.1016/j.jcrysgro.2006.02.006

Article

CAS

Google Scholar

M.V. Kral, A Crystallographic Identification of Intermetallic Phases in Al-Si Alloys, Mater. Lett., 2005, 59, p 2271–2276. https://doi.org/10.1016/j.matlet.2004.05.091

Article

CAS

Google Scholar

T.O. Mbuya, B.O. Odera and S.P. Ng’ang’a, Influence of Iron on Castability and Properties of Aluminium Silicon Alloys: Literature Review, Int. J. Cast Met. Res., 2003, 16, p 451–465. https://doi.org/10.1080/13640461.2003.11819622

Article

CAS

Google Scholar

X.Y. Jiao, C.F. Liu, Z.P. Guo, G.D. Tong, S.L. Ma, Y. Bi, Y.F. Zhang and S.M. Xiong, The Characterization of Fe-Rich Phases in a High-Pressure Die Cast Hypoeutectic Aluminum-Silicon Alloy, J. Mater. Sci. Technol., 2020, 51, p 54–62. https://doi.org/10.1016/j.jmst.2020.02.040

Article

CAS

Google Scholar

J.A. Taylor, Iron-Containing Intermetallic Phases in Al-Si Based Casting Alloys, Procedia, Mater. Sci., 2012, 1, p 19–33. https://doi.org/10.1016/j.mspro.2012.06.004

Article

CAS

Google Scholar

X. Shen, S. Liu, X. Wang, C. Cui, P. Gong, L. Zhao, X. Han and Z. Li, Effect of Cooling Rate on the Microstructure Evolution and Mechanical Properties of iron-Rich Al-Si Alloy, Materials, 2022, 15, p 411.

Article

CAS

PubMed

PubMed Central

Google Scholar

X. Zhang, D. Wang, Y. Zhou, X. Chong, X. Li, H. Zhang and H. Nagaumi, Exploring Crystal Structures, Stability and Mechanical Properties of Fe, Mn-Containing Intermetallics in Al-Si Alloy by Experiments and First-Principles Calculations, J. Alloys Compd., 2021, 876, p 160022. https://doi.org/10.1016/j.jallcom.2021.160022

Article

CAS

Google Scholar

L.A. Narayanan, F.H. Samuel and J.E. Gruzleski, Crystallization Behavior of Iron-Containing Intermetallic Compounds in 319 Aluminum Alloy, Metall. Mater. Trans. A, 1994, 25, p 1761–1773. https://doi.org/10.1007/BF02668540

Article

Google Scholar

B. Wang, J. Wang, X. Liu, Q. Li and X. Liu, Uncovering the Effects of Neutralizing Elements (Co, Mn and Cr) on the Fe-Rich Intermetallic Formation in Al-Si-Cu Alloys, Mater. Sci. Eng. A, 2022, 858, p 144090. https://doi.org/10.1016/j.msea.2022.144090

Article

CAS

Google Scholar

G. Gustafsson, T. Thorvaldsson and G.L. Dunlop, The Influence of Fe and Cr on the Microstructure of Cast Al-Si-Mg Alloys, Metall. Trans. A, 1986, 17, p 45–52. https://doi.org/10.1007/BF02644441

Article

Google Scholar

S.G. Shabestari, The Effect of Iron and Manganese on the Formation of Intermetallic Compounds in Aluminum-Silicon Alloys, Mater. Sci. Eng. A, 2004, 383, p 289–298. https://doi.org/10.1016/j.msea.2004.06.022

Article

CAS

Google Scholar

S. Ferraro, A. Bjurenstedt and S. Seifeddine, On the Formation of Sludge Intermetallic Particles in Secondary Aluminum Alloys, Metall. Mater. Trans. A, 2015, 46A, p 3713–3722. https://doi.org/10.1007/s11661-015-2942-0

Article

CAS

Google Scholar

Y. Fu, G.G. Wang, A. Hu, Y. Li, K.B. Thacker, J.P. Weiler and H. Hu, Formation, Characteristics and Control of Sludge in Al-Containing Magnesium Alloys: An Overview, J. Magnesium Alloys, 2022, 10, p 599–613. https://doi.org/10.1016/j.jma.2021.11.031

Article

CAS

Google Scholar

P.N. Crepeau, Effect of Iron in Al-Si Casting Alloys: a critical Review, AFS Transactions, 1995, 103, p 361–366.

CAS

Google Scholar

S. Ferraro and G. Timelli, Influence of sludge particles on the Tensile Properties of Die-Cast Secondary Aluminum Alloys, Metall. Mater. Trans. B, 2015, 46, p 1022–1034. https://doi.org/10.1007/s11663-014-0260-3

Article

CAS

Google Scholar

M. Kohlhepp, P.J. Uggowitzer, M. Hummel and H.W. Höppel, Formation of Die Soldering and the Influence of Alloying Elements on the Intermetallic Interface, Materials, 2021, 14, p 1580.

Article

CAS

PubMed

PubMed Central

Google Scholar

Q. Han and S. Viswanathan, Analysis of the Mechanism of Die Soldering in Aluminum Die Casting, Metall. Mater. Trans. A, 2003, 34, p 139–146. https://doi.org/10.1007/s11661-003-0215-9

Article

Google Scholar

J.Y. Hwang, H.W. Doty and M.J. Kaufman, The Effects of Mn Additions on the Microstructure and Mechanical Properties of Al-Si-Cu Casting Alloys, Mater. Sci. Eng. A, 2008, 488, p 496–504. https://doi.org/10.1016/j.msea.2007.12.026

Article

CAS

Google Scholar

Z. Li, N. Limodin, A. Tandjaoui, P. Quaegebeur, P. Osmond and D. Balloy, Influence of Sr, Fe and Mn Content and Casting Process on the Microstructures and Mechanical Properties of AlSi7Cu3 Alloy, Mater. Sci. Eng. A, 2017, 689, p 286–297. https://doi.org/10.1016/j.msea.2017.02.041

Article

CAS

Google Scholar

B. Lin, H. Li, R. Xu, H. Xiao, W. Zhang and S. Li, Effects of Vanadium on Modification of Iron-Rich Intermetallics and Mechanical Properties in A356 cast Alloys with 1.5 wt.%Fe, J. Mater. Eng. Perform., 2019, 28, p 475–484. https://doi.org/10.1007/s11665-018-3798-4

Article

CAS

Google Scholar

R. Qin, R.F. Yan, Z.P. Guan, G.Q. Zhang, J.W. Song, M.W. Ren and J.G. Wang, Effect of Vanadium on Fe-Rich Phase, Mechanical Properties and Thermal Conductivity of Hypoeutectic Al-Si Alloy, Mater. Res. Express, 2021, 8, p 026518. https://doi.org/10.1088/2053-1591/abe5f0

Article

CAS

Google Scholar

S.S. Sreeja Kumari, R.M. Pillai, T.P.D. Rajan and B.C. Pai, Effects of Individual and Combined Additions of Be, Mn, Ca and Sr on the Solidification Behaviour, Structure and Mechanical Properties of Al-7Si-0.3Mg-0.8Fe Alloy, Mater. Sci. Eng. A, 2007, 460–461, p 561–573. https://doi.org/10.1016/j.msea.2007.01.082

Article

CAS

Google Scholar

M. Rejaeian, M. Karamouz, M. Emamy and M. Hajizamani, Effects of Be Additions on Microstructure, Hardness and Tensile Properties of A380 Aluminum Alloy, Nonferrous Met. Soc. China., 2015, 25, p 3539–3545. https://doi.org/10.1016/S1003-6326(15)63951-6

Article

CAS

Google Scholar

M. Wang, Y. Guo, H. Wang and S. Zhao, Characterization of Refining the Morphology of Al-Fe-Si in A380 Aluminum Alloy Due to Ca Addition, Processes, 2022, 10, p 672.

