この記事では、[RWTHアーヘン大学]が発行した論文「A cost-efficient process route for the mass production of thin-walled structural aluminum body castings」を紹介します。

1. 概要:

- タイトル: 薄肉構造アルミニウム車体鋳物の大量生産のための費用対効果の高いプロセスルート (A cost-efficient process route for the mass production of thin-walled structural aluminum body castings)

- 著者: モハメド・ユセフ・アーメド・ユセフ (Mohamed Youssef Ahmed Youssef)

- 出版年: 2021年

- 出版ジャーナル/学会: 研究開発成果集、第28巻 (2021年) RWTHアーヘン大学鋳造研究所 (Ergebnisse aus Forschung und Entwicklung, Band 28 (2021) Gießerei-Institut der RWTH Aachen)

- キーワード: 高圧ダイカスト (HPDC) (High pressure die casting (HPDC)), レオメタルTMプロセス (RheoMetalTM process), 薄肉構造アルミニウム車体鋳物 (Thin-walled structural aluminum body castings), コスト計算スタディ (Cost calculation study), 機械的特性 (Mechanical properties), リベット接合性 (Rivetability), 耐衝撃性 (Crash resistance)

A cost-efficient process route for the mass production of thin-walled structural aluminum body castings

本記事では RWTH Aachen University で発行された論文 「A cost-efficient process route for the mass production of thin-walled structural aluminum body castings」を紹介します。

1. 概要:

- タイトル: A cost-efficient process route for the mass production of thin-walled structural aluminum body castings

- 著者: Mohamed Youssef Ahmed Youssef

- 出版年: 2021

- 出版ジャーナル/学会: Ergebnisse aus Forschung und Entwicklung, Band 28 (2021) Gießerei-Institut der RWTH Aachen

- キーワード: 提示なし (論文中にキーワードの記載なし)

2. 概要または序論

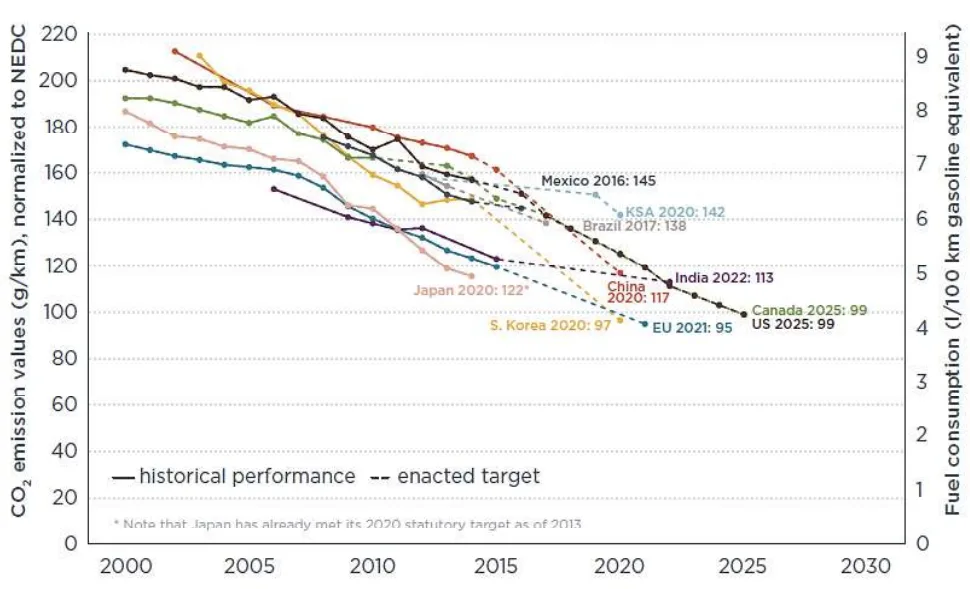

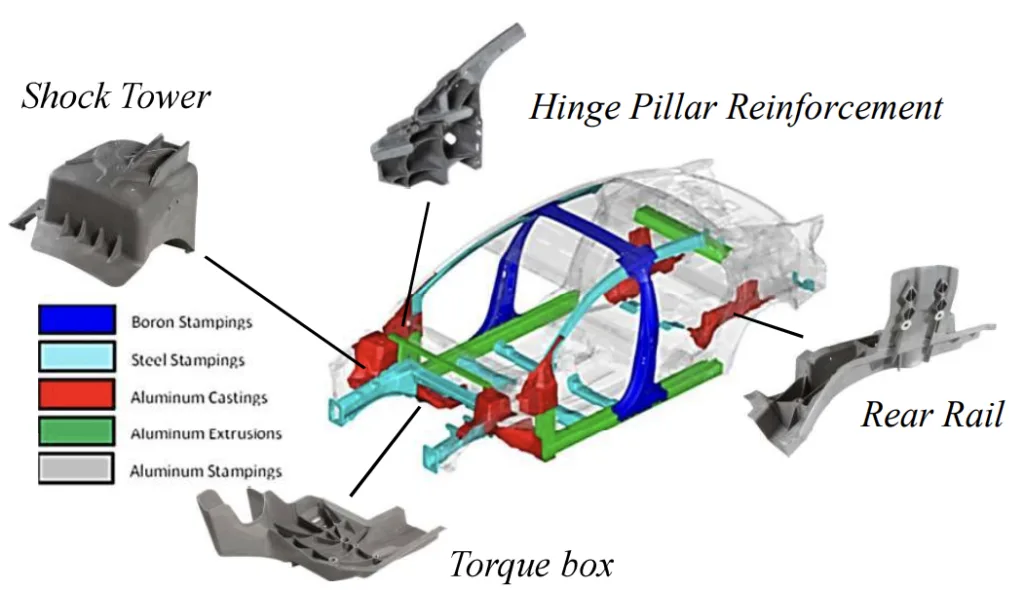

In order to meet the continuous demand for lower CO2 emissions, several approaches have been and still are extensively researched. One of the adopted approaches by the automotive sector, which aims towards an improved fuel efficiency, is the reduction in the weight of the vehicles by replacing their heavy steel sheets with lighter and more functionally integrated aluminium castings. Implementing this approach for the mass production of thin walled structural body castings can be, however, less economical due to its impact on raising the parts’ costs, mainly due to the use of the more expensive raw materials (aluminium alloys). Therefore, within this thesis, it was considered important to investigate the possible means for executing this proposition in a cost-efficient way. For this purpose, a cost calculation study was initially implemented to determine the main cost drivers for the production of a 2020 Ford explorer shock tower. This was followed by an extensive investigation to the findings of this study.

