Mastering HPDC Fluidity: How Silicon, Superheat, and Speed Impact Your Al-Si Alloy Castings

This technical summary is based on the academic paper "Influence of Silicon, Superheat and Injection Speed on the Fluidity of HPDC Al-Si Alloys" by Young-Chan Kim¹, Se-Weon Choi¹, Jae-Ik Cho¹, Cheol-Woo Kim¹, Chang-Seog Kang¹ and Sung-Kil Hong², published in Proceedings of the 12th International Conference on Aluminium Alloys (2010).

Keywords

- Primary Keyword: HPDC Al-Si Alloy Fluidity

- Secondary Keywords: aluminum alloy fluidity, high pressure die casting, silicon content, superheat, injection speed, die casting parameters, melt cleanliness

Executive Summary

- The Challenge: While fluidity is a critical characteristic for casting alloys, its behavior in high pressure die casting (HPDC) of Al-Si alloys has not been sufficiently studied, leaving a gap in process optimization.

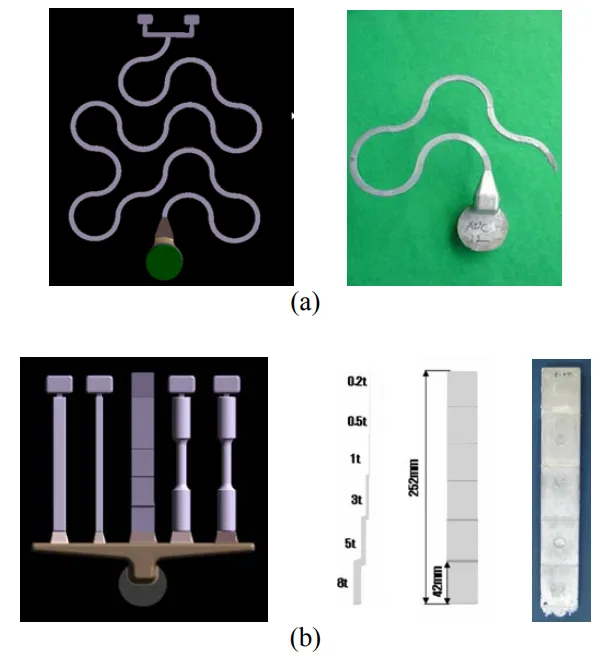

- The Method: Researchers designed serpentine and step-type dies to conduct actual HPDC experiments, systematically varying silicon content, superheat, and injection speed to measure their effects on fluidity length.

- The Key Breakthrough: The study revealed a non-linear relationship between silicon and fluidity, with fluidity decreasing up to 0.8wt% Si before increasing, and demonstrated that superheat, injection speed, and melt cleanliness significantly enhance flow length.

- The Bottom Line: Precise control over silicon content, superheat, and injection speed is essential for maximizing fluidity, ensuring complete die fill, and producing high-quality, complex aluminum components via HPDC.

The Challenge: Why This Research Matters for HPDC Professionals

For engineers in the automotive, aerospace, and electronics industries, aluminum-silicon alloys are the workhorse material for HPDC, accounting for nearly 90% of all aluminum castings. The success of HPDC—a process valued for its efficiency and ability to produce net-shape parts with excellent surface finish—hinges on a critical property: fluidity. Fluidity is the measure of how far molten metal can flow into a die cavity before solidification stops it.

While fluidity testing methods like the spiral test exist for gravity casting, they don't capture the unique physics of HPDC, where high speeds and pressures are involved. The industry has lacked comprehensive data on how key process variables—specifically metal composition (silicon content), superheat, and injection speed—interact to affect fluidity under real-world HPDC conditions. This knowledge gap makes it difficult to optimize processes, prevent misruns, and consistently produce sound, thin-walled components. This study directly addresses that gap.

The Approach: Unpacking the Methodology

To accurately measure fluidity under HPDC conditions, the researchers conducted experiments using a 530-ton cold chamber die-casting machine. They designed two distinct die types to evaluate flow length.

Method 1: Serpentine Die Test

- Purpose: To measure the overall flow length in a complex, winding channel.