Article

CAS

Google Scholar

M. Sha, S. Wu, X. Wang and L. Wan, Effects of Co Addition on Fe-Bearing Intermetallic Compounds and Mechanical Properties of AlSi20Cu2Ni1Fe0.7-1 Alloys, J. Alloys Compd., 2013, 551, p 468–474. https://doi.org/10.1016/j.jallcom.2012.10.181

Article

CAS

Google Scholar

B. Wan, W. Chen, L. Liu, X. Cao, L. Zhou and Z. Fu, Effect of Trace Yttrium Addition on the Microstructure and Tensile Properties of Recycled Al-7Si-0.3Mg-1.0Fe Casting Alloys, Mater. Sci. Eng. A, 2016, 666, p 165–175. https://doi.org/10.1016/j.msea.2016.04.036

Article

CAS

Google Scholar

G.K. Sigworth, The Modification of Al-Si Casting Alloys: Important Practical and Theoretical Aspects, Int. J. Metalcast., 2008, 2, p 19–40. https://doi.org/10.1007/BF03355425

Article

CAS

Google Scholar

M.R.S. Ganesh, N. Reghunath, M.J. Levin, A. Prasad, S. Doondi and K.V. Shankar, Strontium in Al-Si-Mg Alloy: A Review, Met. Mater. Int., 2022, 28, p 1–40. https://doi.org/10.1007/s12540-021-01054-y

Article

CAS

Google Scholar

S. Moniri and A.J. Shahani, Chemical Modification of Degenerate Eutectics: A Review of Recent Advances and Current Issues, J. Mater. Res., 2019, 34, p 20–34. https://doi.org/10.1557/jmr.2018.361

Article

CAS

Google Scholar

S.C. Flood and J.D. Hunt, Modification of Al-Si Eutectic Alloys with Na, Metal, Science, 1981, 15, p 287–294. https://doi.org/10.1179/030634581790426813

Article

CAS

Google Scholar

P. Srirangam, M.J. Kramer and S. Shankar, Effect of Strontium on Liquid Structure of Al-Si Hypoeutectic alloys Using High-Energy X-ray Diffraction, Acta Mater., 2011, 59, p 503–513. https://doi.org/10.1016/j.actamat.2010.09.050

Article

CAS

Google Scholar

M. Timpel, N. Wanderka, R. Schlesiger, T. Yamamoto, N. Lazarev, D. Isheim, G. Schmitz, S. Matsumura and J. Banhart, The Role of Strontium in Modifying Aluminium-Silicon Alloys, Acta Mater., 2012, 60, p 3920–3928. https://doi.org/10.1016/j.actamat.2012.03.031

Article

CAS

Google Scholar

L. Chang, Y. Ding, B. Guo, J. Ding, X. Xia, Y. Tang, C. Li, X. Sun, J. Guo, K. Song, L. Wang, K. Zhou, X. Chen and Y. Liu, Modification Mechanism and Tensile Property of Al-9Si-0.4Mg-0.1Cu Alloy, Mater. Charact., 2022, 184, p 111693. https://doi.org/10.1016/j.matchar.2021.111693

Article

CAS

Google Scholar

J.E. Gruzleski, B.M. Closset, A.F.s. Society, The Treatment of Liquid Aluminum-Silicon Alloys, American Foundrymen's Society Sigworth, 1990, https://api.semanticscholar.org/CorpusID:135795085.

X.F. Bian, Z.H. Zhang, X.F. Liu, Effect of Strontium Modification on Hydrogen Content and Porosity Shape of Al-Si Alloys, Mater. Sci. Forum 331-337 (2000) 361-366, https://www.scientific.net/MSF.331-337.361.

W. Zhang, S. Ma, Z. Wei, P. Bai, The Relationship Between Residual Amount of Sr and Morphology of Eutectic Si Phase in A356 Alloy, Materials 12 (2019) 3222, https://www.mdpi.com/1996-1944/12/19/3222.

Q. Wang, Q. Hao and W. Yu, Effect of Strontium Modification on Porosity Formation in A356 Alloy, Int. J. Metalcast., 2019, 13, p 944–952. https://doi.org/10.1007/s40962-018-00300-1

Article

CAS

Google Scholar

P.D. Lee and S. Sridhar, Direct Observation of the Effect of Strontium on Porosity Formation During the Solidification of Aluminium-Silicon Alloys, Int. J. Cast Met. Res., 2000, 13, p 185–198. https://doi.org/10.1080/13640461.2000.11819401

Article

CAS

Google Scholar

F. Mao, S. Wei, C. Chen, C. Zhang, X. Wang and Z. Cao, Modification of the Silicon Phase and Mechanical Properties in Al-40Zn-6Si Alloy with Eu Addition, Mater. Des., 2020, 186, p 108268. https://doi.org/10.1016/j.matdes.2019.108268

Article

CAS

Google Scholar

P. Pandee, U. Patakham and C. Limmaneevichitr, Microstructural Evolution and Mechanical Properties of Al-7Si-0.3Mg Alloys with Erbium Additions, J. Alloys Compd., 2017, 728, p 844–853. https://doi.org/10.1016/j.jallcom.2017.09.054

Article

CAS

Google Scholar

Z. Shi, Q. Wang, Y. Shi, G. Zhao and R. Zhang, Microstructure and Mechanical Properties of Gd-Modified A356 Aluminum Alloys, J. Rare Earths, 2015, 33, p 1004–1009. https://doi.org/10.1016/S1002-0721(14)60518-4

Article

CAS

Google Scholar

R. Ahmad and M.B.A. Asmael, Influence of Lanthanum on Solidification, Microstructure, and Mechanical Properties of Eutectic Al-Si Piston Alloy, J. Mater. Eng. Perform., 2016, 25, p 2799–2813. https://doi.org/10.1007/s11665-016-2139-8

Article

CAS

Google Scholar

Y.C. Tsai, C.Y. Chou, S.L. Lee, C.K. Lin, J.C. Lin and S.W. Lim, Effect of Trace La Addition on the Microstructures and Mechanical Properties of A356 (Al-7Si-0.35Mg) Aluminum Alloys, J. Alloys Compd., 2009, 487, p 157–162. https://doi.org/10.1016/j.jallcom.2009.07.183

Article

CAS

Google Scholar

W. Liu, W. Xiao, C. Xu, M. Liu and C. Ma, Synergistic Effects of Gd and Zr on Grain Refinement and Eutectic Si Modification of Al-Si Cast Alloy, Mater. Sci. Eng. A, 2017, 693, p 93–100. https://doi.org/10.1016/j.msea.2017.03.097

Article

CAS

Google Scholar

H. Qiu, H. Yan and Z. Hu, Effect of Samarium (Sm) Addition on the Microstructures and Mechanical Properties of Al-7Si-0.7Mg Alloys, J. Alloys Compd., 2013, 567, p 77–81. https://doi.org/10.1016/j.jallcom.2013.03.050

Article

CAS

Google Scholar

S.Z. Lu and A. Hellawell, The Mechanism of Silicon Modification in Aluminum-Silicon Alloys: Impurity Induced Twinning, Metall. Trans. A, 1987, 18, p 1721–1733. https://doi.org/10.1007/BF02646204

Article

Google Scholar

K. Nogita, H. Yasuda, M. Yoshiya, S.D. McDonald, K. Uesugi, A. Takeuchi and Y. Suzuki, The Role of Trace Element Segregation in the Eutectic Modification of Hypoeutectic Al-Si Alloys, J. Alloys Compd., 2010, 489, p 415–420. https://doi.org/10.1016/j.jallcom.2009.09.138

Article

CAS

Google Scholar

J.H. Li, X.D. Wang, T.H. Ludwig, Y. Tsunekawa, L. Arnberg, J.Z. Jiang and P. Schumacher, Modification of Eutectic Si in Al-Si Alloys with Eu Addition, Acta Mater., 2015, 84, p 153–163. https://doi.org/10.1016/j.actamat.2014.10.064

Article

CAS

Google Scholar

Q. Zheng, L. Zhang, H. Jiang, J. Zhao and J. He, Effect Mechanisms of Micro-Alloying Element La on Microstructure and Mechanical Properties of Hypoeutectic Al-Si alloys, J. Mater. Sci. Technol., 2020, 47, p 142–151. https://doi.org/10.1016/j.jmst.2019.12.021

Article

CAS

Google Scholar

Q. Li, S. Zhao, B. Li, Y. Zhu, J. Liu, D. Liu, Y. Lan and T. Xia, Modification of Multi-Component Al-Si Casting Piston Alloys by Addition of Rare Earth Yttrium, Mater. Res. Express, 2019, 6, p 106525. https://doi.org/10.1088/2053-1591/ab36fc

Article

CAS

Google Scholar

L. Shuai, X. Zou, Y. Rao, X. Lu and H. Yan, Synergistic Effects of La and Y on the Microstructure and Mechanical Properties of Cast Al-Si-Cu Alloys, Materials, 2022, 15, p 7283.

