COMPARISON OF FOUNDRY INDUSTRY IN SLOVAKIA AND CZECH REPUBLIC

A Strategic Comparison of the Slovak and Czech Foundry Industries: Key Trends for HPDC Suppliers This technical summary is based ...

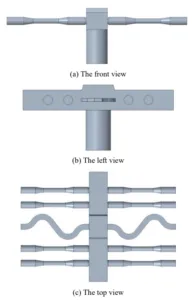

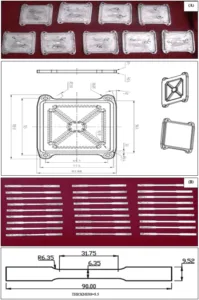

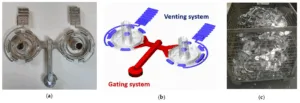

Design and Verification of a New Test Bar Die for LPDC Process Based on Numerical Simulation

Optimizing LPDC Quality: How ProCAST Simulation Validates a New Standard for Test Bar Dies This technical summary is based on ...

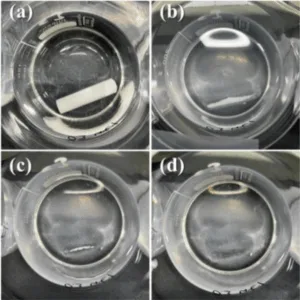

EFFECT OF MATERIAL SEGREGATIONS DUE TO SQUEEZE PARAMETERS ON MECHANICAL PROPERTIES OF HIGH PRESSURE DIECAST PARTS

Unlocking HPDC Strength: Does Squeeze Pin Technology Weaken High-Stress Components? This technical summary is based on the academic paper "EFFECT ...

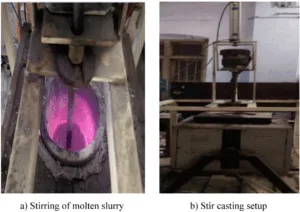

Mechanical Characterization of Aluminium -Titania Metal Matrix Composites

Unlocking Superior Strength: A Deep Dive into Aluminium-Titania Metal Matrix Composites for High-Performance Casting This technical summary is based on ...

Effect of novel grain refiner and Ni alloying additions on microstructure and mechanical properties of Al-Si9.8-Cu3.4 HPDC castings – optimization using Multi Criteria Decision making approach

Boosting HPDC Performance: New Grain Refiner Increases Al-Si-Cu Alloy Strength by Over 12% This technical summary is based on the ...

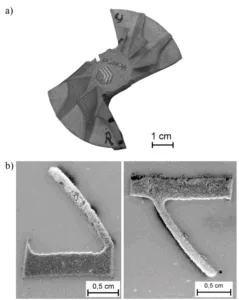

Improving the Mechanical Properties of Salt Core through Reinforcing Fibers

Unlocking Complex HPDC: How 0.3% Glass Fiber Creates a High-Strength Salt Core This technical summary is based on the academic ...

![Fig. 1: Two-parameter Weibull plot for fatigue life of a Sr-modified A356 casting alloy sorted by type of crack origin (pore, oxides, or slip bands) observed on fracture [1, 13]](https://castman.co.kr/wp-content/uploads/image-3359-300x263.webp)

Best practices for making high integrity lightweight metal castings – molten metal composition and cleanliness control

The Secrets to Flawless Castings: A Guide to Molten Metal Control for High Integrity Lightweight Castings This technical summary is ...

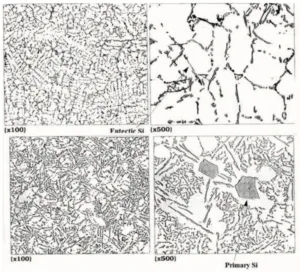

THE STRUCTURE OF CENTRIFUGALLY CAST COMPOSITE CASTING

Can Centrifugal Casting Solve the Thin-Wall Challenge for Metal Matrix Composites? This technical summary is based on the academic paper ...

SEMI SOLID METAL POURING TEMPERATURE EFFECTS ON MECHANICAL PROPERTIES OF AL-SI ALLOY

Optimize Al-Si Alloy Performance: How Pouring Temperature in Semi-Solid Metal Casting Dictates Final Component Strength This technical summary is based ...

Balancing Cost and Quality: Finding the Sweet Spot for Returnable Material in AlSi9Cu3(Fe) HPDC

This technical summary is based on the academic paper "The Influence of Returnable Material on Internal Homogeneity of the High-Pressure ...