Unlocking Superior Hardness in Aluminum Alloys: A Breakthrough in Hybrid AMMC Reinforcement

This technical summary is based on the academic paper "DEVELOPMENT AND TESTING THE PROPERTIES OF HYBRID COMPOSITE USING ALUMINIUM 6061 WITH TiC AND GRAPHENE" by Nishanth Pasupathy, published by the University of Windsor (2021).

![Figure 2 Classification of metal matrix processing [11].](https://castman.co.kr/wp-content/uploads/image-3786.webp)

Keywords

- Primary Keyword: Aluminum Metal Matrix Composite (AMMC)

- Secondary Keywords: Hybrid Composite, Stir Casting, Aluminium 6061, Titanium Carbide (TiC), Graphene Reinforcement, Mechanical Properties, Microstructural Analysis

Executive Summary

- The Challenge: Conventional monolithic aluminum alloys like Al6061 possess desirable lightweight properties but suffer from poor wear resistance and medium strength, limiting their use in high-performance applications.

- The Method: Researchers developed a hybrid Aluminum Metal Matrix Composite (AMMC) by reinforcing an Al6061 matrix with micron-sized Titanium Carbide (TiC) and nano-sized Graphene particles using an optimized two-step stir casting process.

- The Key Breakthrough: The study identified optimal processing parameters (500 rpm stirring speed for a total of 20 minutes) that achieved a uniform particle distribution and significantly increased the material's hardness by up to 30.9% compared to the base Al6061 alloy.

- The Bottom Line: This research demonstrates a viable method for manufacturing advanced hybrid AMMCs with enhanced mechanical properties, paving the way for stronger, more durable lightweight components in the automotive and aerospace industries.

The Challenge: Why This Research Matters for HPDC Professionals

In industries from automotive to aerospace, the demand for materials that offer high strength-to-weight ratios is relentless. While Aluminium 6061 is a workhorse alloy due to its good formability and corrosion resistance, its inherent limitations in hardness and wear resistance are a significant engineering hurdle. Developing composites to overcome these weaknesses is a key area of innovation.

However, manufacturing these advanced composites, particularly those using nano-sized reinforcements like graphene, presents a major challenge: achieving a uniform, homogeneous distribution of reinforcement particles within the metal matrix. Agglomeration (clustering) and porosity are common defects in conventional stir casting, leading to inconsistent material properties and negating the benefits of the reinforcement. This research directly addresses the need for a reliable fabrication technique to produce high-quality, high-performance hybrid AMMCs.

The Approach: Unpacking the Methodology

To overcome the limitations of traditional methods, the research team employed a two-step stir casting technique designed to improve particle wettability and distribution. The methodology was precise and controlled, providing confidence in the results.

Method 1: Material Composition and Preparation

- Matrix: Al6061-T6 alloy (95.7% by weight) was used as the base matrix.

- Reinforcements: The hybrid reinforcement consisted of micron-sized Titanium Carbide (TiC) particles (4% by weight) and nano-sized Graphene particles (0.3% by weight).

- Preparation: The Al6061 was melted in a crucible. The TiC and Graphene reinforcements were preheated separately for 2 hours to remove moisture, which can cause porosity.

Method 2: Two-Step Stir Casting Process

- Step 1 (Semi-Solid State): The molten Al6061 was heated to 750°C and then cooled to a semi-solid state at 600°C. The preheated TiC and Graphene particles were then added. The mixture was stirred mechanically at this semi-solid temperature to enhance wettability and begin particle distribution.

- Step 2 (Liquid State): The temperature was raised back to the liquidus state (750°C) to remove any void fractions. A second stirring process was performed.

- Controlled Variables: Four sample batches (A, B, C, D) were produced by varying the stirring speed (400 rpm and 500 rpm) and total stirring time (10 minutes and 20 minutes) to identify the optimal processing parameters.

- Final Casting: The final composite melt was poured into a preheated mold for solidification.

The Breakthrough: Key Findings & Data

The study's results clearly demonstrate a strong correlation between the stir casting process parameters and the final quality and mechanical properties of the hybrid AMMC.

Finding 1: Optimal Stirring Parameters Yield Uniform Microstructure

Microstructural analysis using Scanning Electron Microscopy (SEM) revealed that higher stirring speed and longer duration were critical for achieving a homogeneous distribution of TiC particles.

- Samples A and B, produced at a lower speed of 400 rpm, showed poor particle distribution, agglomeration, and debonding of the reinforcement from the matrix (Figure 21a, 21b).