Article

CAS

PubMed

PubMed Central

Google Scholar

Y. Cao, X. Chen, Z. Wang, K. Chen, S. Pan, Y. Zhu and Y. Wang, Synergistic Influence of La and Zr on Microstructure and Mechanical Performance of an Al-Si-Mg Alloy at Casting State, J. Alloys Compd., 2022, 902, p 163829. https://doi.org/10.1016/j.jallcom.2022.163829

Article

CAS

Google Scholar

M.G. Mahmoud, Y. Zedan, A.M. Samuel, V. Songmene and F.H. Samuel, The Use of Rare Earth Metals in Al-Si-Cu Casting Alloys, Int. J. Metalcast., 2022, 16, p 535–552. https://doi.org/10.1007/s40962-021-00640-5

Article

CAS

Google Scholar

U. Heo, D.W. Han, S. Kim and C.B. Mo, Microstructure, Mechanical, and Corrosion Properties of Al-10Si and Al-10Si-2Cu Alloys with Different La Contents, Mater. Today Commun., 2022, 32, p 104005. https://doi.org/10.1016/j.mtcomm.2022.104005

Article

CAS

Google Scholar

A.M. Samuel, E.M. Elgallad, M.G. Mahmoud, H.W. Doty, S. Valtierra and F.H. Samuel, Rare Earth Metal-Based Intermetallics Formation in Al-Cu-Mg and Al-Si-Cu-Mg Alloys: A Metallographic Study, Adv. Mater. Sci. Eng., 2018, 2018, p 7607465. https://doi.org/10.1155/2018/7607465

Article

CAS

Google Scholar

H. Yi, D. Zhang, T. Sakata and H. Mori, Microstructures and La-Rich Compounds in a Cu-Containing Hypereutectic Al-Si Alloy, J. Alloys Compd., 2003, 354, p 159–164. https://doi.org/10.1016/S0925-8388(03)00022-7

Article

CAS

Google Scholar

G.S. Mousavi, M. Emamy and J. Rassizadehghani, The Effect of Mischmetal and Heat Treatment on the Microstructure and Tensile Properties of A357 Al-Si Casting Alloy, Mater. Sci. Eng. A, 2012, 556, p 573–581. https://doi.org/10.1016/j.msea.2012.07.029

Article

CAS

Google Scholar

L. Zhang, Q. Zheng, H. Jiang, J. He and J. Zhao, Effect of La Addition on microstructure Evolution of Hypoeutectic Al-6Si Alloys, J. Mater. Sci., 2020, 55, p 7546–7554. https://doi.org/10.1007/s10853-020-04522-9

Article

CAS

Google Scholar

B. Zhao, S. Xing, H. Sun, G. Yan, W. Gao and L. Ou, Effect of Rare-Earth La on Microstructure and Mechanical Properties of Al7Si4CuMg Alloys Prepared by Squeeze Casting, J. Mater. Sci., 2022, 57, p 12064–12083. https://doi.org/10.1007/s10853-022-07358-7

Article

CAS

Google Scholar

B. Zhao, S. Xing, A. Shan, G. Yan and X. Jiang, Influence of La Addition on Fe-Rich Intermetallic Phases Formation and Mechanical Properties of Al-7Si-4Cu-0.35Mg-0.2Fe Alloys Prepared by Squeeze Casting, Intermetallics, 2023, 153, p 107783. https://doi.org/10.1016/j.intermet.2022.107783

Article

CAS

Google Scholar

B. Pourbahari and M. Emamy, Effects of La Intermetallics on the Structure and Tensile Properties of Thin Section Gravity Die-Cast A357 Al Alloy, Mater. Des., 2016, 94, p 111–120. https://doi.org/10.1016/j.matdes.2016.01.039

Article

CAS

Google Scholar

X.Y. Wu, W. Luo, H.R. Zhang, H. Zhang and H.T. Jiang, Effect of La Addition on Microstructure and Mechanical Properties of Hypoeutectic Al-7Si Aluminum Alloy, China Foundry, 2021, 18, p 481–487. https://doi.org/10.1007/s41230-021-0137-4

Article

Google Scholar

O. Gursoy and G. Timelli, Lanthanides: A Focused Review of Eutectic Modification in Hypoeutectic Al-Si alloys, J. Mater. Res. Technol., 2020, 9, p 8652–8666. https://doi.org/10.1016/j.jmrt.2020.05.105

Article

CAS

Google Scholar

K. Nogita, S.D. McDonald and A.K. Dahle, Eutectic Modification of Al-Si Alloys with Rare Earth Metals, Mater. Trans., 2004, 45, p 323–326. https://doi.org/10.2320/matertrans.45.323

Article

CAS

Google Scholar

V. Balaram, Rare Earth Elements: A Review of Applications, Occurrence, Exploration, Analysis, Recycling, and Environmental Impact, Geosci. Front., 2019, 10, p 1285–1303. https://doi.org/10.1016/j.gsf.2018.12.005

Article

CAS

Google Scholar

O.E. Sebaie, A.M. Samuel, F.H. Samuel and H.W. Doty, The Effects of Mischmetal, Cooling Rate and Heat Treatment on the Eutectic Si Particle Characteristics of A319.1, A356.2 and A4131 Al-Si Casting Alloys, Mater. Sci. Eng. A, 2008, 480, p 342–355. https://doi.org/10.1016/j.msea.2007.07.039

Article

CAS

Google Scholar

M.G. Mahmoud, A.M. Samuel, H.W. Doty, S. Valtierra and F.H. Samuel, Effect of Solidification Rate and Rare Earth Metal Addition on the Microstructural Characteristics and Porosity Formation in A356 Alloy, Adv. Mater. Sci. Eng., 2017, 2017, p 5086418. https://doi.org/10.1155/2017/5086418

Article

CAS

Google Scholar

E.M. Elgallad, H.W. Doty, S.A. Alkahtani and F.H. Samuel, Effects of La and Ce Addition on the Modification of Al-Si Based Alloys, Adv. Mater. Sci. Eng., 2016, 2016, p 5027243. https://doi.org/10.1155/2016/5027243

Article

CAS

Google Scholar

E.M. Elgallad, M.F. Ibrahim, H.W. Doty and F.H. Samuel, Microstructural Characterisation of Al-Si Cast alloys containing Rare Earth Additions, Philos. Mag., 2018, 98, p 1337–1359. https://doi.org/10.1080/14786435.2018.1435917

Article

CAS

Google Scholar

A.M. Nabawy, A.M. Samuel, S.A. Alkahtani, K.A. Abuhasel and F.H. Samuel, Role of Cerium, Lanthanum, and Strontium Additions in an Al-Si-Mg (A356) Alloy, Int. J. Mater. Res., 2016, 107, p 446–458. https://doi.org/10.3139/146.111360

Article

CAS

Google Scholar

C. Qiu, S. Miao, X. Li, X. Xia, J. Ding, Y. Wang and W. Zhao, Synergistic Effect of Sr and La on the Microstructure and Mechanical Properties of A3562 Alloy, Mater. Des., 2017, 114, p 563–571. https://doi.org/10.1016/j.matdes.2016.10.061

Article

CAS

Google Scholar

G.K. Sigworth, Modification of Aluminum-Silicon Alloys, ASM International, 2008.

