この紹介論文の内容は、[UFPA/ITEC / PPGEE]によって発行された[EXPERIMENTAL EVALUATION, DIAGNOSIS, AND PREDICTION OF THE IMPACTS OF POWER QUALITY DISTURBANCES IN IE2, IE3, AND IE4 CLASS EFFICIENCY MOTORS.]の記事に基づいています。

![Figure 2-1 - Induction Motor components [2].](https://castman.co.kr/wp-content/uploads/Figure-2-1-Induction-Motor-components-2-png.webp)

1. 概要:

- タイトル: EXPERIMENTAL EVALUATION, DIAGNOSIS, AND PREDICTION OF THE IMPACTS OF POWER QUALITY DISTURBANCES IN IE2, IE3, AND IE4 CLASS EFFICIENCY MOTORS.

- 著者: JONATHAN MUÑOZ TABORA

- 発行年: 2024

- 発行ジャーナル/学会: UFPA/ITEC / PPGEE

- キーワード: Variação de tensão, desequilíbrio de tensão, harmônicos, temperatura, classes de eficiência, motor de imãs permanentes, manutenção preditiva.

2. 抄録:

電気モーターは、世界で最も大きな電気の最終用途であり、産業部門の基本的な部分であり続けています。さらに、技術の進歩により、電気自動車、輸送、ナビゲーションなどの新しいカテゴリにアプリケーションが拡大しました。ヨーロッパはIE4効率モータークラスへのアップグレードを開始しており、他の地域もより高い効率のモータークラスへの移行に従うことが期待されています。一部の地域では、IEC 60038-2009に従って、動作電圧が公称電圧と異なる場合があります。これは、不均衡や電圧高調波などの他の障害とともに、これらの新しい技術の性能に影響を与える可能性があります。このような状況において、予測保全に多大な努力が払われ、SEPに存在するさまざまな障害が存在する状態で回転機械の健全性を診断する上で、その有効性を高めるための新しい提案で既存の技術を改善しています。本研究では、IE2、IE3、IE4クラスの低電力誘導モーターの温度と性能に対する電圧変動、電圧高調波、および過電圧不均衡のさまざまなパーセンテージの影響を評価します。この研究には、エネルギー消費、効率、力率、および温度に関連する重要な指標を得るための技術的、経済的、統計的、および熱分析が含まれています。革新的で補完的な技術を模索するために、本研究では、電気モーター電流波形の周波数領域分析に基づいて、回転機械の完全性を診断するための新しい電気モーター劣化指標(EMDI)も提示します。結果は、理想的な動作条件下では、IE4クラスの永久磁石モーターが電力消費と温度の点でより優れた性能を発揮しますが、非線形特性を持つことを示しています。次に、特定の障害が存在する場合、同じ動作条件下でかご形誘導モーターと比較して性能が低下するため、シナリオが変化します。実施された分析により、導入される新しい電気モーター技術の性能に対する電力システムに存在するさまざまな摂動の影響を特定し、定量化することができます。提案されたモーター状態診断指標に関して、提示された結果は、予測保全の実践の実施を促進する上で、提案されたアプローチの有効性を強く支持しています。本論文のもう1つの重要な貢献は、その結果がホンジュラスの電気モーターに対する最小効率要件の導入のための新しい規制の実施の基礎となることです。

キーワード: 電圧変動、電圧不均衡、高調波、温度、効率クラス、永久磁石モーター、予測保全。

3. 導入:

2015年のパリ協定は、気候変動への取り組みにおいて重要なグローバルステップとなりました。それ以来、エネルギー効率に焦点を当てた政策と規制の実施を推進し、環境目標を達成し、国際的に持続可能な慣行を促進する上で重要な役割を果たしてきました。このような状況において、誘導モーター(IM)は、世界の最終的な電気エネルギー消費量の約53%を占めるエネルギー節約のための重要なカテゴリです[1]。

ブラジルでは、鉱業エネルギー省の文書「国家エネルギー効率計画」[2]によると、産業界は総国家電力の36%を消費し、稼働中の駆動システムはこの電力の68%を消費しています。したがって、国の総電気エネルギーの約35%が電気モーターによって消費されていると報告されています。

三相かご形誘導モーターは、2002年12月11日の大統領令第4.508号の公布により、ブラジルで大統領令によって規制される最初で唯一の機器でした。これにより、ブラジルの電気モーター市場に大きな変化が起こりました。まず、規制はIR1(標準モーター)¹およびIR2(高効率モーター)クラスの最小電力定格を確立しました。IR1クラスよりも低い電力を持つモーター(法令の付録1に示されている特性を含む)は、製造、販売、または輸入できませんでした。この法令は、エネルギーの保全と合理的な使用に関する国家政策を確立する2001年10月17日の法律第10.295号によって裏付けられており、当時「ブラックアウト」として広く知られていたエネルギー危機後に制定された「エネルギー効率法」として知られています。

4. 研究の概要:

研究テーマの背景:

電気モーターは、世界で最も大きな電気の最終用途であり続けており、産業部門の基本的な部分です。技術の進歩により、電気自動車、輸送、ナビゲーションなどの新しいカテゴリにアプリケーションが拡大しました。ヨーロッパはIE4効率モータークラスへのアップグレードを開始しており、他の地域もより高い効率のモータークラスへの移行に従うことが期待されています。

以前の研究の状況:

電気モーターの効率を向上させるためのさまざまな研究が行われており、その結果、さまざまな効率クラスが導入されました。しかし、電力品質の低下が電気モーターの性能に与える影響に関する研究は、依然として不足しています。

研究の目的:

本研究の目的は、電力品質の低下がIE2、IE3、IE4クラスの電気モーターの性能に与える影響を実験的に評価し、新しいモーター状態診断指標を開発して、予測保全の実践を改善することです。

コア研究:

本研究では、電圧変動、電圧不均衡、高調波などがIE2、IE3、IE4クラスの電気モーターの温度と性能に与える影響を分析します。また、新しいモーター状態診断指標を開発して、予測保全の実践を改善します。

5. 研究方法論

研究デザイン:

本研究は、実験的研究と統計的分析を組み合わせた研究です。実験的研究では、電圧変動、電圧不均衡、高調波などの電力品質の低下がIE2、IE3、IE4クラスの電気モーターの温度と性能に与える影響を測定します。統計的分析では、実験的研究から得られたデータを分析して、新しいモーター状態診断指標を開発します。

データ収集と分析方法:

本研究では、実験的研究を通じてデータを収集します。実験的研究では、電圧変動、電圧不均衡、高調波などの電力品質の低下がIE2、IE3、IE4クラスの電気モーターの温度と性能に与える影響を測定します。また、新しいモーター状態診断指標を開発するために、電気モーター電流波形の周波数領域分析を実行します。

研究テーマと範囲:

本研究のテーマは、電力品質の低下がIE2、IE3、IE4クラスの電気モーターの性能に与える影響です。本研究の範囲は、電圧変動、電圧不均衡、高調波などの電力品質の低下とIE2、IE3、IE4クラスの電気モーターに限定されます。

6. 主な結果:

主な結果:

- 理想的な動作条件下では、IE4クラスの永久磁石モーターは電力消費と温度の点でより優れた性能を発揮しますが、非線形特性を持ちます。

- 特定の障害が存在する場合、同じ動作条件下でかご形誘導モーターと比較して性能が低下するため、シナリオが変化します。

- 新しいモーター状態診断指標は、予測保全の実践の実施を促進する上で、効率性を強力に裏付けています。

![Figure 2-3 - Typical fraction of losses in 50-Hz, four-pole squirrel cage induction motors for (a) Losses

variation as a function of output power [8]; (b) Losses variation as a function of load [9].](https://castman.co.kr/wp-content/uploads/image-1775-1024x425.webp)

![Figure 2-5 – Permanent magnet motors: (a) Surface mounted permanent magnet motor (SPM)[22] [23]; (b) Interior permanent magnet motor (IPM) [22] [24].](https://castman.co.kr/wp-content/uploads/image-1776-1024x769.webp)

![Figure 2-6 - Structure of a four-pole LSPMM [28]](https://castman.co.kr/wp-content/uploads/image-1777-1024x690.webp)

![Figure 2-7 - Typical rotor configurations for LSPMM’s :(a) Spoke rotor; (b) W Type magnetic circuit

structure; (c) Swastika magnetic circuit structure; (d) V-type magnetic circuit structure; (e) U-type

magnetic circuit structure; (f) Series-type magnetic circuit structure [29], [30].](https://castman.co.kr/wp-content/uploads/image-1778-1024x678.webp)

![Figure 2-8 – Starting torque in LSPMM and SCIM: (a) Starting behavior of torque components for

LSPMM´s [31]; (b) Torque behavior for IM and LSPMM during starting [26].](https://castman.co.kr/wp-content/uploads/image-1779-1024x329.webp)

図の名前リスト:

- Figure 1-1 - Energy efficiency classes classification and consumption: (a) IEC 60034-30 nominal efficiency class limits, for four-pole motors (0.12-1000-kW power range) [6]; (b) Energy consumption of electric motor systems by efficiency level, 2000-2017 [7].

