Boosting Casting Quality: How Sand Casting Simulation Unlocks Key Insights for HPDC

This technical summary is based on the academic paper "Use of Casting Simulation and Rapid Prototyping in an Undergraduate Course in Manufacturing Processes" by Dr. Mathew Schaefer, published in American Society for Engineering Education (2016).

Keywords

- Primary Keyword: Casting Simulation Software

- Secondary Keywords: Mold Design Optimization, Rapid Prototyping, Directional Solidification, Casting Yield, Sand Casting

Executive Summary

- The Challenge: Designing effective mold layouts to ensure part quality and prevent defects like shrinkage is a complex process that often relies on costly and time-consuming physical trials.

- The Method: The study utilized SolidCast™ casting simulation software and rapid prototyping to iteratively design, analyze, and optimize a sand casting mold system before production.

- The Key Breakthrough: Simulation provides a clear, data-driven visualization of the solidification process, allowing engineers to optimize mold layout, gating, and risers to promote directional solidification, predict defect-prone areas, and dramatically improve material yield.

- The Bottom Line: Integrating casting simulation software into the design phase significantly reduces trial-and-error, improves final part quality, and lowers manufacturing costs by optimizing material usage.

The Challenge: Why This Research Matters for HPDC Professionals

In any casting process, including HPDC, the final quality of a component is intrinsically linked to the manufacturing process itself. Engineers must move beyond designing for function alone and embrace "Design for Manufacturing." This means accounting for the complex physics of molten metal flow, heat transfer, and solidification. The core challenge is to design a mold system—including gates, runners, and risers—that produces a defect-free part efficiently. Traditionally, achieving this has involved a great deal of tribal knowledge and expensive, iterative physical trials. This paper explores a more modern, data-driven approach to solving this fundamental manufacturing problem.

The Approach: Unpacking the Methodology

The study implemented a multi-week project where engineering students designed an original part to be sand-cast in aluminum alloy 355. The process involved several key steps:

- Initial Design: Students created a CAD model of their desired part and an initial mold layout, including gates and risers.

- Simulation & Analysis: Using SolidCast™, a casting simulation software program, they analyzed the cooling and solidification behavior of their design. This allowed them to identify potential problem areas without pouring any metal.

- Iterative Optimization: Based on the simulation results, students were required to create at least three different iterations of their mold layout, providing technical justification for improvements in part quality or manufacturing efficiency (yield).

- Pattern Fabrication: The final, optimized design was sent to a rapid prototyping center for pattern fabrication, primarily using selective laser sintering (SLS) of glass-filled nylon.

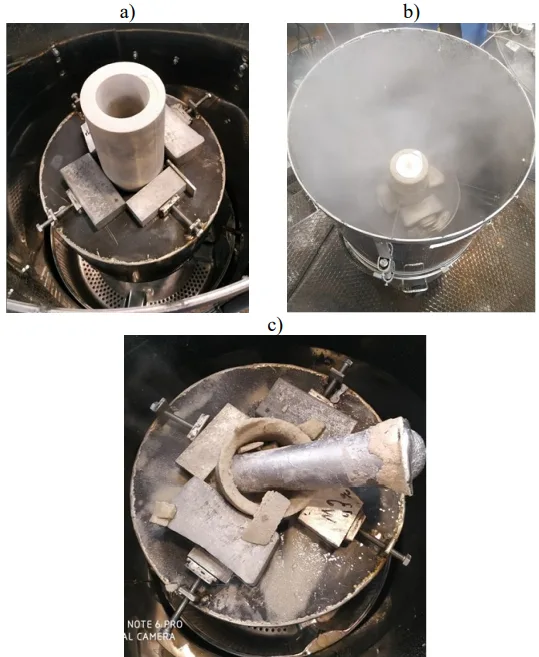

- Casting: Students then used these patterns to create green sand molds and cast their parts in a small-scale foundry.

This methodology mirrors the ideal workflow for modern industrial casting: design, simulate, optimize, and then produce.

The Breakthrough: Key Findings & Data

The study demonstrated how casting simulation software provides actionable insights to solve critical design challenges, leading to higher quality parts and more efficient processes.

Finding 1: Visualizing Solidification to Prevent Shrinkage Defects

The simulation software allowed for the precise analysis of "critical fraction solid time," revealing whether the mold design would function as intended. A poor design allows the runners connecting the riser to the part to freeze prematurely, cutting off the supply of molten metal needed to compensate for shrinkage.