J.E. Hatch, Aluminum: Properties and Physical Metallurgy, ASM International, 1984.

M. Yıldırım and D. Özyürek, The Effects of Mg Amount on the Microstructure and Mechanical Properties of Al-Si-Mg alloys, Mater. Des., 2013, 51, p 767–774. https://doi.org/10.1016/j.matdes.2013.04.089

Article

CAS

Google Scholar

E. Sjölander and S. Seifeddine, The Heat Treatment of Al-Si-Cu-Mg Casting Alloys, J. Mater. Process. Technol., 2010, 210, p 1249–1259. https://doi.org/10.1016/j.jmatprotec.2010.03.020

Article

CAS

Google Scholar

R.I. Mackay and J.E. Gruzleski, Quantification of Magnesium in 356 Alloy via Thermal Analysis, Int. J. Cast Met. Res., 1998, 10, p 255–265. https://doi.org/10.1080/13640461.1998.11819241

Article

CAS

Google Scholar

J.A. Taylor, D.H. St John, J. Barresi and M.J. Couper, Influence of Mg Content on the Microstructure and Solid Solution Chemistry of Al-7%Si-Mg Casting Alloys During Solution Treatment, Mater. Sci. Forum, 2000, 331–337, p 277–282. https://doi.org/10.4028/www.scientific.net/MSF.331-337.277

Article

Google Scholar

X. Wu, H. Zhang, Z. Ma, T. Tao, J. Gui, W. Song, B. Yang and H. Zhang, Interactions Between Fe-Rich Intermetallics and Mg-Si Phase in Al-7Si-xMg Alloys, J. Alloys Compd., 2019, 786, p 205–214. https://doi.org/10.1016/j.jallcom.2019.01.352

Article

CAS

Google Scholar

K. Kim, A. Bobel, S. Baik, M. Walker, P.W. Voorhees and G.B. Olson, Enhanced Coarsening Resistance of Q-Phase in Aluminum Alloys by the Addition of Slow Diffusing Solutes, Mater. Sci. Eng. A, 2018, 735, p 318–323. https://doi.org/10.1016/j.msea.2018.08.059

Article

CAS

Google Scholar

A. Lombardi, C. Ravindran and R. MacKay, Optimization of the Solution Heat Treatment Process to Improve Mechanical Properties of 319 Al Alloy Engine Blocks Using the Billet Casting Method, Mater. Sci. Eng. A, 2015, 633, p 125–135. https://doi.org/10.1016/j.msea.2015.02.076

Article

CAS

Google Scholar

A.M.A. Mohamed, F.H. Samuel and S. Al Kahtani, Influence of Mg and Solution Heat Treatment on the Occurrence of Incipient Melting in Al-Si-Cu-Mg Cast Alloys, Mater. Sci. Eng. A, 2012, 543, p 22–34. https://doi.org/10.1016/j.msea.2012.02.032

Article

CAS

Google Scholar

L. Bourgeois, C. Dwyer, M. Weyland, J.-F. Nie and B.C. Muddle, Structure and Energetics of the Coherent Interface Between the θ’ Precipitate Phase and Aluminium in Al-Cu, Acta Mater., 2011, 59, p 7043–7050. https://doi.org/10.1016/j.actamat.2011.07.059

Article

CAS

Google Scholar

H. Chen, J. Lu, Y. Kong, K. Li, T. Yang, A. Meingast, M. Yang, Q. Lu and Y. Du, Atomic scale Investigation of the Crystal Structure and Interfaces of the β’ Precipitate in Al-Mg-Si Alloys, Acta Mater., 2020, 185, p 193–203. https://doi.org/10.1016/j.actamat.2019.11.059

Article

CAS

Google Scholar

C. Li, Y.Y. Wu, H. Li and X.F. Liu, Morphological Evolution and Growth Mechanism of Primary Mg2Si Phase in Al-Mg2Si Alloys, Acta Mater., 2011, 59, p 1058–1067. https://doi.org/10.1016/j.actamat.2010.10.036

Article

CAS

Google Scholar

J. Geng, T. Hong, Y. Ma, M. Wang, D. Chen, N. Ma and H. Wang, The Solution Treatment of in-situ sub-Micron TiB2/2024 Al Composite, Mater. Des., 2016, 98, p 186–193. https://doi.org/10.1016/j.matdes.2016.03.024

Article

CAS

Google Scholar

Y. He, Z. Jia, R.E. Sanders, Y. Liu, L. Ding, Y. Xing and Q. Liu, Quantitative Study of Dissolution of Mg2Si During Solution Treatment in AA6014 Alloy, J. Alloys Compd., 2017, 703, p 272–279. https://doi.org/10.1016/j.jallcom.2017.01.336

Article

CAS

Google Scholar

H. Li, B. Lin, R. Xu, K. Liu, H. Xiao and Y. Zhao, Enhanced Mechanical Properties of Al-Si-Cu-Mn-Fe Alloys at Elevated Temperatures Through Grain Refinement and Dispersoid Strengthening, Mater. Sci. Technol., 2020, 36, p 307–319. https://doi.org/10.1080/02670836.2019.1705039

Article

CAS

Google Scholar

E. Gariboldi, J.N. Lemke, L. Rovatti, O. Baer, G. Timelli and F. Bonollo, High-Temperature Behavior of High-Pressure Diecast Alloys Based on the Al-Si-Cu System: The Role Played by Chemical Composition, Metals, 2018, 8, p 348.

Article

Google Scholar

C.H. Cáceres, M.B. Djurdjevic, T.J. Stockwell and J.H. Sokolowski, The Effect of Cu Content on the Level of Microporosity in Al-Si-Cu-Mg Casting Alloys, Scr. Mater., 1999, 40, p 631–637. https://doi.org/10.1016/S1359-6462(98)00492-8

Article

Google Scholar

M. Zhang, K. Liu, J. Han, F. Qian, J. Wang and S. Guan, Investigating the Role of Cu, Zr and V on the Evolution of Microstructure and Properties of Al-Si-Mg Cast Alloys, Mater. Today Commun., 2021, 26, p 102055. https://doi.org/10.1016/j.mtcomm.2021.102055

Article

CAS

Google Scholar

H.Y. Zhan, Y.W. Xu, P. Wang, J.F. Wang, J.P. Li and L.P. Zhang, Effects of Magnesium and Copper Additions on Tensile properties of Al-Si-Cr Die Casting Alloy under as-Cast and T5 Conditions, China Foundry, 2023, 20, p 12–22. https://doi.org/10.1007/s41230-022-2082-2

Article

Google Scholar

X. Dong, S. Amirkhanlou and S. Ji, Formation of Strength Platform in Cast Al-Si-Mg-Cu Alloys, Sci. Rep., 2019, 9, p 9582. https://doi.org/10.1038/s41598-019-46134-7

Article

CAS

PubMed

PubMed Central

Google Scholar

J. Sun, G. Zeng, D. Rao, Y. Wang, Y. Yang, L. Pan and Z. Hu, Microstructure and Tensile Properties of a Cast Eutectic Al-Si-Cu Alloy Modified by Zr and V, Met. Mater. Int., 2021, 27, p 5436–5449. https://doi.org/10.1007/s12540-020-00909-0

Article

CAS

Google Scholar

D. Li, K. Liu, X.G. Chen, Influence of Transition Elements (V, Zr and Mo) and Cooling Rate on the Precipitation of Dispersoids in Al-7Si-0.6Cu-0.35Mg foundry alloy, MATEC Web of Conferences, 2020.