- Figure 1-2 - Countries with MEPS for electric motors in 2024.

- Figure 1-3 - Methodology for literature review based on the PRISMA statement.

- Figure 1-4 - Publications related to electric motors in recent years.

- Figure 1-5 - Distribution of publications related to energy forecasting worldwide.

- Figure 1-6 - Distribution of studies by subject area.

- Figure 1-7 - Thematic map of keywords separated by relevant categories.

- Figure 1-8 - Publications related to electric motors diagnosis in the last 20 years.

- Figure 1-9 - General test setup for the power quality disturbances tests..

- Figure 1-10 - General test setup for the electric motor degradation index tests.

- Figure 1-11- Thermographic images of the LSPMM with: (a) 25% of 5th harmonic voltage distortion; (b) 10% of 5th harmonic voltage distortion.

- Figure 2-1 - Induction Motor components [2]…….

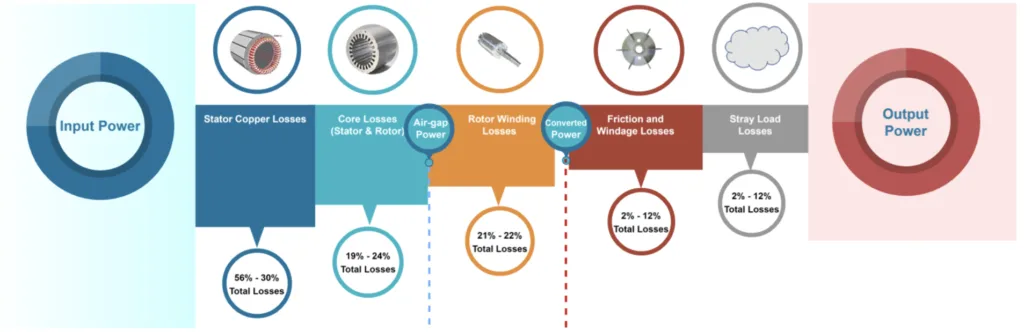

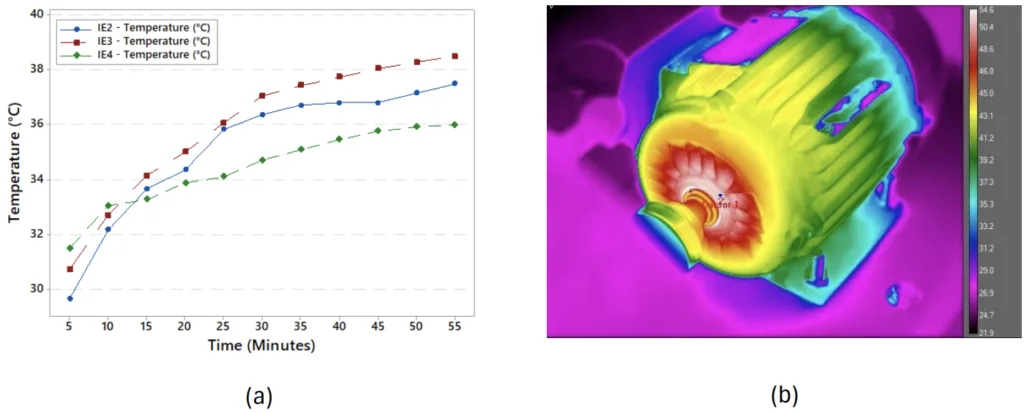

- Figure 2-2 - Distribution of motor losses and percentage of losses for 0.75 kW – 160 kW IM's.

- Figure 2-3 - Typical fraction of losses in 50-Hz, four-pole squirrel cage induction motors for (a) Losses variation as a function of output power [8]; (b) Losses variation as a function of load [9].

- Figure 2-4 - Impact of possible areas of improvement for induction motor performance [11].

- Figure 2-5 - Permanent magnet motors: (a) Surface mounted permanent magnet motor (SPM)[22] [23]; (b) Interior permanent magnet motor (IPM) [22] [24]…

- Figure 2-6 - Structure of a four-pole LSPMM [28]…

- Figure 2-7 - Typical rotor configurations for LSPMM's :(a) Spoke rotor; (b) W Type magnetic circuit structure; (c) Swastika magnetic circuit structure; (d) V-type magnetic circuit structure; (e) U-type magnetic circuit structure; (f) Series-type magnetic circuit structure [29], [30].

- Figure 2-8 Starting torque in LSPMM and SCIM: (a) Starting behavior of torque components for LSPMM ´s [31]; (b) Torque behavior for IM and LSPMM during starting [26].

- Figure 2-9 Comparison between IE2, IE3 and IE4 efficiency class motors (a)Stator currents; (b) Total Harmonic Distortion of Current.

- Figure 2-10 - Consumption in IE2, IE3 and IE4 class motors (a) Total Power; (b) Power F.

- Figure 2-11 - Temperature rise for IE2, IE3 & IE4 IM's classes: (a) Graphics from measurements and (b) LSPMM captured angle.

- Figure 3-1-Additional Negative and zero sequence losses in induction motors. …….. 72

- Figure 3-2 - Flowchart of methodology used to obtain the results from the measurements.

- Figure 3-3 - Current increase for 2nd, 3rd, 5th, 7th and all harmonic order combined for induction motors (a) IE2 SCIM; (b) IE3 SCIM; (c) IE4 LSPMM.

- Figure 3-4 - Total current harmonic distortion (THDI) variation for 2nd, 3rd, 5th, 7th and all harmonic order combined for induction motors (a) IE2 SCIM; (b) IE3 SCIM; (c) IE4 LSPMM.

- Figure 3-5 - Reactive power increase for 2nd, 3rd, 5th, 7th and all harmonic order combined for induction motors (a) IE2 SCIM; (b) IE3 SCIM; (c) IE4 LSPMM.

- Figure 3-6 - Power factor decrease for 2nd, 3rd, 5th, 7th and all harmonic order combined for induction motors (a) IE2 SCIM; (b) IE3 SCIM; (c) IE4 LSPMM.

- Figure 3-7-Temperature rise in the presence of voltage harmonics of 2nd, 3rd, 5th, 7th and all harmonic order combined for induction motors (a) IE2 SCIM; (b) IE3 SCIM; (c) IE4 LSPMM.

- Figure 3-8 - Thermographic images of the LSPMM in presence of 2ndvoltage harmonics in frontal and lateral view (a) Thermal equilibrium frontal view; (b) 25% of 2nd voltage harmonic in frontal view; (c) Thermal equilibrium lateral view; (d) 25% of 2nd voltage harmonic in lateral view

- Figure 3-9 - Thermographic images of the LSPMM in presence of 5th voltage harmonics in frontal and lateral view (a) Thermal equilibrium frontal view; (b) 25% of 5th voltage harmonic in frontal view; (c) Thermal equilibrium lateral view; (d) 25% of 5th voltage harmonic in lateral view

- Figure 3-10 - Correlation matrix between temperature and input parameters in IE2 class SCIM for (a) second harmonic voltage distortion; (b) third harmonic voltage distortion.

- Figure 3-11 - Temperature regression versus motor input parameters for IE2 class SCIM with voltage distortion of (a) 2nd harmonic voltage distortion; (b) 3rd harmonic voltage distortion.

..81 - Figure 3-12 - Correlation matrix between temperature and input parameters in IE3 class SCIM for (a) second harmonic voltage distortion; (b) third harmonic voltage distortion.

- Figure 3-13 - Temperature regression versus motor input parameters for IE3 class SCIM with voltage distortion of (a) 2nd harmonic voltage distortion; (b) 3rd harmonic voltage distortion.

- Figure 3-14 - Correlation matrix between temperature and input parameters in IE4 class LSPMM for (a) second harmonic voltage distortion; (b) third harmonic voltage distortion.

- Figure 3-15 - Temperature regression versus motor input parameters for IE4 class LSPMM with voltage distortion of (a) 2nd harmonic voltage distortion; (b) 3rd harmonic voltage distortion.

- Figure 3-16 Incremental Impact of Voltage distortion on Temperature: (a) Long bars represents a predictor that contribute the newest information to the model; (b) Predictors used in the model (a gray background represents an X variable not in the model)….