- Die Design: The die featured a continuous circular-shaped cavity with a 90 mm diameter, a thickness of 2 mm, and a width of 10 mm.

- Measurement: The final length of the solidified metal flow was measured as the fluidity of the alloy.

Method 2: Step Die Test

- Purpose: To evaluate the ability of the melt to fill progressively thinner sections, simulating complex part features.

- Die Design: The die consisted of 5 steps of constant width (34 mm) with thicknesses decreasing from 8.0 mm down to 0.2 mm.

- Measurement: The total length filled across the steps was measured as the fluidity length.

Key Experimental Variables:

- Alloys: Si-based binary aluminum alloys with 9 different silicon contents (0, 0.4, 0.8, 1.2, 2.0, 3.0, 11.0, 12.0, and 13.0wt%).

- Pouring Temperature (Superheat): Tested at 670, 720, 770, and 820°C.

- Injection Speed: High injection speed was varied from 2.0 to 4.0 m/sec.

- Die Temperature: Maintained at a constant 180°C to isolate other variables.

The Breakthrough: Key Findings & Data

The experiments yielded crucial insights into the factors governing fluidity in HPDC Al-Si alloys.

Finding 1: Silicon Content Has a Non-Linear Effect on Fluidity

Contrary to a simple linear relationship, silicon's impact on fluidity is complex. Using the serpentine die at a 670°C pouring temperature, the study found a distinct trend.

- As shown in Figure 2, as silicon content increased from 0 to 0.8wt%, the fluidity length rapidly decreased. This is because alloys solidify in a mushy mode, which impedes flow more than the progressive solidification of pure metal.

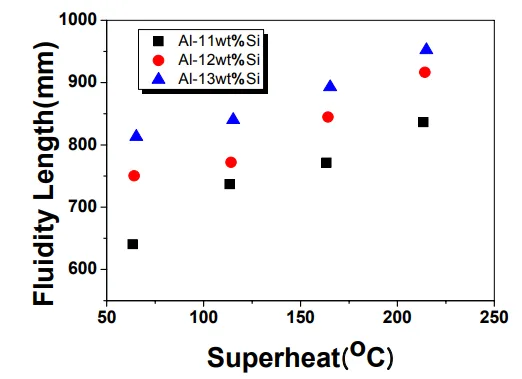

- Beyond 0.8wt% Si, the fluidity length began to increase again. This trend continues past the eutectic composition (~12% Si), with the Al-13%Si alloy showing longer flow than the Al-12%Si alloy. This is attributed to the significant latent heat of fusion generated by silicon during solidification, which keeps the melt fluid for longer.

Finding 2: Superheat and Injection Speed are Powerful Levers for Improving Fluidity

The study confirmed that process parameters have a direct and significant impact on how well a die cavity fills.

- Superheat: As illustrated in Figure 3, for Al-Si alloys with 11, 12, and 13wt% Si, fluidity showed a clear linear improvement with increased superheat. A higher initial melt temperature provides more thermal energy to counteract heat loss to the die, extending flow time.

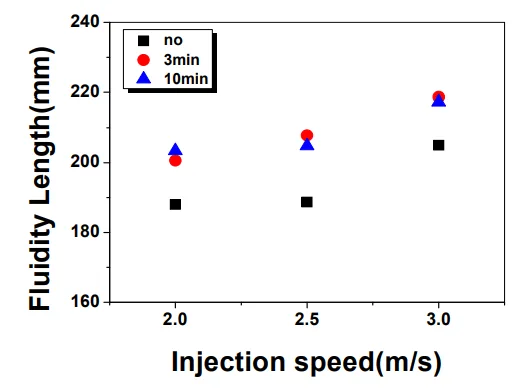

- Injection Speed & Melt Cleanliness: Using the step die with an Al-11.0%Si alloy, researchers found that increasing the high injection speed from 2.0 to 3.0 m/sec increased the flow length (Figure 4). Furthermore, cleaning the melt by purging with nitrogen gas for just 3 minutes significantly improved fluidity at all injection speeds. This highlights that with higher injection speeds and cleaner melt, the alloy can fill much thinner sections (down to 0.2mm) because it can flow at higher solid fractions.