B. Baradarani and R. Raiszadeh, Precipitation Hardening of Cast Zr-Containing A356 Aluminium Alloy, Mater. Des., 2011, 32, p 935–940. https://doi.org/10.1016/j.matdes.2010.08.006

Article

CAS

Google Scholar

Y. Birol, A novel Al-Ti-B alloy for Grain Refining Al-Si Foundry Alloys, J. Alloys Compd., 2009, 486, p 219–222. https://doi.org/10.1016/j.jallcom.2009.07.064

Article

CAS

Google Scholar

R.G. Guan and D. Tie, A Review on Grain Refinement of Aluminum Alloys: Progresses, Challenges and Prospects, Acta Metall. Sin. (Engl. Lett.), 2017, 30, p 409–432. https://doi.org/10.1007/s40195-017-0565-8

Article

CAS

Google Scholar

K.T. Kashyap and T. Chandrashekar, Effects and Mechanisms of Grain Refinement in Aluminium Alloys, Bull. Mater. Sci., 2001, 24, p 345–353. https://doi.org/10.1007/BF02708630

Article

CAS

Google Scholar

B.S. Murty, S.A. Kori and M. Chakraborty, Grain Refinement of Aluminium and its Alloys by Heterogeneous Nucleation and Alloying, Int. Mater. Rev., 2002, 47, p 3–29. https://doi.org/10.1179/095066001225001049

Article

CAS

Google Scholar

G. Gyarmati, L. Bogoly, M. Stawarz, G. Fegyverneki, Z. Kéri, M. Tokár and T. Mende, Grain Refiner Settling and its Effect on the Melt Quality of Aluminum Casting Alloys, Materials, 2022, 15, p 7679. https://doi.org/10.3390/ma15217679

Article

CAS

PubMed

PubMed Central

Google Scholar

Y. Zhang, F. Yan, Y.H. Zhao, C.L. Song and H. Hou, Effect of Ti on Microstructure and Mechanical Properties of Die-Cast Al-Mg-Zn-Si Alloy, Mater. Res. Express, 2020, 7, p 036526. https://doi.org/10.1088/2053-1591/ab7f5d

Article

CAS

Google Scholar

P.S. Mohanty and J.E. Gruzleski, Grain Refinement Mechanisms of Hypoeutectic Al-Si Alloys, Acta Mater., 1996, 44, p 3749–3760. https://doi.org/10.1016/1359-6454(96)00021-3

Article

CAS

Google Scholar

S. Ji, D. Watson, Y. Wang, M. White and Z.Y. Fan, Effect of Ti Addition on Mechanical Properties of High pressure die cast Al-Mg-Si alloys, Mater. Sci. Forum, 2013, 765, p 23–27.

Article

Google Scholar

B.T. Sofyan, D.J. Kharistal, L. Trijati, K. Purba and R.E. Susanto, Grain Refinement of AA333 Aluminium Cast Alloy by Al-Ti Granulated Flux, Mater. Des., 2010, 31, p S36–S43. https://doi.org/10.1016/j.matdes.2010.02.007

Article

CAS

Google Scholar

K. Abdel-Aziz and A. Alogla, Experimental Investigation on the Behavior of AlSiMgMn Alloy Inoculated by Al-5Ti Master Alloy and Fabricated by Die-Casting with Different Mold Wall Thicknesses, Int. J. Eng. Res. Technol., 2020, 13, p 1764. https://doi.org/10.37624/ijert/13.7.2020.1764-1774

Article

Google Scholar

D. Wang, X. Zhang, S. Xu, H. Nagaumi and X. Li, Improvement of Mechanical Properties in Micro-Alloying Al-Si-Mg-Zn Cast Alloy, Mater. Lett., 2021, 283, p 128810. https://doi.org/10.1016/j.matlet.2020.128810

Article

CAS

Google Scholar

J. Feng, S. Hou, S. Chen, F. Zhang, Y. Chen, F. Zhang and D. Li, Effect of minor Ca and Mo Addition on the Microstructure and Mechanical Properties of Semisolid Die-Casting Al-6Mg-2Si-0.6Mn Alloy, J. Mater. Res. Technol., 2022, 21, p 2133–2144. https://doi.org/10.1016/j.jmrt.2022.10.061

Article

CAS

Google Scholar

A.R. Farkoosh, X. Grant Chen and M. Pekguleryuz, Interaction Between Molybdenum and Manganese to form Effective Dispersoids in an Al-Si-Cu-Mg Alloy and their Influence on Creep Resistance, Mater. Sci. Eng. A, 2015, 627, p 127–138. https://doi.org/10.1016/j.msea.2014.12.115

Article

CAS

Google Scholar

E. Kilinc, N. Kiremitci, Y. Birol and E. Dokumaci, Effect of Vanadium and Zirconium Additions on Mechanical Properties and Microstructure of Gravity Die-Cast AlSi9Cu2 Alloy Cylinder Heads, Int. J. Metalcast., 2019, 13, p 137–145. https://doi.org/10.1007/s40962-018-0238-z

Article

CAS

Google Scholar

O. Prach, O. Trudonoshyn, P. Randelzhofer, C. Körner and K. Durst, Multi-Alloying Effect of Sc, Zr, Cr on the Al-Mg-Si-Mn High-Pressure Die Casting Alloys, Mater Charact, 2020, 168, p 110537. https://doi.org/10.1016/j.matchar.2020.110537

Article

CAS

Google Scholar

T. Gao and X. Liu, Replacement with Each Other of Ti and Zr in the Intermetallics of Al-(Si-)Ti-Zr Alloys, J. Mater. Sci. Technol., 2013, 29, p 291–296. https://doi.org/10.1016/j.jmst.2013.01.018

Article

CAS

Google Scholar

Q. Hu, W. Guo and H. Zhao, Influence of Wall Thickness and Intensification Pressure on the Microstructures and Mechanical Properties of AlSi7-SiC Composites Fabricated by the Vacuum-Assisted HPDC Process, Mater. Sci. Eng. A, 2021, 819, p 141470. https://doi.org/10.1016/j.msea.2021.141470

Article

CAS

Google Scholar

Z. Zhang, X.G. Chen and A. Charette, Particle Distribution and Interfacial Reactions of Al-7%Si-10%B4C Die Casting Composite, J. Mater. Sci., 2007, 42, p 7354–7362. https://doi.org/10.1007/s10853-007-1554-5

Article

CAS

Google Scholar

Q. Hu, H. Zhao and F. Li, Microstructures and Properties of SiC Particles Reinforced Aluminum-Matrix Composites Fabricated by Vacuum-Assisted High Pressure Die Casting, Mater. Sci. Eng. A, 2017, 680, p 270–277. https://doi.org/10.1016/j.msea.2016.10.090

Article

CAS

Google Scholar

K.R. Ravi, R.M. Pillai, K.R. Amaranathan, B.C. Pai and M. Chakraborty, Fluidity of Aluminum Alloys and Composites: A Review, J. Alloys Compd., 2008, 456, p 201–210. https://doi.org/10.1016/j.jallcom.2007.02.038

Article

CAS

Google Scholar

Y.M. Youssef, R.J. Dashwood and P.D. Lee, Effect of Clustering on Particle Pushing and Solidification Behaviour in TiB2 Reinforced Aluminium PMMCs, Compos. A, 2005, 36, p 747–763. https://doi.org/10.1016/j.compositesa.2004.10.027

Article

CAS

Google Scholar

Q. Yang, Y. Ma, Z. Chen, G. Ji, M.L. Wang, S.Y. Zhong, Y. Wu, V. Ji and H.W. Wang, A New Powder Metallurgy Routine to Fabricate TiB2/Al-Zn-Mg-Cu Nanocomposites Based on Composite Powders with Pre-Embedded Nanoparticles, Materialia, 2019, 8, p 100458. https://doi.org/10.1016/j.mtla.2019.100458

Article

CAS

Google Scholar

K. Wang, H.Y. Jiang, Y.W. Jia, H. Zhou, Q.D. Wang, B. Ye and W.J. Ding, Nanoparticle-Inhibited Growth of Primary Aluminum in Al-10Si Alloys, Acta Mater., 2016, 103, p 252–263. https://doi.org/10.1016/j.actamat.2015.10.005

Article

CAS

Google Scholar

D.M. Stefanescu, F.R. Juretzko, A. Catalina, B.K. Dhindaw, S. Sen and P.A. Curreri, Particle Engulfment and Pushing by Solidifying Interfaces: Part II. Microgravity Experiments and Theoretical Analysis, Metall. Mater. Trans. A., 1998, 29, p 1697–1706. https://doi.org/10.1007/s11661-998-0092-3