3. 研究背景:

研究トピックの背景:

自動車業界におけるCO2排出量削減の継続的な要求に応えるため、軽量で機能的に統合されたアルミニウム鋳物で重い鋼板を置き換えることによる車両の軽量化が、燃費効率を改善するアプローチの一つとして採用されています。しかし、薄肉構造の車体鋳物を大量生産する場合、主に高価な原材料(アルミニウム合金)の使用により部品コストが上昇するため、経済的とは言えません。

既存研究の状況:

論文中に既存研究の状況に関する詳細な記述はありません。

研究の必要性:

薄肉構造のアルミニウム車体鋳物の大量生産をコスト効率よく行うための方法を調査する必要がある。

4. 研究目的と研究課題:

研究目的:

本論文の主な目的は、薄肉構造のアルミニウム車体鋳物の大量生産(100万~200万個)のための費用対効果の高いプロセスルートを開発することです。

主要な研究:

- コスト計算スタディを実施し、薄肉構造アルミニウム車体鋳物のコストに最も影響を与える要因を特定する。

- HPDC(高圧ダイカスト)およびRheoMetalTM鋳造試験を実施し、最適なプロセスパラメータを導き出す。

- HPDCとRheoMetalTM鋳造試験の結果を比較し、費用対効果の高いプロセスルートを決定する。

研究仮説:

論文中に明示的な研究仮説の記述はありませんが、RheoMetalTMプロセスがHPDCプロセスと比較して、ダイ寿命の改善によりコスト削減に貢献する可能性があるという暗黙の仮説が存在すると考えられます。

5. 研究方法

研究デザイン:

コスト計算スタディ、実験的研究(HPDCおよびRheoMetalTM鋳造試験)、機械的特性評価、SPR接合評価

データ収集方法:

コスト計算ツールによるデータ収集、HPDCおよびRheoMetalTMプロセスによる鋳造品の製造、引張試験、3点曲げ試験、密度測定、SPR接合試験、微細組織観察、SEM-EDS分析、光放射分光分析

分析方法:

コスト分析、機械的特性の比較分析、微細組織観察、統計分析(Minitab、Microsoft Excel)

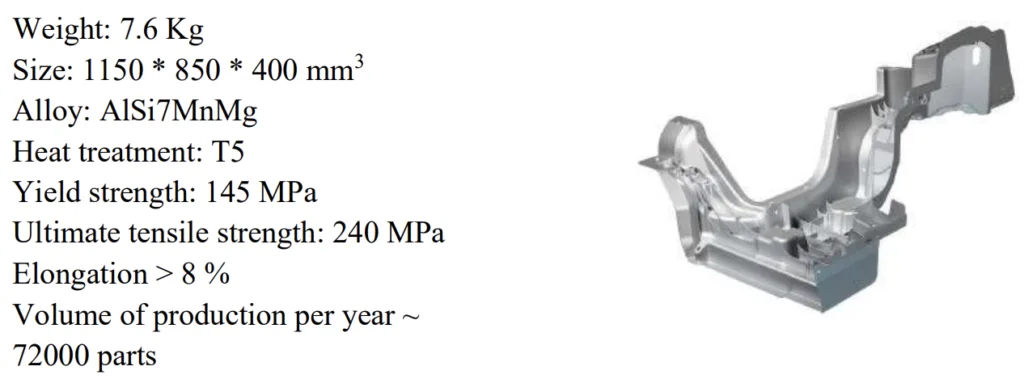

研究対象と範囲:

2020年フォードエクスプローラーのショックタワーを対象としたコスト計算スタディ、板状および部品形状のアルミニウム鋳造試験片、Al-Si系、Al-Mg-Si系、Al-Mg-Fe系の各種アルミニウム合金

6. 主な研究結果:

主要な研究成果:

- 熱処理が構造部品のコストに最も大きな影響を与える。

- アロイをアズキャスト状態で使用すると、高いコスト効率が得られる。

- RheoMetalTMプロセスは、HPDCプロセスよりもコスト削減効果が高い可能性がある(特にダイ寿命の観点から)。

- AlMg4Fe2、MYFORD、AlSi10MnMg-T7が、2020年フォードエクスプローラーのショックタワーの機械的要件を満たす可能性のあるHPDC合金および合金-熱処理の組み合わせとして特定された。

- MYFORDは、実施されたすべての調査において優れた性能を示したため、より適切な候補であると考えられた。

- RheoMetalTMプロセスは、HPDCプロセスよりも衝突抵抗ポテンシャルが低い鋳造部品につながるが、厚みのある部品や小さな部品の製造には改善の余地がある。

提示されたデータの分析:

- Table 0.5: AlMg4Fe2 (D-(3-650) & F-(740)), MYFORD (G-(755)), AlSi10MnMg-T7 は、2020 Ford explorer shock tower の機械的要件を満たす能力を持つ HPDC 合金および合金-熱処理の組み合わせであった。

- Table 0.6: MYFORD (G-(755-30-1100)-R) は、RheoMetalTM 鋳造試験で使用された他の合金よりも優れた性能を発揮した。

図の名前リスト:

- Figure 0.1: The JMatPro® simulations of the AlMg4FeX alloy with (a) X= 1.3% Fe and (b) X= 0.5% Fe (MYFORD).