- Figure 3-17 - Temperature as a function of 2nd voltage harmonic: (a) Prediction plot for Temperature model with 95% of prediction interval; (b) Prediction plot with large residual versus the fitted values.

..86 - Figure 3-18 - Adjusted coefficient of determination (adjusted R2) for generated models presented in Table 2…..

- Figure 3-19 - Line-start permanent magnet motor simulation on FEMM:(a) LSPMM geometry and materials and (b) LSPMM mesh..

- Figure 3-20 - Density flux plot for (a) Nominal conditions; (b) 2nd voltage harmonics and (c) 5th voltage harmonics.

- Figure 3-21- Quarter section of motor illustrating the areas with convection boundary conditions.

- Figure 3-22 - Temperature distribution (in Kelvin) in the motor from the FEMM thermal simulation for: (a) Second Voltage Harmonic and (b) Fifth Voltage Harmonic……… 90

- Figure 3-23 - Comparison between the model and measured temperature for 25% voltage harmonic distortion of 2nd and 5th order harmonics.

- Figure 4-1 - Power derating curve for Induction Motors

- Figure 4-2 - The Complex Voltage Unbalance Factor Diagram [13].

- Figure 4-3 - Induction motor subjected to voltage unbalance: (a) Induction motor with a low maintenance program, (b) Input voltage magnitudes in induction motor terminals.

- Figure 4-4 - Voltage Unbalance supply on a delta-connected IM and the resulting positive (a) and negative (b) sequence components.

- Figure 4-5 - Induction motor voltages when subjected to voltage unbalance (a) Balanced voltage phasors; (b) Unbalanced voltage phasors.

- Figure 4-6 - Positive and negative sequences for impedances for IE2, IE3 and IE4 Class motors(a) Positive sequence and (b) Negative sequence.

- Figure 4-7 - Flowchart of methodology used to obtain the results from the measurements.

- Figure 4-8 - Line and average current for VU in IE4 LSPMM with: (a) 1% Under Voltage; (b) 3% Under Voltage; (c) 4% Under Voltage;(d) 1% Over Voltage; (e) 3% Over Voltage; (f) 4% Over Voltage.

- Figure 4-9 - Average Current for under and over voltage unbalance conditions for: (a) IE2 SCIM; (B) IE3 SCIM; (c) IE4 LSPMM

- Figure 4-10 - Power Factor (a-c) and Positive-Phase sequence voltage variation (d-e) with Under and Over Voltage Unbalance for IE2 Class SCIM, IE3 Class SCIM and IE4 Class LSPMM.

- Figure 4-11 - Total power variation with Under and Over Voltage Unbalance for: (a) IE2 Class SCIM; (b) IE3 Class SCIM; (c) IE4 Class LSPMM.

- Figure 4-12 - Current Total Harmonic Distortion for under and over voltage unbalance conditions for: (a) IE2 SCIM; (b) IE3 SCIM; (c) IE4 LSPMM.

- Figure 4-13 - Frame Temperature with 1% under voltage (a & b); 3% under voltage (c & d); 4% under voltage.

- Figure 4-14 - Frame Temperature with 1% over voltage (a & b); 3% over voltage (c & d); 4% over voltage (e & f).

- Figure 4-15-Temperature increase in IE2, IE3 and IE4 class IM's with: (a) 1% under voltage; (b) 3% under voltage; (c) 4% under voltage; (d) 1% over voltage; (e) 3% over voltage; (f) 4% over voltage.

- Figure 4-16 - Correlation matrix for IE3 Class SCIM motor parameters in the presence of VU with: (a) 4% Under voltage; (b) 4% Over voltage.

- Figure 4-17 - Correlation matrix for IE4 Class LSPMM motor parameters in the presence of VU with: (a) 4% Under voltage; (b) 4% Over voltage.

- Figure 4-18 - Temperature for the IE4 Class LSPMM: (a) Prediction plot for Temperature model with 95% of prediction interval; (b) Highlighting initial motors temperature measurements before applying unbalanced voltage supply.

- Figure 4-19 - Residuals versus fitted or predicted temperature values.

- Figure 4-20 - Adjusted coefficient (Adjusted R²) for generated models presented in Table 7

- Figure 5-1 - Steps toward the implementation of energy efficiency actions on induction motor policies..

- Figure 5-2 - Methodology flowchart.

- Figure 5-3 - Speed variation for IE2, IE3 & IE4 Class motors in presence of 2nd, and combined 2nd, 3rd, 5th and 7th voltage harmonics…

- Figure 5-4 - Speed variation for IE2, IE3 & IE4 Class motors in presence of 5th and 7th voltage harmonics.

- Figure 5-5 - Harmonic currents present in IM´s with harmonic voltage distortion of (a) 2nd harmonic order; (b) 5th harmonic order; (c) 7th harmonic order (d) 2nd, 3rd, 5th and 7th harmonic order combined.

- Figure 5-6 - Speed variation for IE2, IE3 & IE4 Class motors in presence of 0%-4% Voltage Unbalance Conditions with under and over voltages;

- Figure 5-7 Fifth harmonic currents variations for phases a-b-c for the IE3 Class motor for (a) 1% VU with Under Voltage; (b) 4% VU with Under Voltage; (c) 1% VU with Over Voltage; (d) 4% VU with Over Voltage.

- Figure 5-8 - Fifth harmonic currents variations for phases a-b-c for the IE4 Class motor for (a) 1% VU with Under Voltage; (b) 4% VU with Under Voltage; (c) 1% VU with Over Voltage; (d) 4% VU with Over Voltage.

- Figure 5-9 - Seventh harmonic currents variations for phases a-b-c for the IE3 Class motor for (a) 1% VU with Under Voltage; (b) 4% VU with Under Voltage; (c) 1% VU with Over Voltage; (d) 4% VU with Over Voltage ..

- Figure 5-10 - Seventh harmonic currents variations for phases a-b-c for the IE4 Class motor for (a) 1% VU with Under Voltage; (b) 4% VU with Under Voltage; (c) 1% VU with Over Voltage; (d) 4% VU with Over Voltage ..

- Figure 5-11 - Phase “a” harmonic current variation for 4% Voltage unbalance with undervoltage for (a) IE3 and (b) IE4 Class motors

- Figure 5-12 - Phase “a” harmonic current variation for 4% Voltage unbalance with overvoltage for IE3 (a) and IE4 (b) Class motors

- Figure 6-1 - Image of Table 1 of the IEC 60038-2009 standard in relation to allowable voltages in power systems worldwide [5, p. 2009].

- Figure 6-2 - Three-phase nominal voltage by region for a nominal 220 V LSPMM in a delta connection.

- Figure 6-3 - Line-start permanent magnet: (a) Component description in the first panel and (b) magnetic flux lines.

- Figure 6-4 - Experimental input current as a function of load for 0.75 kW: (a) IE4 Class LSPMM and (b) IE3 Class SCIM motor at nominal voltage and frequency conditions.

- Figure 6-5 - Methodology flowchart……..

- Figure 6-6 Experimental input current as a function of load at different voltage magnitudes.

- Figure 6-7 - LSPMM under VV conditions. (a) Active power and (b) current total harmonic distortion.

- Figure 6-8 - Experimental power factor as a function of load under VV conditions…….. 145

- Figure 6-9 - Ridgeline plot of power factor under VV conditions for the LSPMM.

- Figure 6-10 - Contour plots for power factor variation with power and load for IE4 Class motor with (a) 0.90 p.u., (b) 1.00 p.u., and (c) 1.05 p.u.

- Figure 6-11 - Experimental efficiency as a function of load under VV conditions. ……… 147

- Figure 6-12 - Frame temperature variation in the LSPMM under VV conditions. Frontal temperature with (a) 0.90 p.u., (b) 1.00 p.u., and (c) 1.10 p.u.

- Figure 6-13 - Frame temperature variation in the LSPMM under VV conditions. Lateral temperature with (a) 0.90 p.u., (b) 1.00 p.u., and (c) 1.10 p.u.

- Figure 6-14 - Measured absolute temperature under VV conditions: (a) lateral view; (b) frontal view…

- Figure 6-15 - Correlation matrix between voltage magnitude and input parameters in the LSPMM for (a) output load between 0% and 30%, (b) output load between 40% and 70%, and (c) output load between 80% and 125%..

- Figure 6-16 - Consumption as a function of voltage magnitude under different load conditions.

- Figure 6-17 - Representation of the time-of-use tariff pricing scheme considered in the economic analysis.

- Figure 6-18 - Payback for the initial cost of a new motor by changing the LSPMM voltage supply level: (a) without considering the TOU; (b) considering the TOU.

- Figure 7-1 - Graphical representation of the Electric Motor Degradation Index (EMDI) methodology..