Article

Google Scholar

X. Chen and H. Yan, Solid-Liquid Interface Dynamics During Solidification of Al 7075-Al2O3np Based Metal Matrix Composites, Mater. Des., 2016, 94, p 148–158. https://doi.org/10.1016/j.matdes.2016.01.042

Article

CAS

Google Scholar

B. Dong, Q. Li, Z. Wang, T. Liu, H. Yang, S. Shu, L. Chen, F. Qiu, Q. Jiang and L. Zhang, Enhancing Strength-Ductility Synergy and Mechanisms of Al-Based Composites by Size-Tunable in-situ TiB2 Particles with Specific Spatial Distribution, Compos. B, 2021, 217, p 108912. https://doi.org/10.1016/j.compositesb.2021.108912

Article

CAS

Google Scholar

C. Gu, Y. Lu, E. Cinkilic, J. Miao, A. Klarner, X. Yan and A.A. Luo, Predicting Grain Structure in High Pressure Die Casting of Aluminum Alloys: A Coupled Cellular Automaton and Process Model, Comput. Mater. Sci., 2019, 161, p 64–75. https://doi.org/10.1016/j.commatsci.2019.01.029

Article

CAS

Google Scholar

G. Niu, J. Wang, J. Li, J. Ye and J. Mao, The Formation Mechanism of the Chill Fine-Grain Layer with High Supersaturation and its Influence on the Mechanical Properties of Die Casting Al-7Si-05Mg Alloy, Mater. Sci. Eng. A, 2022, 833, p 142544. https://doi.org/10.1016/j.msea.2021.142544

Article

CAS

Google Scholar

M. Wang, D. Chen, Z. Chen, Y. Wu, F. Wang, N. Ma and H. Wang, Mechanical Properties of in-situ TiB2/A356 Composites, Mater. Sci. Eng. A, 2014, 590, p 246–254. https://doi.org/10.1016/j.msea.2013.10.021

Article

CAS

Google Scholar

N. Kumar, G. Gautam, R.K. Gautam, A. Mohan and S. Mohan, Synthesis and Characterization of TiB2 Reinforced Aluminium Matrix Composites: A Review, J. Inst. Eng. (India) Ser., 2016, 97, p 233–253. https://doi.org/10.1007/s40033-015-0091-7

Article

Google Scholar

V. Mohanavel, M. Ravichandran, V. Anandakrishnan, A. Pramanik, M. Meignanamoorthy, A. Karthick and M. Muhibbullah, Mechanical Properties of Titanium Diboride Particles Reinforced Aluminum Alloy Matrix Composites: A Comprehensive Review, Adv. Mater. Sci. Eng., 2021, 2021, p 7602160. https://doi.org/10.1155/2021/7602160

Article

CAS

Google Scholar

X. Dong, H. Youssef, Y. Zhang, H. Yang, S. Wang and S. Ji, Advanced Heat Treated Die-Cast Aluminium Composites Fabricated by TiB2 Nanoparticle Implantation, Mater. Des., 2020, 186, p 108372. https://doi.org/10.1016/j.matdes.2019.108372

Article

CAS

Google Scholar

X. Dong, H. Youssef, X. Zhu, Y. Zhang, S. Wang and S. Ji, High As-Cast Strength Die-Cast AlSi9Cu2Mg Alloy Prepared by Nanoparticle Strengthening with Industrially Acceptable Ductility, J. Alloys Compd., 2021, 852, p 156873. https://doi.org/10.1016/j.jallcom.2020.156873

Article

CAS

Google Scholar

Y. Li, S. Xi, G. Ma, Y. Xiao, L. Li, Z. Yuan, Y. He, R. Zhou and Y. Jiang, Understanding the Influencing Mechanism of Sub-Micron Sized TiB2p on the Microstructures and Properties of Rheological Squeeze Casting Hypereutectic Al-Si Alloys, J. Mater. Res. Technol., 2021, 14, p 57–68. https://doi.org/10.1016/j.jmrt.2021.06.048

Article

CAS

Google Scholar

S.S. Ahn, S. Pathan, J.M. Koo, C.H. Baeg, C.U. Jeong, H.T. Son, Y.H. Kim, K.H. Lee and S.J. Hong, Enhancement of the Mechanical Properties in Al-Si-Cu-Fe-Mg Alloys with Various Processing Parameters, Materials (Basel), 2018, 11, p 150. https://doi.org/10.3390/ma11112150

Article

CAS

Google Scholar

Q.G. Wang and C.H. Cáceres, The Fracture Mode in Al-Si-Mg Casting Alloys, Mater. Sci. Eng. A, 1998, 241, p 72–82. https://doi.org/10.1016/S0921-5093(97)00476-0

Article

Google Scholar

S. Xi, G. Ma, L. Li, Y. Zhang, X. Yu, Y. Li and R. Zhou, Microstructures and Mechanical Properties of 4 wt%TiB2/Al-Si-Cu-Zn (T6) Composite Thin-Walled Shell Housing Fabricated by High Pressure Die Casting, Mater. Res. Express, 2021, 8, p 036514. https://doi.org/10.1088/2053-1591/abecae

Article

CAS

Google Scholar

S. Amirkhanlou, S. Ji, Y. Zhang, D. Watson and Z. Fan, High Modulus Al-Si-Mg-Cu/Mg2Si-TiB2 Hybrid Nanocomposite: Microstructural Characteristics and Micromechanics-Based Analysis, J. Alloys Compd., 2017, 694, p 313–324. https://doi.org/10.1016/j.jallcom.2016.10.016

Article

CAS

Google Scholar

G. Liu, M. Karim, S. Wang, D. Eskin and B. McKay, Processing of SiC Nano-Reinforced AlSi9Cu3 Composites by Stir Mixing, Ultrasonication and High Pressure Die Casting, J. Mater. Res. Technol., 2022, 18, p 2384–2398. https://doi.org/10.1016/j.jmrt.2022.03.132

Article

CAS

Google Scholar

E.J. Vinarcik, High Integrity Die Casting Processes, Wiley-Interscience, USA, 2003.

Google Scholar

E. Lordan, Y. Zhang, K. Dou, A. Jacot, C. Tzileroglou, S. Wang, Y. Wang, J. Patel, J. Lazaro-Nebreda, X. Zhou, T. Hashimoto and Z. Fan, High-Pressure Die Casting: A Review of Progress from the EPSRC Future LiME Hub, Metals, 2022, 12, p 1575.

Article

CAS

Google Scholar

M. Patel, P. Krishna and M.B. Parappagoudar, Modelling of Squeeze Casting Process using Design of Experiments and Response Surface Methodology, Int. J. Cast Met. Res., 2015, 28, p 167–180. https://doi.org/10.1179/1743133614Y.0000000144

Article

Google Scholar

S. Ji, Y. Wang, D. Watson and Z. Fan, Microstructural Evolution and Solidification Behavior of Al-Mg-Si Alloy in High-Pressure Die Casting, Metall. Mater. Trans. A, 2013, 44, p 3185–3197. https://doi.org/10.1007/s11661-013-1663-5

Article

CAS

Google Scholar

Y. Liu, Y. Zhang, W. Liu, X. Jiao, H. Nishat, D. Ajavavarakula, H. Chen and S. Xiong, Enhanced Mechanical Properties and Thermal Conductivity of high-Pressure die-Cast AlMg6Si2MnZr Alloy by Controlling the Externally Solidified Crystals, J. Mater. Process. Technol., 2022, 306, 117645. https://doi.org/10.1016/j.jmatprotec.2022.117645

Article

CAS

Google Scholar

K. Dou, Y. Zhang, E. Lordan, A. Jacot and Z. Fan, Understanding the Initial Solidification Behavior for Al-Si Alloy in Cold Chamber High-Pressure Die Casting (CC-HPDC) Process Combining Experimental and Modeling Approach, Metall. Mater. Trans. A, 2022, 53, p 3110–3124. https://doi.org/10.1007/s11661-022-06731-0