- Sample D, fabricated with the highest speed (500 rpm) and longest time (20 minutes), exhibited an "Excellent" and uniform distribution of TiC particles throughout the aluminum matrix (Figure 21d, Table 8). While minor voids were present, the overall microstructure was superior.

Finding 2: Significant Hardness Improvement Achieved

The addition of hard TiC and Graphene reinforcements, combined with the optimized processing of Sample D, resulted in a substantial increase in macro-hardness.

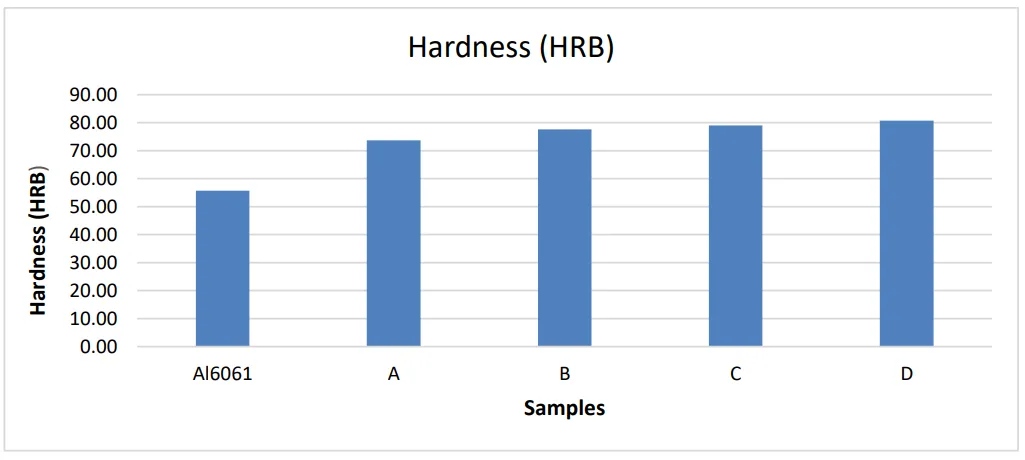

- Rockwell B hardness tests were conducted on all samples. As shown in Figure 22, the base Al6061-T6 had an average hardness of 55.73 HRB.

- The hardness of the composite samples increased progressively with improved processing parameters. Sample D achieved the highest average hardness of 80.73 HRB.

- According to the paper, this represents a hardness increase ranging from 22.4% to 30.9% over the monolithic Al6061, directly confirming the effectiveness of the hybrid reinforcement and fabrication method.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that implementing a two-step stir casting process, with careful control over stirring speed and duration in both semi-solid and liquid states, may contribute to significantly reducing reinforcement agglomeration and improving material consistency.

- For Quality Control Teams: The data in Figure 21 and Table 9 of the paper illustrates the effect of processing conditions on microstructure and hardness. The SEM images provide a clear visual reference for identifying defects like particle clustering and debonding, which could inform new quality inspection criteria for advanced composites.

- For Design Engineers: The findings indicate that the successful incorporation of hybrid reinforcements like TiC and Graphene can elevate the mechanical properties of standard alloys like Al6061. This opens the possibility of designing lighter components for applications that previously required heavier materials, without sacrificing hardness or wear resistance.

Paper Details

DEVELOPMENT AND TESTING THE PROPERTIES OF HYBRID COMPOSITE USING ALUMINIUM 6061 WITH TiC AND GRAPHENE

1. Overview:

- Title: DEVELOPMENT AND TESTING THE PROPERTIES OF HYBRID COMPOSITE USING ALUMINIUM 6061 WITH TiC AND GRAPHENE

- Author: Nishanth Pasupathy

- Year of publication: 2021

- Journal/academic society of publication: University of Windsor, Scholarship at UWindsor, Major Papers

- Keywords: Aluminum Metal Matrix Composite (AMMC), Aluminium 6061, TiC, Graphene, Two-step stir casting, Hardness, Microstructure

2. Abstract:

Aluminum is more widely employed metal in industries due to its advantageous characteristics. But there are some limitations in the usage of aluminum which can be resolved by developing composites with reinforcement. So, AMMC is gaining more recognition in the industrial sector with regards to its mechanical behavior and possess good thermal conductance. Aluminum based MMC reinforced with TiC and graphene particles were developed successfully by two step stir casting. Two step stir casting was incorporated to overcome the disadvantages of the traditional stir casting technique that results in increased porosity and agglomeration which results in the non-homogeneous distribution of the particles. The stirring speed and stirring time play a vital role in the microstructure and mechanical properties of the final fabricated composite. The weight percentage of Al6061 is 95.7% is reinforced with TiC of 4% and Graphene of 0.3% under the parameters of stirring speeds 400 and 500 rpm and with stirring time of 10 and 20 minutes. To estimate this, mechanical property such as hardness is analyzed for pure aluminum and the reinforced composite with different stirring conditions that proves the enhanced properties of the developed hybrid composite. In addition to this, the SEM analysis were done to test the homogeneity of the particle distribution in the matrix.