- Figure 7-2-General test setup.

- Figure 7-3-Methodology Flowchart.

- Figure 7-4-EMDI calculation in dB for the nominal voltage operation condition and loading varying from 30% to 125% of nominal for: (a) IE2 Class motor and (b) IE3 Class motor.

- Figure 7-5-Single phasing triggered in IE3 Class motor to evaluate the EMDI.

- Figure 7-6-EMDI calculation in dB for a single phase-loss in the IE3 Class motor. …… 166

- Figure 7-7-Input current variation as a function of load in VV conditions.

- Figure 7-8 - EMDI calculation in VV conditions for nominal load condition.

- Figure 7-9 - Pumping System at the Federal University of Pará: (a) 15 kW SCIM and (b) Power quality analyzer for electric motors consumption measurement.

- Figure 7-10- Voltage magnitude variation for the electric motor input.

- Figure 7-11- Measured input line currents as a function of time.

- Figure 7-12-Electric motor diagnosis indicator comparison in VV conditions.

- Figure 10-1-IE2 Class induction motor nameplate.

- Figure 10-2 - IE2 Class induction motor parameters.

- Figure 10-3- IE3 Class induction motor nameplate.

- Figure 10-4-IE2 Class induction motor parameters.

- Figure 10-5-IE4 Class line-start permanent magnet motor nameplate.

7. 結論:

本研究では、電力品質の低下がIE2、IE3、IE4クラスの電気モーターの性能に与える影響を分析し、新しいモーター状態診断指標を開発して、予測保全の実践を改善しました。本研究の結果は、電力品質の低下が電気モーターの性能に与える影響を理解し、予測保全の実践を改善するのに役立ちます。

8. 参考文献:

- [1] International Energy Agency (IEA), "Publications." Accessed: Aug. 15, 2019. [Online]. Available: https://www.iea-4e.org/publications

- [2] "Plano Nacional de Eficiência Energética - Plano Nacional de Eficiência Energética - Ministério de Minas e Energia." Accessed: Mar. 08, 2020. [Online]. Available: http://www.mme.gov.br/web/guest/secretarias/planejamento-e-desenvolvimento-energetico/publicacoes/plano-nacional-de-eficiencia-energetica

- [3] IEC 60034-30-1:2014, “Rotating electrical machines - Part 30-1: Efficiency classes of line operated AC motors (IE code)." Accessed: Aug. 15, 2019. [Online]. Available: https://webstore.iec.ch/publication/136

- [4] OFFICIAL DIARY OF THE UNION, “INTERMINISTERIAL ORDINANCE N° 1, OF 29 JUNE 2017 - National Press." Accessed: Mar. 08, 2020. [Online]. Available: http://www.in.gov.br/materia

- [5] A. Anibal, B. Rob, B. Conrad U., D. Martin, and H. William, “Motor MEPS Guide, 1st Edition Zurich Switzerland, February." 1st Edition Zurich Switzerland, Feb. 2009. Accessed: May 27, 2020. [Online]. Available: https://www.motorsystems.org/files/otherfiles/0000/0100/meps_guide_feb2009.pdf

- [6] F. J. T. E. Ferreira, B. Leprettre, and A. T. de Almeida, "Comparison of Protection Requirements in IE2-, IE3-, and IE4-Class Motors,” IEEE Transactions on Industry Applications, vol. 52, no. 4, pp. 3603-3610, Jul. 2016, doi: 10.1109/TIA.2016.2545647.

- [7] International Energy Agency (IEA), "Energy Efficiency 2018 - Analysis and outlooks to 2040 - en - OECD." Accessed: Aug. 15, 2019. [Online]. Available: http://www.oecd.org/publications/energy-efficiency-2018-9789264024304-en.htm

- [8] P. Waide and C. Brunner, “Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems," Jan. 2011.

- [9] J. Fong, F. J. T. E. Ferreira, A. M. Silva, and A. T. de Almeida, “IEC61800-9 System Standards as a Tool to Boost the Efficiency of Electric Motor Driven Systems Worldwide," Inventions, vol. 5, no. 2, Art. no. 2, Jun. 2020, doi: 10.3390/inventions5020020.

- [10] A. T. de Almeida, F. J. T. E. Ferreira, and J. Fong, "Perspectives on Electric Motor Market Transformation for a Net Zero Carbon Economy,” Energies, vol. 16, no. 3, Art. no. 3, Jan. 2023, doi: 10.3390/en16031248.

- [11] "WEG Uso Eficiente da Energía Elétrica." Accessed: Mar. 08, 2020. [Online]. Available: https://d335luupugsy2.cloudfront.net/cms/files/92176/1580492002Cartilha_Weg_versaoWE3_INTERATIVA.pdf

- [12] R. Werle, C. U. Brunner, and R. Tieben, “Swiss motor efficiency program EASY: results 2010 - 2014,” p. 14.

- [13] F. J. T. E. Ferreira and A. T. de Almeida, “Induction motor downsizing as a low-cost strategy to save energy," Journal of Cleaner Production, vol. 24, pp. 117-131, Mar. 2012, doi: 10.1016/j.jclepro.2011.11.014.

- [14] "Optimized Rewinding of Oversized Induction Motors | IEEE Conference Publication | IEEE Xplore." Accessed: Feb. 10, 2024. [Online]. Available: https://ieeexplore.ieee.org/document/10238885

- [15] ANEEL, “CALL N°. 002/2015 PRIORITY ENERGY EFFICIENCY PROJECT: ‘ENCOURAGING THE REPLACEMENT OF ELECTRIC MOTORS: PROMOTING ENERGY EFFICIENCY IN THE DRIVING POWER SEGMENT.” Accessed: Mar. 08, 2020. [Online]. Available: https://www.aneel.gov.br/sala-de-imprensa-exibicao/-/asset_publisher/XGPXSqdMFHrE/content/chamada-de-projeto-para-incentivar-substituicao-de-motores-eletricos-e-prorrogada/656877?inheritRedirect=false

- [16] "National Electric Energy Agency ANEEL." Accessed: Apr. 04, 2020. [Online]. Available: https://www.aneel.gov.br/

- [17] A. T. D. Almeida, F. J. T. E. Ferreira, and A. Quintino, "Technical and economical considerations on super high-efficiency three-phase motors,” in 48th IEEE Industrial Commercial Power Systems Conference, May 2012, pp. 1–13. doi: 10.1109/ICPS.2012.6229618.

- [18] WEG, "See+." Accessed: Mar. 08, 2020. [Online]. Available: https://www.weg.net/see+/pages/regua.jsp

- [19] H. Abusaada and A. Elshater, “Notes on Developing Research Review in Urban Planning and Urban Design Based on PRISMA Statement,” Social Sciences, vol. 11, no. 9, Art. no. 9, Sep. 2022, doi: 10.3390/socsci11090391.

- [20] D. Moher, A. Liberati, J. Tetzlaff, and D. G. Altman, “Preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement," BMJ, vol. 339, p. b2535, Jul. 2009, doi: 10.1136/bmj.b2535.

- [21] U.S. Department of Energy, Energy Efficiency & Renewable Energy, "Premium Efficiency Motor Selection and Application Guide – A Handbook for Industry," Energy.gov. Accessed: Aug. 15, 2019. [Online]. Available: https://www.energy.gov/eere/amo/downloads/premium-efficiency-motor-selection-and-application-guide-handbook-industry

- [22] F. J. T. E. Ferreira, G. Baoming, and A. T. de Almeida, "Reliability and Operation of High-Efficiency Induction Motors,” IEEE Transactions on Industry Applications, vol. 52, no. 6, pp. 4628-4637, Nov. 2016, doi: 10.1109/TIA.2016.2600677.

- [23] A. Hassanpour Isfahani and S. Vaez-Zadeh, "Line start permanent magnet synchronous motors: Challenges and opportunities,” Energy, vol. 34, no. 11, pp. 1755–1763, Nov. 2009, doi: 10.1016/j.energy.2009.04.022.

- [24] M. G. Kahrisangi, A. H. Isfahani, S. Vaez-Zadeh, and M. R. Sebdani, "Line-start permanent magnet synchronous motors versus induction motors: A comparative study," Front. Electr. Electron. Eng., vol. 7, no. 4, pp. 459-466, Dec. 2012, doi: 10.1007/s11460-012-0217-8.

- [25] A. T. de Almeida, F. J. T. E. Ferreira, and G. Baoming, "Beyond Induction Motors—Technology Trends to Move Up Efficiency,” IEEE Transactions on Industry Applications, vol. 50, no. 3, pp. 2103–2114, May 2014, doi: 10.1109/TIA.2013.2288425.