Article

CAS

Google Scholar

S. Otarawanna, C.M. Gourlay, H.I. Laukli and A.K. Dahle, Formation of the Surface Layer in Hypoeutectic Al-Alloy High-Pressure Die Castings, Mater. Chem. Phys., 2011, 130, p 251–258. https://doi.org/10.1016/j.matchemphys.2011.06.035

Article

CAS

Google Scholar

L.F. Gomes, C.L. Kugelmeier, A. Garcia, C.A. Della Rovere and J.E. Spinelli, Influences of Alloying Elements and Dendritic Spacing on the Corrosion Behavior of Al-Si-Ag Alloys, J. Mater. Res. Technol., 2021, 15, p 5880–5893. https://doi.org/10.1016/j.jmrt.2021.11.043

Article

CAS

Google Scholar

S. Otarawanna, C.M. Gourlay, H.I. Laukli and A.K. Dahle, The Thickness of Defect Bands in High-Pressure Die Castings, Mater Charact., 2009, 60, p 1432–1441. https://doi.org/10.1016/j.matchar.2009.06.016

Article

CAS

Google Scholar

A.K. Dahle, S. Sannes, D.H. John and H. Westengen, Formation of Defect Bands in High Pressure Die Cast Magnesium Alloys, J. Light Met., 2001, 1, p 99–103. https://doi.org/10.1016/S1471-5317(01)00002-5

Article

Google Scholar

H. Cao and M. Wessen, Characteristics of Microstructure and Banded Defects in Die Cast AM50 Magnesium Components, Int. J. Cast Met. Res., 2005, 18, p 377–384. https://doi.org/10.1179/136404605225023216

Article

CAS

Google Scholar

H.P. Cao, On Some Characteristics of Microstructure and Defects in Die-Cast Magnesium Components, Mater. Sci. Forum, 2005, 488–489, p 283–286. https://doi.org/10.4028/www.scientific.net/MSF.488-489.283

Article

Google Scholar

C.M. Gourlay and A.K. Dahle, Dilatant Shear Bands in Solidifying Metals, Nature, 2007, 445, p 70–73. https://doi.org/10.1038/nature05426

Article

CAS

PubMed

Google Scholar

G. Timelli and A. Fabrizi, The effects of Microstructure Heterogeneities and Casting Defects on the Mechanical Properties of High-Pressure Die-Cast AlSi9Cu3(Fe) Alloys, Metall. Mater. Trans. A, 2014, 45, p 5486–5498. https://doi.org/10.1007/s11661-014-2515-7

Article

CAS

Google Scholar

H.I. Laukli, C.M. Gourlay, A.K. Dahle and O. Lohne, Effects of Si Content on Defect Band Formation in Hypoeutectic Al-Si Die Castings, Mater. Sci. Eng. A, 2005, 413–414, p 92–97. https://doi.org/10.1016/j.msea.2005.08.194

Article

CAS

Google Scholar

B. Meylan, S. Terzi, C.M. Gourlay and A.K. Dahle, Dilatancy and Rheology at 0–60% Solid During Equiaxed Solidification, Acta Mater., 2011, 59, p 3091–3101. https://doi.org/10.1016/j.actamat.2011.01.049

Article

CAS

Google Scholar

S. Ji, H. Yang, X. Cui and Z. Fan, Macro-Heterogeneities in Microstructures, Concentrations, Defects and Tensile Properties of Die Cast Al-Mg-Si Alloys, Mater. Sci. Technol., 2017, 33, p 2223–2233. https://doi.org/10.1080/02670836.2017.1334309

Article

CAS

Google Scholar

A.K. Dahle and L. Arnberg, Development of Strength in Solidifying Aluminium alloys, Acta Mater., 1997, 45, p 547–559. https://doi.org/10.1016/S1359-6454(96)00203-0

Article

CAS

Google Scholar

C.M. Gourlay, B. Meylan and A.K. Dahle, Shear Mechanisms at 0–50% Solid During Equiaxed Dendritic Solidification of an AZ91 Magnesium Alloy, Acta Mater., 2008, 56, p 3403–3413. https://doi.org/10.1016/j.actamat.2008.03.020

Article

CAS

Google Scholar

C.M. Gourlay, T. Nagira, A.K. Dahle, N. Nakatsuka, K. Uesugi and H. Yasuda, Synchrotron Radiography of Direct-Shear in Semi-Solid Alloys, Mater. Sci. Eng., 2012, 27, p 012086. https://doi.org/10.1088/1757-899X/27/1/012086

Article

CAS

Google Scholar

L. Yuan, C. O’Sullivan and C.M. Gourlay, Exploring Dendrite Coherency with the Discrete Element Method, Acta Mater., 2012, 60, p 1334–1345. https://doi.org/10.1016/j.actamat.2011.11.042

Article

CAS

Google Scholar

S.G. Shabestari and E. Ghaniabadi, Effect of Ca and Rotation Speed on Microstructure and Solidification Parameters of AZ91 Magnesium Alloy Produced by Semi-Solid Casting Through Rotating Container Process, Trans. Nonferrous Met. Soc. China, 2023, 33, p 396–408. https://doi.org/10.1016/S1003-6326(22)66115-6

Article

CAS

Google Scholar

C.M. Gourlay, H.I. Laukli and A.K. Dahle, Defect Band Characteristics in Mg-Al and Al-Si High-Pressure Die Castings, Metall. Mater. Trans. A, 2007, 38, p 1833–1844. https://doi.org/10.1007/s11661-007-9243-1

Article

CAS

Google Scholar

Y.Y. Hou, M.W. Wu, B.H. Tian, X.B. Li and S.M. Xiong, Characteristics and Formation Mechanisms of Defect Bands in Vacuum-Assisted High-Pressure Die Casting AE44 Alloy, Trans. Nonferrous Met. Soc. China, 2022, 32, p 1852–1865. https://doi.org/10.1016/S1003-6326(22)65913-2

Article

CAS

Google Scholar

Y.Y. Hou, M.W. Wu, F. Huang, X.B. Li and S.M. Xiong, Defect Band Formation in High Pressure Die Casting AE44 Magnesium Alloy, China Foundry, 2022, 19, p 201–210. https://doi.org/10.1007/s41230-022-1220-1

Article

Google Scholar

F. Liu, H. Zhao, B. Chen and H. Zheng, Investigation on Microstructure Heterogeneity of the HPDC AlSiMgMnCu Alloy Through 3D Electron Microscopy, Mater. Des., 2022, 218, p 110679. https://doi.org/10.1016/j.matdes.2022.110679

Article

CAS

Google Scholar

T. Wang, J. Huang, H. Fu, K. Yu and S. Yao, Influence of Process Parameters on Filling and Feeding Capacity During High-Pressure Die-Casting Process, Appl. Sci., 2022, 12, p 4757.

Article

CAS

Google Scholar

A.R. Adamane, L. Arnberg, E. Fiorese, G. Timelli and F. Bonollo, Influence of Injection Parameters on the Porosity and Tensile Properties of High-Pressure Die Cast Al-Si Alloys: a review, Int. J. Metalcast., 2015, 9, p 43–53. https://doi.org/10.1007/BF03355601

Article

Google Scholar

X. Li, S.M. Xiong and Z. Guo, Improved Mechanical Properties in Vacuum-Assist High-Pressure Die Casting of AZ91D Alloy, J. Mater. Process. Technol., 2016, 231, p 1–7. https://doi.org/10.1016/j.jmatprotec.2015.12.005

Article

CAS

Google Scholar

E. Fiorese and F. Bonollo, Simultaneous Effect of Plunger Motion Profile, Pressure, and Temperature on the Quality of High-Pressure Die-Cast Aluminum Alloys, Metall. Mater. Trans. A, 2016, 47, p 6453–6465. https://doi.org/10.1007/s11661-016-3732-z

Article

CAS

Google Scholar

M.S. Dargusch, G. Dour, N. Schauer, C.M. Dinnis and G. Savage, The Influence of Pressure During Solidification of High Pressure Die Cast Aluminium Telecommunications Components, J. Mater. Process. Technol., 2006, 180, p 37–43. https://doi.org/10.1016/j.jmatprotec.2006.05.001

Article

CAS

Google Scholar

H.J. Kang, P.H. Yoon, G.H. Lee, J.Y. Park, B.J. Jung, J.Y. Lee, C.U. Lee, E.S. Kim and Y.S. Choi, Evaluation of the Gas Porosity and Mechanical Properties of Vacuum Assisted Pore-Free Die-Cast Al-Si-Cu Alloy, Vacuum, 2021, 184, p 109917. https://doi.org/10.1016/j.vacuum.2020.109917

Article

CAS

Google Scholar

P. Szalva and I.N. Orbulov, The Effect of Vacuum Degree on the Porosity and Mechanical Properties of Die Cast AlSi9Cu3(Fe) Alloy, Resolut. Disc., 2018, 3, p 33–38.