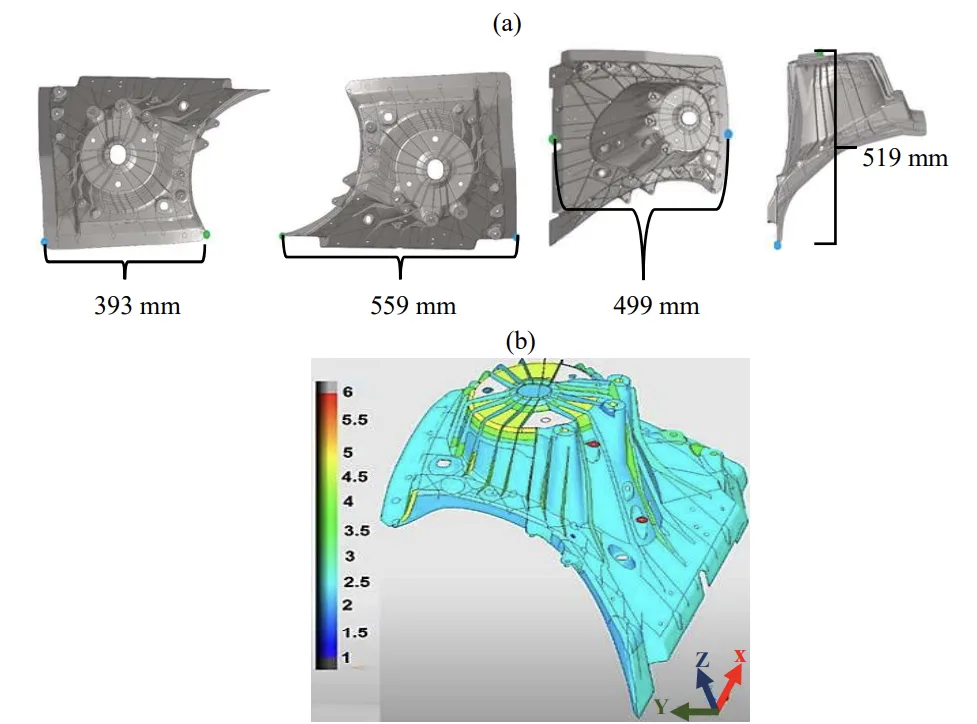

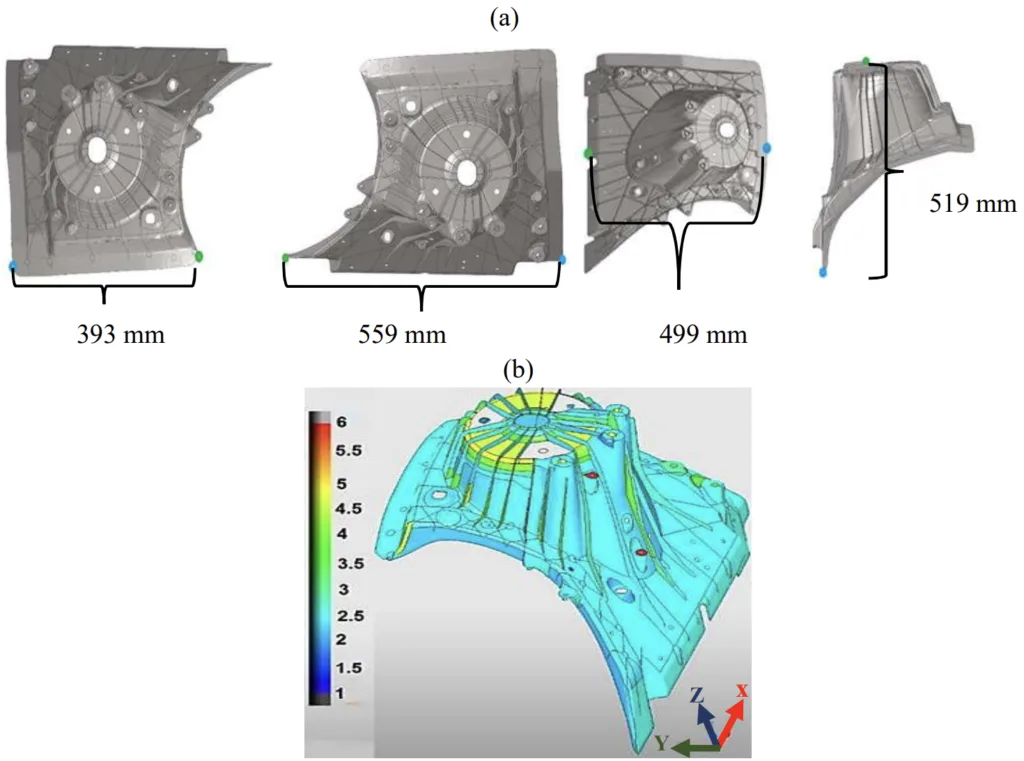

- Figure 0.2: (a) The geometrical dimensions and (b) the thickness distribution (mm) of the 2020 Ford explorer aluminium shock tower.

- Figure 2.1: Porsche 911- rear Longitudinal rail (Magna BDW technologies Soest GmbH).

- Figure 2.2: Jaguar XE/XF- Front shock tower (Magna BDW technologies Soest GmbH).

- Figure 2.3: Range rover- rear longitudinal frame (Magna BDW technologies Soest GmbH) .

- Figure 2.4: The casting processes and the extent of their implementation in the automotive industry (13).

- Figure 2.5: The properties of the different casting methods (14).

- Figure 2.6: The different die-casting processes (15).

- Figure 2.7: (a) The effect of the gate velocity on the pore fraction and on (b) the mechanical properties (modified from (18)).

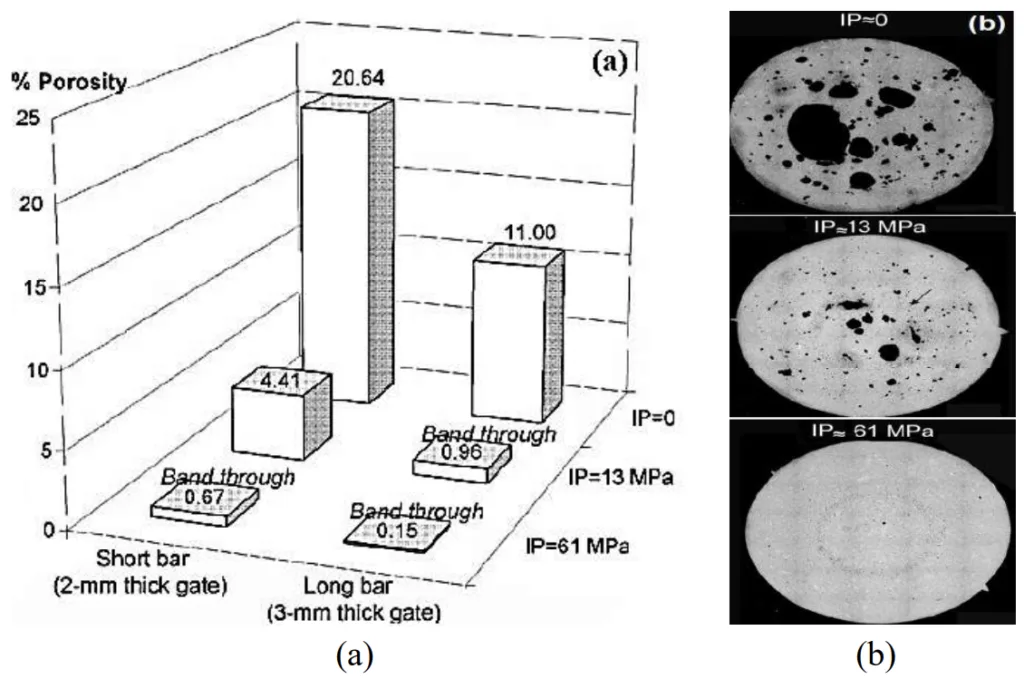

- Figure 2.8: The effect of the intensification pressure (IP) on (a) the porosity content and (b) the macrostructures of the high pressure die castings (modified from (21)).

- Figure 2.9: The concept of vacuum assisted die casting (22).

- Figure 2.10: The structure of the cold flake and its accompanying oxide layer (28).

- Figure 2.11: Shear bands in a HPDC test bar of an AlSi7Mg0.3 alloy (30).

- Figure 2.12:The typical die casting microstructures of the AlSi7 alloy that are formed using (a) the conventional liquid die casting process and (b) the semi-solid casting process (38).

- Figure 2.13: Different technologies for the semi-solid casting of the metallic alloys (modified from (40)).