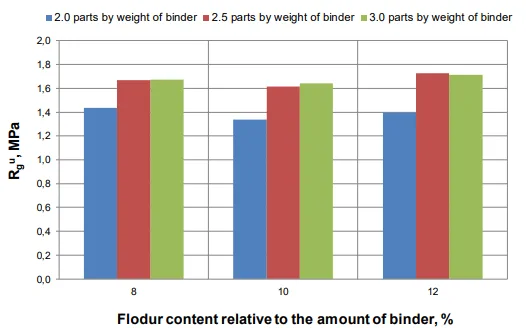

As shown in Figure 4, the initial mold design (left plot) showed that the runners were completely solidified at 0.20 minutes, while large regions of the parts were still liquid. This would lead to shrinkage voids. In the improved design (right plot), the pathways remained un-solidified further into the process (0.275 minutes), ensuring the riser could effectively feed the parts as they cooled. Furthermore, Figure 5 illustrates how simulation can predict material density, showing the poor design was susceptible to porosity (plotted at a 98% density threshold) while the improved design showed very small regions of low porosity (plotted at a 99% threshold).

Finding 2: Optimizing Riser Design to Maximize Material Yield

Beyond part quality, simulation is a powerful tool for improving manufacturing efficiency. In an example involving a bearing cap (Figure 10), the initial design produced good solidification results but was highly inefficient.

The initial layout had a material yield of only 25%, with the part weighing 0.041 lbs. and the total part, gate, and riser weighing 0.161 lbs. By using the simulation software to analyze changes—including modifying the riser from cylindrical to rectangular, reducing its volume, shortening the gate, and adjusting the gating position—the students developed a new design. This optimized layout increased the material yield from 25% to 44%, a significant improvement that would translate directly to lower material costs in a production environment.

Practical Implications for R&D and Operations

While this study was conducted in a sand casting context, its principles are directly applicable to the challenges faced in High Pressure Die Casting.

- For Process Engineers: This study suggests that adjusting gating and runner dimensions to control solidification timing is critical. While HPDC doesn't use risers in the same way, the principle of ensuring the gate area is the last to freeze to properly feed the part cavity remains paramount for preventing shrinkage porosity.

- For Quality Control Teams: The data in Figure 5, which shows material density plots, illustrates the power of simulation to predict the location of internal porosity. This could inform new quality inspection criteria, allowing QC teams to focus non-destructive testing on historically problematic areas identified during the simulation phase.

- For Design Engineers: The findings indicate that part geometry itself can be modified to promote directional solidification (as seen in Figures 6 and 7). This reinforces a key DFM principle: subtle changes to part thickness can guide the cooling process, making the component inherently easier to cast without defects.

Paper Details

Use of Casting Simulation and Rapid Prototyping in an Undergraduate Course in Manufacturing Processes

1. Overview:

- Title: Use of Casting Simulation and Rapid Prototyping in an Undergraduate Course in Manufacturing Processes

- Author: Dr. Mathew Schaefer

- Year of publication: 2016

- Journal/academic society of publication: American Society for Engineering Education

- Keywords: Casting Simulation, Rapid Prototyping, Sand Casting, Manufacturing Processes, Engineering Education

2. Abstract:

Mechanical Engineering students at Milwaukee School of Engineering (MSOE) study manufacturing processes in the junior year. Part of their study in this course is a project to create an original casting. This project encompasses several steps. First is to design the part and the associated mold system (gates & risers) for sand-casting the part. Next, students analyze performance of their mold layout through the use of SolidCast casting simulation software and make improvements to the initial mold layout. A final version of the casting design is submitted to the MSOE rapid prototyping center for fabrication of the casting patterns. The last step is to make an aluminum sand-cast part, in a small-scale foundry in MSOE’s labs. The project emphasizes the basic premise of the course; a manufactured part must be designed within the limitations and capabilities of the manufacturing process.

3. Introduction:

Mechanical Engineering students at Milwaukee School of Engineering (MSOE) study manufacturing processes in the junior year. This is an overview course where students learn about a wide range of manufacturing processes. The major course outcome is to develop an understanding of the capabilities and limitations of various manufacturing processes commonly used to make mechanical components. To design a specific component, students must take into account the service conditions and design requirements. For the Manufacturing course, the ideal is for students to understand how the selection of a manufacturing process will also influence the dimensions and characteristics of their part design. To facilitate this, students at MSOE complete a casting design project.

4. Summary of the study:

Background of the research topic:

The research focuses on integrating modern engineering tools—specifically casting simulation software and rapid prototyping—into an undergraduate manufacturing course to provide a more practical and effective design experience.

Status of previous research:

In previous years, the course lab was an informative exercise where students made sand cast parts based on simple "rule of thumb" calculations (e.g., Chvorinov's rule for riser design). This approach lacked the depth of a true engineering design experience.

Purpose of the study:

The purpose was to transform the lab from a simple demonstration into a true engineering design project. By implementing SolidCast™ and rapid prototyping, the goal was for students to learn key course outcomes at a much higher level, approaching mold design as a fluids problem, a heat transfer problem, and a manufacturing quality and cost problem.