Practical Implications for R&D and Operations

- For Process Engineers: This study suggests that for alloys with low silicon content (<1.65wt%), simply increasing silicon may not improve fluidity and could be detrimental. Instead, focusing on increasing superheat (within acceptable limits) and optimizing injection speed profiles are more effective strategies for reducing misruns in thin-walled sections.

- For Quality Control Teams: The data in Figure 4 illustrates the dramatic effect of melt cleanliness on fluidity. This provides a strong case for implementing or tightening standards for melt treatment and gas purging, as inclusions and dissolved gas are proven to be significant inhibitors of flow.

- For Design Engineers: The findings indicate that the minimum fillable wall thickness is not just a function of the alloy, but a dynamic interplay of injection speed and melt quality. When designing components with very thin sections (e.g., <0.5mm), specifying a higher-fluidity alloy (like a hypereutectic Al-Si) and a process window that includes high injection speeds and stringent melt cleaning protocols is critical for manufacturing success.

Paper Details

Influence of Silicon, Superheat and Injection Speed on the Fluidity of HPDC Al-Si Alloys

1. Overview:

- Title: Influence of Silicon, Superheat and Injection Speed on the Fluidity of HPDC Al-Si Alloys

- Author: Young-Chan Kim¹, Se-Weon Choi¹, Jae-Ik Cho¹, Cheol-Woo Kim¹, Chang-Seog Kang¹ and Sung-Kil Hong²

- Year of publication: 2010

- Journal/academic society of publication: Proceedings of the 12th International Conference on Aluminium Alloys, ©2010 The Japan Institute of Light Metals

- Keywords: fluidity, aluminum alloy, HPDC, superheat, injection speed

2. Abstract:

It is generally known that silicon influences the fluidity of aluminum alloys. There are several techniques to evaluate the fluidity of aluminum for gravity casting such as using spiral or serpentine type mold and vacuum suction test. However, fluidity of aluminum in high pressure die-casting has not been sufficiently studied. Therefore, in this study the relationship between the fluidity and silicon contents as well as superheat of pouring aluminum alloy and injection speed were studied. A serpentine and step type dies for evaluating the fluidity of aluminum were designed and actual die casting experiments were conducted for aluminum by varying the parameters such as superheat, injection speed and the content of silicon. As the silicon contents increased up to 0.8wt%, the fluidity length measured was rapidly decreased but it started to increase with more than 0.8wt%Si. Amount of superheat has significant effect on fluidity as well. Markedly improved fluidity length was quite evident with increased superheat. The fluidity step was filled more with the cleaner melt and even 3 minutes of gas purging increased fluidity value significantly.

3. Introduction:

The demand for aluminum casting alloys has increased in the automotive, aerospace, and electronics industries due to their combination of light weight, strength, and corrosion resistance. Aluminum-silicon alloys are among the most important casting alloys, constituting nearly 90% of all aluminum castings. High pressure die casting (HPDC) is a widely used net-shape manufacturing process where molten metal is injected into a mould at high speeds and solidified under high pressure. HPDC is an economical and efficient method for producing components with good surface finish and dimensional accuracy. Fluidity, a measure of the distance molten material flows before solidification, is a critical characteristic for casting alloys. While fluidity has been investigated by many researchers, process variations, especially concerning metal composition in common cast alloys, are not well documented.

4. Summary of the study:

Background of the research topic:

Fluidity is a primary characteristic of casting alloys, determining the ability to fill a mold cavity. In HPDC, factors such as high pressure, die temperature, and superheat must be considered in addition to common factors like viscosity, surface tension, and impurity levels.

Status of previous research:

Existing methods for measuring fluidity, such as the spiral test and vacuum suction technique (Ragone testing method), are more suitable for gravity casting conditions. Very limited research has been conducted on the fluidity of aluminum alloys specifically within the HPDC process.

Purpose of the study:

To investigate the relationship between fluidity and key parameters in HPDC of Al-Si alloys. The study focused on the effects of silicon content, superheat of the pouring alloy, and injection speed.