3. Introduction:

Composite materials combine two or more materials to achieve superior properties over individual components. Metal Matrix Composites (MMCs), specifically Aluminum-based MMCs (AMMCs), are gaining prominence for their low weight-to-strength ratios, high thermal conductivity, and stiffness. This research focuses on developing a hybrid AMMC using an Aluminium 6061 matrix, which is widely used but limited by medium strength and poor wear resistance. The study aims to enhance these properties by incorporating two reinforcement materials: micron-sized Titanium Carbide (TiC) and nano-sized Graphene. A significant challenge in composite manufacturing is achieving a uniform distribution of reinforcement particles, as conventional methods can lead to agglomeration and porosity. This research investigates the use of a two-step stir casting method to address these manufacturing challenges and evaluates the impact of varying process parameters (stirring speed and time) on the microstructure and mechanical properties of the resulting hybrid composite.

4. Summary of the study:

Background of the research topic:

The study is situated within the field of materials science, specifically focusing on the development of Aluminum Metal Matrix Composites (AMMCs). AMMCs are engineered materials designed to improve the properties of monolithic aluminum alloys, such as strength, hardness, and wear resistance, making them suitable for demanding applications in the automotive, aerospace, and electronics industries.

Status of previous research:

Previous research has established stir casting as a common and economical method for producing AMMCs. However, conventional stir casting suffers from drawbacks such as non-uniform particle distribution, poor wettability between the matrix and reinforcement, and porosity. Studies have explored various reinforcements like SiC, WC, and TiC, noting that process parameters like stirring speed and time are critical. The use of nano-particles has been shown to improve properties, but consistent fabrication remains a challenge. Two-step stir casting has emerged as a promising technique to mitigate the issues of agglomeration and porosity seen in single-step methods.

Purpose of the study:

The primary purpose of this research is to fabricate and test a hybrid AMMC using an Al6061 matrix reinforced with both micron-sized TiC and nano-sized Graphene. The objectives are to:

1. Fabricate the hybrid AMMC using a two-step stir casting technique.

2. Optimize the process parameters (stirring speed and time) to achieve a homogeneous distribution of the reinforcement particles.

3. Analyze the microstructure of the developed composite to assess particle distribution and identify any defects.

4. Examine the mechanical properties, specifically Rockwell hardness, of the produced AMMC to quantify the improvement over the base alloy.

Core study:

The core of the study involved the fabrication of four distinct samples of Al6061/4%TiC/0.3%Graphene composite. The fabrication was performed using a two-step stir casting method where reinforcements were added in a semi-solid state before the slurry was reheated and stirred again in a liquid state. The key variables were stirring speed (400 rpm and 500 rpm) and total stirring duration (10 minutes and 20 minutes). After fabrication, the samples were machined and subjected to two primary analyses: microstructural characterization using Scanning Electron Microscopy (SEM) and mechanical property evaluation via Rockwell B hardness testing. The results were then compared across the different processing conditions and against a baseline of pure Al6061-T6 alloy to determine the optimal parameters for achieving uniform particle distribution and maximum hardness enhancement.

5. Research Methodology

Research Design:

The study employed an experimental research design to investigate the effects of process parameters on the properties of a hybrid AMMC. Four experimental groups (Samples A, B, C, D) were created by systematically varying two independent variables: stirring speed (two levels: 400 rpm, 500 rpm) and total stirring time (two levels: 10 mins, 20 mins). A control group of unreinforced Al6061-T6 was used as a baseline for comparison. The dependent variables measured were the microstructural quality (particle distribution, presence of defects) and Rockwell hardness.

Data Collection and Analysis Methods:

- Fabrication: Composites were produced using a two-step stir casting furnace with a mechanical stirrer. Material composition was fixed at 95.7% Al6061, 4% TiC, and 0.3% Graphene by weight.