Core study:

The core study involved students designing a part and its associated sand-casting mold system. They were required to use SolidCast™ software to analyze and iteratively improve their mold layout for better quality (promoting directional solidification) or higher efficiency (yield). Their final designs were fabricated using rapid prototyping and then physically cast in a lab foundry.

5. Research Methodology

Research Design:

The study was structured as a 7-week project within a 10-week course. It involved a combination of software tutorials, hands-on mold-making practice, independent simulation analysis, and a final casting lab.

Data Collection and Analysis Methods:

Students used SolidCast™ simulation software to analyze their CAD models. The software simulates heat transfer and solidification, providing outputs like "critical fraction solid time" and "material density" plots. Students were required to analyze at least three different mold layouts and provide a technical report justifying their final design based on the simulation data.

Research Topics and Scope:

The scope was limited to green sand casting of aluminum alloy 355. The simulation analysis focused on cooling and solidification, not fluid flow (which would require the FlowCast™ module). The project covered part design, mold layout design (gating, risers), simulation analysis, pattern creation via rapid prototyping, and physical casting.

6. Key Results:

Key Results:

- The use of casting simulation software successfully transformed a demonstrative lab into a true engineering design experience.

- Students were able to use simulation results to identify and correct poor mold designs that would have led to shrinkage defects. For example, they could ensure runners remained molten long enough to feed the part cavity.

- Students successfully used simulation to optimize designs for manufacturing efficiency, as demonstrated by an example where material yield was increased from 25% to 44% by redesigning the riser and gating system.

- The study showed that rapid prototyping, specifically SLS of glass-filled nylon, is an effective method for creating patterns for sand casting, requiring lower draft angles (5 degrees) than other methods like LOM (10 degrees).

- The project provided students with tangible experience in "Design for Manufacturing," forcing them to consider process limitations like draft angles, minimum wall thickness, and the promotion of directional solidification.

Figure Name List:

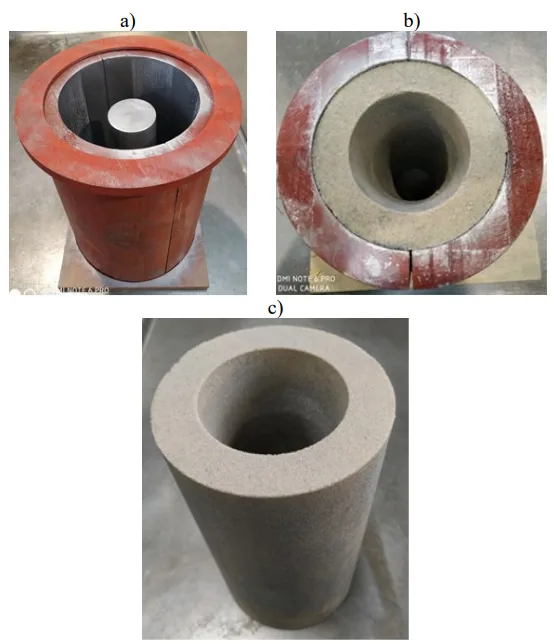

- Figure 1 Two examples of a complete mold layout. Casting on the left is shown in the orientation it was cast. Two parts in the foreground, cylindrical riser in the middle and the down sprue in the background. The thin protrusions up from the parts are vents, which filled with aluminum as the mold filled. Casting on the right is shown in an upside-down orientation from how it was cast. Four parts around a central riser and the down sprue and pouring cup on the right of the picture.

- Figure 2: Left: a simple part used for the SolidCast™ tutorial exercise. The part is 2" long and 1” deep. Right: SolidCast™ result for solidification of the part alone. This plot shows “critical fraction solid time”, which essentially indicates that the outer regions of the part has solidified and the round (darker) region has not at 0.25 minutes. As expected, the last material to solidify is in the thickest region of the casting.

- Figure 3: one possible arrangement of 3 parts around a central riser.

- Figure 4: Illustrates some good and bad mold characteristics. Critical fraction solid time is plotted.

- Figure 5 For the same to mold layouts shown in Figure 4 above. These are material density plots. Mold system on the right show very small regions of low porosity (threshold for the plot is 99%) and mold on the left show larger regions susceptible to porosity, even though plotted at a lower threshold 98% (lower % density = more porosity = worse part). The conclusion would be that the mold on the right will make better quality parts.

- Figure 6: Student part as designed in SolidWorks. Rapid prototyped version of the part and the Final cast version of the part.

- Figure 7: Student part with thickness changes to add details to the image and promote directional solidification. Photo shows rapid prototype pattern, which was later used to make the final cast part.

- Figure 8 Two possible mold layouts for making a C-clamp and a business card holder.