Core study:

The study involved designing and fabricating two types of dies (serpentine and step) to evaluate fluidity under actual HPDC conditions. Experiments were conducted by varying silicon content in binary Al-Si alloys, the pouring temperature (superheat), and the injection speed. The influence of melt cleanliness via gas purging was also examined.

5. Research Methodology

Research Design:

An experimental study was conducted using a cold chamber die-casting machine (530-ton locking force). Two custom dies, a serpentine type and a step type, were used to measure fluidity length under different process conditions.

Data Collection and Analysis Methods:

Binary Al-Si alloys with nine different silicon levels (0 to 13.0wt%) were prepared. Pouring temperatures were set at 670, 720, 770, and 820°C. The die was pre-heated to 180°C. High injection speeds were varied (0.35, 0.5, 1.0, 2.0, 3.0, and 4.0 m/sec). For some tests, the melt was cleaned by purging with nitrogen gas for 3 or 10 minutes. The primary data collected was the final flow length of the solidified casting in millimeters.

Research Topics and Scope:

The research focused on quantifying the influence of three main variables on the fluidity of Al-Si alloys in an HPDC process:

1. Silicon content (from 0wt% to 13.0wt%).

2. Superheat (the difference between pouring temperature and liquidus temperature).

3. High injection speed (from 2.0 to 3.0 m/sec for the step die test).

The effect of melt cleanliness was also investigated as a related factor.

6. Key Results:

Key Results:

- Silicon content significantly affects fluidity. Fluidity decreased as Si content increased to 0.8wt%, then increased with further additions of Si. The minimum fluidity was observed near 0.8wt% Si, not the maximum solid solubility limit of 1.65wt% Si.

- Hypereutectic Al-13%Si alloy exhibited greater fluidity than the eutectic Al-12%Si alloy, likely due to the higher latent heat of fusion from silicon.

- Superheat has a significant positive effect on fluidity. A linear relationship was observed where increased superheat led to markedly improved fluidity length.

- Higher injection speeds (from 2.0 to 3.0 m/sec) increased the flow length in the step die test, enabling the alloy to fill thinner sections.

- Melt cleanliness is a critical factor. Purging the melt with nitrogen gas for just 3 minutes significantly increased fluidity values.

Figure Name List:

- Fig. 1 Schematic drawing of fluidity test die for die casting; (a) Serpentine type, (b) Step type

- Fig. 2 The results of fluidity serpentine test on the silicon contents

- Fig. 3 The effect of silicon contents and superheat on fluidity

- Fig. 4 The effect of melt treatment and injection speed on fluidity

7. Conclusion:

- Serpentine and step type dies were successfully designed for evaluating aluminum fluidity in the die casting process.

- Fluidity decreased as silicon content increased to 0.8wt% and then increased with more than 0.8wt%Si. The minimum fluidity at a composition near 1%Si was attributed to the purity of the ingots and the heat generated during silicon solidification.

- The amount of superheat has a significant positive effect on fluidity.

- Increasing the high injection speed from 2.0 to 3.0 m/sec increased the flow length of the step. High injection speed allows the alloy to flow at much higher solid fractions.

- Melt cleanliness is a significant factor, as dissolved gas and inclusions effectively decrease the fluidity of the alloys.

8. References:

- [1] L.F. Mondolfo. Aluminum: structures and properties. (Butter-worth: England, 1979) pp. 756-757.

- [2] ASM handbook, casting, (Metal Park, Ohio: ASM international, 1989) pp. 785-791.

- [3] Kori SA, Murthy BS, Chakraborthy M. Development of an efficient grain refiner for Al-7Si alloy and its modification with strontium. Mater Sci Eng 2000; A283; 94-104

- [4] ASTM Standard E647. Standard test method for measurement of fatigue crack growth rates. (Annu Book ASTM Stand, 2000);03.01

- [5] Lasa L, Ibabe JMR. Effect of composition and processing route on the wear behavior of Al-Si alloys, Scr Mater 2002;03.01

- [6] N. Kawagoishi, H. Nishitani, T. Toyohiiro, N. Yamamoto, T. Tsuno, Trans. Jpn. Soc. Mech. Eng. 60-570 (1994) 358-363

- [7] H. Ikeda, T. Toriyama, Y. Murakami, Trans. Jpn. Soc. Mech. Eng. 57-238, A (1991) 1320-1325.