- [26] F. J. T. E. Ferreira, A. M. Silva, V. P. B. Aguiar, R. S. T. Pontes, E. C. Quispe, and A. T. de Almeida, "Overview of Retrofitting Options in Induction Motors to Improve Their Efficiency and Reliability," in 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/ICPS Europe), Jun. 2018, pp. 1-12. doi: 10.1109/EEEIC.2018.8493887.

- [27] M. GWOŹDZIEWICZ and L. ANTAL, “INVESTIGATION OF LINE START PERMANENT MAGNET SYNCHRONOUS MOTOR AND INDUCTION MOTOR PROPERTIES, Prace Naukowe Instytutu Maszyn, Napędów i Pomiarów Elektrycznych, Politechniki Wrocławskiej." Prace Naukowe Instytutu Maszyn, Napędów i Pomiarów Elektrycznych, Politechniki Wrocławskiej., 2010. [Online]. Available: https://pdfs.semanticscholar.org/e9ce/18be7c97cf70342b3135d9cd8364e14538bb.pdf

- [28] C. Debruyne, S. Derammelaere, J. Desmet, and L. Vandevelde, “Comparative study of the influence of harmonic voltage distortion on the efficiency of induction machines versus line start permanent magnet machines,” in 2012 IEEE 15th International Conference on Harmonics and Quality of Power, Hong Kong, China: IEEE, Jun. 2012, pp. 342-349. doi: 10.1109/ICHQP.2012.6381217.

- [29] V. P. B. Aguiar, R. S. T. Pontes, and F. J. T. E. Ferreira, “Technical and Economic Evaluation of Efficiency Improvement after Rewinding in Low-Power Induction Motors: A Brazilian Case," Energies, vol. 11, no. 7, Art. no. 7, Jul. 2018, doi: 10.3390/en11071701.

- [30] H. Kim, Y. Park, H.-C. Liu, P.-W. Han, and J. Lee, “Study on Line-Start Permanent Magnet Assistance Synchronous Reluctance Motor for Improving Efficiency and Power Factor,” Energies, vol. 13, no. 2, Art. no. 2, Jan. 2020, doi: 10.3390/en13020384.

- [31] C. Debruyne, “Impact of voltage distortion on energy efficiency of induction machines and line start permanent magnet machines,” dissertation, Ghent University, 2014. Accessed: Aug. 15, 2019. [Online]. Available: http://hdl.handle.net/1854/LU-4383637

- [32] İ. Tarımer, “Investigation of the Effects of Rotor Pole Geometry and Permanent,” 1, vol. 90, no. 2, pp. 67-72, 2009, doi: 10.5755/j01.eee.90.2.10512.

- [33] T. J. E. Miller, "Synchronization of Line-Start Permanent-Magnet AC Motors,” IEEE Transactions on Power Apparatus and Systems, vol. PAS-103, no. 7, pp. 1822-1828, Jul. 1984, doi: 10.1109/TPAS.1984.318630.

- [34] A. Chama, A. Sorgdrager, and R.-J. Wang, “Analytical synchronization analysis of line-start permanent magnet synchronous motors,” Progress In Electromagnetics Research M, vol. 48, pp. 183-193, Jun. 2016, doi: 10.2528/PIERM16050311.

- [35] "Design and Analysis of a Hybrid Permanent Magnet Assisted Synchronous Reluctance Motor Considering Magnetic Saliency and PM Usage - IEEE Journals & Magazine." Accessed: May 16, 2020. [Online]. Available: https://ieeexplore.ieee.org/document/8115172

- [36] M. J. Melfi, S. D. Rogers, S. Evon, and B. Martin, “Permanent Magnet Motors for Energy Savings in Industrial Applications," in 2006 Record of Conference Papers - IEEE Industry Applications Society 53rd Annual Petroleum and Chemical Industry Conference, Sep. 2006, pp. 1-8. doi: 10.1109/PCICON.2006.359695.

- [37] A. Takahashi, S. Kikuchi, K. Miyata, and A. Binder, “Asynchronous Torque of Line-Starting Permanent-Magnet Synchronous Motors,” IEEE Transactions on Energy Conversion, vol. 30, no. 2, pp. 498-506, Jun. 2015, doi: 10.1109/TEC.2014.2361836.

- [38] C. Vavra, “Understanding permanent magnet motors," Control Engineering.

- [39] A. T. de Almeida, J. Fong, H. Falkner, and P. Bertoldi, “Policy options to promote energy efficient electric motors and drives in the EU," Renewable and Sustainable Energy Reviews, vol. 74, pp. 1275-1286, Jul. 2017, doi: 10.1016/j.rser.2017.01.112.

- [40] A. De Almeida, J. Fong, C. U. Brunner, R. Werle, and M. Van Werkhoven, “New technology trends and policy needs in energy efficient motor systems - A major opportunity for energy and carbon savings," Renewable and Sustainable Energy Reviews, vol. 115, p. 109384, Nov. 2019, doi: 10.1016/j.rser.2019.109384.

- [41] F. J. T. E. Ferreira and A. T. de Almeida, “Induction motor downsizing as a low-cost strategy to save energy," Journal of Cleaner Production, vol. 24, pp. 117-131, Mar. 2012, doi: 10.1016/j.jclepro.2011.11.014.

- [42] "Minimum Energy Performance Standards (MEPS) – Policies," IEA. Accessed: Jul. 26, 2020. [Online]. Available: https://www.iea.org/policies/333-minimum-energy-performance-standards-meps

- [43] "IEC 60034-7:2020 | IEC Webstore." Accessed: Feb. 11, 2024. [Online]. Available: https://webstore.iec.ch/publication/64225

- [44] S. Singh and A. Singh, "Steady-state Performance Assessment of Induction Motor under Unbalanced Voltage Condition,” Electric Power Components and Systems, vol. 41, Oct. 2013, doi: 10.1080/15325008.2013.817492.

- [45] D. Zhang, R. An, and T. Wu, “Effect of Voltage Unbalance and Distortion on the Loss Characteristics of Three Phase Cage Induction Motor,” IET Electric Power Applications, vol. 12, Oct. 2017, doi: 10.1049/iet-epa.2017.0464.

- [46] A. B. F. Neves, M. V. B. de Mendonça, A. de L. Ferreira Filho, and G. Z. Rosa, "Effects of voltage unbalance and harmonic distortion on the torque and efficiency of a Three-Phase Induction Motor," in 2016 17th International Conference on Harmonics and Quality of Power (ICHQP), Oct. 2016, pp. 943-948. doi: 10.1109/ICHQP.2016.7783350.

- [47] W. Abu-Elhaija and A. Muetze, “A voltage unbalance factor coding technique for three-phase induction motors,” International Transactions on Electrical Energy Systems, vol. 28, no. 6, p. e2554, 2018, doi: 10.1002/etep.2554.

- [48] E. Quispe, “Efectos del desequilibrio de tensiones sobre la operación del motor de inducción trifásico. Énfasis en la caracterización del desequilibrio de tensiones y el efecto sobre la potencia nominal," 2012. doi: 10.13140/RG.2.1.3406.7287.

- [49] NEMA MG1-2016, “Motors and Generators." Accessed: Aug. 15, 2019. [Online]. Available: https://www.nema.org/Standards/Pages/Motors-and-Generators.aspx

- [50] "IEEE Recommended Practice for Monitoring Electric Power Quality,” IEEE Std 1159-2019 (Revision of IEEE Std 1159-2009), pp. 1–98, Aug. 2019, doi: 10.1109/IEEESTD.2019.8796486.

- [51] "Power Quality Indices and Objectives,” e-cigre. Accessed: Apr. 04, 2020. [Online]. Available: https://e-cigre.org/publication/261-power-quality-indices-and-objectives

- [52] Ching-Yin Lee, “Effects of unbalanced voltage on the operation performance of a three-phase induction motor,” IEEE Transactions on Energy Conversion, vol. 14, no. 2, pp. 202-208, Jun. 1999, doi: 10.1109/60.766984.

- [53] M. Kostic, "Effects of Voltage Quality on Induction Motors' Efficient Energy Usage," Induction Motors - Modelling and Control, Nov. 2012, doi: 10.5772/51223.

- [54] P. Gnaciński, “Gnacinski P. Thermal loss of life and load-carrying capacity of marine induction motors. Energy Conversion and Management, vol. 78: 574-583, Febr. 2014,” Energy Conversion and Management, vol. 78, pp. 574-583, Feb. 2014, doi: 10.1016/j.enconman.2013.11.023.