Article

Google Scholar

R.Y. Jou, Investigations of the High Vacuum Die Castings of Dumbbell Specimens, Mater. Sci. Forum, 2009, 628–629, p 727–734.

Article

Google Scholar

W.B. Lee and H.Y. Lu, Modeling of Air Back Pressure in Die-Casting Dies, J. Mater. Process. Technol., 1999, 91, p 264–269. https://doi.org/10.1016/S0924-0136(98)00418-X

Article

Google Scholar

X.P. Niu, B.H. Hu, I. Pinwill and H. Li, Vacuum Assisted High Pressure Die Casting of Aluminium Alloys, J. Mater. Process. Technol., 2000, 105, p 119–127. https://doi.org/10.1016/S0924-0136(00)00545-8

Article

Google Scholar

H. Cao, Q. Sun, Q. Pu, L. Wang, M. Huang, Z. Luo and J. Che, Effect of Vacuum Degree and T6 Treatment on the Microstructure and Mechanical Properties of Al-Si-Cu Alloy Die Castings, Vacuum, 2020, 172, p 109063. https://doi.org/10.1016/j.vacuum.2019.109063

Article

CAS

Google Scholar

H. Yang, S. Ji, D. Watson and Z. Fan, Repeatability of Tensile Properties in High Pressure Die-Castings of an Al-Mg-Si-Mn alloy, Met. Mater. Int., 2015, 21, p 936–943. https://doi.org/10.1007/s12540-015-5108-0

Article

CAS

Google Scholar

Y. Wang, S.M. Xing, X.H. Ao and T.Y. Wang, Microstructure Evolution of A380 Aluminum Alloy During Rheological Process under Applied Pressure, China Foundry, 2019, 16, p 371–379. https://doi.org/10.1007/s41230-019-9013-x

Article

Google Scholar

R. Li, L. Liu, L. Zhang, J. Sun, Y. Shi and B. Yu, Effect of Squeeze Casting on Microstructure and Mechanical Properties of Hypereutectic Al-xSi Alloys, J. Mater. Sci. Technol., 2017, 33, p 404–410. https://doi.org/10.1016/j.jmst.2017.02.004

Article

CAS

Google Scholar

Z. Fan, W. Song, H.R. Zhang, B.S. Zhou, X.Y. Wu, L.N. Jia and H. Zhang, Effect of Holding Pressure on Density and Cooling Rate of Cast Al-Si Alloy During Additive Pressure Casting, China Foundry, 2019, 16, p 363–370. https://doi.org/10.1007/s41230-019-9085-7

Article

Google Scholar

K.T. Chiang, N.M. Liu and T.C. Tsai, Modeling and Analysis of the Effects of Processing Parameters on the Performance Characteristics in the High Pressure die Casting Process of Al-Si alloys, Int. J. Adv. Manuf. Technol., 2009, 41, p 1076–1084. https://doi.org/10.1007/s00170-008-1559-5

Article

Google Scholar

S. Otarawanna, H.I. Laukli, C.M. Gourlay and A.K. Dahle, Feeding Mechanisms in High-Pressure Die Castings, Metall. Mater. Trans. A, 2010, 41, p 1836–1846. https://doi.org/10.1007/s11661-010-0222-6

Article

CAS

Google Scholar

C.P. Hong, S.M. Lee and H.F. Shen, Prevention of Macrodefects in Squeeze Casting of an Al-7 wt Pct Si Alloy, Metall. Mater. Trans. B, 2000, 31, p 297–305. https://doi.org/10.1007/s11663-000-0048-5

Article

Google Scholar

Q.G. Wang, D. Apelian and D.A. Lados, Fatigue Behavior of A356/357 Aluminum Cast Alloys. Part II-Effect of Microstructural Constituents, J. Light Met., 2001, 1, p 85–97. https://doi.org/10.1016/S1471-5317(00)00009-2

Article

Google Scholar

G. Timelli, D. Caliari and J. Rakhmonov, Influence of Process Parameters and Sr Addition on the Microstructure and Casting Defects of LPDC A356 Alloy for Engine Blocks, J. Mater. Sci. Technol., 2016, 32, p 515–523. https://doi.org/10.1016/j.jmst.2016.03.010

Article

CAS

Google Scholar

X. Wu, H. Zhang, Z. Ma, L. Jia and H. Zhang, Effect of Holding Pressure on Microstructure and Mechanical Properties of A356 Aluminum Alloy, J. Mater. Eng. Perform., 2018, 27, p 483–491. https://doi.org/10.1007/s11665-017-2920-3

Article

CAS

Google Scholar

M.R. Ghomashchi and A. Vikhrov, Squeeze Casting: An Overview, J. Mater. Process. Technol., 2000, 101, p 1–9. https://doi.org/10.1016/S0924-0136(99)00291-5

Article

Google Scholar

E. Lordan, Y. Zhang, K. Dou, A. Jacot, C. Tzileroglou, P. Blake and Z. Fan, On the Probabilistic Nature of High-Pressure Die Casting, Mater. Sci. Eng. A, 2021, 817, p 141391. https://doi.org/10.1016/j.msea.2021.141391

Article

CAS

Google Scholar

C.T. Wang, J. Yao, H.D. Zhao and R.S. Yang, Influence of Intensification Pressures on Pores in Die-Cast ADC12 Alloys, China Foundry, 2019, 16, p 184–189. https://doi.org/10.1007/s41230-019-8171-1

Article

Google Scholar

M.S. Dargusch, A. Hamasaiid, G. Dour, N. Balasubramani and D.H. StJohn, The Influence of in-cavity Pressure on Heat Transfer and Porosity Formation During High-Pressure Die Casting of A380 Alloy, JOM, 2020, 72, p 3798–3805. https://doi.org/10.1007/s11837-020-04341-y

Article

CAS

Google Scholar

S.L. dos Santos, R.A. Antunes and S.F. Santos, Influence of Injection Temperature and Pressure on the Microstructure, Mechanical and Corrosion Properties of a AlSiCu Alloy Processed by HPDC, Mater. Des., 2015, 88, p 1071–1081. https://doi.org/10.1016/j.matdes.2015.09.095

Article

CAS

Google Scholar

L. Patnaik, I. Saravanan and S. Kumar, Die Casting Parameters and Simulations for Crankcase of Automobile Using MAGMAsoft, Materials Today Proceedings, 2020, 22, p 563–571. https://doi.org/10.1016/j.matpr.2019.08.208

Article

CAS

Google Scholar

W. Liu, T. Peng, Y. Kishita, Y. Umeda, R. Tang, W. Tang and L. Hu, Critical Life Cycle Inventory for Aluminum Die Casting: A Lightweight-Vehicle Manufacturing Enabling Technology, Appl. Energy, 2021, 304, p 117814. https://doi.org/10.1016/j.apenergy.2021.117814

Article

CAS

Google Scholar

P. Szalva and I.N. Orbulov, The Effect of Vacuum on the Mechanical Properties of Die Cast Aluminum AlSi9Cu3(Fe) Alloy, Int. J. Metalcast., 2019, 13, p 853–864. https://doi.org/10.1007/s40962-018-00302-z

Article

CAS

Google Scholar