- Figure 2.14: The main stages in thixocasting (41).

- Figure 2.15: Different techniques of melt stirring: (a) mechanical stirring, (b) passive stirring, (c) electromagnetic vertical stirring, (d) electromagnetic horizontal stirring (39).

- Figure 2.16: A typical thixocasting microstructure of the A356 alloy with regions of entrapped liquid (44).

- Figure 2.17: Illustration of the process steps in rheocasting (45).

- Figure 2.18: The slurry preparation in the RheoMetalTM process: Step 1) pouring the melt into the ladle, Step 2) inserting the rotating enthalpy exchange material (EEM) into the melt, step 3) the semi-solid slurry is formed (48).

- Figure 2.19: An illustration of the Semi-Solid Rheocasting process (S.S.R.TM) (41).

- Figure 2.20: A schematic diagram of the RheoMetalTM process (source: RheoMetal AB).

- Figure 2.21: (a) Dock cleat (b) LED housing and (c) Brackets for the telecom industry.

- Figure 2.22: The influence of the rotation speed on the (a) average size of the α1-Al phase, (b) the fraction of the α1-Al phase, (c) the slurry formation time and the cooling rate.

- Figure 2.23: The influence of the melt superheat on the (a) average size of the α1-Al phase, (b) the fraction of the α1-Al phase, (c) the slurry formation time and the cooling rate.

- Figure 2.24: The combined influence of the melt superheat and the EEM amount on (a) the average size of the α1-Al phase, (b) the fraction of the α1-Al phase, (c) the slurry formation time and the cooling rate.

- Figure 2.25: (a) Eutectic rich bands and (b) porosity bands that can develop in Rheocast parts (54).

- Figure 2.26: The microstructure of a rheocast radio filter (a) near the gate and (b) near the vent (49).

- Figure 2.27: The hypoeutectic Al-Si phase diagram (61).

- Figure 2.28 : The time - temperature graphs of the different heat treatments.

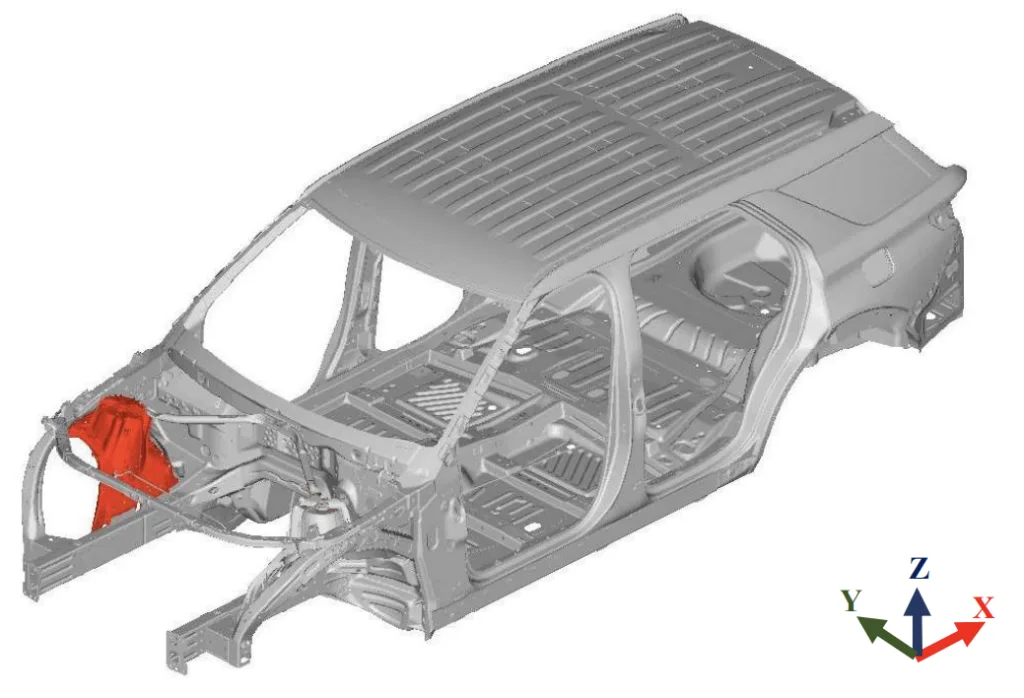

- Figure 3.1: An aluminium shock tower (red) in the 2020 Ford explorer’s body.

- Figure 3.2: The outline of the expenses of investment section in the calculation tool.

- Figure 3.3:The aluminium alloy prices per ton in $ from January 2016 till December 2018 according to the London Metal Exchange (modified from (71)).

- Figure 3.4: The cost per part breakdown chart according to the RheoMetalTM and the HPDC process scenarios.

- Figure 4.1: (a) The geometrical dimensions and (b) the thickness distribution (mm) of the 2020 Ford explorer aluminium shock tower.

- Figure 4.2: The experimental approach.

- Figure 4.3: The HPDC setup consisting of (a) the holding electric resistance furnace, (b) the shot sleeve, ladle & robot arm and (c) the vacuum assisted die.

- Figure 4.4: The dimensions of the plates from supplier 1.

- Figure 4.5: The die cavity’s design for the HPDC trials at supplier 1.

- Figure 4.6: The dimensions of the plates from supplier 2.

- Figure 4.7: The setup consisting of (a) the induction furnace, (b) the EEM production station and (c) the slurry production station.

- Figure 4.8: (a) The EEM’s height before adjustment (casted EEM), (b) the sawing machine and (c) the EEM’s height after adjustment (hEEM).

- Figure 4.9: The slurry making process.

- Figure 4.10: The die cavity’s design for the RheoMetalTM casting trials at supplier 1.

- Figure 4.11: (a) The top view, (b) the bottom view and the (c) side view of the part.

- Figure 4.12: (a) The 800-ton HPDC machine, (b) the die and the second robot arm and (c) the moving tray.

- Figure 4.13: The different pre-steps for the production of the semi-solid slurry.

- Figure 4.14: The phase diagram of the standard AlMg4Fe2 alloy with 1.5-1.7%Fe and 4.5% Mg (modified from (77)).

- Figure 4.15: The suggested enhancement to the standard AlMg4Fe2 alloy, as demonstrated by the circle and the arrow (modified from (77)).

- Figure 4.16: The JMatPro® simulation for the Al-Mg-Fe alloy with a 1.3%Fe.

- Figure 4.17: The JMatPro® simulation for the MYFORD alloy.

- Figure 4.18: The exact geometrical dimensions of the Type E sample in mm (6).

- Figure 4.19: The exact geometrical dimensions of the mini samples in mm.

- Figure 4.20: A 3D model of the supplier 1 plate and the tensile testing samples.

- Figure 4.21: (a) The initial dimension, (b) the extra 1 mm and (c) the final dimension of the (i) mini sample and the (ii) Type E sample in mm.