- [55] A. H. Bonnett, "The impact that voltage and frequency variations have on AC induction motor performance and life in accordance with NEMA MG-1 standards," in Conference Record of 1999 Annual Pulp and Paper Industry Technical Conference (Cat. No.99CH36338), Seattle, WA, USA: IEEE, 1999, pp. 16-26. doi: 10.1109/PAPCON.1999.779341.

- [56] Yaw-Juen Wang, “Analysis of effects of three-phase voltage unbalance on induction motors with emphasis on the angle of the complex voltage unbalance factor,” IEEE Transactions on Energy Conversion, vol. 16, no. 3, pp. 270-275, Sep. 2001, doi: 10.1109/60.937207.

- [57] E. El-Kharashi, M. El-Dessouki, J. G. Massoud, A. W. Farid, and M. A. Al-Ahmar, "The use of the current complex factor to determine the precise output energy of the induction motor," Electric Power Systems Research, vol. 154, pp. 23–36, Jan. 2018, doi: 10.1016/j.epsr.2017.08.008.

- [58] A. L. Ferreira Filho, J. A. A. Cormane, D. C. Garcia, M. V. C. Costa, M. A. G. Oliveira, and F. A. do Nascimento, "Analysis of the complex voltage unbalance factor behavior resulting from the variation of voltage magnitudes and angles,” in Proceedings of 14th International Conference on Harmonics and Quality of Power ICHQP 2010, Sep. 2010, pp. 1–7. doi: 10.1109/ICHQP.2010.5625315.

- [59] A. I. Adekitan, "A New Definition of Voltage Unbalance Using Supply Phase Shift,” J Control Autom Electr Syst, vol. 31, no. 3, pp. 718-725, Jun. 2020, doi: 10.1007/s40313-020-00579-8.

- [60] M. T. Jonathan, E. Ortiz de Matos, T. M. Soares, M. E. de L. Tostes, and J. C. Paye, "Fifth & Seventh Harmonic Effects on the Performance of IE2, IE3 & IE4 Induction Motor Classes,” in Proceedings of the 13th Latin-American Congress on Electricity Generation and Transmission - CLAGTEE 2019, Santiago, Chile, Oct. 2019, p. 6. [Online]. Available: http://www.clagtee2019.pucv.cl/2019/book.html

- [61] M. T. Jonathan, T. M. Soares, M. E. de L. Tostes, E. Ortiz de Matos, and C. E. Moreira, "Impactos do 50 Harmônico na Temperatura de Motores Elétricos Classes IE2, IE3 e IE4.," in Conferência Brasileira sobre Qualidade da Energia Elétrica (CBQEE), São Paulo, Brazil, Sep. 2019, p. 6. [Online]. Available: http://sbqee.org.br/cbqee/

- [62] A. T. de Almeida, F. J. T. E. Ferreira, and J. A. C. Fong, “Standards for Super-Premium Efficiency class for electric motors," in Conference Record 2009 IEEE Industrial Commercial Power Systems Technical Conference, May 2009, pp. 1–8. doi: 10.1109/ICPS.2009.5463983.

- [63] C. Debruyne, L. Vandevelde, and J. Desmet, “Harmonic effects on Induction and Line Start Permanent Magnet Machines,” in International Conference on Energy Efficiency in Motor Driven Systems (EEMODS 2013), Rio de Janeiro, RJ, Brazil, Oct. 2013.

- [64] T. Zawilak and J. Zawilak, “MINIMIZATION OF HIGHER HARMONICS IN LINE-START PERMANENT MAGNET SYNCHRONOUS MOTOR,” Przeglad Elektrotechniczny, vol. 84, Jan. 2008.

- [65] E. Vera, “Optimal design of line-start permanent magnet synchronous motors of high efficiency. Electric power. Ecole Centrale de Lille, 2015. English. NNT: 2015ECLI0022. tel-01308575," 2015.

- [66] F. Ferreira, M. V. Cistelecan, and A. de Almeida, "Voltage Unbalance Impact on the Performance of Line-Start Permanent-Magnet Synchronous Motors.," Nantes, France, 2009.

- [67] F. Kalluf, C. Pompermaier, M. V. F. da Luz, and N. Sadowski, “Braking torque analysis of the single phase line-start permanent magnet synchronous motor," The XIX International Conference on Electrical Machines - ICEM 2010, 2010, doi: 10.1109/ICELMACH.2010.5608211.

- [68] A. Kumar and A. Srivastava, "Performance Comparison of Two Different Rotor Topologies of Line Start Permanent Magnet Synchronous Motors,” Engineering Technology, vol. 5, p. 8.

- [69] Mingji Liu, Zhi Han, Yawei Pei, and Pengfei Shi, “Optimization of permanent magnet motor air-gap flux density based on the non-uniform air gap,” in Proceedings 2013 International Conference on Mechatronic Sciences, Electric Engineering and Computer (MEC), Dec. 2013, pp. 3422-3426. doi: 10.1109/MEC.2013.6885604.

- [70] A. Sorgdrager, R.-J. Wang, and A. J. Grobler, “Transient performance optimisation of line-start permanent magnet synchronous motors using Taguchi regression rate method," Jan. 2017.

- [71] X. Zeng, L. Quan, X. Zhu, L. Xu, and F. Liu, "Investigation of an Asymmetrical Rotor Hybrid Permanent Magnet Motor for Approaching Maximum Output Torque,” IEEE Transactions on Applied Superconductivity, vol. 29, no. 2, pp. 1–4, Mar. 2019, doi: 10.1109/TASC.2019.2893708.

- [72] F. J. T. E. Ferreira, J. Alberto, and A. T. de Almeida, "Voltage Unbalance Impact on Coil-Side Temperature Rise in a Delta-Connected, Dual-Winding Induction Motor,” in 2020 IEEE International Conference on Industrial Technology (ICIT), Feb. 2020, pp. 925-930. doi: 10.1109/ICIT45562.2020.9067201.

- [73] "IEEE Recommended Practice for Monitoring Electric Power Quality,” IEEE Std 1159-1995, pp. i-, 1995, doi: 10.1109/IEEESTD.1995.79050.

- [74] E. C. de Lima, J. M. de C. Filho, and J. S. de Sá, “Diagnosis of induction motors operating under distorted and unbalanced voltages," in 2016 17th International Conference on Harmonics and Quality of Power (ICHQP), Oct. 2016, pp. 786-791. doi: 10.1109/ICHQP.2016.7783368.

- [75] E. F. Fuchs, D. J. Roesler, and M. A. S. Masoum, “Are harmonic recommendations according to IEEE and IEC too restrictive?," IEEE Transactions on Power Delivery, vol. 19, no. 4, pp. 1775-1786, Oct. 2004, doi: 10.1109/TPWRD.2003.822538.

- [76] A. Munoz R. and G. Nahmias C., “Mechanical vibration of three-phase induction motors fed by nonsinusoidal currents," in 3rd International Power Electronic Congress. Technical Proceedings. CIEP '94, Aug. 1994, pp. 166–172. doi: 10.1109/CIEP.1994.494416.

- [77] X. Song, J. Hu, H. Zhu, and J. Zhang, “Effects of the Slot Harmonics on the Stator Current in an Induction Motor with Bearing Fault,” Mathematical Problems in Engineering. Accessed: Jun. 16, 2020. [Online]. Available: https://www.hindawi.com/journals/mpe/2017/2640796/

- [78] "Static air-gap eccentricity fault diagnosis using rotor slot harmonics in line neutral voltage of three-phase squirrel cage induction motor,” ResearchGate. Accessed: Jun. 15, 2020. [Online]. Available: https://www.researchgate.net/publication/306417959_Static_air-gap_eccentricity_fault_diagnosis_using_rotor_slot_harmonics_in_line_neutral_voltage_of_three-phase_squirrel_cage_induction_motor

- [79] M. Kordestani, A. A. Safavi, and M. Saif, "Harmonic Fault Diagnosis in Power Quality System Using Harmonic Wavelet," Jul. 2017. doi: 10.1016/j.ifacol.2017.08.2370.

- [80] "Fault diagnosis and condition monitoring of electrical machines - A Review | Request PDF," ResearchGate. Accessed: Jun. 16, 2020. [Online]. Available: https://www.researchgate.net/publication/224713187_Fault_diagnosis_and_condition_monitoring_of_electrical_machines_-_A_Review

- [81] W. Li and C. Mechefske, "Induction motor fault detection using vibration and stator current methods," Insight - Non-Destructive Testing and Condition Monitoring, vol. 46, pp. 473–478, Aug. 2004, doi: 10.1784/insi.46.8.473.39379.