- Microstructural Analysis: Specimens were prepared by cutting and polishing. A JEOL JSM 6360 Scanning Electron Microscope (SEM) was used to capture images of the microstructure to analyze particle distribution, agglomeration, voids, and debonding.

- Mechanical Testing: A FIE RASNE-3 macro hardness tester was used to perform Rockwell hardness testing according to the ASTM E18 standard. The Rockwell B scale (HRB) with a 1/16-inch steel ball indenter was used. Hardness was measured at three different positions on each sample, and the values were averaged to ensure accuracy.

- Data Analysis: The collected data was analyzed comparatively. SEM images were visually inspected to qualitatively assess the microstructural integrity. The average hardness values of the four composite samples were compared with each other and with the baseline Al6061 to quantify the effect of the processing parameters.

Research Topics and Scope:

The research is focused on the development and characterization of a specific hybrid composite: Al6061 reinforced with TiC and Graphene. The scope is limited to the two-step stir casting fabrication method. The investigation of process parameters is confined to two stirring speeds and two stirring times. The characterization of the composite is limited to microstructural analysis via SEM and mechanical property evaluation via Rockwell hardness testing. The study does not investigate other properties such as tensile strength, wear rate, or thermal conductivity.

6. Key Results:

Key Results:

- The two-step stir casting process was successfully used to fabricate the hybrid Al6061/TiC/Graphene composite.

- Microstructural analysis revealed that stirring speed and time significantly impact the distribution of reinforcement particles. Sample D, processed at 500 rpm for a total of 20 minutes, showed an "Excellent" uniform distribution of TiC particles, whereas samples processed at 400 rpm showed "Poor" distribution with particle agglomeration and debonding.

- The presence of minor voids was observed in samples processed at 500 rpm (Samples C and D), likely due to gas entrapment.

- The addition of TiC and Graphene reinforcements led to a significant increase in hardness. The average Rockwell B hardness increased from 55.73 HRB for the base Al6061-T6 alloy to a maximum of 80.73 HRB for Sample D.

- The study concludes that increasing both stirring speed and stirring time improves the microstructural and mechanical properties of the composite, with 500 rpm and 20 minutes of stirring identified as the optimal parameters among those tested.

Figure Name List:

- Figure 1 Classification of composites.

- Figure 2 Classification of metal matrix processing [11].

- Figure 3 North America Metal Matrix Composites Market, By End-Use, 2014 – 2024 (USD MILLION) [12].

- Figure 4 Metal Matrix Composite reinforcement types.

- Figure 5 Particle reinforcement [29]

- Figure 6 Fibre reinforcement [29]

- Figure 7 Sheet reinforcement [29]

- Figure 8 Continuous reinforcement [29]

- Figure 9 Steps involved in conventional stir casting process.

- Figure 10 Stir casting process [42]

- Figure 11 Schematic diagram of squeeze casting process [50]

- Figure 12 Rockwell hardness digital machine [54]

- Figure 13 Scanning Electron Microscope [58].

- Figure 14 Overview of steps involved in Two step stir casting process.

- Figure 15 Stir casting machine

- Figure 16 Time temperature curve

- Figure 17 Specimen before and after machining.

- Figure 18 Rockwell hardness indentation [60].

- Figure 19 (a) Rockwell hardness testing machine (b) Specimen under testing.

- Figure 20 Specimen after wire cut.

- Figure 21 Shows the SEM images of (a) sample A (b) sample B (c) sample C (d) sample D

- Figure 22 Rockwell hardness (HRB)

7. Conclusion:

The fabrication of a hybrid AMMC using a two-step stir casting process was successfully demonstrated. The study optimized process parameters, concluding that higher stirring speed (500 rpm) and longer stirring time (20 minutes total) result in a more uniform distribution of TiC reinforcement particles within the Al6061 matrix. This improved microstructure directly translated to enhanced mechanical properties, with the hardness of the composite increasing by up to 30.9% compared to the monolithic Al6061 alloy. While the two-step process reduced particle agglomeration, minor voids were still present in the best samples. The results confirm that increasing stirring speed and time enhances the microstructural and mechanical properties of the composite, paving the way for uniform particle distribution.

8. References:

- [1] P. Garg, A. Jamwal, D. Kumar, K. K. Sadasivuni, C. M. Hussain, and P. Gupta, "Advance research progresses in aluminium matrix composites: manufacturing & applications,” J. Mater. Res. Technol., vol. 8, no. 5, pp. 4924-4939, 2019.