- Figure 4.22: The top and side views of a mini sample (a)before and (b)after preparation.

- Figure 4.23: The extracted tensile test samples from the (a) supplier 1 plates, (b) supplier 2 plates and (c) supplier 3 parts.

- Figure 4.24: The tensile test setup for the mini and the Type E samples.

- Figure 4.25: The different test speeds during tensile testing.

- Figure 4.26: (a) The setup of the 3-point bending test and (b) the important dimensions (4).

- Figure 4.27: The dimensions of the bending test samples.

- Figure 4.28: The location of the 3-point bending test samples in the (a) supplier 1 plates, (b) supplier 2 plates and (c) supplier 3 parts.

- Figure 4.29: (a) An example of a bending angle and (b) the bending angle measuring tool.

- Figure 4.30: The setup for the density measurement trials.

- Figure 4.31: The positions of the SPR samples in (a) the supplier 1 plates (thickness = 3.1 mm) and (b) the supplier 2 plates (thickness = 2.65 mm).

- Figure 4.32: An example of a good SPR joint (86).

- Figure 4.33: The flat die design (88).

- Figure 4.34: Henrob SPR setup for manual trials.

- Figure 4.35: (a) The joint making using the SPR process (86) and (b) the connected structures.

- Figure 4.36: An example of the (a) circumferential cracks, (b) deep radial cracks and (c) light radial cracks.

- Figure 4.37: The 25 mm * 100 mm lap shear test samples.

- Figure 4.38: The SPR trials on the parts from supplier 3.

- Figure 4.39: The location of the extracted samples from (a) the supplier 1 plates, (b) the supplier 2 plates and (c) the supplier 3 parts.

- Figure 4.40: An example of a hot mounted sample.

- Figure 4.41: The positions a, b and c in the supplier 1 plates.

- Figure 4.42: (a) The total elongation values (%) of the different samples and (b) their respective positions in the plates.

- Figure 4.43: (a) The total elongation values (%) of the different sample types and (b) the outline of the samples in one of the investigated plates.

- Figure 4.44: (a) The effect of the sample orientation on the total elongation values (%), (b) the positions of the longitudinal and perpendicular samples in respect to each other, (c) the location of the extracted longitudinal samples and (d) the location of the extracted perpendicular samples.

- Figure 4.45: The consistency of the HPDC process at supplier 1 using the (a) Type E samples and the (b) mini tensile test samples.

- Figure 5.1: The influence of the melt flow velocity on the total elongation (%) of AlMg4Fe2.

- Figure 5.2: The influence of the melt flow velocity on the total elongation (%) of (a) AlSi7Mg0.3 and (b) AlMg6Si2MnZr.

- Figure 5.3: The influence of the melt flow velocity on the total elongation (%) of AlMg5Si2Mn.

- Figure 5.4: The influence of the intensification pressure on the total elongation (%) of AlMg4Fe2.

- Figure 5.5: The comparison between the different HPDC alloys and alloy-heat treatment combinations in terms of their (a) Rp0.2 values (MPa), (c) Rm values (MPa) and (c) total elongation values (%).

- Figure 5.6: The comparison between the different HPDC alloys in terms of their (a) Rp0.2 values (MPa), (c) Rm values (MPa) and (c) total elongation values (%).

- Figure 5.7: The force-displacement chart of the Al-Si alloys and alloy-heat treatment combinations.

- Figure 5.8: The energy-displacement diagram of the Al-Si alloys and alloy-heat treatment combinations.

- Figure 5.9: The simulated force-displacement chart of the Al-Si alloys and alloy-heat treatment combinations.

- Figure 5.10 : The simulated energy-displacement chart of the Al-Si alloys and alloy-heat treatment combinations.

- Figure 5.11: The force-displacement chart of all the HPDC alloys and alloy-heat treatment combinations that were used for the casting of the plates.

- Figure 5.12: The energy-displacement chart of all the HPDC alloys and alloy-heat treatment combinations that were used for the casting of the plates.

- Figure 5.13: The force-displacement chart of the HPDC alloys that were used at supplier 3.

- Figure 5.14: The energy-displacement chart of the HPDC alloys that were used at supplier 3.

- Figure 6.1: The influence of the intensification pressure on the total elongation (%) of the AlMg4Fe2 alloy.

- Figure 6.2: The comparison between the different RheoMetalTM alloys in terms of their (a) Rp0.2 values (MPa), (c) Rm values (MPa) and (c) total elongation values (%).

- Figure 6.3: The comparison between the different RheoMetalTM alloys in terms of their (a) Rp0.2 values (MPa), (c) Rm values (MPa) and (c) total elongation values (%).

- Figure 6.4: The force-displacement chart for the RheoMetalTM alloys that were used for the casting of the plates at supplier 1.

- Figure 6.5: The energy-displacement chart for the RheoMetalTM alloys that were used for the casting of the plates at supplier 1.

- Figure 6.6: The force-displacement chart of the RheoMetalTM alloys that were used at supplier 3.

- Figure 6.7: The energy-displacement chart of the RheoMetalTM alloys that were used at supplier 3.

- Figure 6.8:The force-displacement chart for D-(50-4.63-575-1000)-R.

- Figure 7.1: The shrinkage porosities in the microstructures of (a) AlMg5Si2Mn (B-(3.5-650)) and (b) AlMg6Si2MnZr (C-(3.5-650)).

- Figure 7.2: The 500x microstructural images of (a) AlSi10MnMg-F and (b) AlSi10MnMg-T7.

- Figure 7.3: Dislocations overcoming a precipitate a) by shearing or b) by looping (Orowan mechanism) and c) the effect of the dislocations passing mechanism on the total yield strength of the alloy (65).

- Figure 7.4: (a) The Rp0.2 values (MPa), (b) the Rm values (MPa) and (c) the total elongation values (%) of AlSi10MnMg-T7.

- Figure 7.5: The 200x microstructural images of (a) AlSi10MnMg (H) and of (b) AlMg4Fe2 (D-(3-650)).

- Figure 7.6: The 500x microstructural images of (a) AlMg4Fe2 (F-740C) and of (b) MYFORD (G-755C).

- Figure 7.7: The total elongation (%) chart for the investigated RheoMetalTM alloys at supplier 1.

- Figure 7.8: The 500x microstructural images of (a) the AlMg4Fe2 alloy (F-750R-1100-30C) and of (b) the MYFORD alloy (G-755R-1100-30C).

- Figure 7.9: The crash resistance potentials of the RheoMetalTM parts (red) and the parts produced by HPDC (black).

- Figure 5.10 : The simulated energy-displacement chart of the Al-Si alloys and alloy-heat treatment combinations.