- [82] IEC 60034-7:1992, ““Classification of types of constructions and mounting arrangements (IM Code))." Accessed: Aug. 15, 2019. [Online]. Available: https://webstore.iec.ch/publication/145

- [83] L. Aarniovuori, M. Niemelä, J. Pyrhönen, W. Cao, and E. B. Agamloh, “Loss Components and Performance of Modern Induction Motors," in 2018 XIII International Conference on Electrical Machines (ICEM), Sep. 2018, pp. 1253-1259. doi: 10.1109/ICELMACH.2018.8507189.

- [84] H. O. Mirzamani and A. L. Choobari, "Study of harmonics effects on performance of induction motors," in Proceedings of the 4th WSEAS international conference on Applications of electrical engineering, in AEE'05. Prague, Czech Republic: World Scientific and Engineering Academy and Society (WSEAS), Mar. 2005, pp. 389–394.

- [85] H. G. Beleiu, V. Maier, S. G. Pavel, I. Birou, C. S. Pică, and P. C. Dărab, “Harmonics Consequences on Drive Systems with Induction Motor," Applied Sciences, vol. 10, no. 4, Art. no. 4, Jan. 2020, doi: 10.3390/app10041528.

- [86] C. Debruyne, J. Desmet, S. Derammelaere, and L. Vandevelde, "Derating factors for direct online induction machines when supplied with voltage harmonics: A critical view," in 2011 IEEE International Electric Machines Drives Conference (IEMDC), May 2011, pp. 1048–1052. doi: 10.1109/IEMDC.2011.5994745.

- [87] S. X. Duarte and N. Kagan, “A Power-Quality Index to Assess the Impact of Voltage Harmonic Distortions and Unbalance to Three-Phase Induction Motors,” IEEE Transactions on Power Delivery, vol. 25, no. 3, pp. 1846–1854, Jul. 2010, doi: 10.1109/TPWRD.2010.2044665.

- [88] H. O. Mirzamani and A. L. Choobari, “Study of harmonics effects on performance of induction motors," 2005.

- [89] "519-2014 - IEEE Recommended Practice and Requirements for Harmonic Control in Electric Power Systems." Accessed: May 15, 2020. [Online]. Available: https://standards.ieee.org/standard/519-2014.html

- [90] M. Kordestani, M. Saif, M. E. Orchard, R. Razavi-Far, and K. Khorasani, “Failure Prognosis and Applications—A Survey of Recent Literature,” IEEE Transactions on Reliability, pp. 1–21, 2019, doi: 10.1109/TR.2019.2930195.

- [91] S. M. K. Zaman and X. Liang, “An Effective Induction Motor Fault Diagnosis Approach Using Graph-Based Semi-Supervised Learning," IEEE Access, vol. 9, pp. 7471-7482, 2021, doi: 10.1109/ACCESS.2021.3049193.

- [92] F. J. T. E. Ferreira, A. T. de Almeida, J. F. S. Carvalho, and M. V. Cistelecan, "Experiments to observe the impact of power quality and voltage-source inverters on the temperature of three-phase cage induction motors using an infra-red camera," in 2009 IEEE International Electric Machines and Drives Conference, May 2009, pp. 1311–1318. doi: 10.1109/IEMDC.2009.5075373.

- [93] J. T. Allan, "The effect of voltage variation on the operation of induction motors,” Transactions of the South African Institute of Electrical Engineers, vol. 20, no. 6, pp. 137–155, Jun. 1929.

- [94] "Power savings obtained from supply voltage variation on squirrel cage induction motors | IEEE Conference Publication | IEEE Xplore." Accessed: Apr. 19, 2023. [Online]. Available: https://ieeexplore.ieee.org/document/4763392

- [95] "Investigation of voltage and frequency variation on induction motor core and copper losses | IEEE Conference Publication | IEEE Xplore." Accessed: Apr. 19, 2023. [Online]. Available: https://ieeexplore.ieee.org/document/7934894

- [96] E. B. Agamloh, S. Peele, and J. Grappe, "A comparative analysis of voltage magnitude deviation and unbalance on standard and premium efficient induction motors,” in Conference Record of 2012 Annual IEEE Pulp and Paper Industry Technical Conference (PPIC), Jun. 2012, pp. 1–8. doi: 10.1109/PPIC.2012.6293004.

- [97] "The impact that voltage and frequency variations have on AC induction motor performance and life in accordance with NEMA MG-1 standards." Accessed: Sep. 15, 2022. [Online]. Available: https://ieeexplore.ieee.org/document/779341

- [98] A. H. Bonnett, "The impact that voltage and frequency variations have on AC induction motor performance and life in accordance with NEMA MG-1 standards," in Conference Record of 1999 Annual Pulp and Paper Industry Technical Conference (Cat. No.99CH36338), Jun. 1999, pp. 16-26. doi: 10.1109/PAPCON.1999.779341.

- [99] N. Mendes et al., “ANN for Motor Loading Diagnosis under Voltage Variation Conditions,” in 2023 IEEE Kansas Power and Energy Conference (KPEC), Apr. 2023, pp. 1-6. doi: 10.1109/ΚΡEC58008.2023.10215414.

- [100] J. M. Tabora, L. C. D. S. Júnior, M. E. de L. Tostes, E. O. de Matos, and U. H. Bezerra, "Efficient Electric Motors Performance Under Voltage Variation Conditions,” in 2023 IEEE Kansas Power and Energy Conference (KPEC), Apr. 2023, pp. 1–6. doi: 10.1109/ΚΡEC58008.2023.10215475.

- [101] M. Kostic, M. Ivanovic, and S. Minic, “Reduction of electric energy consumption in induction motor drives by setting supply voltage," in 2012 2nd International Symposium On Environment Friendly Energies And Applications, Jun. 2012, pp. 128-133. doi: 10.1109/EFEA.2012.6294073.

- [102] K. Zhao, L. Cheng, C. Zhang, D. Nie, and W. Cai, “Induction motors lifetime expectancy analysis subject to regular voltage fluctuations," in 2017 IEEE Electrical Power and Energy Conference (EPEC), Oct. 2017, pp. 1–6. doi: 10.1109/EPEC.2017.8286230.

- [103] W. Wang and Z. Lu, “Analysis of Model Predictive Current-Controlled Permanent Magnet Synchronous Motor Drives with Inaccurate DC Bus Voltage Measurement," Energies, vol. 13, no. 2, Art. no. 2, Jan. 2020, doi: 10.3390/en13020353.

- [104] H.-J. Lee and J.-G. Shon, “Improved Voltage Flux-Weakening Strategy of Permanent Magnet Synchronous Motor in High-Speed Operation," Energies, vol. 14, no. 22, Art. no. 22, Jan. 2021, doi: 10.3390/en14227464.

- [105] A. Sikora, A. Zielonka, and M. Woźniak, “Minimization of Energy Losses in the BLDC Motor for Improved Control and Power Supply of the System under Static Load," Sensors, vol. 22, no. 3, Art. no. 3, Jan. 2022, doi: 10.3390/s22031058.

- [106] A. Sikora and M. Woźniak, “Impact of Current Pulsation on BLDC Motor Parameters,” Sensors, vol. 21, no. 2, Art. no. 2, Jan. 2021, doi: 10.3390/s21020587.

- [107] "World Energy Outlook 2019 - Analysis," IEA. Accessed: Jun. 10, 2022. [Online]. Available: https://www.iea.org/reports/world-energy-outlook-2019

- [108] D. F. de Souza, F. A. M. Salotti, I. L. Sauer, H. Tatizawa, A. T. de Almeida, and A. G. Kanashiro, “An assessment of the impact of Brazilian energy efficiency policies for electric motors,” Energy Nexus, vol. 5, p. 100033, Mar. 2022, doi: 10.1016/j.nexus.2021.100033.

- [109] J. M. Tabora et al., “Virtual Modeling and Experimental Validation of the Line-Start Permanent Magnet Motor in the Presence of Harmonics," Energies, vol. 15, no. 22, Art. no. 22, Jan. 2022, doi: 10.3390/en15228603.

- [110] F. J. T. E. Ferreira, G. Baoming, and A. T. de Almeida, “Stator Winding Connection-Mode Management in Line-Start Permanent Magnet Motors to Improve Their Efficiency and Power Factor,” IEEE Transactions on Energy Conversion, vol. 28, no. 3, pp. 523-534, Sep. 2013, doi: 10.1109/TEC.2013.2270084.

- [111] J. M. Tabora, M. E. de Lima Tostes, E. O. de Matos, and U. H. Bezerra, "Voltage Unbalance amp; Variations Impacts on IE4 Class LSPMM," in 2021 14th IEEE International Conference on Industry Applications (INDUSCON), Aug. 2021, pp. 940-946. doi: 10.1109/INDUSCON51756.2021.9529505.