- Figure 9 SolidCast™ simulation results, critical fraction solid time at the point where solidification of parts is nearly complete. Both are showing directional solidification back toward the riser, which is a “good” result. In the layout on the top, directional solidification is toward the middle of each part. In the second layout, directional solidification is from one end to the other.

- Figure 10 Two possible mold layouts for making a bearing cap. On the left is the initial design which shows very good directional solidification back toward the gate and riser. Critical fraction solid time results are shown. On the right is an optional mold layout and riser design analyzed by the students.

- Figure 11 Design of a mantis (?). The rapid prototype process used had no problem with fine details in the wings and body of the mantis. The casting process was able to reproduce some of those details, but, there were also problems with inadequate draft on the inside border.

- Figure 12 Replica of an oversized penny. Fine details in the surface of the part turned out surprisingly well.

- Figure 13 Casting the finished parts in MSOE's foundry.

7. Conclusion:

The successful implementation of SolidCast™ simulation and rapid prototyping elevated the student learning experience from a simple lab exercise to a comprehensive engineering design project. In the past, students could only observe the casting process. Now, they can approach mold design as a complex problem involving fluid dynamics, heat transfer, manufacturing quality, and cost. This project reinforces the core premise of the course: a manufactured part must be designed with the limitations and capabilities of the manufacturing process in mind.

8. References:

- [No references were listed in the provided paper.]

Expert Q&A: Your Top Questions Answered

Q1: Why was SolidCast™ chosen for this study instead of a more complex flow and solidification software?

A1: The paper states that SolidCast™ was used to analyze cooling and solidification, which are the critical factors for preventing shrinkage defects and optimizing riser design in sand casting. While a module for flow analysis (FlowCast™) exists, the author notes that level of analysis was beyond what could be taught in the available time. This focused approach allowed students to master the core concepts of heat transfer and solidification design effectively.

Q2: Figure 4 shows a "good" and "bad" design. What is the key difference that makes one better?

A2: The key difference is the solidification time of the runners connecting the riser to the parts. In the "bad" design (left), the simulation shows the runners solidify at 0.20 minutes, effectively isolating the still-molten parts from the riser. In the "good" design (right), the runners were redesigned to remain molten longer (up to 0.275 minutes), ensuring a continuous path for liquid metal to flow from the riser to feed the parts as they shrink during solidification, thus preventing defects.

Q3: How significant was the yield improvement in the bearing cap example (Figure 10)?

A3: The improvement was highly significant from a manufacturing cost perspective. The initial design had a poor yield of only 25%. Through simulation-driven changes to the riser (shape, volume) and gating (length, position), the students developed a new layout that increased the yield to 44%. This nearly doubles the material efficiency, demonstrating how simulation can directly impact the profitability of a cast component.

Q4: What role did rapid prototyping play in this process?

A4: Rapid prototyping served as the bridge between the digital design and the physical casting. It allowed students to quickly and accurately fabricate the complex patterns from their final, optimized CAD models. The paper notes that selective laser sintering (SLS) of glass-filled nylon was particularly effective, as it produced durable patterns with a good surface finish that required less draft (5 degrees) for removal from the sand mold compared to other methods like Laminated Object Manufacturing (10 degrees).

Q5: The paper emphasizes "directional solidification." Why is this so critical for casting quality?

A5: Directional solidification is the principle of controlling the cooling sequence so that the part freezes progressively from the points farthest from the riser back towards the riser itself. This is critical because as metal solidifies, it shrinks. By ensuring a continuous path of molten metal from the riser to the solidifying front, the riser can feed this shrinkage and prevent the formation of internal voids or porosity. A part that solidifies randomly or from the outside-in will trap pockets of liquid metal that form defects when they shrink.

Conclusion: Paving the Way for Higher Quality and Productivity

This research powerfully demonstrates that the integration of casting simulation software is no longer a luxury, but a fundamental tool for modern manufacturing. By simulating the complex physics of solidification, engineers can move beyond guesswork and "rules of thumb" to design mold systems that are optimized for both quality and efficiency from the very first iteration. The ability to visualize heat flow, predict defects, and maximize material yield before cutting a single tool is a transformative advantage. These principles of front-loading the design and analysis process are directly applicable to improving outcomes in High Pressure Die Casting.

At CASTMAN, we are committed to applying the latest industry research to help our customers achieve higher productivity and quality. If the challenges discussed in this paper align with your operational goals, contact our engineering team to explore how these principles can be implemented in your components.

Copyright Information

- This content is a summary and analysis based on the paper "Use of Casting Simulation and Rapid Prototyping in an Undergraduate Course in Manufacturing Processes" by "Dr. Mathew Schaefer".

- Source: Paper ID #15374, ASEE's 123rd Annual Conference & Exposition, New Orleans, LA, June 26-29, 2016.

This material is for informational purposes only. Unauthorized commercial use is prohibited.

Copyright © 2025 CASTMAN. All rights reserved.