7. 結論:

主な調査結果の要約:

この論文では、薄肉構造アルミニウム車体鋳物の費用対効果の高い大量生産のためのプロセスルートの開発を目的として、HPDCとRheoMetalTMの2つの鋳造プロセスと、Al-Si、Al-Mg-Si、Al-Mg-Fe系の各種合金について、コスト計算、機械的特性評価、接合性評価を行った。その結果、MYFORD合金が最も有望な材料であり、HPDCプロセスがより費用対効果の高い鋳造プロセスであることが示唆された。

研究の学術的意義:

この研究は、薄肉構造アルミニウム車体鋳物の大量生産におけるコスト効率と機械的特性の両立に関する知見を提供し、自動車業界における軽量化技術の進展に貢献する。また、RheoMetalTMプロセスの適用範囲や最適プロセスパラメータに関する詳細なデータを提供し、半凝固鋳造技術の発展に寄与する。

実際的な意味:

MYFORD合金とHPDCプロセスの組み合わせは、薄肉構造アルミニウム車体鋳物の費用対効果の高い大量生産のための有望なソリューションとなりうる。自動車メーカーは、この研究成果を活用することで、軽量化とコスト削減を両立した車体構造の開発が可能になる。

研究の限界と今後の研究分野:

本研究では、特定の合金と鋳造条件に焦点を当てており、他の合金やプロセスパラメータの組み合わせについては検討の余地がある。また、腐食試験や疲労試験など、長期的な信頼性評価は実施されていない。今後の研究では、これらの点を考慮し、より広範な条件での評価や、実用環境下での耐久性評価を行うことが望ましい。さらに、RheoMetalTMプロセスの改善、特に薄肉部品における衝突抵抗ポテンシャルの向上や、より厚みのある部品や小さな部品への適用拡大などが今後の課題として挙げられる。

8. 参考文献:

- Rio Tinto. Aluminium: Your guide to automotive innovation. [Online] 2019. [Cited: November 11, 2019.]

- Aluminium Rheinfelden GmbH. Handbook- Primary aluminum casting alloys. [Online] 2017. [Cited: September 12, 2019.]

- Stena Aluminium. Aluminium alloy EN AB-42000. [Online] [Cited: October 30, 2019.]

- Verband der Automobilindustrie (VDA). VDA 238-100 : Plate bending test for metallic materials. Berlin : VDA, 2010.

- International Organization for Standardization (ISO). ISO 6892-1. METALLIC MATERIALS - TENSILE TESTING - Part 1: Method of test at room temperature. Geneva : ISO, 2016.

- Deutsches Institut für Normung (DIN). DIN 50125: Prüfung metallischer Werkstoffe- Zugproben. Berlin : Beuth Verlag, 2016.

- Hoegh-Guldberg, O., et al. Impacts of 1.5ºC Global Warming on Natural and Human Systems. [book auth.] V. Masson-Delmotte, et al. Global Warming of 1.5°C. An IPCC Special Report on the impacts of global warming of 1.5°C above pre-industrial levels and related global greenhouse gas emission pathways, in the context of strengthening the global response to the threat of climate change. Geneva : The intergovernmental panel on climate change (ipcc), 2018.

- Yang, Z. and Bandivadekar, A. 2017 Global update: Light-duty vehicle greenhouse gas and fuel economy standards. [Online] [Cited: May 29, 2018.]

- Ducker Worldwide LLC. 2015 North American Light Vehicle Aluminum Content Study. [Online] 2014. [Cited: November 7, 2019.]

- Goede, M., et al. Super Light Car—lightweight construction thanks to a multi-material design and function integration. European Transport Research Review. 2009, Vol. 1, 1, pp. 5-10.

- NADCA Design. Die Casting vs Metal Extrusion. [Online] NADCA Design. [Cited: November 11, 2019.]

- Yuksel, G., et al. MMLV: NVH Sound Package Development and Full Vehicle testing, SAE Technical Paper 2015-01-1615. SAE International. 2015.

- European Aluminum Association. The Aluminum Automotive manual, Manufacturing-casting methods. [Online] 2002. [Cited: May 23, 2019.]

- The American Foundry Society Technical Dept. Aluminium Alloys. Engineered casting solutions. 2006, Vol. 8, 4, pp. 30-34.

- AZoM. Aluminium Casting Techniques - Sand Casting and Die Casting Processes. [Online] 2002. [Cited: July 4, 2018.]

- Foundry Lexicon. [Online] Foundry Lexicon. [Cited: April 24, 2019.]

- Karban, Robert. The effects of intensification pressure, gate velocity, and intermediate shot velocity on the internal quality of aluminum die castings. s.l. : Purdue University, PHD thesis, 2000.

- D. R. Gunasegaram, B. R. Finnin, F. B. Polivka. Melt flow velocity in high pressure die casting: its effect of microstructure and mechanical properties in an Al-Si alloy. Materials Science and Technology. 2007, Vol. 23, 7, pp. 847-856.

- Herman, E.A. Gating Die Casting Dies. Rosemont,IL : NADCA, 1996.

- Fiorese, E, et al. Influence of injection parameters on the porosity and tensile properties of high-pressure die cast Al-Si alloys: A review. International Journal of metalcasting. 2015, Vol. 1, 9, pp. 43-53.

- Otarawanna, S., et al. Feeding mechanisms in High-pressure die castings. Metallurgical and Materials Transactions A. 2010, Vol. 41, 7, pp. 1836-1846.

- Niu, X.P., et al. Vaccum assisted high pressure die casting of aluminium alloys. Journal of Materials Processing Technology. 2000, Vol. 105, 1-2, pp. 119-127.

- SUN, S., Yuan, B. and Liu, M. Effects of moulding sands and wall thickness on microstructure and mechanical properties of Sr-modified A356 Aluminum casting alloy. Transactions of Nonferrous Metals Society of China. 2012, Vol. 22, 8, pp. 1884-1890.

- Djurdjevic, M.B. and Grzincic, M. The Effect of Major Alloying Elements on the size of secondary dendrite arm spacing in the As-cast Al-Si-Cu Alloys. ARCHIEVES of FOUNDARY ENGINEERING. 2012, Vol. 12, 1, pp. 19-24.

- K. Radhakrishna and S. Seshan. Dendritic arm spacing and mechanical properties of Aluminium Alloy castings. Cast Metals. 1989, Vol. 2, 1, pp. 34-38.

- Hartlieb, M. High Integrity Die Casting: A Holistic Approach To Improved Die Casting Quality. [Online] [Cited: November 7, 2019.]

- Pasligh, Niels. Hybride formschlüssige Strukturverbindungen in Leichtbaustrukturen aus Stahlblech und Aluminiumdruckguss. s.l. : Giesserei-Instiut der RWTH Aachen, Dissertation, 2011.

- Ahamed, A. and Kato, H. Influence of Casting Defects on Tensile properties of ADC12 Aluminum Allo Die-Castings. Materials Transactions. 2008, Vol. 49, 7, pp. 1621-1628.