- [112] J. M. Tabora, F. V. Vieira Bezerra, T. M. Soares, E. Ortiz de Matos, M. E. de Lima Tostes, and U. Holanda Bezerra, "Electric Motor Degradation Indicator in Non-Ideal Supply Conditions," in 2023 IEEE Workshop on Power Electronics and Power Quality Applications (PEPQA), Oct. 2023, pp. 1–5. doi: 10.1109/PEPQA59611.2023.10325777.

- [113] D. López-Pérez and J. Antonino-Daviu, “Application of Infrared Thermography to Failure Detection in Industrial Induction Motors: Case Stories,” IEEE Transactions on Industry Applications, vol. 53, no. 3, pp. 1901–1908, May 2017, doi: 10.1109/TIA.2017.2655008.

- [114] A. Mahami, C. Rahmoune, T. Bettahar, and D. Benazzouz, "Induction motor condition monitoring using infrared thermography imaging and ensemble learning techniques,” Advances in Mechanical Engineering, vol. 13, no. 11, p. 16878140211060956, Nov. 2021, doi: 10.1177/16878140211060956.

- [115] M. Manana, A. Arroyo, A. Ortiz, C. J. Renedo, S. Perez, and F. Delgado, “Field winding fault diagnosis in DC motors during manufacturing using thermal monitoring,” Applied Thermal Engineering, vol. 31, no. 5, pp. 978–983, Apr. 2011, doi: 10.1016/j.applthermaleng.2010.11.023.

- [116] G. Singh, T. C. Anil Kumar, and V. N. A. Naikan, “Fault diagnosis of induction motor cooling system using infrared thermography,” in 2016 IEEE 6th International Conference on Power Systems (ICPS), Mar. 2016, pp. 1–4. doi: 10.1109/ICPES.2016.7584040.

- [117] M. Ghods, J. Faiz, A. A. Pourmoosa, and S. Khosrogorji, “Analytical Evaluation of Core Losses, Thermal Modelling and Insulation Lifespan Prediction for Induction Motor in Presence of Harmonic and Voltage Unbalance," International Journal of Engineering, vol. 34, no. 5, pp. 1213–1224, May 2021, doi: 10.5829/ije.2021.34.05b.14.

- [118] J. M. Tabora, M. E. De Lima Tostes, E. O. De Matos, U. H. Bezerra, T. M. Soares, and B. S. De Albuquerque, “Assessing Voltage Unbalance Conditions in IE2, IE3 and IE4 Classes Induction Motors," IEEE Access, vol. 8, pp. 186725–186739, 2020, doi: 10.1109/ACCESS.2020.3029794.

- [119] J. Muñoz Tabora, M. E. de Lima Tostes, E. Ortiz de Matos, T. Mota Soares, and U. H. Bezerra, "Voltage Harmonic Impacts on Electric Motors: A Comparison between IE2, IE3 and IE4 Induction Motor Classes," Energies, vol. 13, no. 13, Art. no. 13, Jan. 2020, doi: 10.3390/en13133333.

- [120] W. R. Finley, M. M. Howdowanec, and W. G. Holter, "Diagnosing motor vibration problems," in Conference Record of 2000 Annual Pulp and Paper Industry Technical Conference (Cat. No.00CH37111), Jun. 2000, pp. 165-180. doi: 10.1109/PAPCON.2000.854217.

- [121] V. Climente-Alarcon, J. A. Antonino-Daviu, F. Vedreño-Santos, and R. Puche-Panadero, "Vibration Transient Detection of Broken Rotor Bars by PSH Sidebands,” IEEE Transactions on Industry Applications, vol. 49, no. 6, pp. 2576–2582, Nov. 2013, doi: 10.1109/TIA.2013.2265872.

- [122] I. Ibrahim, R. Silva, M. H. Mohammadi, V. Ghorbanian, and D. A. Lowther, “Surrogate-Based Acoustic Noise Prediction of Electric Motors,” IEEE Transactions on Magnetics, vol. 56, no. 2, pp. 1-4, Feb. 2020, doi: 10.1109/TMAG.2019.2945407.

- [123] S. Sathyan, U. Aydin, and A. Belahcen, “Acoustic Noise Computation of Electrical Motors Using the Boundary Element Method," Energies, vol. 13, no. 1, Art. no. 1, Jan. 2020, doi: 10.3390/en13010245.

- [124] M. Liu, K. W. han, J. Hu, W. Xu, and J. Rodriguez, “Model Predictive irect Speed ontrol With Torque Oscillation Reduction for PMSM rives,” IEEE Transactions on Industrial Informatics, vol. 15, no. 9, pp. 4944–4956, Sep. 2019, doi: 10.1109/TII.2019.2898004.

- [125] . Saito, M. Kuroishi, and H. Nakai, “Vibration Prediction Method of Electric Machines by using Experimental Transfer Function and Magnetostatic Finite Element nalysis,” J. Phys.: Conf. Ser., vol. 744, p. 012088, Sep. 2016, doi: 10.1088/1742-6596/744/1/012088.

- [126] G. . Stone, M. K. W. Stranges, and . G. unn, “ ommon Questions on Partial ischarge Testing: A Review of Recent Developments in IEEE and IEC Standards for Offline and Online Testing of Motor and Generator Stator Windings,” IEEE Industry Applications Magazine, vol. 22, no. 1, pp. 14–19, Jan. 2016, doi: 10.1109/MIAS.2015.2458337.

- [127] G. . Stone, H. G. Sedding, and . han, “Experience With Online Partial-Discharge Measurement in High-Voltage Inverter-Fed Motors,” IEEE Transactions on Industry Applications, vol. 54, no. 1, pp. 866–872, Jan. 2018, doi: 10.1109/TIA.2017.2740280.

- [128] B. Hu et al., “ Partial ischarge Study of Medium-Voltage Motor Winding Insulation Under woLevel Voltage Pulses With High v/ t,” IEEE Open Journal of Power Electronics, vol. 2, pp. 225–235, 2021, doi: 10.1109/OJPEL.2021.3069780.

- [129] I. Zamudio-Ramirez, R. A. Osornio-Rios, J. A. Antonino-Daviu, H. Razik, and R. de J. omeroTroncoso, “Magnetic Flux nalysis for the ondition Monitoring of Electric Machines: Review,” IEEE Transactions on Industrial Informatics, vol. 18, no. 5, pp. 2895–2908, May 2022, doi:10.1109/TII.2021.3070581.

- [130] E. L. Bonaldi, L. E. de L. de Oliveira, J. G. B. da Silva, G. Lambert-Torresm, and L. E. B. da Silva, Predictive Maintenance by Electrical Signature Analysis to Induction Motors. IntechOpen, 2012. doi:10.5772/48045.

- [131] J. Antonino- aviu, “Electrical Monitoring under Transient onditions: New Paradigm in Electric Motors Predictive Maintenance,” Applied Sciences, vol. 10, no. 17, Art. no. 17, Jan. 2020, doi:10.3390/app10176137.

- [132] . houdhary, . Goyal, S. L. Shimi, and . kula, “ ondition Monitoring and Fault iagnosis of Induction Motors: Review,” Arch Computat Methods Eng, vol. 26, no. 4, pp. 1221–1238, Sep. 2019, doi: 10.1007/s11831-018-9286-z.

- [133] T. Ince, S. Kiranyaz, L. Eren, M. skar, and M. Gabbou , “Real-Time Motor Fault Detection by 1-D onvolutional Neural Networks,” IEEE Transactions on Industrial Electronics, vol. 63, no. 11, pp. 7067–7075, Nov. 2016, doi: 10.1109/TIE.2016.2582729.

- [134] B. G. Joung, W. J. Lee, . Huang, and J. W. Sutherland, “ evelopment and pplication of a Method for Real Time Motor Fault etection,” Procedia Manufacturing, vol. 49, pp. 94–98, Jan. 2020, doi:10.1016/j.promfg.2020.07.002.

- [135] M. Şimşir, R. Bayır, and Y. Uyaroğlu, “Real-Time Monitoring and Fault Diagnosis of a Low Power Hub Motor Using Feedforward Neural Network,” Computational Intelligence and Neuroscience, vol. 2016, p. e7129376, Dec. 2015, doi: 10.1155/2016/7129376.

- [136] H. Zhang, B. Ge, and B. Han, “Real-Time Motor Fault iagnosis Based on T N and ttention,” Machines, vol. 10, no. 4, Art. no. 4, Apr. 2022, doi: 10.3390/machines10040249.

9. 著作権:

- この資料は、"[author]"の論文です。 "[paper title]"に基づいています。

- 論文の出典: [DOI URL]

この資料は上記の論文に基づいて要約されており、商業目的で無断で使用することを禁じます。

Copyright © 2025 CASTMAN. All rights reserved.