- [8] A. Street, The Die Casting Books, (portcullis Press Ltd., 1977) pp. 3-16, pp. 625-641

- [9] Lang G. (1972), Aluminum, 48(10) 664-672

- [10] K.L. Clark, Proc. Inst. Br. Foundrymen A52 (1945-1946) 39

- [11] K.L. Clark, AFS Trans, 54 (1946) 37-48

- [12] J.E. Worthington, J. Inst. Br. Foundrymen A144 (1950) 43

- [13]V. Kondic, H.J. Kozlowski, J. Inst. Met. 75 (1949), 665

- [14] P. Bastein, A. Portevin, J. Inst. Met. 45 (1934), 54

Expert Q&A: Your Top Questions Answered

Q1: The paper states the theoretical minimum fluidity for Al-Si alloys is near 1.65wt% Si, but the experiment found it at 0.8wt% Si. Why the difference?

A1: The paper attributes this discrepancy to two factors: the purity of the commercial aluminum ingots used and the heat generated during the solidification of silicon. This suggests that in practical HPDC applications, the theoretical minimum may not align perfectly with experimental results, and process engineers should validate fluidity characteristics for their specific raw materials rather than relying solely on theory.

Q2: Why were two different die types, serpentine and step, used in the study?

A2: The two dies were designed to evaluate different aspects of fluidity. The serpentine die (Fig. 1a) measures the total distance the metal can flow in a long, uniform, and complex channel, representing overall castability. The step die (Fig. 1b) is designed to test the alloy's ability to fill sections of progressively decreasing thickness, which is critical for producing parts with thin walls and fine details.

Q3: How significant is melt cleanliness compared to process parameters like injection speed?

A3: Figure 4 shows that melt cleanliness is highly significant. While increasing injection speed from 2.0 to 3.0 m/s improves fluidity, a melt purged with nitrogen for just 3 minutes shows a substantially higher fluidity length at every injection speed tested. This indicates that removing dissolved gas and inclusions provides a foundational improvement that is then further enhanced by optimizing injection parameters.

Q4: The study focuses on Al-Si binary alloys. How might these findings apply to more complex commercial alloys like A380, which contain copper and other elements?

A4: While this study provides a fundamental understanding using a binary system, the principles are broadly applicable. The effects of superheat and injection speed on fluidity are fundamental physical phenomena that will hold true for complex alloys. However, additional alloying elements will alter the solidification range and mode, which would shift the specific silicon content at which minimum fluidity occurs. Engineers would need to conduct similar evaluations for their specific commercial alloys.

Q5: What is the practical takeaway from the finding that hypereutectic Al-13%Si has better fluidity than eutectic Al-12%Si?

A5: This finding is important for part design and alloy selection. It demonstrates that the latent heat of fusion from primary silicon in hypereutectic alloys can be a powerful driver of fluidity. For components with extremely long flow paths or very thin sections, selecting a hypereutectic alloy like Al-13%Si could be a more effective solution for achieving complete die fill than simply increasing the superheat on a eutectic alloy, which might have other process drawbacks.

Conclusion: Paving the Way for Higher Quality and Productivity

This research provides a clear, data-driven framework for understanding and controlling HPDC Al-Si Alloy Fluidity. The study moves beyond theoretical models to deliver practical insights, demonstrating that fluidity is not governed by a single variable but by the sophisticated interplay of alloy composition, thermal management (superheat), and process dynamics (injection speed and melt cleanliness). By mastering these parameters, manufacturers can push the boundaries of part complexity, reduce scrap rates from misruns, and improve overall operational efficiency.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

This content is a summary and analysis based on the paper "Influence of Silicon, Superheat and Injection Speed on the Fluidity of HPDC Al-Si Alloys" by "Young-Chan Kim, Se-Weon Choi, Jae-Ik Cho, Cheol-Woo Kim, Chang-Seog Kang and Sung-Kil Hong".

Source: Proceedings of the 12th International Conference on Aluminium Alloys, September 5-9, 2010, Yokohama, Japan, pp. 1780-1785

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.