- Cao, X. and Campbell, J. Oxide inclusion defects in Al-Si-Mg cast alloys. Canadian Metallurgical Quarterly. 2005, Vol. 44, 4, pp. 435-448.

- C.M.Gourlay and A.K.Dahle. Dilatant shear bands in solidifying metals. Nature. 2007, Vol. 445, 7123, pp. 70-73.

- Ghosh, A. Segregation in cast products. SADHANA. 2001, Vol. 26, 1-2, pp. 5-24.

- Midson, S.P. and Jackson, A. A comparison of Thixocasting and Rheocasting. 67th World Foundry Congress (wfc06): Casting the Future. Harrogate, UK : Institute of Cast Metals Engineers, 2006, pp. 1081-1090.

- Midson, S.P., Thornhill, L.E. and Young, K. Proc.5th Int.Conf. On Semi-Solid Processing of Alloys & Composites. Golden, Colorado : Colorado School of Mines, 1998. p 181.

- Jolly, M. Prof. John Campbell's Ten Rules for Making Relaible Castings. JOM. 2005, Vol. 57, 5, pp. 19-28.

- Nafisi, Shahrooz and Ghomashchi, Reza. Grain refining of conventional and semi-solid A356 Al-Si alloy. s.l. : Journal of Materials Processing Technology, 2006. Vol 174 pp 371-383.

- Flemings, M.C. Behaviour of metal alloys in the semi-solid state. Metallurgical Transactions A. 1991, Vol. 22, 5, pp. 957-981.

- McCartney, D.G. Grain refining of aluminium and its alloys using inoculants. International Material Reviews. 1989, Vol. 13, 5, pp. 247-260.

- Pola, A, Toci, M and Kapronas, P. Microstructure and properties of Semi-Solid Aluminum Alloys: A literature review. 2018, Vol. 8, 3, p. 181.

- Gerhard, H., et al. Semi-solid Forming of Aluminium and Steel-Introduction and overview. [book auth.] H. Gerhard and R Kopp. Thixoforming: Semi-Solid Metal Processing. Weinheim : WILEY-VCH Verlag GmbH & Co. KGaA, 2009.

- Czerwinski, F. The basics of modern semi-solid metal processing. JOM. 2006, Vol. 58, 6, pp. 17-20.

- Yurko, James A, Martinez, Raul A. and C.Flemmings, Merton. The use of Semi Solid Rheocasting (SSR) for Aluminum automotive castings. s.l. : SAE paper 2003-01-0433., 2003.

- Fan, Z. Semisolid metal processing. International Materials Reviews. 2002, Vol. 47, 2, pp. 49-85.

- Kirkwood, D. H., et al. Semi-Solid Processing of Alloys. Berlin, Heidelberg : Springer, 2010.

- Modigell, M., Annalisa, P. and Marialaura, T. Rheological Characterization of Semi-Solid Metals: A Review. Metals. 2018, Vol. 8, 4, pp. 245-268.

- Basner, T. Rheocasting of semi solid A357 Aluminum, SAE paper :2000-01-0059. SAE International. 2000.

- Midson, S.P. Rheocasting processes for Semi-Solid Casting of Aluminium Alloys. Die Casting Engineer. 2006, Vol. 1, pp. 48-51.

- C.P, Hong, and J.M, Kim. Development of Advanced Rheocasting Process and its applications. Solid State Phenomena. 2006, Vols. 116-117, pp. 44-53.

- Patent: WO/2006/062, 482. A method of and a device for producing a liquid-solid metal composition. Filling date: 2006, Inventors: Wessen, M; Cao, H.

- Payandeh, Mostafa. Rheocasting of Aluminium Alloys, Process and components characteristics. Jönköping university, PhD thesis, 2016.

- H.Cao, M.Wessén & O.Granath. Effect of injection velocity on porosity formation in Al rheocast component using Rheometal process. International Journal of Cast Metals Research. 2010, Vol. 23, 3, pp. 158-163.

- Lee, J., Seok, H. and Lee, H. Effect of the Gate Geometry and the Injection Speed on the Flow. Metals and Materials International. 2003, Vol. 9, 4, pp. 351-357.

- O.Granath, M.Wessen and H.Cao. Determining the effect of the slurry process parameters on semisolid A356 alloy microstructures produced by Rheometal process. International Journl of Cast Metals Research. 2008, Vol. 21, 5, pp. 349-356.

- Bladh, M., Wessen, M. and Dahle, A.K. Shear band formation in shaped Rheocast Aluminium component at various plunger velocities. Trans.Nonferrous Met. Soc. China. 2010, Vol. 20, 9, pp. 1749-1755.

- Payandeh, M., Jarfors, A. and Wessen, M. Influence of microstructural inhomogenity on fracture behaviour in SSM-HPDC Al-Si-Cu-Fe component with low Si content. Solid state phenomena. Vols. 216-217, pp. 67-74.

- Zhu, Baiwei. On the influence of Si on Anodising and Mechanical properties of Cast Aluminium Alloys. Jönköping University, Licentiate thesis, 2017.

- Hegde, S. and Prabhu, K.N. Modification of eutectic silicon in Al-Si alloys. Journal of Materials science. 2008, Vol. 43, 9, pp. 3009-3027.

- Zhu, X., et al. The effects of varying Mg and Si levels on the microstructural inhomogenity and eutectic Mg2Si morphology in die-cast Al-Mg-Si alloys. Journal of Materials Science. 2019, Vol. 54, 7, pp. 5773-5787.

- Yuan, W. and Liang, Z. Effect of Zr addition on properties of Al-Mg-Si aluminum alloy used for all aluminium alloy conductor. Materials and Design. 2011, Vol. 32, 8, pp. 4195-4200.

- Ji, S., et al. Effect of iron on the microstructure and mechanical property of Al-Mg-Si-Mn and Al-Mg-Si diecast alloys. Materials Science and Engineering A. 2013, Vol. 564, pp. 130-139.

- Hwang, J.Y., Doty, H.W. and Kaufman, M.J. The effects of Mn additions on the microstructure and mechanical properties of Al-Si-Cu casting alloys. Materials Science and Engineering A. 2008, Vol. 488, 1-2, pp. 496-504.

- Murray, J.L. and McAlister, A.J. Bulletin of Alloy Phase Diagrams. 1984, Vol. 5, 1, pp. 86-112.

- Zeru, G.T., Mose, B.R. and Mutuli, S.M. The fluidity of a Model Recycle-Friendly Al-Si Cats Alloy for Automotive Engine Cylinder Head Application. International Journal of Engineering Research & Technology (IJERT). 2014, Vol. 3, 8.

- Timelli, G. and Bonollo, F. Fluidity of aluminium die casting alloys. International Journal Of Cast Metals Research. 2007, Vol. 20, 6, pp. 304-311.