- [2] S. J. James, M. Ganesan, P. Santhamoorthy, and P. Kuppan, "Development of hybrid aluminium metal matrix composite and study of property," Mater. Today Proc., vol. 5, no. 5, pp. 13048–13054, 2018.

- [3] B. V. Ramnath et al., “Aluminium metal matrix composites-a review," Rev Adv Mater Sci, vol. 38, no. 5, pp. 55–60, 2014.

- [4] S. Verma and P. S. Rao, "Study on Mechanical Behavior of Aluminum Alloy 6061 Based Composites a Review," IOSR J. Mech. Civ. Eng. IOSR-JMCE, vol. 15, no. 4, pp. 16–20, 2018.

- [5] M. Raviraj, C. Sharanprabhu, and G. Mohankumar, “Experimental analysis on processing and properties of Al-TiC metal matrix composites," Procedia Mater. Sci., vol. 5, pp. 2032-2038, 2014.

- (References continue as listed in the original paper)

Expert Q&A: Your Top Questions Answered

Q1: Why was a two-step stir casting method chosen over a conventional single-step process?

A1: The paper adopts a two-step stir casting method to specifically overcome the primary disadvantages of conventional techniques, which include non-uniform reinforcement distribution, increased porosity, and poor wettability. By introducing the reinforcements in a semi-solid state (Step 1), the process promotes better initial wetting between the particles and the matrix. The second stirring step in the full liquid state helps to break up any initial clusters and further homogenize the mixture, reducing agglomeration and improving the final microstructural quality.

Q2: What was the rationale for selecting a hybrid reinforcement of TiC and Graphene instead of a single reinforcement type?

A2: The paper leverages the distinct advantages of both materials. Titanium Carbide (TiC) is selected for its super-hard, heat-resistant properties, which are known to significantly improve hardness and wear resistance in composites. Graphene, a nano-sized reinforcement, was chosen for its exceptional tensile strength (~130 GPa), high thermal conductivity, and cost-efficiency. The goal of using this hybrid combination is to create a composite that benefits from the properties of both, achieving a greater overall enhancement than could be obtained from a single reinforcement.

Q3: The study found that 500 rpm and 20 minutes of stirring were optimal. What defects were observed at lower speeds and shorter times?

A3: At the lower speed of 400 rpm (Samples A and B), the SEM analysis revealed significant microstructural defects. These included "Poor" particle distribution, leading to agglomeration where TiC particles clustered together instead of dispersing evenly. Furthermore, the analysis showed debonding, where the reinforcement particles were pulled out of the matrix, indicating a weak interface bond. These defects undermine the composite's integrity and lead to lower hardness values.

Q4: The best sample (Sample D) still showed the presence of voids. What is the cause, and how might this be mitigated in an industrial setting?

A4: The paper suggests the voids observed in Sample D may be due to gas entrapment during the vigorous stirring process or from elastic deformation. While the two-step method reduces many defects, it doesn't completely eliminate porosity. The paper proposes that further optimization of stirring conditions and employing a proper machining setup could reduce these air gaps. In an industrial context, this could also involve vacuum-assisted casting or post-processing techniques like hot isostatic pressing (HIP) to close internal porosity.

Q5: Why was the Rockwell B scale chosen for hardness testing instead of other methods like Vickers?

A5: The paper explicitly states its preference for the Rockwell B scale over Vickers. The reason provided is that the Rockwell test produces a "greater indentation," which was deemed necessary "to ensure accuracy in the composite measurements." This suggests that for a macro-level hardness assessment of a composite material with distributed particles, a larger indentation provides a more representative value of the bulk material's properties, averaging out the localized effects of individual hard particles and the softer matrix.

Conclusion: Paving the Way for Higher Quality and Productivity

The challenge of enhancing the mechanical properties of lightweight alloys without introducing manufacturing defects is a critical pursuit in modern materials engineering. This research successfully demonstrates that a meticulously controlled two-step stir casting process can produce a hybrid Aluminum Metal Matrix Composite (AMMC) with a uniform microstructure and significantly improved hardness. By identifying optimal stirring parameters, this study provides a clear pathway to overcoming common issues like particle agglomeration, unlocking the full potential of advanced reinforcements like Titanium Carbide and Graphene.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "DEVELOPMENT AND TESTING THE PROPERTIES OF HYBRID COMPOSITE USING ALUMINIUM 6061 WITH TiC AND GRAPHENE" by "Nishanth Pasupathy".

Source: https://scholar.uwindsor.ca/major-papers/159

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.