- Gwózdz, M and Kwapisz, K. Influence of ageing process on the microstructure and mechanical properties of aluminium-silicon cast alloys - Al-9%Si-3%Cu and Al-9%Si-0.4%Mg. s.l. : Jönköping University, Bachelor thesis, 2008.

- Mohamed, A.M.A. and Samuel, F.H. A Review on the Heat Treatment of Al-Si-Cu/Mg Casting Alloys. Heat treatment - Conventional and novel applications. s.l. : IntechOpen, 2012, pp. 55-72.

- Katgerman, L and Eskin, D. Hardening, annealing and aging. [book auth.] G.E Totten and D.S Mackenzie. Handbook of Aluminum: Vol. 1: Physical Metallurgy and Processes. New York : Marcel Dekker, Inc, 2003, pp. 269-271.

- Bühler AG. Carat. The solution with highest value creation for sophisticated parts. [Online] 2018. [Cited: May 24, 2019.]

- Tecnopres. Hydraulic 4 columns Trimming presses. [Online] 2018. [Cited: May 24, 2019.]

- KMA Umwelttechnik GmbH. KMA press release GIFA 2007. [Online] 2007. [Cited: November 8, 2019.]

- STØTEK Inc. Holding Furnace (STE) / (STET). [Online] STØTEK Inc. [Cited: July 27, 2018.]

- The London Metal Exchange. LME Aluminum alloy. [Online] The London Metal Exchange, 2019. [Cited: January 24, 2019.]

- Kaufmann, H. and Uggowitzer, P.J. Metallurgy and Processing of High Integrity Light Metal Pressure Castings. Berlin : SCHIELE & SCHÖN, 2014.

- Han, Q., Kenik, E.A. and Viswanathan, S. Die soldering in aluminium die casting. Office of Scientific & Technical Information Technical Reports. 2000.

- Abdulhadi, H.A., et al. Thermal Fatigue of Die-Casting Dies: An Overview. MATEC Web of Conferences, ICMER 2015. 2016, Vols. 74, 00032.

- Visi-trak worldwide, LLC. High-Q-Cast. [Online] [Cited: July 23, 2018.]

- Midson, S.P., Minkler, R.B. and Brucher, H.G. Gating of Semi-Solid Aluminum Castings. Proc 6th Inter. Conf. on Semi-Solid Processing of Alloys and Composites. Turin, Italy : s.n., 2000, pp. 67-71.

- Aluminium Rheinfelden GmbH. Primary aluminum- HPDC alloys for Structural Casts in Vehicle Construction. [Online] 2017. [Cited: November 8, 2019.]

- Gulliver, G.H. The quantitative effect of rapid cooling upon the constitution of binary alloys. J.Inst.Met. 1909, Vol. 9, pp. 120-157.

- Scheil, E. Comments on the layer crystal formation. Z.Metallkd. 1942, Vol. 34, pp. 70-72.

- ESAB. ESAB knowledge center. [Online] ESAB. [Cited: May 24, 2019.]

- Techni waterjet. Waterjet advantages. [Online] Techni waterjet, 2018. [Cited: May 24, 2019.]

- SMU department of physics. Mechanics laboratery manual - Archimedes' Principle and Buoyancy. [Online] SMU department of physics, 2002. [Cited: March 8, 2019.]

- Abbas, M., St.Pierre, G.R. and Mobley, C.E. Microporosity of Air Cast and Vacuum Cast Aluminium Alloys. AFS Transactions. 1986, Vol. 49, pp. 47-56.

- He, X., Pearson, I. and Young, K. Self-pierce riveting for sheet materials: State of the art. Journal of Materials Processing Technology. 2008, Vol. 199, 1-3, pp. 27-36.

- Li, D., et al. Self-piercing riveting- a review. The International Journal of Advanced Manufacturing Technology. 2017, Vol. 92, 5-8, pp. 1777-1824.

- Atlas Copco Group. Henrob self-pierce riveting. [Online] [Cited: August 6, 2019.]

- . Henrob BG-Rivet. [Online] [Cited: August 7, 2019.]

- . Henrob die catalogue. [Online] [Cited: November 8, 2019.]

- Stephens, E.V. Mechanical strength of self-piercing riveting. [book auth.] A Chrysanthou and X Sun. Self-Piercing Riveting: Properties, Processes and Applications. s.l. : Woodhead Publishing Limited, 2014.

- Li, D, et al. Influence of Die Profiles and Cracks on Joint Quality and Mechanical Strengths of High Strength Aluminium Alloy Joint. Advanced Materials Research. 2012, Vol. 548, pp. 398-405.

- SCG polymer solutions incorporated. SEM Analysis | SEM-EDS Analysis. [Online] SCG polymer solutions incorporated. [Cited: March 20, 2019.]

- Encyclopaedia Britannica. Spectrochemical analysis. [Online] Encyclopaedia Britannica. [Cited: January 22, 2019.]

- OTARAWANNA, S. and DAHLE, A.K. Casting of aluminium alloys. [book auth.] Roger Lumely. Fundemetals of Aluminium Metallurgy: Production, Processing and Applications. s.l. : Woodhead Publishing Limited, 2011.

- Porcaro, R., et al. The behaviour of a self-piercing riveted connection under quasi-static loading conditions. International Journal of solids and structures. 2006, Vol. 43, 17, pp. 5110-5131.

- Park, J.M., et al. High-strength bulk Al-based bimodal ultrafine eutectic composite with enhanced plasticity. Journal of Materials Research. 2009, Vol. 24, 8, pp. 2605-2609.

- Wang, Q.G., Caceres, C.H. and Griffiths, J.R. Damage by Eutectic Particle Cracking in Aluminum Casting Alloys A356/357. Metallurgical and Materials Transactions A. 2003, Vol. 34, 12, pp. 2901-2912.

- Verma, A., et al. Influence of cooling rate on the Fe intermetallic formation in an AA6063 Al alloy. Journal of Alloys and Compounds. 2013, Vol. 555, pp. 274-282.

- Bielomatik. Minimal Quantity Lubrication (MQL) Systems in Metal Cutting. [Online] [Cited: October 25, 2019.]

- Vicario, I., et al. Development of high pressure die casting dies with internal refrigeration and sensors with reinforced cast steels. International Journal of Manufacturing Engineering. 2014, Vol. 2015, Article ID 287986, pp. 1-10.

9. 著作権:

- この資料は、"[Mohamed Youssef Ahmed Youssef]"氏の論文: "[A cost-efficient process route for the mass production of thin-walled structural aluminum body castings]"に基づいています。

- 論文ソース: 10.18154/RWTH-2021-03555

この資料は上記の論文に基づいて要約されたものであり、商業目的での無断使用は禁止されています。

Copyright © 2025 CASTMAN. All rights reserved.